Content Menu

● Introduction to Spray Booths

● Environmental Impact of Manual Spray Booths

>> Waste Management in Manual Booths

>> Energy Efficiency

● Environmental Impact of Automatic Spray Booths

>> Waste Reduction

>> Energy Efficiency and Resource Optimization

>> Enhanced Air Quality

● Comparison of Environmental Benefits

● Regulatory Compliance and Safety

● Future of Spray Booth Technology

● Conclusion

● Frequently Asked Questions

● Citations:

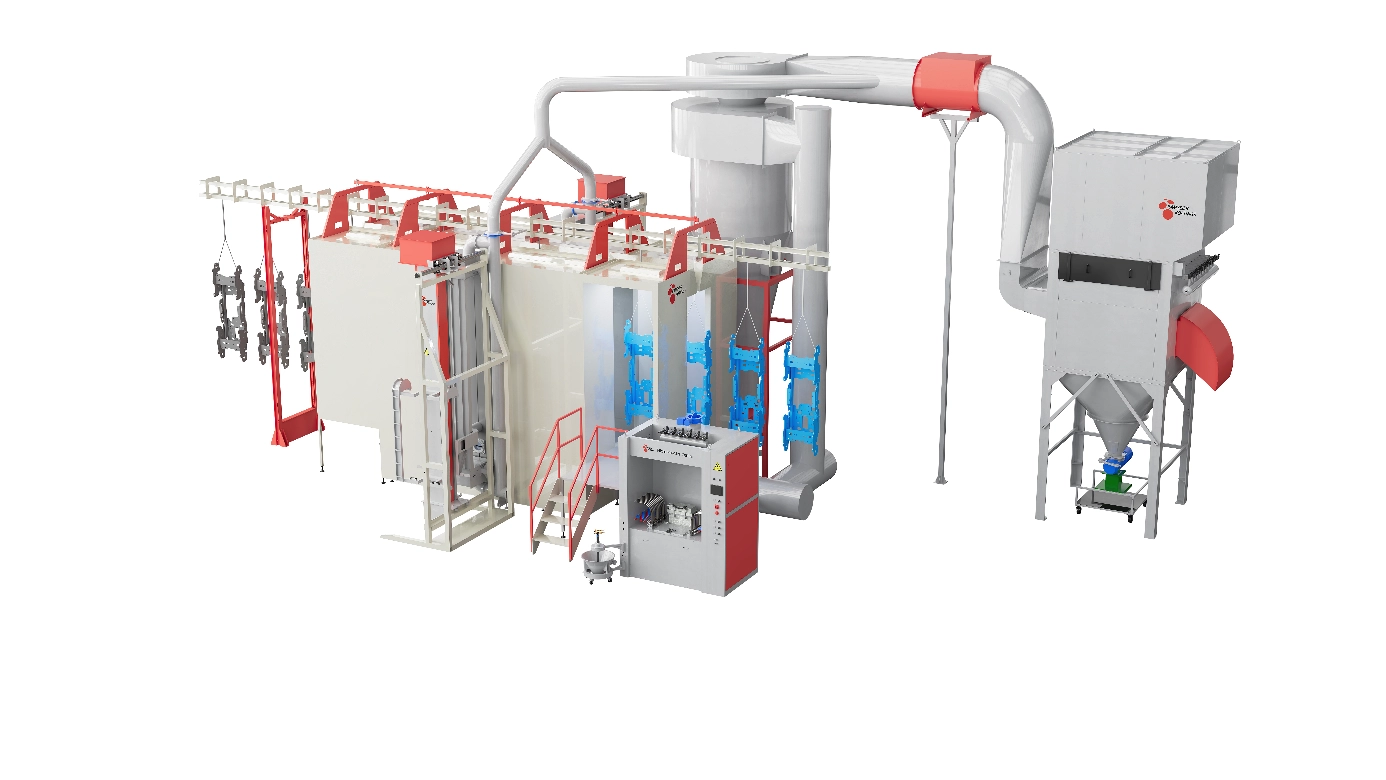

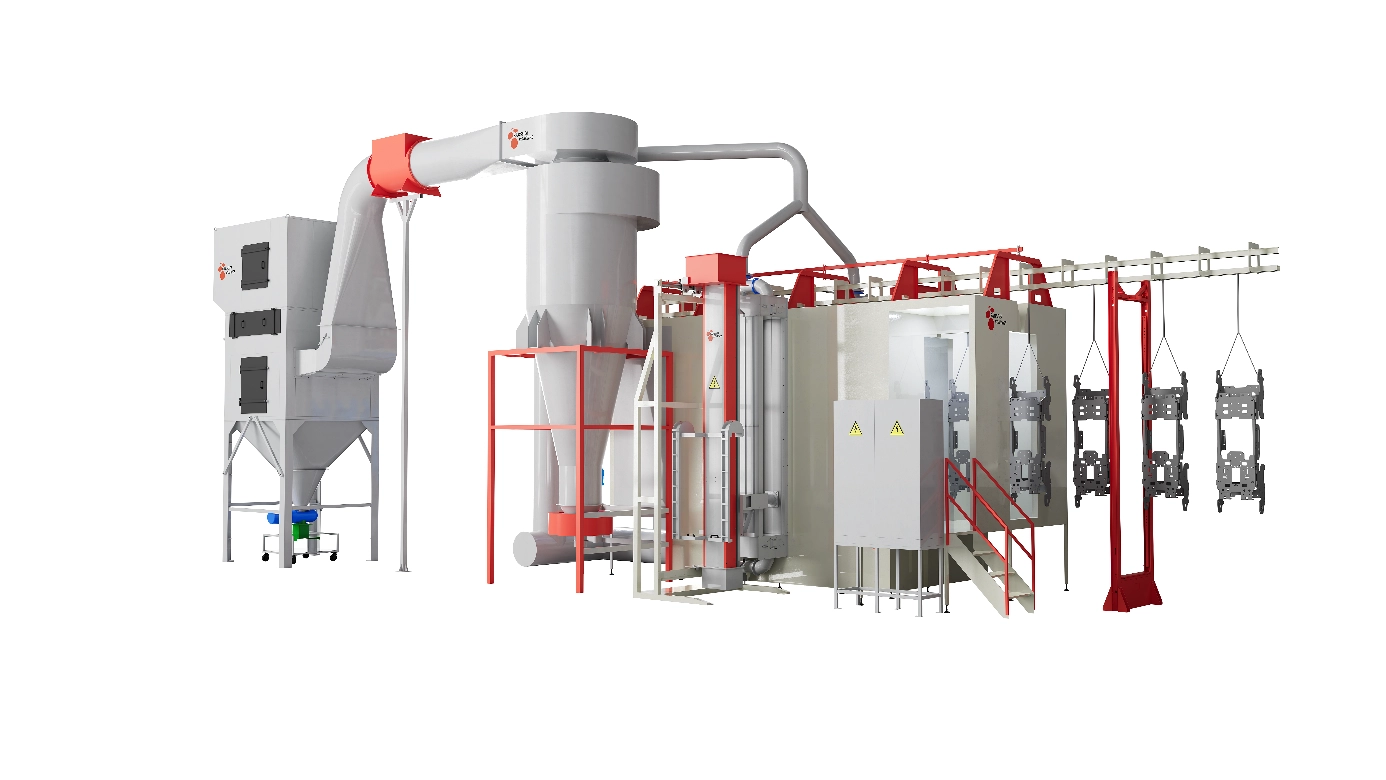

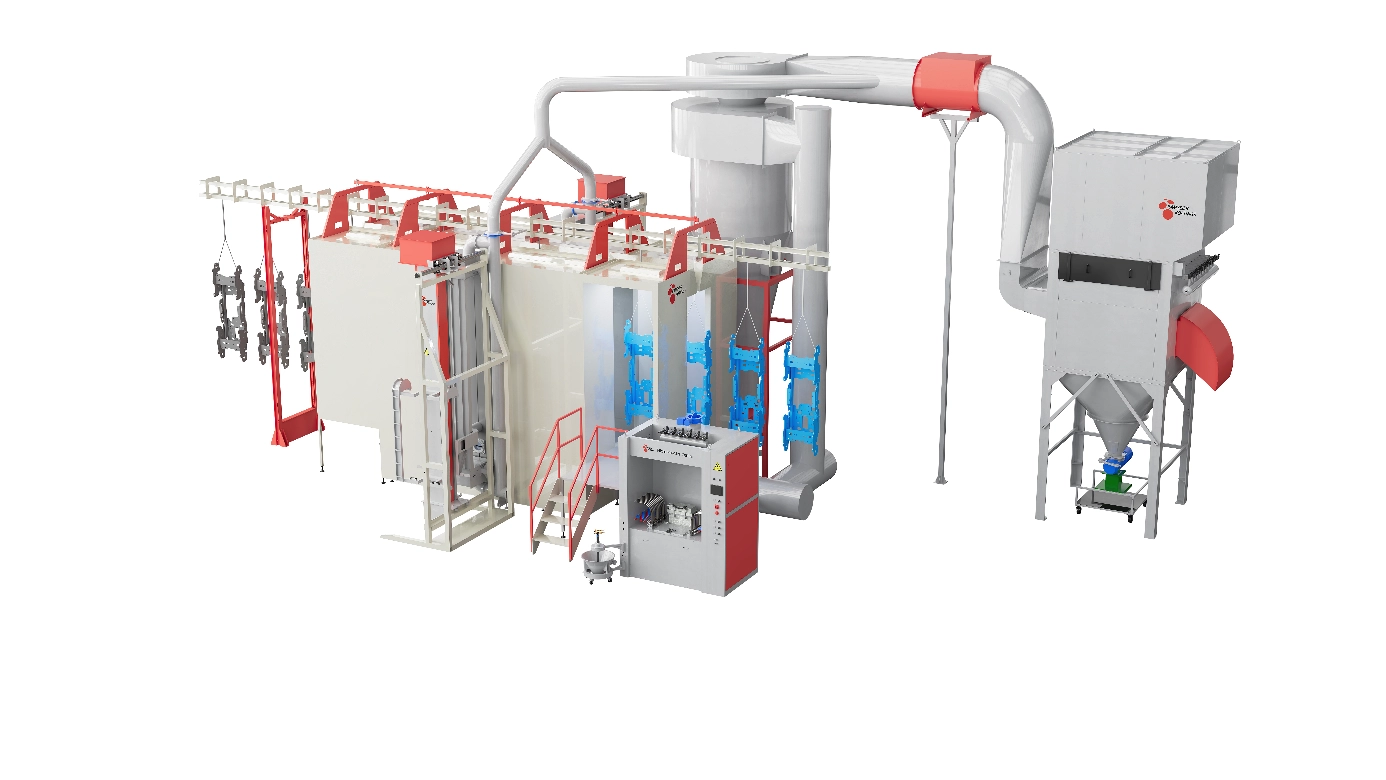

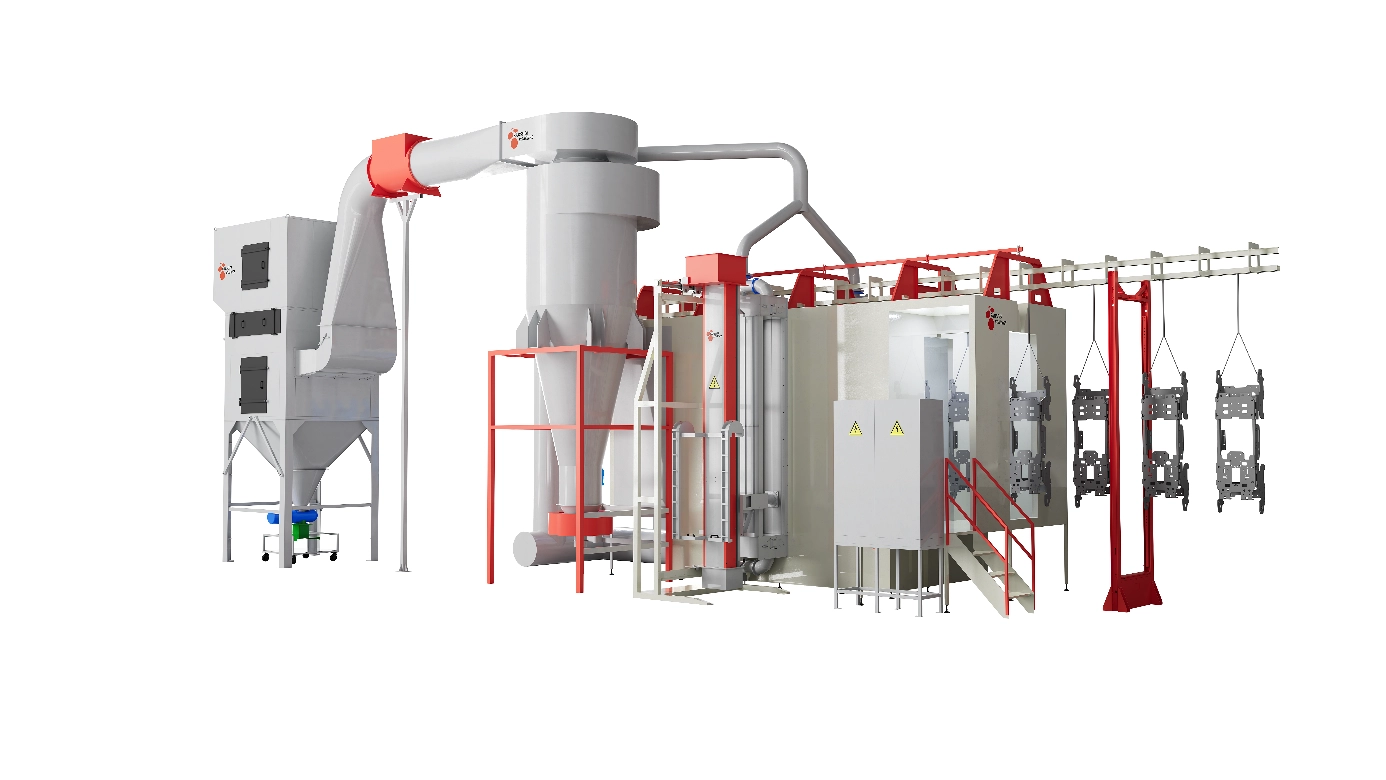

In the realm of industrial painting, spray booths play a pivotal role in ensuring both high-quality finishes and environmental sustainability. As industries face increasingly stringent environmental regulations, the choice between automatic and manual spray booths becomes crucial. This article delves into the environmental benefits of each type, exploring how they contribute to reducing pollution and enhancing operational efficiency.

Introduction to Spray Booths

Spray booths are enclosed environments designed to contain the painting process, minimizing the release of harmful substances into the atmosphere. They are equipped with advanced filtration systems that capture volatile organic compounds (VOCs) and particulates, which are major contributors to air pollution. By controlling these emissions, spray booths not only protect the environment but also ensure a safer workspace for employees.

Environmental Impact of Manual Spray Booths

Manual spray booths rely on human operators to apply paint, which can lead to inconsistencies in application and higher levels of overspray. While manual booths offer flexibility and precision, especially for custom jobs, they require skilled labor and can result in increased waste. The manual process often involves more direct exposure to harmful fumes and particles, necessitating robust ventilation systems to maintain air quality.

Waste Management in Manual Booths

Manual booths can generate significant waste due to overspray, which, if not managed properly, can contribute to environmental pollution. However, with proper containment and collection systems, this waste can be minimized. The key challenge lies in ensuring that the ventilation and filtration systems are adequate to handle the variable output of manual operations.

Energy Efficiency

Manual booths typically consume less energy compared to automated systems since they do not require complex machinery. However, the energy efficiency is often offset by the increased labor costs and potential for human error, which can lead to rework and additional resource consumption.

Environmental Impact of Automatic Spray Booths

Automatic spray booths utilize advanced technology to streamline the painting process, ensuring uniform application and reduced waste. These systems are designed to optimize paint usage, minimizing overspray and the associated environmental impact. By automating the process, businesses can achieve greater efficiency, reduce labor costs, and enhance product quality.

Waste Reduction

Automated booths are highly effective in reducing waste. They apply paint with precision, ensuring that less paint is wasted as overspray. This not only conserves resources but also reduces the amount of hazardous waste generated during the painting process.

Energy Efficiency and Resource Optimization

While automated booths consume more energy than manual ones due to the machinery involved, they offer significant long-term benefits. Advanced technologies such as regenerative dry filtration systems can recycle process air, reducing the energy needed to condition new air. This approach not only lowers operational costs but also decreases the environmental footprint by minimizing energy consumption.

Enhanced Air Quality

Automated booths are equipped with sophisticated air filtration systems that capture VOCs and particulates more efficiently than manual booths. This ensures cleaner air is released into the environment, contributing to better air quality and compliance with stringent environmental regulations.

Comparison of Environmental Benefits

| Feature | Manual Spray Booths | Automatic Spray Booths |

| Waste Management | Higher potential for waste due to overspray | Efficient waste reduction through precise application |

| Energy Efficiency | Generally less energy-intensive | More energy consumption but with potential for optimization through advanced technologies |

| Air Quality | Requires robust ventilation to maintain air quality | Equipped with advanced filtration systems for better air quality |

| Environmental Compliance | Can struggle with regulatory compliance due to variable emissions | Designed to meet and exceed environmental standards |

Regulatory Compliance and Safety

Both manual and automatic spray booths must adhere to environmental regulations. However, automated systems are more likely to meet these standards consistently due to their controlled environment and advanced filtration capabilities. This not only helps businesses avoid fines but also enhances their reputation by demonstrating a commitment to sustainability.

Future of Spray Booth Technology

As technology continues to evolve, spray booths are becoming increasingly sophisticated. Innovations such as smart controls, integrated recycling systems, and eco-friendly materials are redefining the industry. These advancements not only reduce environmental impact but also offer businesses strategic advantages in terms of cost savings and brand reputation.

Conclusion

In conclusion, while both manual and automatic spray booths offer environmental benefits, automated systems generally provide better environmental protection due to their precision, efficiency, and advanced filtration capabilities. As industries strive for sustainability, investing in automated spray booths can be a strategic move towards reducing environmental footprint while enhancing operational efficiency.

---

Frequently Asked Questions

1. What are the primary environmental benefits of using spray booths?

- Spray booths reduce VOC emissions, minimize waste, and improve air quality by capturing harmful particles and fumes.

2. How do automated spray booths enhance environmental protection compared to manual booths?

- Automated booths offer precise paint application, reducing waste and VOC emissions, and are equipped with advanced filtration systems for better air quality.

3. What role do filtration systems play in spray booths?

- Filtration systems capture VOCs and particulates, ensuring cleaner air is released into the environment and maintaining compliance with environmental regulations.

4. How can businesses ensure regulatory compliance with spray booth operations?

- By using spray booths equipped with advanced filtration and ventilation systems, businesses can meet and exceed environmental standards, avoiding fines and enhancing their reputation.

5. What are some future trends in spray booth technology?

- Future trends include the integration of smart controls, eco-friendly materials, and advanced recycling systems to further reduce environmental impact and enhance operational efficiency.

Citations:

[1] https://www.truteksystems.co.in/blogDetail/The-Impact-of-Paint-Booths-on-Environmental-Sustainability

[2] https://airknowledge.gov/ILT/TOXC220/Current/CI/04TOXC220_Handout_Innovative_Spray_Booth_Technology.pdf

[3] https://www.airblasteurospraydirect.com/blog/what-are-the-environmental-benefits-of-using-a-paint-booth/

[4] https://www.joboncoating.com/electrostatic-powder-coating-booth/eco-friendly-pvc-spray-booth-system.html

[5] https://pfsspraybooths.com/advantages-of-using-automated-spray-booths-in-your-operation

[6] https://www.pbmetalfinishingsystems.com/news/comparing-manual-vs-automated-spray-equipment-for-industrial-applications

[7] https://www.linkedin.com/pulse/environmental-friendly-paint-booths-revolutionizing-ipcac

[8] https://www.codinter.com/en/spray-booths-a-complete-guide/

[9] https://www.tceq.texas.gov/assistance/air/spray.html

[10] https://roboticpaint.com/how-to-select-a-suitable-paint-booth/

[11] https://www.dbmtec.com/en/industrial-spray-booths/

[12] https://www.spraysystems.com/essential-design-elements-of-a-spray-booth-coatings-involved-in-the-finishing-process/

[13] https://www.sprayboothshop.com/blog/spray-booth-regulations-for-colorado/

[14] https://marathonspraybooths.com/top-benefits-of-outdoor-spray-booths-for-truck-painting/

[15] https://mobileenvironmentalsolutions.com/auto-spray-booth/

[16] https://www.epa.gov/sites/default/files/2013-12/documents/auto_refinishing_spray_booth_filters.pdf

[17] https://pfsspraybooths.com/ai-powered-spray-booths-smarter-faster-better-finishes

[18] https://www.durr.com/en/products/paint-shop-application-technology/air-pollution-control

[19] https://alliedcleanrooms.com/paint-booths-types-and-benefits/

[20] https://puretemac.com/future-trends-in-automatic-spray-painting-machine-systems.html

[21] https://www.spraysystems.com/nfpa-33-a-guide-to-fire-safety-compliance-for-paint-spray-booths/

[22] https://vocal.media/humans/understanding-the-benefits-of-using-a-spray-booth-in-lake-park

[23] https://dongdaspraybooth.en.made-in-china.com/product/fJxYHKkvqhpu/China-Eco-Friendly-Auto-Spray-Booth-with-Energy-Saving-Features.html

[24] https://www.platinghome.com/fa/scientific-articles/member-of-the-electroplating-association/spray-booths

[25] https://www.spraysystems.com/nfpa-33/

[26] https://oaspub.epa.gov/eims/eimscomm.getfile?p_download_id=490027

[27] https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=30004PX0.TXT

[28] http://www.osha.gov/spray-operations/controlling-hazards

[29] https://www.chgcoating.com/sale-50538085-eco-friendly-liquid-wet-painting-booth-with-automatic-manual-spray-coating.html

[30] https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=30003TQW.TXT

[31] https://apps.dtic.mil/sti/tr/pdf/ADA364070.pdf

[32] https://www.junair-spraybooths.co.uk/advantages-of-going-green-with-your-spray-booth/

[33] https://giffininc.com/products-systems/spraybooths/

[34] https://www.usiitalia.com/en/risk-of-fire-in-a-spray-booth-and-prevention/

[35] https://vocal.media/journal/the-future-is-here-the-exciting-developments-in-spray-booth-technology

[36] https://www.powdersprayline.com/Difference-between-Automatic-Powder-Coating-Equipment-and-Manual-Painting-Equipment-id3227601.html

[37] https://19january2017snapshot.epa.gov/sites/production/files/2013-12/documents/auto_refinishing_spray_booth_filters.pdf

[38] https://www.iqsdirectory.com/articles/paint-finishing-equipment/paint-spray-booths.html

[39] https://www.ramseierkoatings.com/what-are-the-key-differences-between-automatic-and-manual-spray-booths.html

[40] https://www.ssindustries.com.au/news/manual-vs-automatic-paint-gun-which-one-should-choose/

[41] https://www.ramseierkoatings.com/is-an-automatic-spray-booth-system-more-efficient-than-a-manual-one.html

[42] https://jmcautomotiveequipment.com/pages/buyers-guide/automotive-paint-booth-guide.html

[43] https://vntvietnam.vn/comparison-of-automatic-and-manual-powder-coating-systems

[44] https://www.reddit.com/r/Autobody/comments/1eoba99/my_neighbor_set_up_a_spray_booth_in_his_backyard/

[45] https://www.nmfrc.org/pdf/pf/020303.html

[46] https://www.paintbooth.com/how-do-paint-booths-control-overspray-and-emissions/

[47] https://www.zparint.com/how-to-keep-your-spray-booth-eco-friendly/

[48] https://www.cwimachinery.com/ecocarbon-spray-booths/ecocarbon-woodworking-spray-booth

[49] https://www.warrenforensics.com/wp-content/uploads/2013/11/Recirculation-Paint-Spray-Booths.pdf

[50] https://www.ttxinc.com/liquid-spray-booths

[51] https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=P100P6SY.TXT

China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.