Content Menu

● Introduction

● Understanding Automatic Reciprocators

>> What are Automatic Reciprocators?

>> Common Uses and Industries

>> Key Features

● Understanding Manual Application

>> What is Manual Application?

>> Industries and Scenarios

>> Advantages of Manual Application

● Performance Comparison

>> Speed and Efficiency

>> Precision and Consistency

>> Quality of Finish or Application

>> Fatigue and Ergonomics

● Cost Comparison

>> Initial Investment

>> Operational Costs

>> Return on Investment (ROI)

>> Maintenance and Downtime

● Factors Influencing the Choice Between Automatic Reciprocators and Manual Application

>> Production Volume

>> Complexity of Task

>> Skill Availability

>> Budget Constraints

>> Safety Considerations

● Case Study Examples

>> Manufacturing Scenario

>> Artisanal Application

● Future Trends and Innovations

>> Integration with Robotics and AI

>> Energy Efficiency Improvements

>> Modular and Portable Designs

● Conclusion

● Related Questions and Answers

>> 1. What are the primary benefits of automatic reciprocators over manual methods?

>> 2. When should a business opt for manual application instead of automation?

>> 3. How does the initial cost of automatic reciprocators compare to manual tools?

>> 4. Can automatic reciprocators fully replace manual workers?

>> 5. What are examples of industries benefiting most from automatic reciprocators?

Introduction

In today's fast-paced world, efficiency and precision are paramount in many applications across industries. When it comes to tools and techniques for performing repetitive tasks, the choice often comes down to automatic reciprocators versus manual application methods. Both approaches have their own sets of advantages and disadvantages. This article explores the performance and cost differences between automatic reciprocators and manual applications, providing a comprehensive analysis to help businesses and individuals make informed decisions.

Understanding Automatic Reciprocators

What are Automatic Reciprocators?

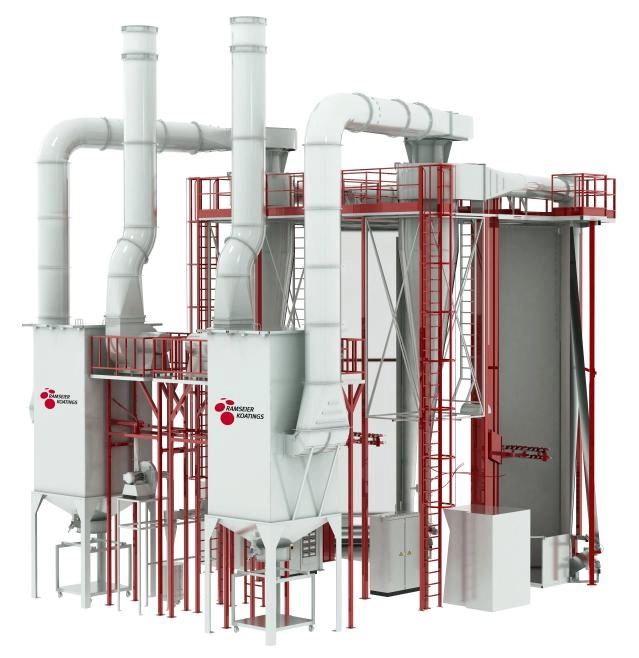

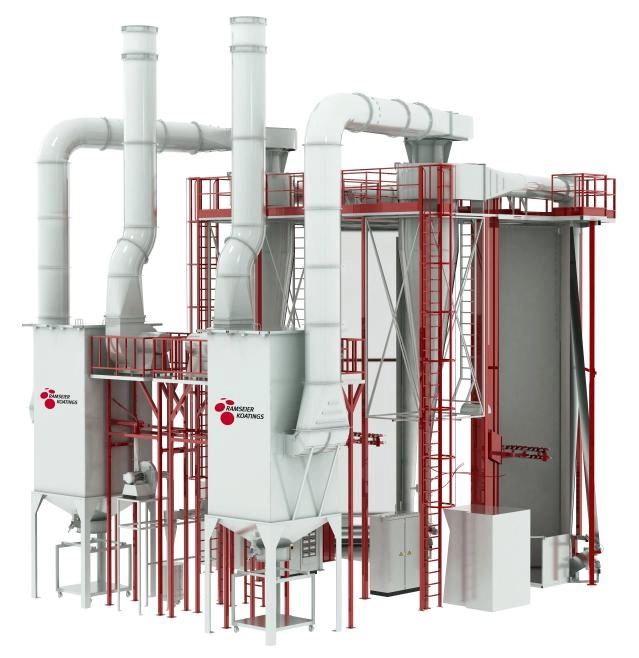

Automatic reciprocators are tools or machines designed to perform repeated motion automatically. These devices convert rotary motion into back-and-forth (reciprocating) movement, which can be applied for various purposes such as sealing, cutting, polishing, or applying substances evenly over surfaces without manual intervention.

Common Uses and Industries

Automatic reciprocators are prevalent in industries that require repetitive precision work, including:

- Manufacturing assembly lines

- Automotive repair and maintenance

- Construction and woodworking

- Textile production

- Food processing and packaging

Key Features

- Consistent Performance: They deliver uniform motion, reducing human error.

- Time Efficiency: Automate processes that would otherwise be time-consuming.

- Safety: Reduce operator fatigue and risk of repetitive strain injuries.

- Programmable: Many models can be adjusted for speed, stroke length, and force applied.

Understanding Manual Application

What is Manual Application?

Manual application methods involve a person physically performing the task without the aid of automated reciprocating machinery. This could include using handheld tools, brushes, or rollers to apply finishes, or manually moving parts back and forth in repetitive tasks.

Industries and Scenarios

Manual applications are still widely used in artisanship, craft production, small-scale manufacturing, and tasks where human judgment or dexterity is required. Examples include:

- Hand-painting decorative items

- Small batch manufacturing

- Repair works where precision is essential

- Situations requiring variable application pressure or pattern

Advantages of Manual Application

- Flexibility: Operators adapt quickly to variances and complex details.

- Lower Initial Investment: No need for expensive machinery.

- Control: Direct handling allows subtle adjustments.

- Simplicity: Easier to set up and requires less technical knowledge.

Performance Comparison

Speed and Efficiency

Automatic reciprocators generally outperform manual application in speed due to their ability to maintain constant motion without breaks. This reduces cycle time and increases throughput. Manual application is limited by human endurance and can be slower, especially over prolonged periods.

Precision and Consistency

The uniform motion of automatic reciprocators guarantees consistent output quality, minimizing defects and rework. Manual application may vary between operators and even within the same operator's work due to fatigue or distractions.

Quality of Finish or Application

While automatic reciprocators provide consistency, manual application may achieve superior results in tasks requiring discretion, finesse, and variable pressure. Skilled workers can adapt to surface irregularities and artistic nuances better than machines.

Fatigue and Ergonomics

Repetitive manual work can cause operator fatigue and injuries. Automatic reciprocators reduce the physical strain by taking over repetitive motions. Ergonomically, automated systems also provide more standardization in work conditions.

Cost Comparison

Initial Investment

Automatic reciprocators typically involve higher upfront costs owing to the complexity of machinery, necessary control systems, and installation. Manual application often requires only basic tools and minimal upfront expenditure.

Operational Costs

Automated systems may incur ongoing costs for maintenance, electricity, and parts replacement. They may also need trained personnel for operation and troubleshooting. Manual application costs are mostly labor-related, including wages and potential downtime.

Return on Investment (ROI)

Although automatic reciprocators cost more initially, the higher output, reduced waste, and lesser error rate can lead to faster ROI. Manual application may have a slower ROI but can be cost-effective where automation complexity is unnecessary or where craftsmanship is valued.

Maintenance and Downtime

Automatic reciprocators require regular maintenance to ensure reliability. Malfunctions can lead to costly downtime. Manual application avoids machine breakdowns but is susceptible to human error and productivity fluctuations.

Factors Influencing the Choice Between Automatic Reciprocators and Manual Application

Production Volume

High-volume production favors automatic reciprocators as they can sustain high speeds and output. Small or custom batch production may be better suited to manual application due to flexibility and lower cost.

Complexity of Task

Tasks with simple, repetitive motions are ideal for automation. Complex or variable tasks requiring judgment might benefit more from human skill in manual application.

Skill Availability

If trained operators or artisans are available, manual application can be viable. When skilled labor is scarce or costly, automation helps maintain consistent output.

Budget Constraints

Limited budgets may push companies towards manual application initially, despite slower long-term benefits of automation.

Safety Considerations

Automating dangerous or ergonomically challenging tasks can improve workplace safety and reduce injury risks.

Case Study Examples

Manufacturing Scenario

A mid-sized automotive parts manufacturer switched from manual sanding to automatic reciprocators. The change resulted in a 30% increase in throughput and a significant reduction in defect rates. Although initial investment was high, the company saved money over the next two years through less rework and reduced labor costs.

Artisanal Application

A small furniture workshop maintained manual finishing to allow workers to apply unique touches and react to wood grain variations. Here, manual application preserved product quality and upheld brand reputation, despite longer production times.

Future Trends and Innovations

Integration with Robotics and AI

Next-generation automatic reciprocators are being integrated with robotic arms and AI algorithms. These systems can adapt strokes and pressure dynamically based on real-time feedback, narrowing the gap between machine consistency and human finesse.

Energy Efficiency Improvements

Manufacturers focus on making reciprocators more energy-efficient, reducing operational costs and environmental footprints.

Modular and Portable Designs

New designs provide flexibility through modularity and portability, enabling smaller businesses to adopt automation without large infrastructure investments.

Conclusion

Both automatic reciprocators and manual application methods carry intrinsic strengths and limitations. Automatic reciprocators excel in speed, consistency, and reducing physical strain, making them ideal for high-volume, repetitive tasks. On the other hand, manual application offers flexibility, artistic control, and lower initial costs, better suited for customized or complex tasks.

Selecting the best approach depends on the specific industry, task requirements, production volume, available budget, and desired quality outcomes. An informed evaluation considering both performance and cost will ensure optimal investment and productivity gains.

Related Questions and Answers

1. What are the primary benefits of automatic reciprocators over manual methods?

Automatic reciprocators provide increased speed, consistent performance, lower risk of operator fatigue, and reduced error rates compared to manual methods.

2. When should a business opt for manual application instead of automation?

Manual application is preferable when tasks require high flexibility, artistic detail, small batch sizes, or when budget constraints limit machine acquisition.

3. How does the initial cost of automatic reciprocators compare to manual tools?

Automatic reciprocators usually require a significantly higher initial investment than manual tools, which are often inexpensive and simple.

4. Can automatic reciprocators fully replace manual workers?

In some repetitive and simple tasks, yes. However, many complex or highly skilled tasks still require manual input for quality and adaptability.

5. What are examples of industries benefiting most from automatic reciprocators?

Industries such as automotive manufacturing, electronics assembly, packaging, and woodworking benefit greatly from using automatic reciprocators.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.