Content Menu

● Understanding Powder Hoppers

>> What is a Powder Hopper?

>> Types of Powder Hoppers

● Factors Influencing the Need for Specialized Hoppers

>> Powder Characteristics

>> Production Requirements

>> Cost Considerations

● Advantages of Specialized Hoppers

>> Improved Flow Characteristics

>> Enhanced Quality Control

>> Flexibility in Production

● Disadvantages of Specialized Hoppers

>> Higher Costs

>> Complexity in Design

>> Limited Use Cases

● Conclusion

● Frequently Asked Questions

>> 1. What types of powders require specialized hoppers?

>> 2. How do I know if my powder needs a specialized hopper?

>> 3. Are specialized hoppers more expensive than standard hoppers?

>> 4. Can a single hopper handle multiple powder types?

>> 5. What maintenance is required for specialized hoppers?

In the world of manufacturing and processing, the choice of equipment can significantly impact efficiency, quality, and cost. One such piece of equipment is the powder hopper, a crucial component in various industries, including pharmaceuticals, food processing, and powder coating. This article explores whether specialized hoppers are necessary for different powder types, examining the factors that influence this decision.

Understanding Powder Hoppers

What is a Powder Hopper?

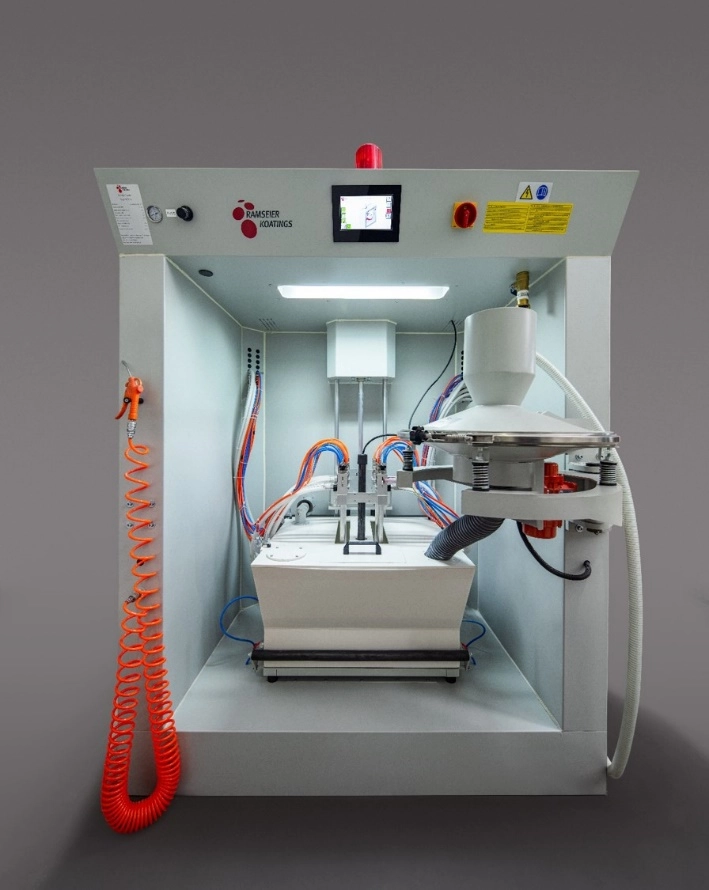

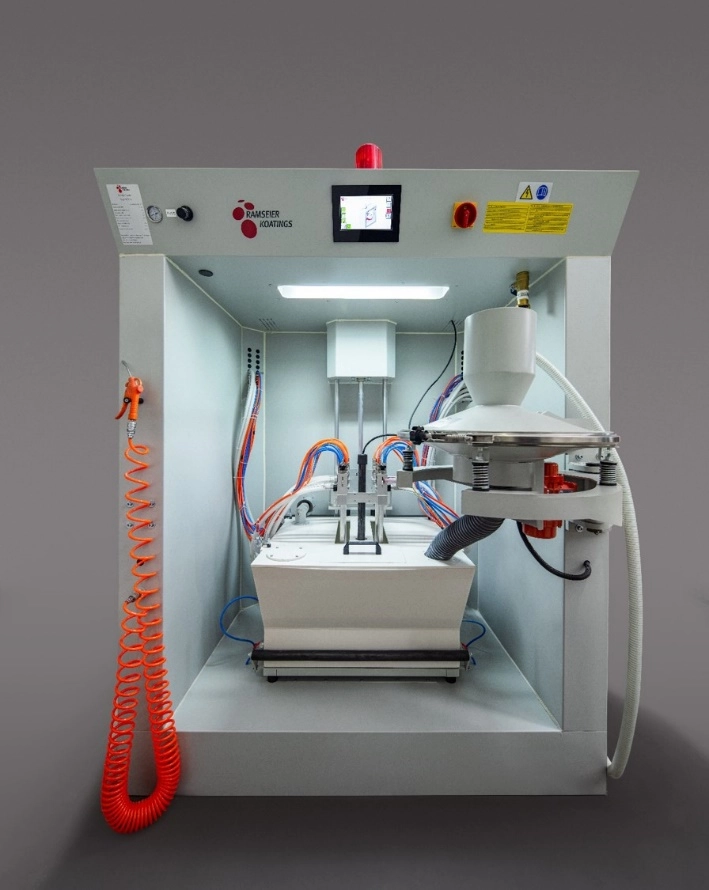

A powder hopper is a storage container designed to hold bulk powders and facilitate their controlled discharge into processing equipment. Hoppers come in various shapes and sizes, tailored to the specific characteristics of the powders they handle. The design of a hopper can affect the flowability of the powder, the risk of clogs, and the overall efficiency of the production process.

Types of Powder Hoppers

There are several types of hoppers, each suited for different applications:

- Gravity Hoppers: These rely on gravity to discharge powder and are suitable for free-flowing materials.

- Pneumatic Hoppers: These use air pressure to move powders, ideal for cohesive or sticky materials.

- Vibratory Hoppers: These employ vibrations to enhance flow, useful for powders that tend to clump.

- Fluidized Hoppers: These create a fluid-like state in the powder, improving flow characteristics for certain applications.

Factors Influencing the Need for Specialized Hoppers

Powder Characteristics

The type of powder being processed is a primary factor in determining the need for a specialized hopper. Key characteristics include:

- Flowability: Powders with poor flowability may require hoppers designed to promote better flow, such as those with specific shapes or internal features.

- Cohesiveness: Sticky or cohesive powders often necessitate pneumatic or vibratory hoppers to prevent clogs.

- Particle Size: Fine powders may behave differently than coarse powders, influencing the choice of hopper design.

Production Requirements

The specific requirements of the production process also play a crucial role:

- Volume: High-volume production may benefit from larger hoppers that can hold more material, reducing the frequency of refills.

- Color Changes: In industries like powder coating, frequent color changes can complicate hopper use. Specialized hoppers may be needed to minimize contamination between colors.

- Consistency: Maintaining a consistent flow of powder is vital for quality control. Hoppers that can adapt to different powder types may be necessary to ensure uniformity.

Cost Considerations

Investing in specialized hoppers can be costly. Manufacturers must weigh the benefits against the potential return on investment. Factors to consider include:

- Initial Costs: Specialized hoppers often come with higher upfront costs due to their design and features.

- Maintenance: More complex hoppers may require more maintenance, impacting long-term operational costs.

- Efficiency Gains: If a specialized hopper significantly improves efficiency or product quality, the investment may be justified.

Advantages of Specialized Hoppers

Improved Flow Characteristics

Specialized hoppers can enhance the flow of challenging powders, reducing the risk of clogs and ensuring a steady supply to downstream processes. This is particularly important in high-speed production environments where downtime can be costly.

Enhanced Quality Control

By using hoppers designed for specific powder types, manufacturers can achieve better consistency in product quality. This is crucial in industries like pharmaceuticals, where precise dosing is essential.

Flexibility in Production

Hoppers that can accommodate various powder types allow manufacturers to be more flexible in their production processes. This adaptability can lead to increased efficiency and reduced waste.

Disadvantages of Specialized Hoppers

Higher Costs

The initial investment for specialized hoppers can be significant, which may not be feasible for all manufacturers, especially smaller operations.

Complexity in Design

Specialized hoppers may require more intricate designs, leading to potential challenges in maintenance and operation. This complexity can also result in longer lead times for repairs or replacements.

Limited Use Cases

Some specialized hoppers may only be suitable for specific powders, limiting their versatility. Manufacturers must carefully consider their product range when investing in such equipment.

Conclusion

The decision to use specialized hoppers for different powder types depends on various factors, including powder characteristics, production requirements, and cost considerations. While specialized hoppers can offer significant advantages in terms of flow characteristics and quality control, they also come with higher costs and complexity. Manufacturers must evaluate their specific needs and weigh the benefits against the potential drawbacks to make an informed decision.

Frequently Asked Questions

1. What types of powders require specialized hoppers?

Specialized hoppers are often needed for cohesive, sticky, or fine powders that may clog standard hoppers.

2. How do I know if my powder needs a specialized hopper?

Consider the flowability, cohesiveness, and particle size of your powder. If these characteristics pose challenges in processing, a specialized hopper may be necessary.

3. Are specialized hoppers more expensive than standard hoppers?

Yes, specialized hoppers typically have higher initial costs due to their design and features tailored for specific powder types.

4. Can a single hopper handle multiple powder types?

Some hoppers are designed to be versatile and can handle various powder types, but this may depend on the specific characteristics of the powders involved.

5. What maintenance is required for specialized hoppers?

Maintenance requirements vary by design, but specialized hoppers may need more frequent cleaning and checks to ensure optimal performance, especially when handling different powders.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.