Content Menu

● Introduction

● Understanding Powder Coating

>> What is Powder Coating?

>> Advantages of Powder Coating

● The Role of Industry 4.0 in Powder Coating

>> What is Industry 4.0?

>> Key Technologies in Industry 4.0

● Data Management Systems in Powder Coating

>> Importance of Data Management Systems

>> Features of Modern Data Management Systems

● Enhancing Automation in Powder Coating

>> Automation Technologies in Powder Coating

>> Benefits of Automation

● Challenges in Implementing Industry 4.0 in Powder Coating

>> Initial Investment Costs

>> Integration with Existing Systems

>> Workforce Training

● Future Trends in Powder Coating Automation

>> Increased Use of AI and Machine Learning

>> Greater Emphasis on Sustainability

>> Enhanced Customization Capabilities

● Conclusion

● Frequently Asked Questions

>> 1. What is powder coating?

>> 2. How does Industry 4.0 impact powder coating?

>> 3. What are the benefits of using a data management system in powder coating?

>> 4. What challenges do companies face when implementing Industry 4.0 technologies?

>> 5. What future trends can we expect in powder coating automation?

Introduction

The manufacturing landscape is undergoing a significant transformation with the advent of Industry 4.0, characterized by the integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics. One of the sectors poised to benefit immensely from these advancements is powder coating. This article explores how data management systems and Industry 4.0 technologies are revolutionizing powder coating automation, enhancing efficiency, quality, and sustainability.

Understanding Powder Coating

What is Powder Coating?

Powder coating is a finishing process that applies a dry powder to a surface, which is then cured under heat to form a hard, durable finish. This method is widely used in various industries, including automotive, furniture, and appliances, due to its superior finish and environmental benefits compared to traditional liquid coatings.

Advantages of Powder Coating

- Durability: Powder-coated surfaces are more resistant to chipping, scratching, and fading.

- Environmental Benefits: Powder coating produces minimal volatile organic compounds (VOCs), making it a more eco-friendly option.

- Cost-Effectiveness: The process is efficient, reducing waste and energy consumption.

The Role of Industry 4.0 in Powder Coating

What is Industry 4.0?

Industry 4.0 refers to the fourth industrial revolution, which emphasizes the use of smart technologies in manufacturing. It integrates cyber-physical systems, IoT, and cloud computing to create interconnected manufacturing environments that enhance operational efficiency.

Key Technologies in Industry 4.0

1. IoT: Enables real-time monitoring and control of manufacturing processes.

2. Big Data Analytics: Analyzes vast amounts of data to optimize production and predict maintenance needs.

3. Artificial Intelligence: Enhances decision-making processes through machine learning and predictive analytics.

Data Management Systems in Powder Coating

Importance of Data Management Systems

Data management systems are crucial for collecting, storing, and analyzing data generated during the powder coating process. These systems facilitate better decision-making, improve process control, and enhance overall productivity.

Features of Modern Data Management Systems

- Real-Time Monitoring: Provides instant feedback on production processes, allowing for quick adjustments.

- Data Integration: Combines data from various sources, enabling comprehensive analysis.

- User-Friendly Interfaces: Simplifies the operation for users, making it easier to manage complex systems.

Enhancing Automation in Powder Coating

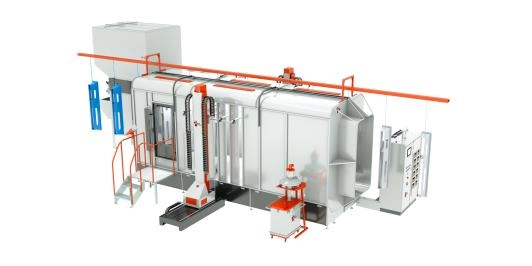

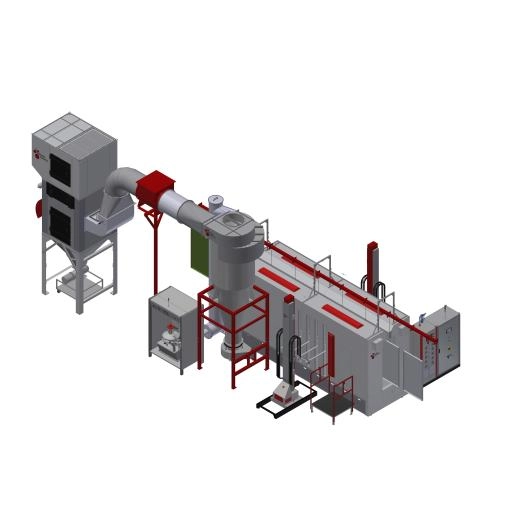

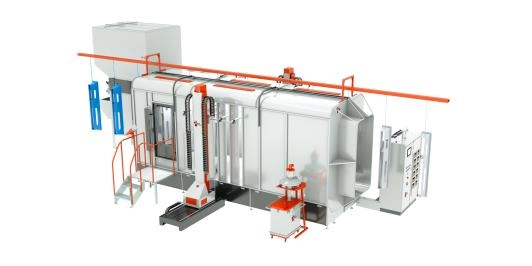

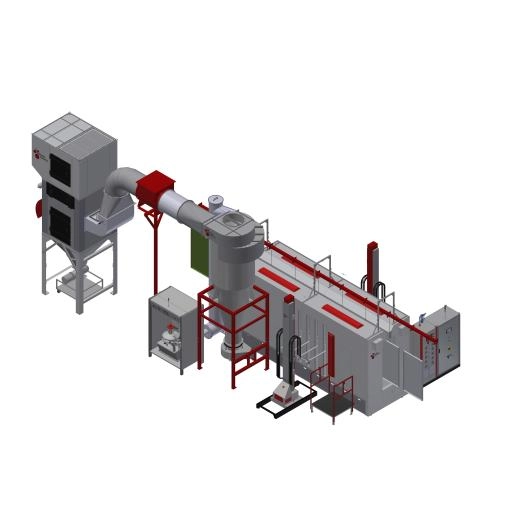

Automation Technologies in Powder Coating

Automation in powder coating involves the use of robotic systems and automated equipment to streamline the coating process. This includes:

- Robotic Spray Systems: Ensure consistent application of powder with minimal waste.

- Automated Curing Ovens: Optimize the curing process for better finish quality.

- Smart Control Systems: Allow for precise control over various parameters, enhancing the quality of the coating.

Benefits of Automation

- Increased Efficiency: Automation reduces cycle times and increases throughput.

- Improved Quality Control: Automated systems provide consistent results, reducing defects.

- Cost Savings: Lower labor costs and reduced material waste contribute to overall savings.

Challenges in Implementing Industry 4.0 in Powder Coating

Initial Investment Costs

The transition to Industry 4.0 technologies requires significant upfront investment in equipment and training. Companies must weigh these costs against the long-term benefits of increased efficiency and reduced operational costs.

Integration with Existing Systems

Integrating new technologies with legacy systems can be challenging. Companies must ensure compatibility and may need to invest in additional infrastructure to support new data management systems.

Workforce Training

As automation and data management systems become more prevalent, there is a growing need for skilled workers who can operate and maintain these advanced systems. Companies must invest in training programs to upskill their workforce.

Future Trends in Powder Coating Automation

Increased Use of AI and Machine Learning

AI and machine learning will play a crucial role in the future of powder coating automation. These technologies can analyze production data to identify patterns, predict maintenance needs, and optimize processes in real-time.

Greater Emphasis on Sustainability

As environmental concerns continue to rise, the powder coating industry will increasingly focus on sustainable practices. This includes using eco-friendly materials and processes, as well as optimizing energy consumption through smart technologies.

Enhanced Customization Capabilities

With advancements in automation and data management, manufacturers will be able to offer more customized powder coating solutions. This flexibility will allow companies to meet specific customer needs while maintaining efficiency.

Conclusion

The integration of data management systems and Industry 4.0 technologies is set to transform the powder coating industry. By enhancing automation, improving efficiency, and promoting sustainability, these advancements will enable manufacturers to remain competitive in a rapidly evolving market. As the industry continues to embrace these changes, the future of powder coating looks promising, with opportunities for innovation and growth.

Frequently Asked Questions

1. What is powder coating?

Powder coating is a finishing process that applies a dry powder to a surface, which is then cured under heat to form a hard, durable finish.

2. How does Industry 4.0 impact powder coating?

Industry 4.0 introduces smart technologies that enhance automation, improve efficiency, and enable real-time data analysis in powder coating processes.

3. What are the benefits of using a data management system in powder coating?

Data management systems facilitate real-time monitoring, data integration, and improved decision-making, leading to enhanced productivity and quality control.

4. What challenges do companies face when implementing Industry 4.0 technologies?

Challenges include high initial investment costs, integration with existing systems, and the need for workforce training.

5. What future trends can we expect in powder coating automation?

Future trends include increased use of AI and machine learning, greater emphasis on sustainability, and enhanced customization capabilities.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.