Content Menu

● Understanding Powder Hoppers

>> What is a Powder Hopper?

>> Importance of Powder Hoppers in Coating Lines

● Key Factors to Consider When Selecting Powder Hoppers

>> 1. Material Compatibility

>> 2. Hopper Size and Capacity

>> 3. Dispensing Mechanism

>> 4. Powder Flow Characteristics

>> 5. Maintenance and Cleaning

● Types of Powder Hoppers

>> 1. Standard Powder Hoppers

>> 2. High-Capacity Hoppers

>> 3. Custom Hoppers

>> 4. Mobile Hoppers

● Installation Considerations

>> 1. Location

>> 2. Support Structure

>> 3. Connection to Coating Equipment

● Operational Best Practices

>> 1. Regular Maintenance

>> 2. Monitor Powder Quality

>> 3. Train Operators

● Conclusion

>> Frequently Asked Questions

In the world of industrial coating, the efficiency and effectiveness of the coating process are paramount. One of the critical components that can significantly influence these factors is the powder hopper. This guide aims to provide a comprehensive overview of selecting the right powder hoppers for complex coating lines, ensuring optimal performance and productivity.

Understanding Powder Hoppers

What is a Powder Hopper?

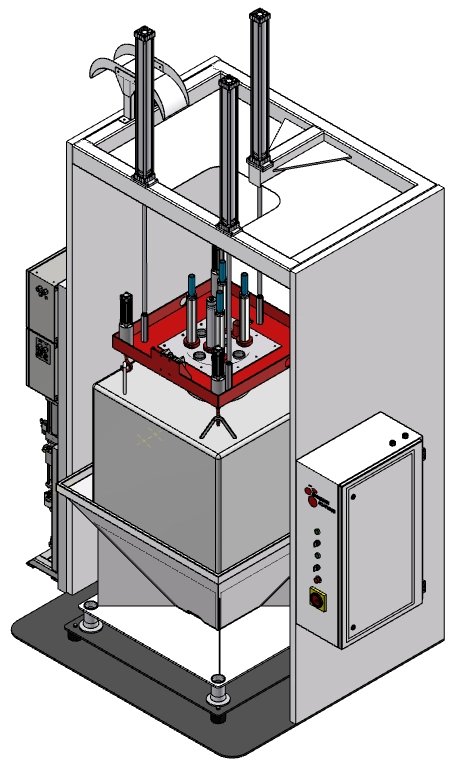

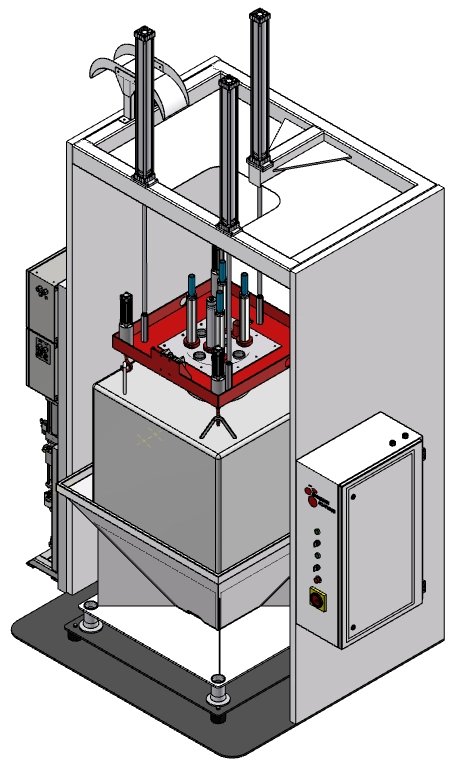

A powder hopper is a storage container designed to hold and dispense powder materials used in various coating processes, such as powder coating. These hoppers are essential in maintaining a consistent supply of powder to the coating equipment, ensuring that the application process runs smoothly without interruptions.

Importance of Powder Hoppers in Coating Lines

The role of powder hoppers in coating lines cannot be overstated. They help in:

- Maintaining Consistency: A well-designed hopper ensures a steady flow of powder, which is crucial for achieving uniform coating thickness.

- Reducing Downtime: By providing a reliable supply of powder, hoppers minimize the need for frequent refills, thus reducing downtime.

- Enhancing Quality: Properly managed powder hoppers can help prevent contamination and ensure that the powder remains in optimal condition for application.

Key Factors to Consider When Selecting Powder Hoppers

When choosing a powder hopper for your coating line, several factors must be taken into account to ensure that it meets your specific needs.

1. Material Compatibility

The first consideration is the compatibility of the hopper material with the powder being used. Different powders have varying properties, and the hopper material must be able to withstand these without degrading. Common materials for hoppers include:

- Stainless Steel: Known for its durability and resistance to corrosion, stainless steel is a popular choice for many applications.

- Polyethylene: This material is lightweight and resistant to many chemicals, making it suitable for certain powder types.

2. Hopper Size and Capacity

The size of the hopper is another critical factor. It should be large enough to hold an adequate supply of powder for your production needs but not so large that it becomes cumbersome. Consider the following:

- Production Volume: Estimate the amount of powder required for your production runs to determine the appropriate hopper size.

- Space Constraints: Ensure that the hopper fits within the available space in your facility.

3. Dispensing Mechanism

The dispensing mechanism of the hopper is vital for controlling the flow of powder. There are several types of dispensing mechanisms, including:

- Gravity Feed: This is the simplest form, relying on gravity to dispense powder. It is suitable for free-flowing powders.

- Auger Feed: An auger system can provide more precise control over the amount of powder dispensed, making it ideal for powders that do not flow easily.

4. Powder Flow Characteristics

Understanding the flow characteristics of the powder you are using is essential. Some powders flow freely, while others may clump or bridge. This can affect the choice of hopper design and dispensing mechanism. Consider conducting flow tests to determine the best hopper configuration.

5. Maintenance and Cleaning

Hoppers require regular maintenance and cleaning to ensure optimal performance. When selecting a hopper, consider:

- Ease of Access: Choose a design that allows for easy access for cleaning and maintenance.

- Material Properties: Some materials are easier to clean than others. Stainless steel, for example, can be cleaned more thoroughly than some plastics.

Types of Powder Hoppers

There are various types of powder hoppers available, each designed for specific applications and requirements.

1. Standard Powder Hoppers

These are the most common type of hoppers used in coating lines. They are typically made from stainless steel or plastic and are designed for general-purpose use. Standard hoppers are suitable for a wide range of powder types and are often used in smaller production setups.

2. High-Capacity Hoppers

For larger production lines, high-capacity hoppers are essential. These hoppers can hold a significant amount of powder, reducing the frequency of refills. They are often equipped with advanced dispensing mechanisms to ensure a consistent flow of powder.

3. Custom Hoppers

In some cases, standard hoppers may not meet specific production needs. Custom hoppers can be designed to fit unique requirements, such as specific dimensions, materials, or dispensing mechanisms. Working with a manufacturer to create a custom solution can ensure that all operational needs are met.

4. Mobile Hoppers

Mobile hoppers are designed for flexibility and can be moved around the production floor as needed. This is particularly useful in facilities where multiple coating lines are in operation. Mobile hoppers can be equipped with wheels and can be connected to various coating systems.

Installation Considerations

Proper installation of powder hoppers is crucial for their performance. Here are some key points to consider during installation:

1. Location

The location of the hopper should allow for easy access for refilling and maintenance. It should also be positioned to minimize the distance between the hopper and the coating equipment to reduce powder loss during transfer.

2. Support Structure

Ensure that the hopper is installed on a stable support structure that can handle its weight when filled with powder. This is particularly important for larger hoppers.

3. Connection to Coating Equipment

The hopper must be properly connected to the coating equipment to ensure a seamless flow of powder. This may involve using flexible tubing or rigid piping, depending on the design of the coating line.

Operational Best Practices

To maximize the efficiency of powder hoppers in your coating line, consider the following best practices:

1. Regular Maintenance

Implement a regular maintenance schedule to check for wear and tear, clean the hopper, and ensure that the dispensing mechanism is functioning correctly.

2. Monitor Powder Quality

Regularly check the quality of the powder being used. Contaminated or degraded powder can lead to poor coating results. Store powder in a cool, dry place to maintain its quality.

3. Train Operators

Ensure that all operators are trained in the proper use and maintenance of the powder hoppers. This includes understanding how to refill the hopper, clean it, and troubleshoot common issues.

Conclusion

Selecting the right powder hopper for complex coating lines is a critical decision that can impact the efficiency and quality of the coating process. By considering factors such as material compatibility, size, dispensing mechanisms, and maintenance needs, you can choose a hopper that meets your specific requirements. Regular maintenance and operator training are also essential to ensure optimal performance.

Frequently Asked Questions

1. What is the best material for a powder hopper?

- The best material depends on the type of powder being used. Stainless steel is durable and resistant to corrosion, while polyethylene is lightweight and chemical-resistant.

2. How do I determine the right size for a powder hopper?

- Consider your production volume and space constraints. Estimate the amount of powder needed for your production runs to select an appropriate size.

3. What type of dispensing mechanism is best for my application?

- Gravity feed is suitable for free-flowing powders, while auger feed provides more precise control for powders that do not flow easily.

4. How often should I clean my powder hopper?

- Regular cleaning is essential to maintain powder quality and hopper performance. Establish a cleaning schedule based on your production needs.

5. Can I customize a powder hopper for my specific needs?

- Yes, many manufacturers offer custom hopper solutions tailored to unique requirements, including size, material, and dispensing mechanisms.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.