Content Menu

● What Is Automation in Powder Coating?

● How Automation Transforms Powder Coating for Manufacturers

>> Enhanced Efficiency and Productivity

>> Consistent Quality and Finish

>> Reduced Costs and Waste

● Key Components of Automated Powder Coating Systems

>> Robotic Spray Guns and Nozzles

>> Automated Conveyor Systems

>> Powder Recovery Units

>> Curing Ovens with Temperature Controls

>> Integrated Sensors and Control Systems

● Benefits Beyond the Production Line

>> Improved Worker Safety

>> Environmental Compliance

>> Flexibility and Scalability

● Challenges and Considerations in Automation Adoption

● Future Trends in Powder Coating Automation

● Common Questions & Answers Related to Automation in Powder Coating

What Is Automation in Powder Coating?

Automation in powder coating refers to the use of robotic and computerized systems to control the entire coating process, from powder application to curing. Traditional manual methods depend heavily on skilled operators to spray powder evenly on parts, which can be inconsistent and slower. Automated powder coating lines integrate conveyors, robotic spray arms, sensors, and curing ovens in a seamless flow, allowing continuous, precise, and repeatable operations.

How Automation Transforms Powder Coating for Manufacturers

Enhanced Efficiency and Productivity

Automated powder coating systems drastically reduce manual labor by handling spraying, material feeding, conveying, and curing operations with minimal human intervention. The integration of conveyors and reciprocators allows for continuous production flow, eliminating idle times associated with manual setups and frequent breaks. Automation can operate at higher speeds with consistent spraying parameters programmed for each product type, shortening production cycles and increasing throughput.

Moreover, automation improves energy efficiency by optimizing conveyor speeds and adjusting power use in real-time according to workload, resulting in lower operational costs and environmental impact. These systems also enable manufacturers to scale production quickly to respond to market demands without compromising quality.

Consistent Quality and Finish

One of the biggest challenges in manual powder coating is achieving uniform coating thickness and color consistency across complex parts and large batches. Automated systems use precision-controlled robotic arms and nozzles to apply the exact amount of powder evenly on every surface, regardless of shape or size. This leads to a flawless finish with minimal defects such as patches, runs, or uneven coverage.

Integrated sensors and monitoring technologies enable real-time adjustments and fault detection during spraying, ensuring every piece meets stringent quality standards. The automation also minimizes overspray and powder waste by accurately controlling the powder delivery, which improves process yield and reduces raw material costs.

Reduced Costs and Waste

Automation in powder coating systems results in significant cost savings over time. By minimizing human involvement, manufacturers reduce the likelihood of errors that lead to rework or scrapped parts. The precision of automated systems means less powder is wasted, and with powder recovery modules, reclaimed overspray powder can be recycled back into the process.

In addition, energy-efficient designs lower electricity consumption during curing and conveying. Labor costs also decrease because fewer operators are needed to supervise fully automated lines. Altogether, these benefits create a strong return on investment despite higher initial setup costs.

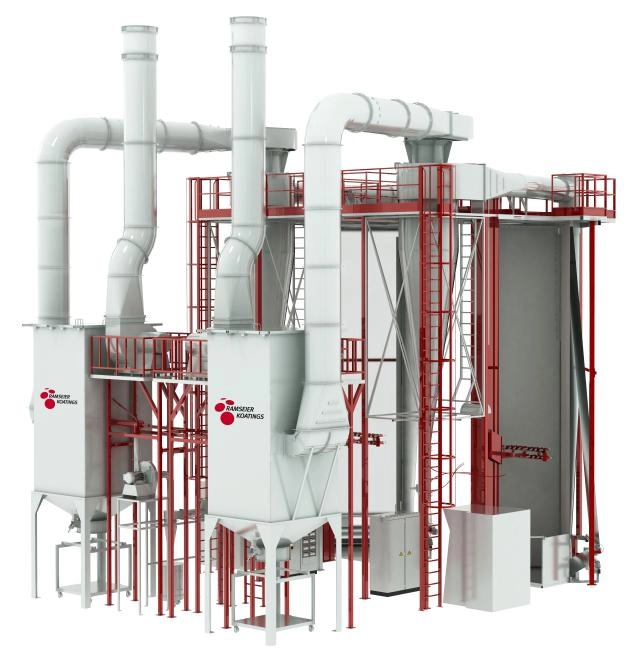

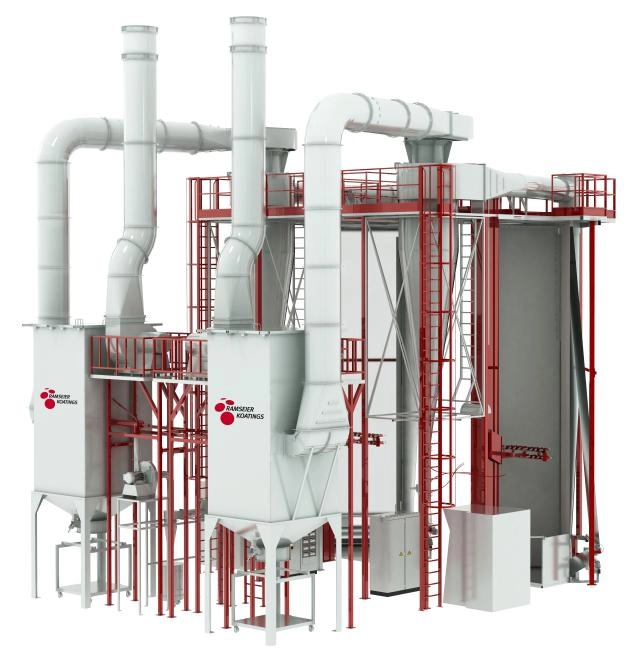

Key Components of Automated Powder Coating Systems

Robotic Spray Guns and Nozzles

Robotic arms equipped with electrostatic spray guns apply powder with programmed precision. These guns create an electrostatic charge that attracts powder particles to the grounded workpiece, ensuring efficient and uniform coating. Multiple spray guns can be synchronized to cover all angles swiftly.

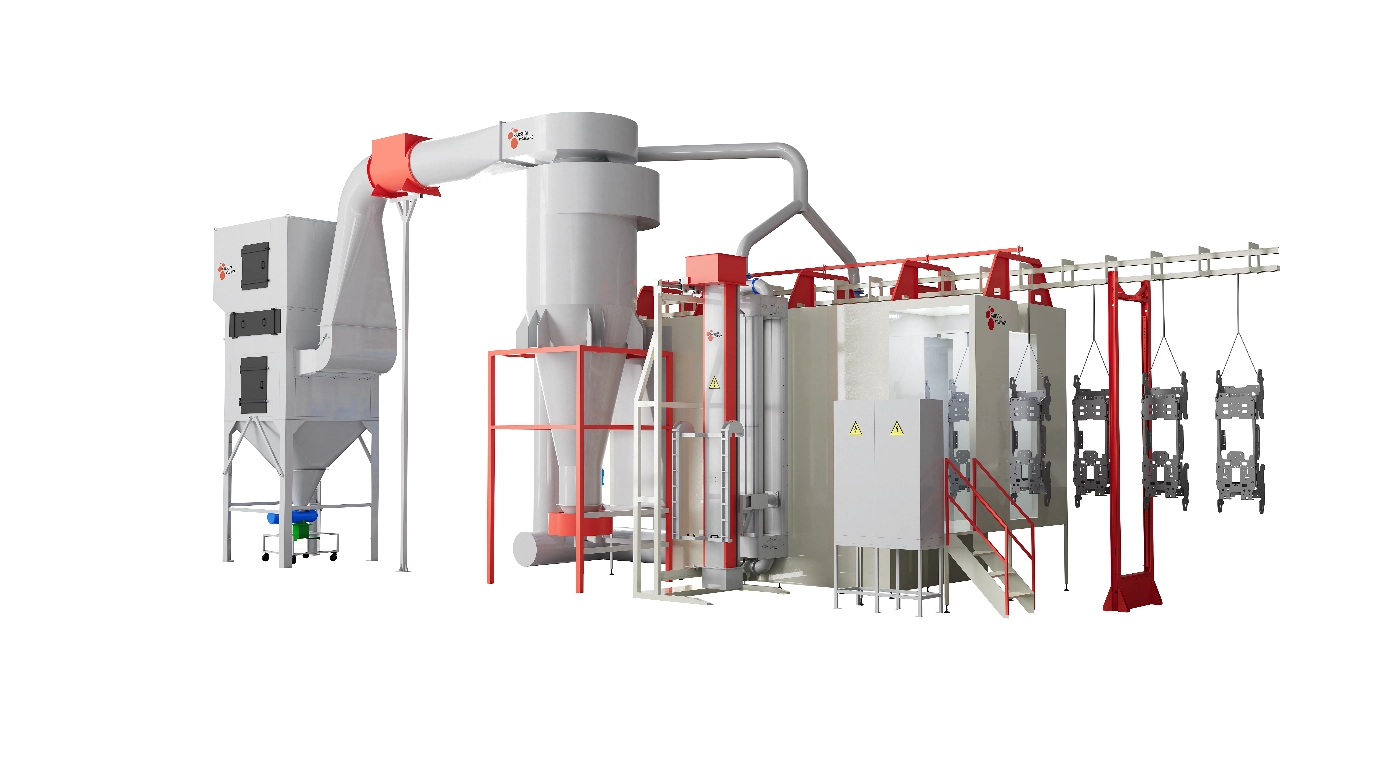

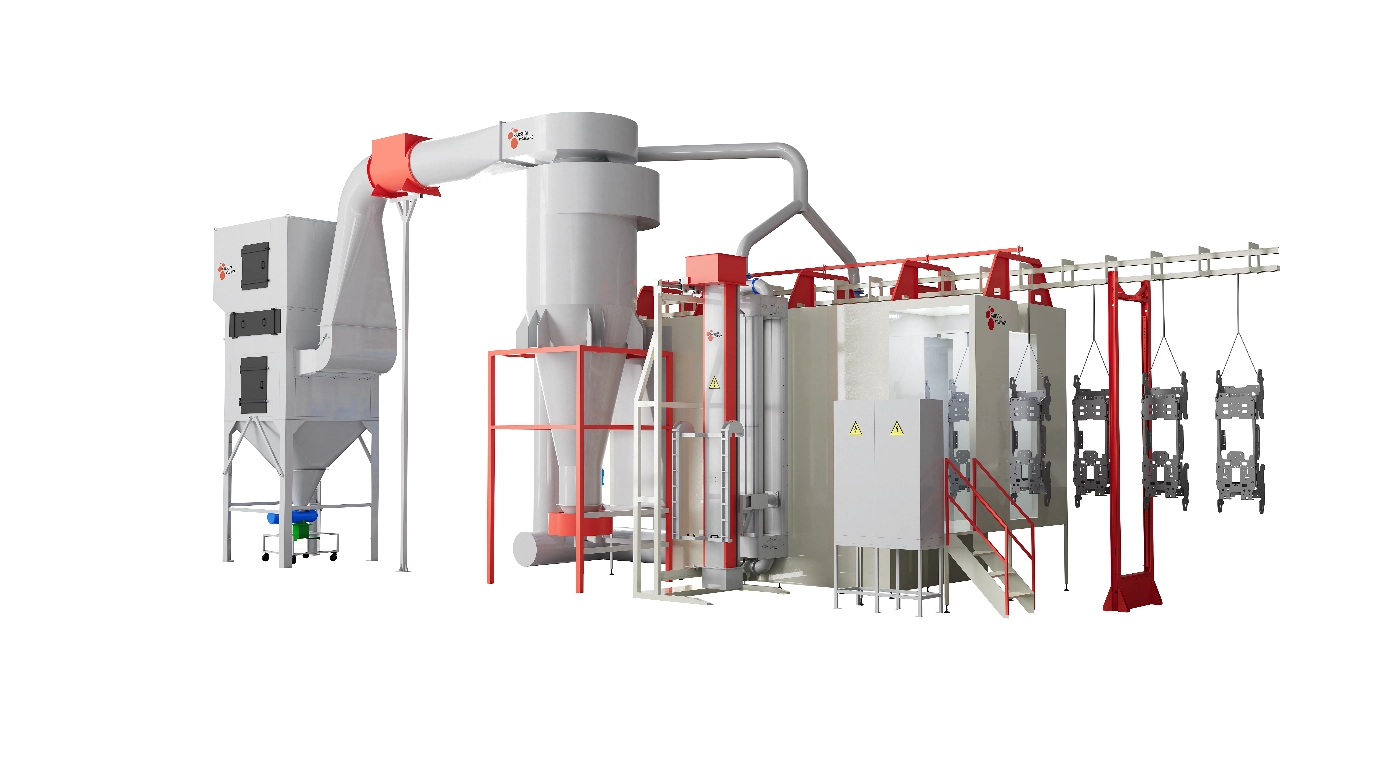

Automated Conveyor Systems

Conveyors transport parts through different process stages—from loading, spraying, to curing—in a controlled and timed manner. Their speed and direction can be adjusted dynamically to optimize throughput and maintain coating quality.

Powder Recovery Units

These units capture overspray powder that does not adhere to parts and recycle it back into the system, reducing waste and lowering powder consumption.

Curing Ovens with Temperature Controls

After powder application, parts pass through curing ovens where the powder melts and bonds to the substrate, forming a durable finish. Automation enables precise temperature control and cycle timing, essential for consistent coating performance.

Integrated Sensors and Control Systems

Sensors monitor parameters such as powder flow rate, spray pattern, air pressure, and curing temperature in real-time. The control system uses this data to automatically adjust settings or pause the line if quality deviations occur, ensuring continuous optimal operation.

Benefits Beyond the Production Line

Improved Worker Safety

Automation reduces workers' direct exposure to powder particles and chemicals, a significant health benefit. Minimizing manual spraying lowers risks related to inhalation of hazardous substances and physical strain from repetitive tasks.

Environmental Compliance

Automated systems optimize powder usage and reduce emissions of airborne particulates, helping manufacturers comply with increasingly stringent environmental regulations. Energy-efficient equipment and powder recycling contribute to greener production practices.

Flexibility and Scalability

Modern automated powder coating lines can be reprogrammed and adjusted to coat different product types and sizes as needed. This flexibility allows manufacturers to quickly adapt to new product lines or changes in demand, making automation a versatile investment.

Challenges and Considerations in Automation Adoption

While automation offers many advantages, manufacturers must consider factors such as initial capital investment, required technical expertise for setup and maintenance, and integration with existing production lines. Training staff to operate and troubleshoot automated equipment is also essential for maximizing benefits and minimizing downtime.

Future Trends in Powder Coating Automation

The future of powder coating automation points toward increased intelligence and connectivity. Integration with Industry 4.0 technologies such as IoT sensors, AI-based quality control, and big data analytics will enable predictive maintenance, further reduce defects, and optimize resource use.

Robotic systems will become more flexible and capable of handling complex part geometries and customized coatings, broadening the application range of automated powder coating in high-precision industries like aerospace, automotive, and electronics.

Common Questions & Answers Related to Automation in Powder Coating

Q1: How does automation improve the quality of powder coating?

Automation applies powder uniformly and precisely using robotic spray guns, reducing variability and ensuring consistent finish across all parts.

Q2: Can automation reduce powder waste?

Yes, automated powder coating systems optimize powder delivery and often include powder recovery units that recycle overspray, significantly minimizing waste.

Q3: Is automated powder coating cost-effective for small manufacturers?

While initial costs can be high, automation reduces labor, material waste, and rework costs, making it beneficial in the long run, especially for growing businesses.

Q4: How does automation enhance worker safety in powder coating?

By reducing manual spraying, automation limits workers' exposure to airborne powder and harmful chemicals, improving workplace safety.

Q5: What types of products benefit most from automated powder coating?

Industries requiring high precision and consistency, such as automotive, appliances, electronics, and construction materials, gain the most from automation in powder coating.

[1] https://intechfinishing.com/2025/01/30/the-role-of-automation-in-powder-coating-enhancing-precision-and-productivity/

[2] https://mdx.mdict.org/%E6%8C%89%E8%AF%8D%E5%85%B8%E8%AF%AD%E7%A7%8D%E6%9D%A5%E5%88%86%E7%B1%BB/%E8%8B%B1%E8%AF%AD/%E8%8B%B1%E8%AF%AD%E4%B8%93%E4%B8%9A%E8%AF%8D%E5%85%B8/%5B%E8%8B%B1-%E6%B1%89%5D/%5B%E8%8B%B1-%E6%B1%89%5D%206%E4%B8%87%E5%A4%9A%E4%B8%AA%E5%8F%A5%E5%AD%90%E9%A3%9E%E8%B7%836.0%E5%8F%A5%E5%BA%93%E5%AF%BC%E5%87%BA%EF%BC%88%E9%99%84%E6%BA%90%E6%96%87%E4%BB%B6%EF%BC%89/%5B%E8%8B%B1-%E6%B1%89%5D%206%E4%B8%87%E5%A4%9A%E4%B8%AA%E5%8F%A5%E5%AD%90%E9%A3%9E%E8%B7%836.0%E5%8F%A5%E5%BA%93%E5%AF%BC%E5%87%BA%EF%BC%88%E9%99%84%E6%BA%90%E6%96%87%E4%BB%B6%EF%BC%89.txt

[3] https://www.hinahcoatingline.com/news/why-choose-automated-powder-coating-line

[4] https://www.scribd.com/document/10317685/%E5%A4%A7%E5%AD%A6%E7%A7%91%E6%8A%80%E8%8B%B1%E8%AF%AD

[5] https://www.rohnerspraybooths.com/blog/integrating-automation-into-your-finishing-process

[6] https://huggingface.co/openbmb/cpm-bee-1b/commit/bd72a61dd7a59086ed7456f1dfcaa995c8ec58a3.diff

[7] https://www.ltcoatingline.com/resources/4-benefits-of-an-automated-powder-coating-system.html

[8] https://reasonablechoice.net/en/blog/automation-of-powder-coating-application

[9] https://blog.isa.org/4-benefits-of-an-automated-powder-coating-system

[10] https://cwfinishing.net/automation-coating-enhancing-quality-and-speed/

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.