Content Menu

● Understanding Powder Coating and Its Challenges

>> What is Powder Coating?

>> Challenges in the Powder Coating Industry

● The Role of Integrated Data Management Systems

>> What Are Integrated Data Management Systems?

>> Key Features of Integrated Data Management Systems

● Benefits of Using Integrated Data Management Systems

>> Enhanced Quality Control

>> Increased Operational Efficiency

>> Better Inventory Management

>> Improved Decision-Making

● Case Studies: Success Stories in the Powder Coating Industry

>> Leading Companies Adopting Integrated Systems

>> Impact on Business Performance

● Future Trends in Integrated Data Management Systems

>> The Rise of Smart Technologies

>> Sustainability and Environmental Considerations

>> Customization and Flexibility

● Conclusion

● Frequently Asked Questions

>> 1. What are the main benefits of integrated data management systems in powder coating?

>> 2. How do these systems improve quality control?

>> 3. Can integrated data management systems help reduce costs?

>> 4. What role do predictive analytics play in these systems?

>> 5. How is the future of integrated data management systems expected to evolve?

In the rapidly evolving landscape of manufacturing, particularly in the powder coating industry, the integration of data management systems has become a pivotal strategy for leading companies. These systems not only streamline operations but also enhance quality control, reduce costs, and improve overall efficiency. This article delves into the reasons why global powder coating leaders are increasingly adopting integrated data management systems, exploring their benefits, functionalities, and the future of this technology in the industry.

Understanding Powder Coating and Its Challenges

What is Powder Coating?

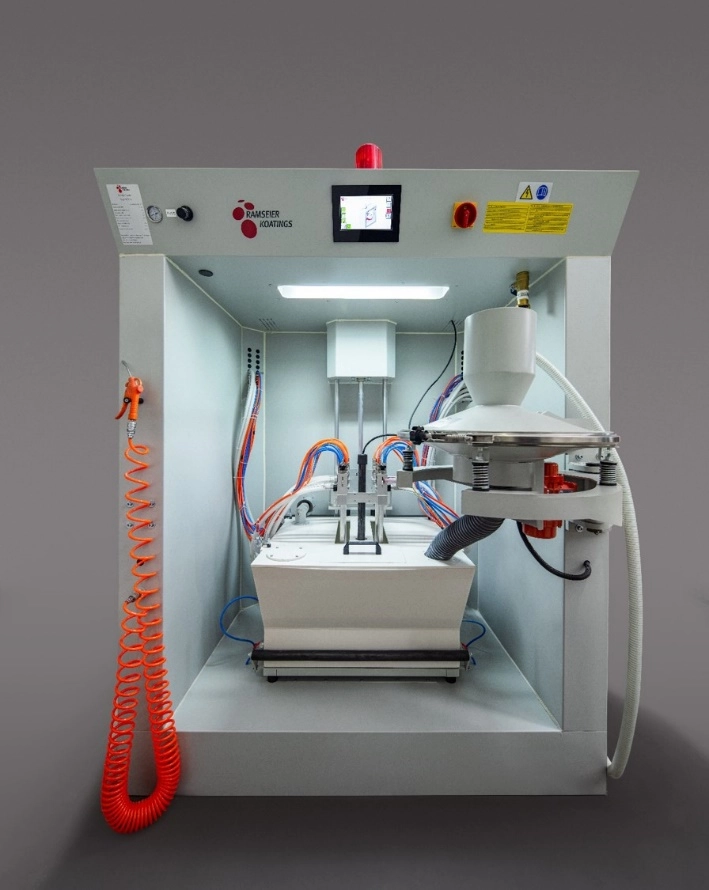

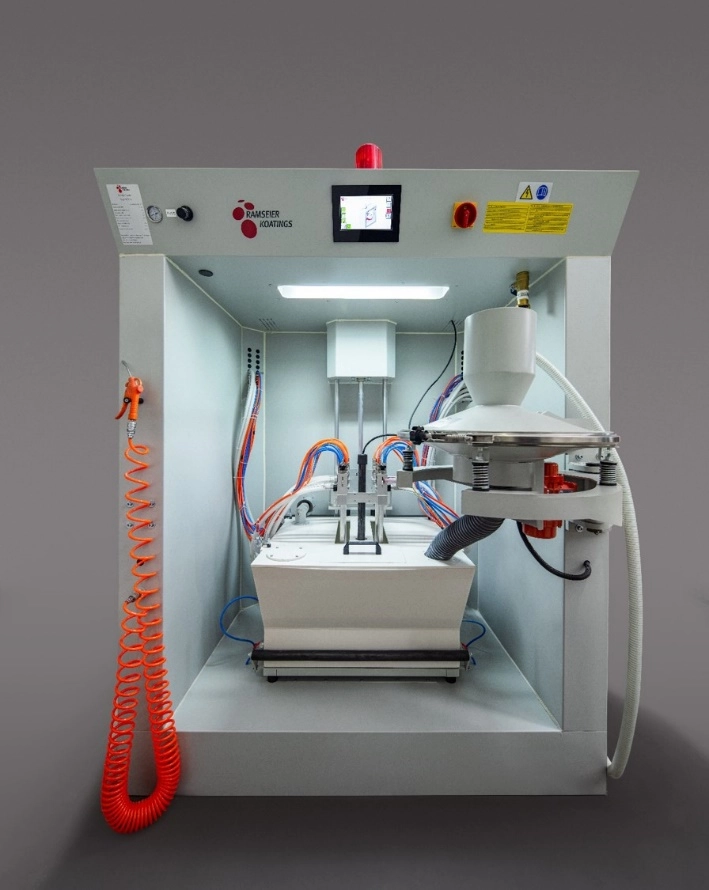

Powder coating is a finishing process that applies a dry powder to a surface, which is then cured under heat to form a hard, durable finish. This method is widely used in various industries, including automotive, appliances, and furniture, due to its superior finish and environmental benefits compared to traditional liquid coatings.

Challenges in the Powder Coating Industry

Despite its advantages, the powder coating industry faces several challenges:

- Quality Control: Ensuring consistent quality across batches can be difficult, especially with variations in raw materials and environmental conditions.

- Inventory Management: Tracking inventory levels and managing supply chains efficiently is crucial to avoid production delays.

- Operational Efficiency: Manufacturers often struggle with optimizing processes and minimizing downtime.

- Data Silos: Many companies operate with fragmented data systems, leading to inefficiencies and miscommunication.

The Role of Integrated Data Management Systems

What Are Integrated Data Management Systems?

Integrated data management systems are comprehensive platforms that consolidate data from various sources within an organization. They facilitate real-time data collection, analysis, and reporting, enabling manufacturers to make informed decisions quickly.

Key Features of Integrated Data Management Systems

1. Real-Time Data Monitoring: These systems provide live updates on production processes, allowing for immediate adjustments and interventions.

2. Centralized Data Repository: All data is stored in a single location, making it accessible to all stakeholders and reducing the risk of errors.

3. Automation of Routine Tasks: By automating tasks such as inventory tracking and quality checks, these systems free up valuable time for employees to focus on more strategic activities.

4. Predictive Analytics: Advanced analytics capabilities help predict equipment failures and maintenance needs, reducing downtime and improving reliability.

Benefits of Using Integrated Data Management Systems

Enhanced Quality Control

One of the primary benefits of integrated data management systems is improved quality control. By providing real-time insights into the coating process, manufacturers can quickly identify and rectify issues, ensuring that every batch meets quality standards. This capability is crucial in maintaining customer satisfaction and reducing waste.

Increased Operational Efficiency

Integrated systems streamline operations by automating workflows and reducing manual data entry. This efficiency leads to faster production times and lower operational costs. For instance, manufacturers can optimize machine usage and minimize idle time, significantly enhancing productivity.

Better Inventory Management

With integrated data management systems, companies can track inventory levels in real-time, ensuring that they have the right materials on hand when needed. This capability helps prevent production delays and reduces excess inventory, leading to cost savings.

Improved Decision-Making

Access to centralized, real-time data empowers managers and executives to make informed decisions quickly. Whether it's adjusting production schedules or reallocating resources, having accurate data at their fingertips allows for more strategic planning and execution.

Case Studies: Success Stories in the Powder Coating Industry

Leading Companies Adopting Integrated Systems

1. WAGNER Industrial Solutions: Their COATIFY platform integrates IoT technology to provide real-time monitoring of the powder coating process, enhancing transparency and control.

2. PPG Industries: By leveraging advanced data analytics, PPG has improved its operational efficiency and product quality, solidifying its position as a market leader.

3. AkzoNobel: This company has integrated smart technologies into its powder coating processes, resulting in significant improvements in sustainability and cost-effectiveness.

Impact on Business Performance

These companies have reported substantial improvements in key performance indicators (KPIs) such as production speed, quality consistency, and customer satisfaction. The integration of data management systems has not only streamlined their operations but also positioned them as leaders in innovation within the industry.

Future Trends in Integrated Data Management Systems

The Rise of Smart Technologies

As the powder coating industry continues to evolve, the integration of smart technologies such as artificial intelligence (AI) and machine learning (ML) is expected to play a significant role. These technologies will enhance predictive analytics capabilities, allowing manufacturers to anticipate issues before they arise and optimize their processes further.

Sustainability and Environmental Considerations

With increasing pressure to adopt sustainable practices, integrated data management systems will also help companies track their environmental impact. By monitoring energy usage and waste production, manufacturers can implement strategies to reduce their carbon footprint and comply with regulatory requirements.

Customization and Flexibility

The future of integrated data management systems will likely see a shift towards more customizable solutions that cater to the specific needs of individual manufacturers. This flexibility will enable companies to adapt their systems as their operations grow and change.

Conclusion

The adoption of integrated data management systems is transforming the powder coating industry, enabling companies to enhance quality control, improve operational efficiency, and make data-driven decisions. As technology continues to advance, these systems will play an increasingly vital role in shaping the future of manufacturing. By embracing these innovations, global powder coating leaders are not only improving their own operations but also setting new standards for the industry as a whole.

Frequently Asked Questions

1. What are the main benefits of integrated data management systems in powder coating?

Integrated data management systems enhance quality control, increase operational efficiency, improve inventory management, and facilitate better decision-making.

2. How do these systems improve quality control?

They provide real-time insights into the coating process, allowing manufacturers to quickly identify and rectify issues, ensuring consistent quality across batches.

3. Can integrated data management systems help reduce costs?

Yes, by streamlining operations and minimizing downtime, these systems can lead to significant cost savings in production.

4. What role do predictive analytics play in these systems?

Predictive analytics help anticipate equipment failures and maintenance needs, allowing manufacturers to address potential issues before they disrupt production.

5. How is the future of integrated data management systems expected to evolve?

The future will likely see the integration of smart technologies, increased customization, and a focus on sustainability, further enhancing the capabilities of these systems.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.