Content Menu

● What is Swinger Technology in Powder Coating?

● How Swinger Technology Transforms Powder Coating Lines

>> Enhanced Coverage and Quality

>> Increased Transfer Efficiency and Powder Utilization

● Automation and Flexibility: Key Benefits of Swinger Technology

>> Integration with Automated Line Controls

>> Adaptability to Various Part Sizes and Complex Geometries

● Productivity Improvements Through Swinger Technology

>> Faster Cycle Times and Continuous Operation

>> Labor Savings and Workforce Safety

● Economic and Environmental Advantages

>> Cost Effectiveness

>> Environmental Impact

● Technical Features of Advanced Swinger Powder Coating Systems

>> Motion Control and Precision

>> Powder Feeding and Gun Management

>> Multi-Color and Multi-Product Handling

● Practical Applications and Industries Benefiting from Swinger Technology

● Challenges and Future Trends

>> Potential Challenges

>> Future Developments

● Frequently Asked Questions (FAQs)

Powder coating has become a preferred finish in many industries due to its durability, environmental benefits, and aesthetic appeal. As manufacturing evolves toward higher automation and efficiency, swinger technology is increasingly incorporated into automated powder coating lines. This article explores the advantages of swinger technology, its impact on coating quality and productivity, and why it represents a modern solution for efficient powder coating.

What is Swinger Technology in Powder Coating?

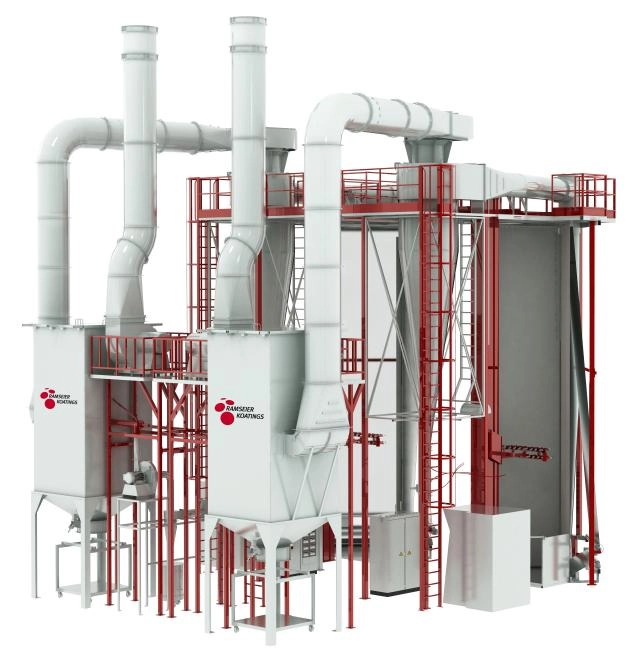

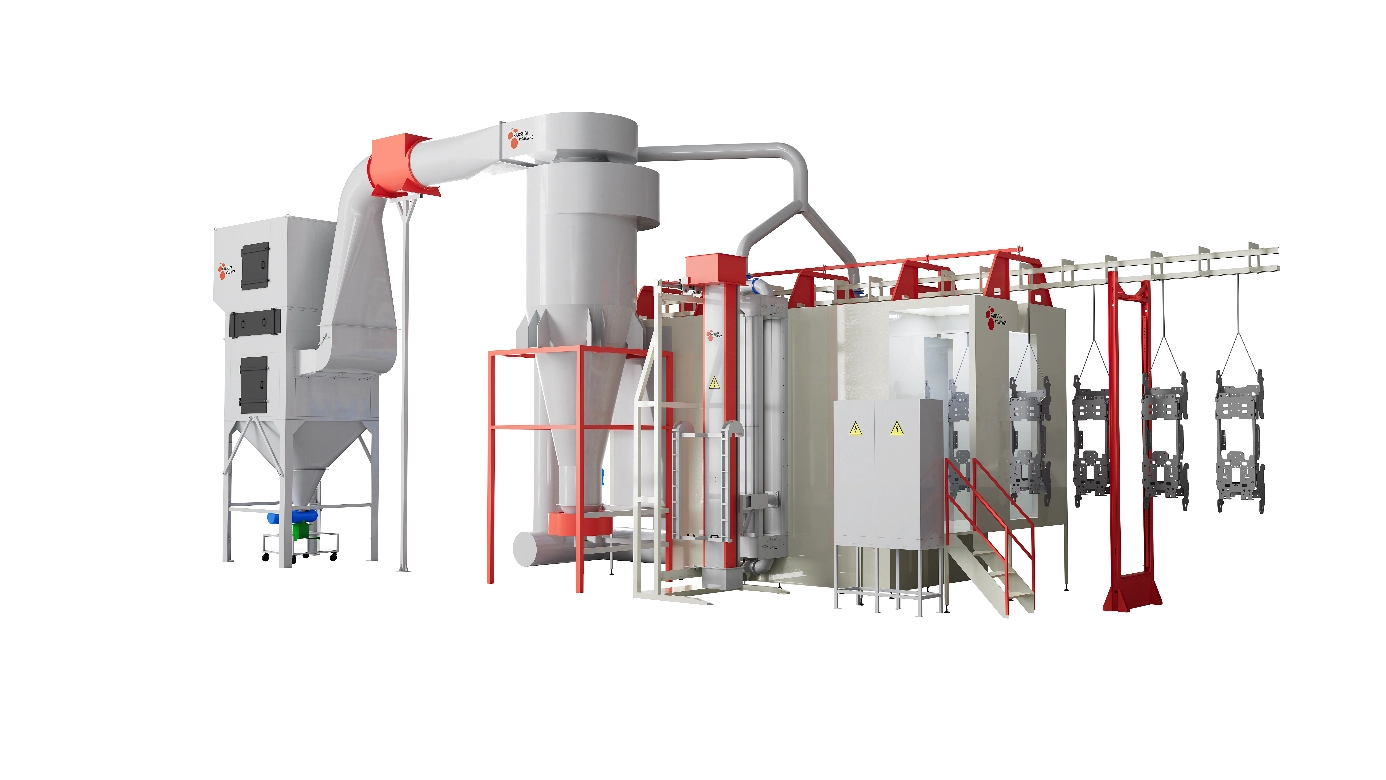

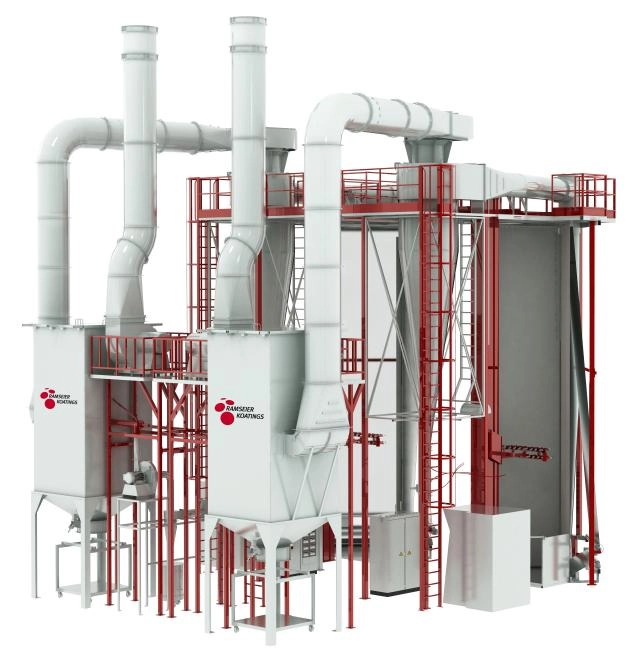

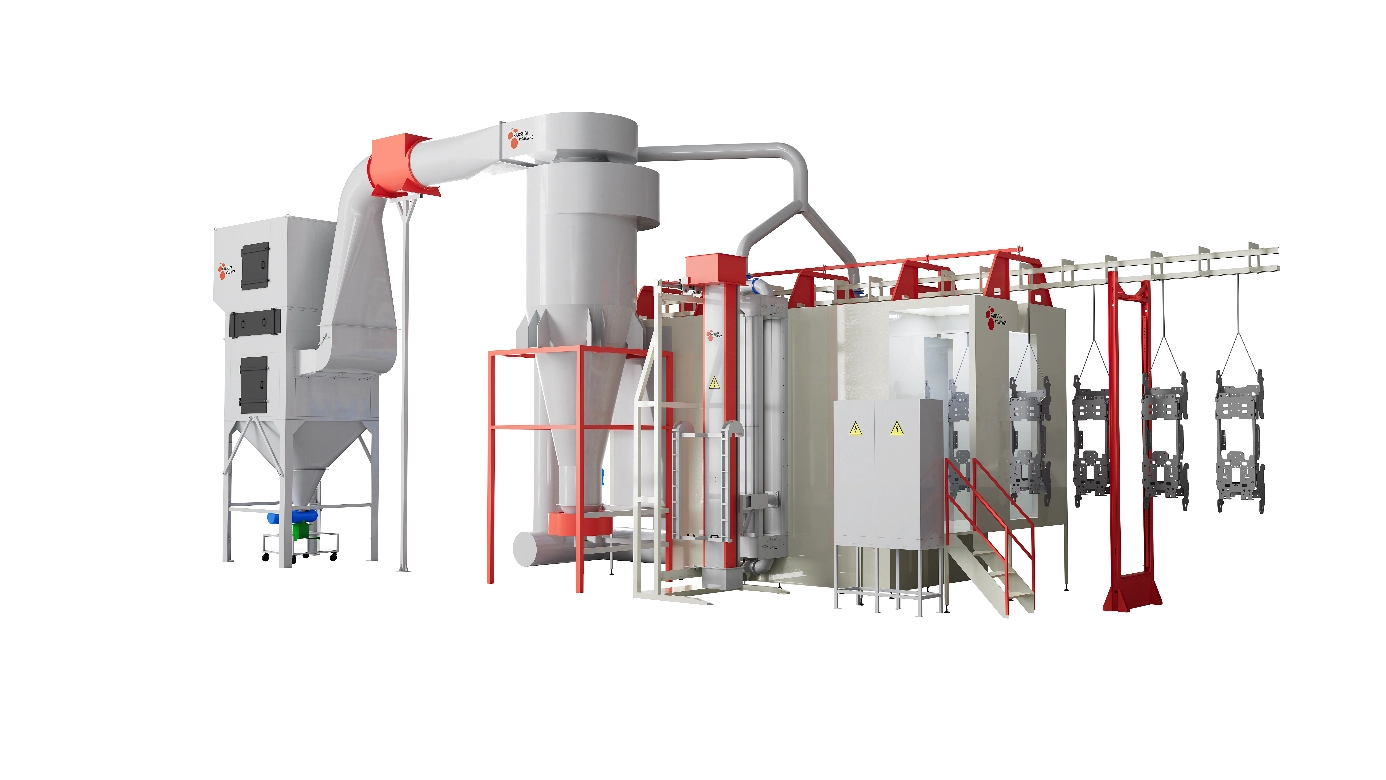

Swinger technology refers to a system where spray guns are mounted on mechanical arms or swinging mechanisms that oscillate or rotate to coat parts dynamically and uniformly. Unlike fixed or stationary guns, swinger guns move back and forth or in arcs to ensure consistent coverage across complex geometries or large surfaces. This technology can be integrated into automated powder coating lines, either combined with fixed guns or as standalone systems.

How Swinger Technology Transforms Powder Coating Lines

Enhanced Coverage and Quality

One of the fundamental benefits of swinger technology is its ability to achieve uniform and thorough coverage on parts, especially those with complex shapes or irregular surfaces. The swinging movement allows powder particles to reach corners, grooves, and hidden areas better than fixed gun setups, reducing touch-up requirements and defects.

This dynamic motion coupled with high-precision control systems leads to superior coating quality. The swing arms synchronize with the conveyor movement, enabling a stable powder cloud and efficient transfer efficiency, which helps produce durable and attractive finishes.

Increased Transfer Efficiency and Powder Utilization

Swinger systems improve transfer efficiency by maintaining optimal spray angles and distances dynamically during motion. This reduces overspray and waste, leading to better powder utilization and cost savings. The automation also enables consistent spray parameters, which is difficult to achieve manually or with static guns.

Additionally, the use of responsive gun control units and powder feed technologies within swinger systems ensures a continuous and consistent powder feed. This reduces interruptions and guarantees steady application.

Automation and Flexibility: Key Benefits of Swinger Technology

Integration with Automated Line Controls

Swinger technology is often paired with centralized control cabinets that unify spray gun operations. Parameters such as oscillation speed, spray duration, powder output, and voltage can be set and adjusted from a single interface, enabling efficient and flexible process control.

Such integration supports quick changes between production batches, facilitating multi-color or multi-product runs with minimal downtime. Automated cleaning features during color changes further enhance operational efficiency and powder management.

Adaptability to Various Part Sizes and Complex Geometries

Unlike static spray systems limited by their fixed position, swinger technology can be adjusted and programmed to match the specific dimension and shape of the parts on the conveyor. This flexibility means the same system can coat small automotive components as well as large industrial parts, often without requiring major mechanical adjustment.

With the swinging mechanism, spray guns maintain optimal coverage angles even when coating intricate areas, often unreachable by fixed guns, resulting in fewer defects and labor-intensive reworks.

Productivity Improvements Through Swinger Technology

Faster Cycle Times and Continuous Operation

Swinger mechanisms allow multiple spray guns to work in coordinated oscillation patterns, which increases the effective spray area and speeds up the coating cycle. By reducing the need for manual intervention and periodic repositioning, lines can maintain high throughput without sacrificing coating quality.

Coupled with overhead conveyor systems, swinger-based powder coating lines ensure smooth part transfers, minimizing bottlenecks and line stoppages.

Labor Savings and Workforce Safety

Automated swinger powder coating systems reduce the dependency on skilled manual labor, especially for complex or large-scale coating jobs. This results in lower labor costs and mitigates human error and inconsistency.

Furthermore, automation improves workforce safety by decreasing workers' exposure to powder particles and spray environments, which can contain hazardous materials if not controlled properly.

Economic and Environmental Advantages

Cost Effectiveness

Though the initial investment in swinger technology and automation might be higher than traditional manual or fixed-gun systems, the long-term savings in powder consumption, labor costs, rework, and material waste are significant. The precise control and uniform application help extend powder usage, lowering operational expenses.

Environmental Impact

Swinger systems, combined with powder recovery and filtering mechanisms, facilitate higher recycling rates of over-sprayed powders. This reduces airborne particles released into the environment and minimizes waste, supporting sustainable manufacturing practices.

The efficient use of powders and automated cleaning also means less frequent disposal and lower emissions, contributing to compliance with environmental regulations.

Technical Features of Advanced Swinger Powder Coating Systems

Motion Control and Precision

Sophisticated swinger powder coating systems use linear rails, frequency-controlled motors, and PLC automation to deliver stable, precise gun movement. This technology allows:

- Adjustable stroke length and speed to adapt to different part geometries.

- Smooth reciprocating motions that avoid coating inconsistencies.

- Storable program settings for quick changeovers and consistent reproduction of coating parameters.

Powder Feeding and Gun Management

Modern swinger technology integrates with advanced powder feed units that deliver uniform, quantifiable powder streams to guns. Features include:

- Continuous powder feeding minimizing interruptions.

- Automatic cleaning during color changes to reduce labor.

- Customizable gun counts and configurations for scalability.

Multi-Color and Multi-Product Handling

With dual hopper and multi-color switch technologies, swinger systems can coat parts in multiple colors sequentially or simultaneously. This flexibility supports complex production requirements and expands product possibilities without extensive manual handling.

Practical Applications and Industries Benefiting from Swinger Technology

Industries including automotive, appliances, electronics, construction materials, and metal fabrication widely adopt swinger technology in powder coating for the following reasons:

- Coating complex assemblies requiring consistent finishes.

- Reducing environmental footprint by optimizing powder usage.

- Achieving high-volume production efficiencies.

- Meeting high finish quality standards demanded by automotive and consumer goods markets.

Many manufacturers utilize swinger-equipped automated lines to meet the challenges of diverse part designs, high throughput, and regulatory compliance simultaneously.

Challenges and Future Trends

Potential Challenges

- Initial setup and calibration require skilled engineering to optimize swing parameters.

- Maintenance of mechanical swinger arms may be complex compared with fixed guns.

- Integration with existing conveyor and powder recovery systems needs careful design.

Future Developments

- Enhanced robotics combined with swinger arms may enable even greater flexibility, including 3D motion capabilities.

- Machine learning algorithms could optimize spray patterns dynamically for various parts in real-time.

- Continued innovation in powder recovery and environmental controls will bolster sustainability.

Frequently Asked Questions (FAQs)

Q1: What distinguishes swinger technology from fixed powder coating guns?

*Swinger technology uses oscillating mechanical arms to move spray guns dynamically, providing more uniform coverage and better access to complex parts than fixed guns.*

Q2: How does swinger technology improve powder utilization?

*By maintaining optimal spray angles and distances dynamically, swinger systems reduce overspray and waste, increasing the amount of powder effectively deposited on parts.*

Q3: Can swinger powder coating systems be integrated with existing automated lines?

*Yes, swinger technology is designed for integration with overhead conveyors, automated controls, powder feeding, and recovery systems to create highly efficient coating lines.*

Q4: What types of products benefit most from swinger powder coating technology?

*Products with complex geometries, large surface areas, or those requiring multiple colors particularly benefit from swinger technology's flexibility and precision.*

Q5: Is swinger technology environmentally friendly?

*Yes, swinger systems often incorporate powder recovery and filtration, minimizing waste and emissions, thus supporting sustainable manufacturing practices.*

[1] https://www.wagner-group.com/us/industry/products/powder-coating/product/s-line-system/

[2] https://huggingface.co/facebook/xm_transformer_unity_en-hk/resolve/main/en_zh_spm.dict?download=true

[3] https://www.colourspray.com/automatic-powder-coating-line.html

[4] https://raw.githubusercontent.com/hermitdave/FrequencyWords/master/content/2016/zh/zh_50k.txt

[5] https://innovationtechllc.com/solutions/powder-coating/

[6] https://www.scribd.com/document/498929761/%E5%8F%8C%E8%89%B2%E8%A1%A8%E8%A7%A3%E8%8B%B1%E8%AF%AD%E8%AF%8D%E6%B1%87

[7] https://www.gemapowdercoating.com/en/products/powder-management-centers-and-hoppers/opticenter-all-in-one-oc11

[8] https://www.cs.cmu.edu/afs/cs.cmu.edu/project/cmt-40/Nice/Transfer/Chinese/xferlexicon.txt

[9] https://www.ramseierkoatings.com/how-to-choose-the-right-swinger-powder-coating-system-for-your-production-line.html

[10] https://www.scribd.com/document/10317685/%E5%A4%A7%E5%AD%A6%E7%A7%91%E6%8A%80%E8%8B%B1%E8%AF%AD

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.