Content Menu

● Understanding Powder Coating Booths

>> What is a Powder Coating Booth?

>> Components of a Powder Coating Booth

● Introduction to Automation in Powder Coating Booths

>> What Does Automation Mean in This Context?

>> Levels of Automation

● The Technologies Driving Automation

>> Robotic Powder Coating Systems

>> Sensors and Quality Monitoring

>> Software for Process Control

● Benefits of Automation in Powder Coating Booths

>> Improved Efficiency and Productivity

>> Enhanced Coating Quality

>> Safety and Environmental Compliance

>> Cost Savings Over Time

● Challenges and Considerations

>> High Initial Investment

>> Technical Expertise Required

>> Flexibility and Customization

>> Integration with Existing Systems

● Implementation Best Practices

>> Assess Production Needs and Goals

>> Invest in Training and Support

>> Pilot Testing and Validation

>> Prioritize Safety and Compliance

● Future Trends in Automation for Powder Coating

>> Artificial Intelligence and Machine Learning

>> Internet of Things (IoT) Integration

>> Enhanced Robotics

>> Sustainable and Green Technologies

● Frequently Asked Questions

>> How does automation improve powder coating consistency?

>> Is automation suitable for small production runs?

>> What safety improvements come with automated powder coating booths?

>> How does powder recovery work in automated booths?

>> What maintenance is required for automated powder coating booths?

Powder coating is widely acclaimed for its durability and environmental benefits in finishing metals and other materials. The integration of automation into powder coating booths is revolutionizing this industry, enhancing efficiency, consistency, and safety. This article delves into the essentials of automation in powder coating booths, exploring the technology, benefits, challenges, and future trends.

Understanding Powder Coating Booths

What is a Powder Coating Booth?

A powder coating booth is an enclosed area where powder coating is applied to parts or products. It contains the spray guns, recovery systems for overspray, and ventilation setup to manage the powder and airflow. The booth ensures the powder does not contaminate the work environment and maximizes the recycling of unused powder.

Components of a Powder Coating Booth

Key components include:

- Spray guns: Devices that atomize and propel the powder onto the part.

- Powder recovery system: Captures and recycles overspray powder.

- Ventilation and filtration system: Maintains air quality and removes excess powder from the air.

- Conveyor system: Moves parts through the booth for continuous processing.

Introduction to Automation in Powder Coating Booths

What Does Automation Mean in This Context?

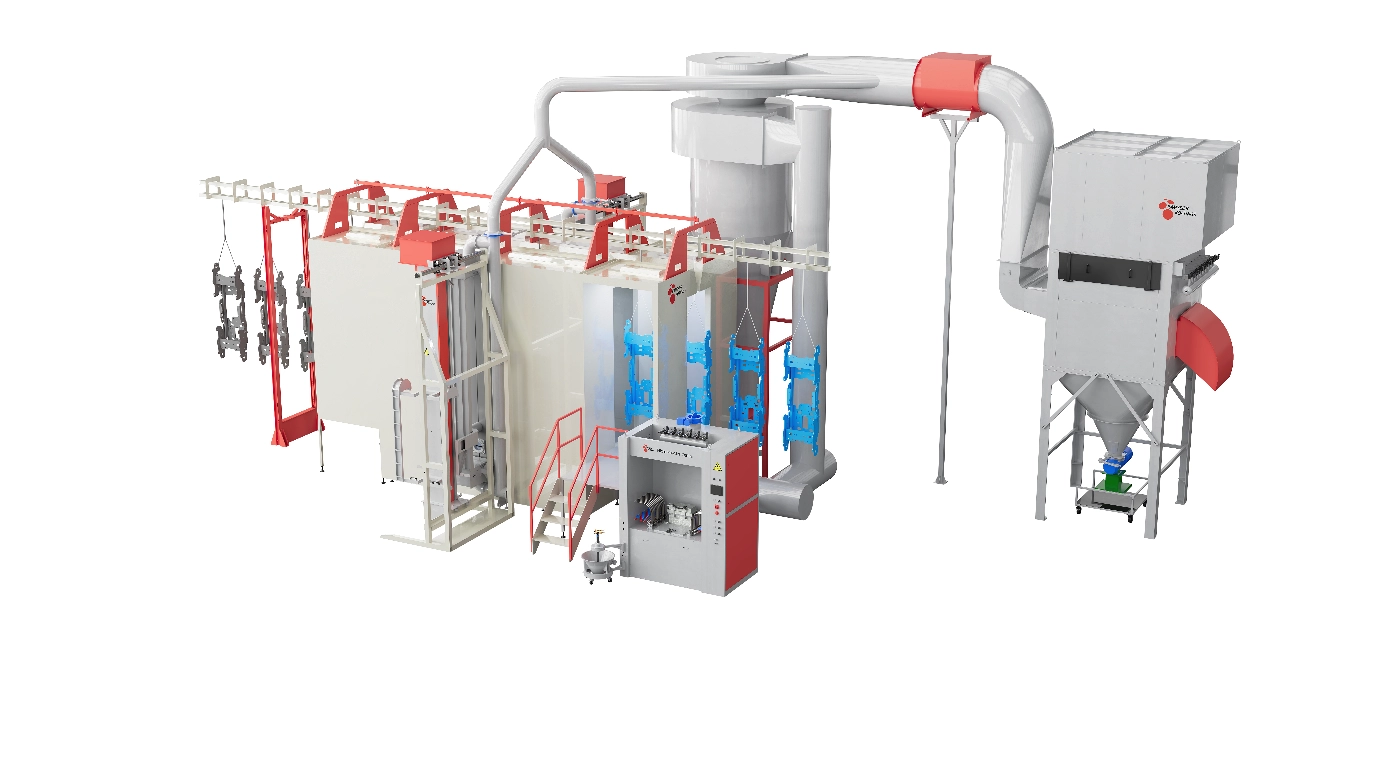

Automation in powder coating booths refers to the use of machines and control systems to perform tasks traditionally done manually. This includes robotic arms directing spray guns, sensors monitoring application quality, and software controlling the entire process from powder feed to curing.

Levels of Automation

Automation can be classified into several levels:

- Semi-automated booths: Operators still manage some processes, but machinery controls others, such as powder feed rate or booth ventilation.

- Fully automated booths: Robotic systems handle powder application, part handling, and process monitoring without human intervention.

The Technologies Driving Automation

Robotic Powder Coating Systems

Robotics are central to automation in powder coating. Industrial robots equipped with spray guns can coat complex shapes consistently and with high repeatability. Programmable paths ensure full coverage while reducing overspray and material waste.

Sensors and Quality Monitoring

Advanced sensors measure variables like powder thickness, temperature, and humidity, adjusting parameters in real time for optimal coating. Cameras and laser scanning verify surface coverage and detect defects, ensuring quality control.

Software for Process Control

Integrated software platforms synchronize robotic motion, powder feed, airflow control, and conveyor speed. Data analytics help operators optimize cycle times and predict maintenance needs, reducing downtime.

Benefits of Automation in Powder Coating Booths

Improved Efficiency and Productivity

Automation significantly speeds up the powder coating process. Robots operate continuously without fatigue, increasing throughput and consistency. Automated powder recovery ensures less waste and better use of materials.

Enhanced Coating Quality

Precision control systems minimize human error. Automated spray patterns lead to uniform coating thickness and better adhesion, reducing rework and defects.

Safety and Environmental Compliance

Automated booths reduce worker exposure to powders and chemicals, lowering health risks. Precise powder delivery matched with efficient recovery systems minimizes airborne emissions, supporting environmental regulations.

Cost Savings Over Time

Although initial investment is high, automation reduces labor costs and material waste. Energy optimized systems cut operational expenses, and predictive maintenance avoids costly breakdowns.

Challenges and Considerations

High Initial Investment

The cost of integrating robotics and advanced controls can be a barrier for small and medium enterprises. However, scaling according to production needs can help mitigate this.

Technical Expertise Required

Operating and maintaining automated systems requires trained personnel. Staff must be skilled in robotics programming, system troubleshooting, and software management.

Flexibility and Customization

Some highly intricate or small batch jobs might still require manual coating due to the complexity of programming robots or setup time involved.

Integration with Existing Systems

Retrofitting automation into an older booth might involve significant modification. Compatibility with conveyors, curing ovens, and powder supply systems must be ensured.

Implementation Best Practices

Assess Production Needs and Goals

Evaluate volume, product diversity, and quality requirements before designing automation solutions. A tailored approach ensures optimal ROI.

Invest in Training and Support

Partner with suppliers offering comprehensive training and after-sales support. Continuous skill development for operators is vital.

Pilot Testing and Validation

Before full deployment, conduct pilot runs to identify bottlenecks and calibrate the system to specific product characteristics.

Prioritize Safety and Compliance

Design booths to meet health and environmental standards, incorporating emergency stops, ventilation controls, and regular maintenance checks.

Future Trends in Automation for Powder Coating

Artificial Intelligence and Machine Learning

AI can analyze data to optimize coating parameters automatically, predict failures, and increase throughput.

Internet of Things (IoT) Integration

IoT sensors connected to cloud platforms allow real-time remote monitoring and predictive maintenance, reducing downtime.

Enhanced Robotics

Next-generation robots will have better dexterity, faster operations, and collaborative features allowing safe human-robot interactions.

Sustainable and Green Technologies

Automation will focus increasingly on reducing energy consumption, improving powder recovery, and adopting environmentally-friendly coatings.

Frequently Asked Questions

How does automation improve powder coating consistency?

Automation uses robotic arms programmed for precise movements and spray parameters, ensuring every part receives uniform coverage without the inconsistencies of manual spraying.

Is automation suitable for small production runs?

While automation is ideal for high-volume production due to upfront costs, flexible robotic systems can be configured for small batch sizes, although manual processes might still be more cost-effective for very limited runs.

What safety improvements come with automated powder coating booths?

Automation minimizes human exposure to powders and hazardous chemicals by replacing manual spraying with enclosed robotic systems, supported by advanced ventilation and filtration.

How does powder recovery work in automated booths?

Powder recovery systems vacuum overspray powder, filter and recycle it back into the system, significantly reducing waste and lowering material costs while maintaining air quality.

What maintenance is required for automated powder coating booths?

Regular cleaning of powder recovery filters, calibration of robots and sensors, lubrication of moving parts, and software updates are essential to keep automated booths running efficiently.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.