Content Menu

● Understanding Reciprocators

>> What is a Reciprocator?

>> How Do Reciprocators Work?

● Applications of Reciprocators

>> 1. Manufacturing and Automation

>>> Enhanced Precision in CNC Machines

>>> Increased Efficiency in Assembly Lines

>> 2. Robotics

>>> Superior Motion Control

>>> Versatility in Applications

>> 3. Automotive Industry

>>> Improved Engine Performance

>>> Enhanced Transmission Systems

>> 4. Medical Devices

>>> Precision in Surgical Instruments

>>> Improved Drug Delivery Systems

>> 5. Aerospace Applications

>>> Enhanced Control in Flight Systems

>>> Improved Landing Gear Mechanisms

● Advantages of Reciprocators Over Traditional Methods

>> Increased Efficiency

>> Enhanced Precision

>> Versatility

>> Reduced Labor Costs

>> Improved Safety

● Challenges and Considerations

>> Initial Investment

>> Maintenance Requirements

>> Training and Adaptation

● Conclusion

>> Frequently Asked Questions

In the ever-evolving landscape of technology and engineering, the quest for efficiency and effectiveness drives innovation. One of the most significant advancements in various fields is the development of reciprocators. These devices, which convert linear motion into rotary motion or vice versa, have proven to be superior in numerous applications compared to traditional methods. This article explores the top applications where reciprocators outperform conventional techniques, highlighting their advantages, mechanisms, and real-world implementations.

Understanding Reciprocators

What is a Reciprocator?

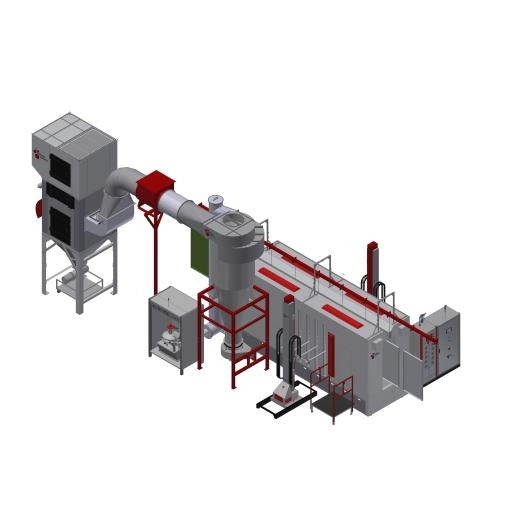

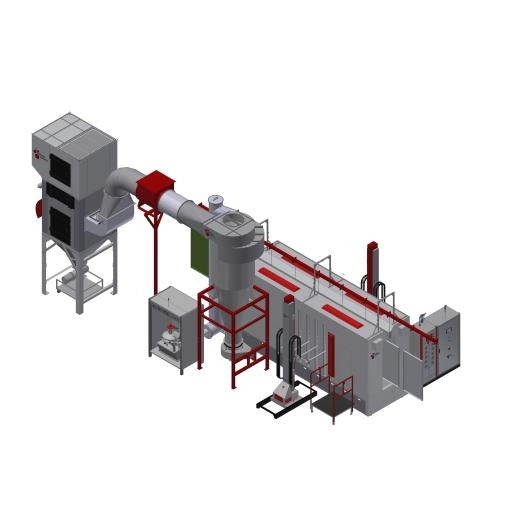

A reciprocator is a mechanical device that produces linear motion in a back-and-forth manner. This motion can be harnessed in various applications, from manufacturing to robotics. Reciprocators are often used in conjunction with other mechanisms, such as gears and levers, to achieve desired outcomes.

How Do Reciprocators Work?

Reciprocators typically operate through a combination of mechanical components, including pistons, rods, and crankshafts. The basic principle involves converting rotary motion into linear motion, allowing for precise control and movement. This mechanism is particularly beneficial in applications requiring repetitive tasks, as it enhances speed and accuracy.

Applications of Reciprocators

1. Manufacturing and Automation

Enhanced Precision in CNC Machines

Computer Numerical Control (CNC) machines are pivotal in modern manufacturing. Reciprocators play a crucial role in these machines by providing precise control over cutting tools. Unlike traditional methods that may rely on manual adjustments, reciprocators ensure consistent and accurate movements, resulting in higher quality products and reduced waste.

Increased Efficiency in Assembly Lines

In assembly line operations, reciprocators can significantly enhance efficiency. They automate repetitive tasks, such as placing components or fastening screws, which traditionally required manual labor. This automation not only speeds up production but also minimizes human error, leading to improved overall productivity.

2. Robotics

Superior Motion Control

In robotics, the ability to control motion accurately is paramount. Reciprocators enable robots to perform complex tasks with precision, such as picking and placing objects. Traditional methods may struggle with the intricacies of motion control, but reciprocators provide the necessary flexibility and responsiveness.

Versatility in Applications

Robots equipped with reciprocators can adapt to various tasks, from welding to painting. This versatility is a significant advantage over traditional robotic systems, which may be limited in their capabilities. The ability to switch between tasks seamlessly enhances operational efficiency and reduces downtime.

3. Automotive Industry

Improved Engine Performance

In the automotive sector, reciprocators are integral to engine design. They facilitate the movement of pistons within cylinders, converting fuel energy into mechanical energy. This process is more efficient than traditional methods, leading to improved fuel economy and reduced emissions.

Enhanced Transmission Systems

Reciprocators also play a vital role in modern transmission systems. They allow for smoother gear shifts and better power distribution, enhancing the overall driving experience. Traditional transmission methods often result in lag and inefficiency, whereas reciprocators provide a more responsive and dynamic performance.

4. Medical Devices

Precision in Surgical Instruments

In the medical field, precision is critical. Reciprocators are used in various surgical instruments, such as robotic surgical systems, to ensure accurate movements. Traditional manual instruments may lack the precision required for delicate procedures, while reciprocators enhance control and reduce the risk of errors.

Improved Drug Delivery Systems

Reciprocators are also utilized in drug delivery systems, where precise dosing is essential. These systems can deliver medication in controlled amounts, ensuring patients receive the correct dosage. Traditional delivery methods may lead to inconsistencies, whereas reciprocators provide reliable and accurate administration.

5. Aerospace Applications

Enhanced Control in Flight Systems

In aerospace engineering, reciprocators are used in flight control systems to manage the movement of control surfaces, such as ailerons and elevators. This application requires high precision and responsiveness, which reciprocators can provide more effectively than traditional systems.

Improved Landing Gear Mechanisms

Reciprocators are also employed in landing gear mechanisms, allowing for smooth deployment and retraction. Traditional landing gear systems may experience delays or malfunctions, but reciprocators ensure reliable operation, enhancing safety during takeoff and landing.

Advantages of Reciprocators Over Traditional Methods

Increased Efficiency

One of the primary advantages of reciprocators is their ability to increase efficiency. By automating tasks and providing precise control, they reduce the time and effort required to complete processes. This efficiency translates into cost savings and improved productivity across various industries.

Enhanced Precision

Reciprocators offer superior precision compared to traditional methods. Their ability to control motion accurately minimizes errors and ensures consistent results. This precision is particularly crucial in applications where even minor deviations can lead to significant issues.

Versatility

Reciprocators are versatile devices that can be adapted for various applications. Their ability to perform multiple tasks makes them an attractive option for industries looking to streamline operations and reduce the need for specialized equipment.

Reduced Labor Costs

By automating tasks, reciprocators can significantly reduce labor costs. Traditional methods often require a substantial workforce to perform repetitive tasks, whereas reciprocators can handle these processes with minimal human intervention.

Improved Safety

In many applications, reciprocators enhance safety by reducing the risk of human error. Automated systems can perform tasks that may be dangerous for humans, such as handling hazardous materials or operating heavy machinery.

Challenges and Considerations

Initial Investment

While reciprocators offer numerous advantages, the initial investment can be a barrier for some businesses. The cost of implementing these systems may be higher than traditional methods, but the long-term benefits often outweigh the initial expenses.

Maintenance Requirements

Reciprocators require regular maintenance to ensure optimal performance. Businesses must be prepared to invest in maintenance and repairs to keep these systems running efficiently.

Training and Adaptation

Implementing reciprocators may require training for employees to adapt to new technologies. Organizations must consider the learning curve associated with these systems and provide adequate training to ensure a smooth transition.

Conclusion

Reciprocators represent a significant advancement in various applications, outperforming traditional methods in efficiency, precision, and versatility. From manufacturing and robotics to the automotive and medical fields, these devices are transforming how tasks are performed. While challenges exist, the benefits of adopting reciprocators far outweigh the drawbacks, making them a valuable asset in modern technology.

Frequently Asked Questions

1. What are the main advantages of using reciprocators?

- Reciprocators offer increased efficiency, enhanced precision, versatility, reduced labor costs, and improved safety.

2. In which industries are reciprocators commonly used?

- Reciprocators are widely used in manufacturing, robotics, automotive, medical devices, and aerospace applications.

3. What challenges are associated with implementing reciprocators?

- Challenges include initial investment costs, maintenance requirements, and the need for employee training.

4. How do reciprocators improve precision in manufacturing?

- They provide accurate control over movements, reducing errors and ensuring consistent results in production processes.

5. Can reciprocators be adapted for multiple tasks?

- Yes, reciprocators are versatile and can be used for various applications, making them suitable for different tasks within an industry.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.