Content Menu

● Understanding Automatic Spray Booths

>> What is an Automatic Spray Booth?

>> Importance of Throughput in Manufacturing

● The Role of Smart Control Systems

>> What are Smart Control Systems?

>> Key Features of Smart Control Systems

● Enhancing Throughput with Smart Control Systems

>> Optimizing Cycle Time

>> Reducing Downtime

>> Improving Quality Control

>> Streamlining Workflow

● Case Studies: Success Stories

>> Automotive Industry

>> Furniture Manufacturing

● Future Trends in Smart Control Systems

>> Increased Automation

>> Enhanced Data Integration

>> Sustainability Considerations

● Conclusion

>> Questions and Answers

In the modern manufacturing landscape, efficiency and quality are paramount. Automatic spray booths play a crucial role in various industries, particularly in automotive and furniture manufacturing, where they are used for painting and finishing products. The integration of smart control systems into these booths has revolutionized the way manufacturers approach throughput and quality control. This article explores how these advanced systems enhance productivity, reduce waste, and improve overall operational efficiency.

Understanding Automatic Spray Booths

What is an Automatic Spray Booth?

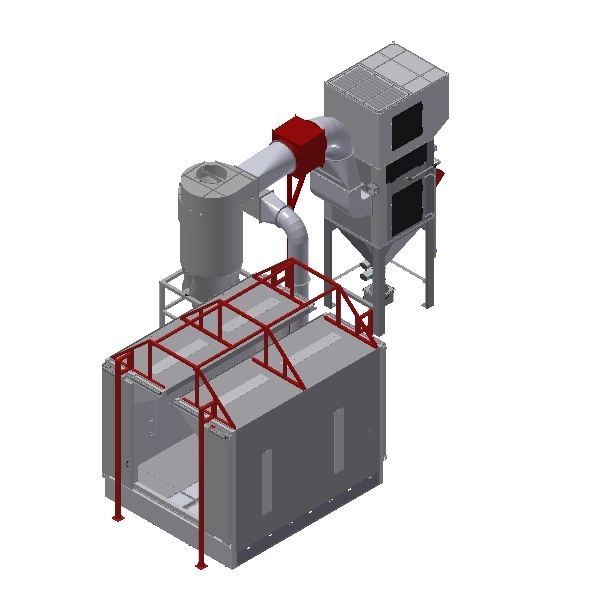

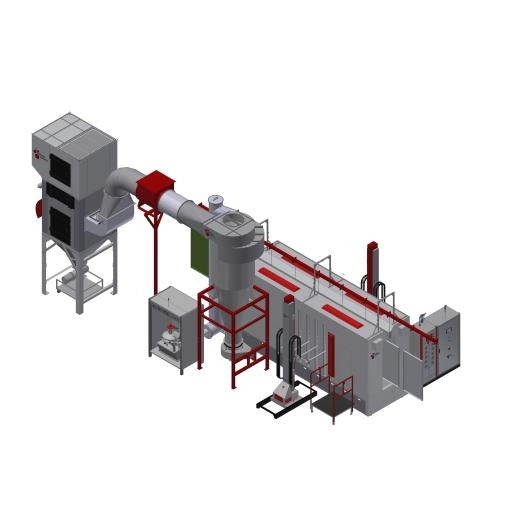

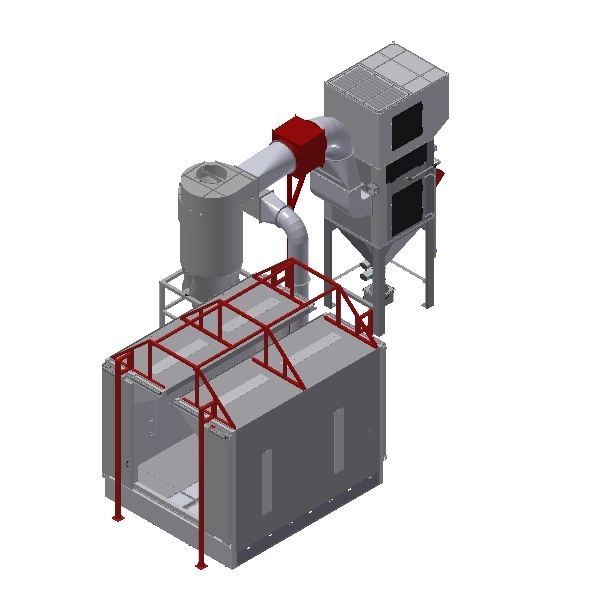

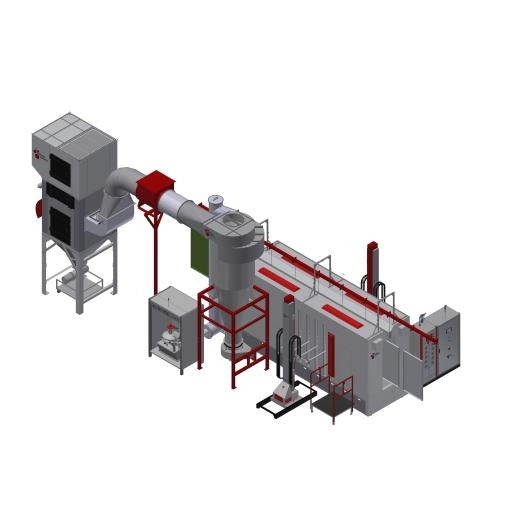

An automatic spray booth is a controlled environment designed for the application of paint, varnish, or other coatings on products. These booths are equipped with various features to ensure that the application process is efficient, safe, and environmentally friendly. The primary functions of an automatic spray booth include:

- Controlled Environment: Maintaining optimal temperature and humidity levels to ensure proper paint application.

- Airflow Management: Ensuring that overspray is minimized and that the air quality is maintained.

- Automated Application: Utilizing robotic arms or automated systems to apply coatings uniformly.

Importance of Throughput in Manufacturing

Throughput refers to the amount of material or items produced in a given period. In manufacturing, high throughput is essential for meeting customer demands and maximizing profitability. Factors that influence throughput in spray booths include:

- Cycle Time: The time taken to complete one full cycle of painting and drying.

- Downtime: Any period when the booth is not operational due to maintenance or other issues.

- Quality Control: Ensuring that the finished products meet quality standards without excessive rework.

The Role of Smart Control Systems

What are Smart Control Systems?

Smart control systems are advanced technologies that utilize data analytics, machine learning, and automation to optimize processes. In the context of automatic spray booths, these systems can monitor and control various parameters in real-time, leading to significant improvements in throughput.

Key Features of Smart Control Systems

1. Real-Time Monitoring: Continuous tracking of environmental conditions, equipment performance, and application quality.

2. Data Analytics: Analyzing historical data to identify trends and optimize processes.

3. Predictive Maintenance: Using data to predict when equipment is likely to fail, allowing for proactive maintenance.

4. Automated Adjustments: Automatically adjusting parameters such as airflow, temperature, and spray patterns based on real-time data.

Enhancing Throughput with Smart Control Systems

Optimizing Cycle Time

One of the primary ways smart control systems boost throughput is by optimizing cycle time. By continuously monitoring the drying process and environmental conditions, these systems can adjust the drying times and conditions to ensure that products are ready for the next stage of production as quickly as possible. This reduces bottlenecks and increases the overall efficiency of the manufacturing process.

Reducing Downtime

Downtime can significantly impact throughput. Smart control systems help minimize downtime through predictive maintenance. By analyzing data from equipment sensors, these systems can predict when a machine is likely to fail and schedule maintenance before a breakdown occurs. This proactive approach ensures that the spray booth remains operational, thereby maximizing production time.

Improving Quality Control

Quality control is critical in manufacturing, especially in industries where aesthetics are important. Smart control systems enhance quality control by providing real-time feedback on the application process. For instance, if the system detects that the paint is not adhering properly or that the finish is uneven, it can automatically adjust the spray parameters or alert operators to take corrective action. This reduces the need for rework and ensures that products meet quality standards.

Streamlining Workflow

Smart control systems can also streamline workflow within the spray booth. By integrating with other manufacturing systems, these controls can coordinate the movement of products through the booth, ensuring that each item is processed in the most efficient order. This integration helps to eliminate unnecessary delays and ensures that the production line operates smoothly.

Case Studies: Success Stories

Automotive Industry

In the automotive industry, a leading manufacturer implemented a smart control system in their spray booth. By integrating real-time monitoring and predictive maintenance, they reduced their cycle time by 20% and decreased downtime by 15%. The result was a significant increase in throughput, allowing them to meet rising customer demands without compromising quality.

Furniture Manufacturing

A furniture manufacturer faced challenges with inconsistent paint application and high rework rates. By adopting a smart control system, they were able to monitor the application process closely and make real-time adjustments. This led to a 30% reduction in rework and a 25% increase in throughput, demonstrating the effectiveness of smart technology in enhancing operational efficiency.

Future Trends in Smart Control Systems

Increased Automation

As technology continues to evolve, we can expect to see even greater levels of automation in spray booths. Future smart control systems will likely incorporate advanced robotics and artificial intelligence, allowing for more precise control over the painting process and further improvements in throughput.

Enhanced Data Integration

The future of smart control systems will also involve enhanced data integration. By connecting with other manufacturing systems, these controls will provide a more comprehensive view of the production process, enabling manufacturers to make more informed decisions and optimize their operations further.

Sustainability Considerations

Sustainability is becoming increasingly important in manufacturing. Smart control systems can help reduce waste and energy consumption in spray booths by optimizing processes and minimizing overspray. As manufacturers strive to meet environmental regulations and consumer expectations, these systems will play a crucial role in achieving sustainability goals.

Conclusion

The integration of smart control systems in automatic spray booths represents a significant advancement in manufacturing technology. By optimizing cycle times, reducing downtime, improving quality control, and streamlining workflows, these systems enhance throughput and overall operational efficiency. As technology continues to evolve, the potential for further improvements in manufacturing processes is immense. Manufacturers who embrace these innovations will be well-positioned to meet the challenges of the future.

Questions and Answers

1. What is the primary function of an automatic spray booth?

- The primary function is to provide a controlled environment for the application of paint and coatings on products.

2. How do smart control systems enhance throughput?

- They optimize cycle times, reduce downtime through predictive maintenance, improve quality control, and streamline workflows.

3. What role does real-time monitoring play in smart control systems?

- Real-time monitoring allows for continuous tracking of environmental conditions and equipment performance, enabling immediate adjustments to optimize processes.

4. What are some benefits of predictive maintenance in spray booths?

- Predictive maintenance helps minimize downtime by anticipating equipment failures and scheduling maintenance proactively.

5. How can smart control systems contribute to sustainability in manufacturing?

- They can reduce waste and energy consumption by optimizing processes and minimizing overspray, helping manufacturers meet environmental goals.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.