Content Menu

● Understanding Reciprocators

>> What Are Reciprocators?

>> How Do Reciprocators Work?

● The Importance of Reciprocators in Coating Facilities

>> Enhanced Efficiency and Productivity

>> Consistency and Quality Control

>> Reduction of Material Waste

>> Improved Worker Safety

● Types of Reciprocators

>> Pneumatic Reciprocators

>> Electric Reciprocators

>> Hydraulic Reciprocators

● Key Benefits of Reciprocators in Automated Coating

>> 1. Increased Throughput

>> 2. Customization and Flexibility

>> 3. Cost-Effectiveness

>> 4. Enhanced Coating Quality

>> 5. Simplified Maintenance

● Future Trends in Automated Coating Technologies

>> Integration of AI and Machine Learning

>> Increased Use of Robotics

>> Sustainability Initiatives

● Conclusion

>> Frequently Asked Questions

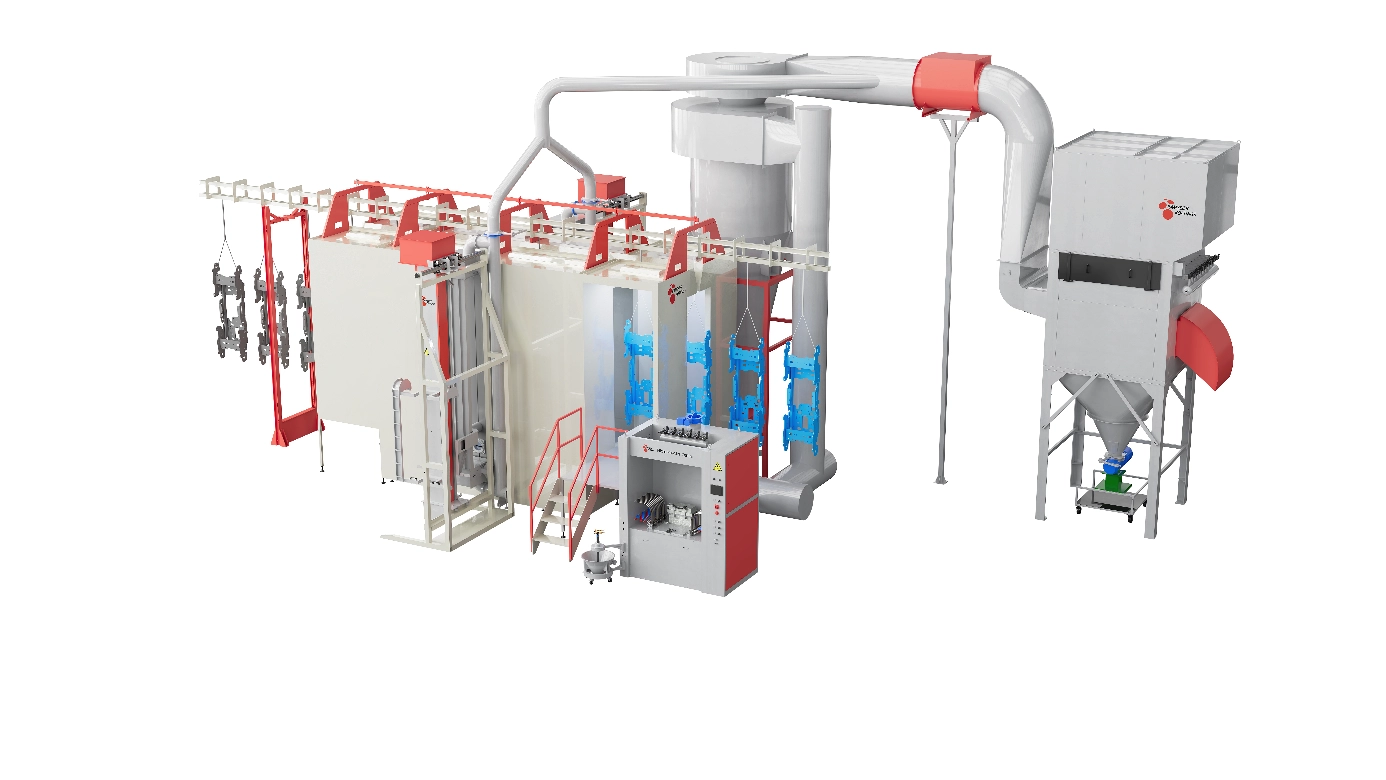

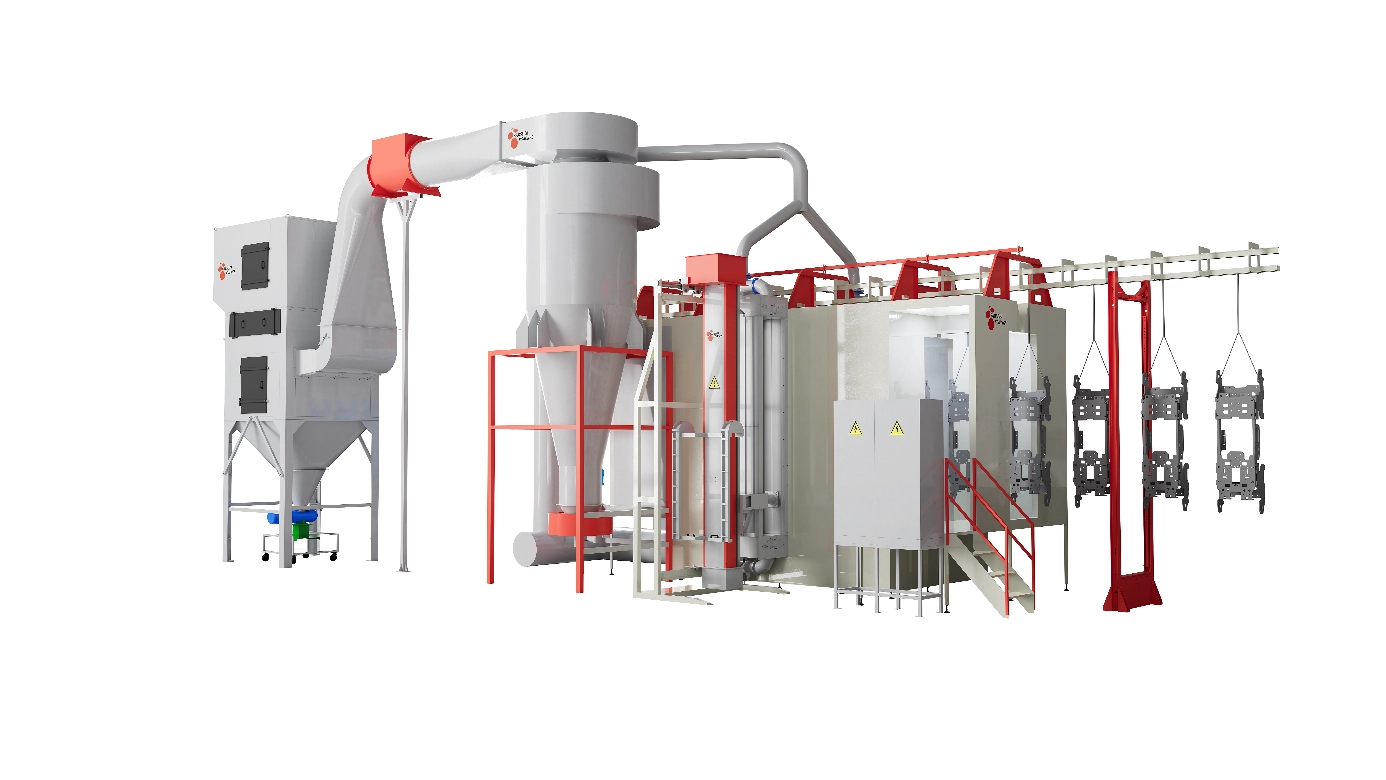

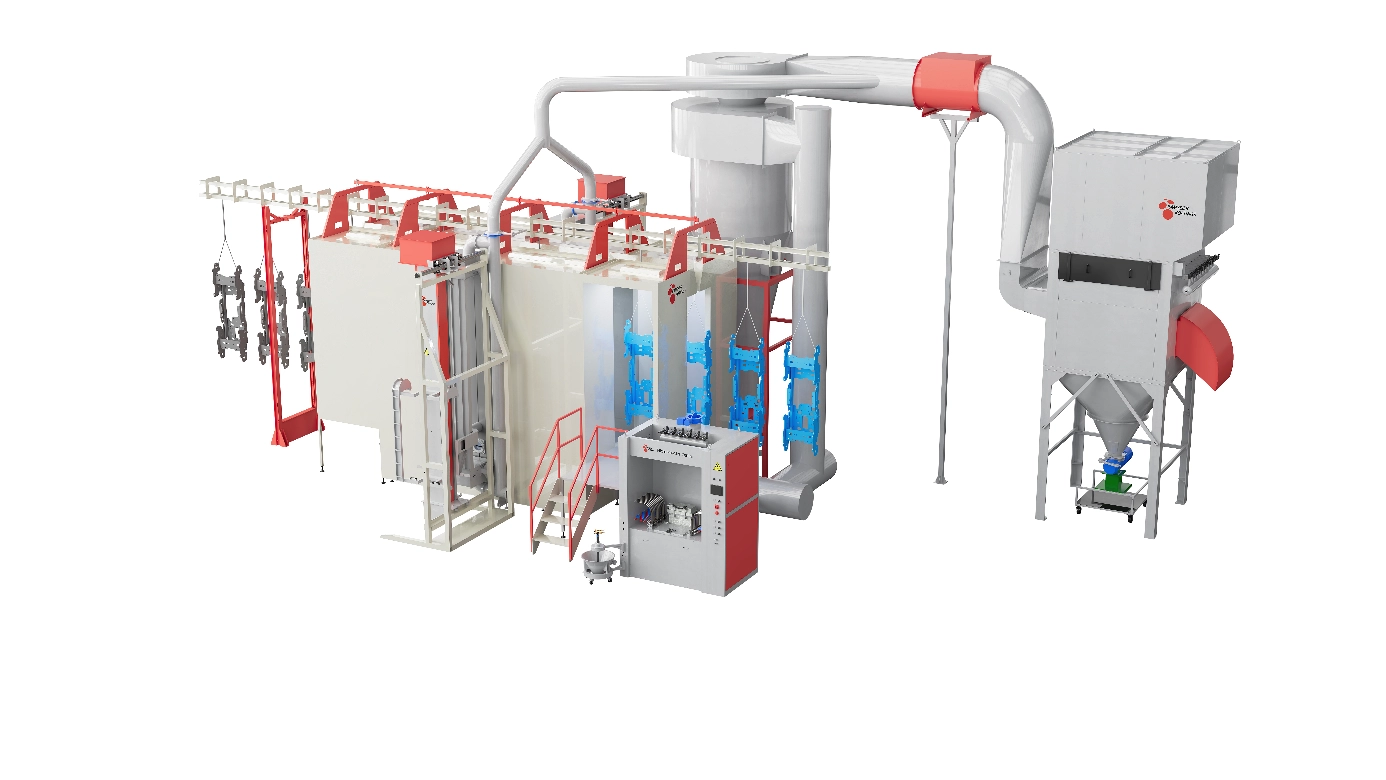

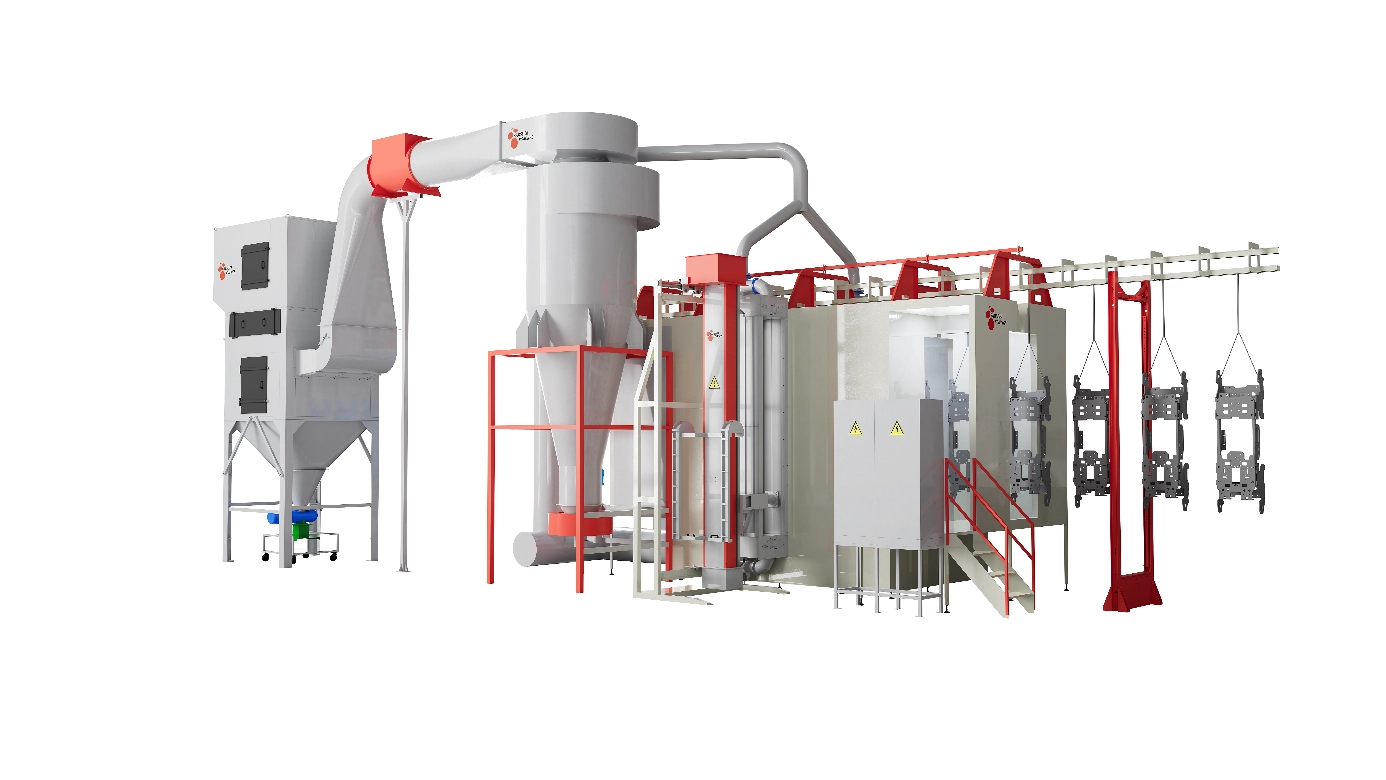

In the realm of modern manufacturing, particularly in coating applications, the integration of automation has revolutionized processes, enhancing efficiency, consistency, and safety. Among the various components that contribute to this transformation, reciprocators stand out as essential devices in fully automated coating facilities. This article delves into the significance of reciprocators, their operational mechanics, benefits, and the future of automated coating technologies.

Understanding Reciprocators

What Are Reciprocators?

Reciprocators are automated mechanical devices designed to move spray guns in a controlled back-and-forth motion. This movement is crucial for ensuring a uniform and consistent application of coatings, whether powder or liquid, across the surfaces of various workpieces. They are particularly vital in high-volume production environments such as automotive, aerospace, and appliance manufacturing, where precision and repeatability are paramount.

How Do Reciprocators Work?

Reciprocators operate by utilizing programmable controls to dictate the speed, stroke length, and movement patterns of the spray guns. This automation allows for precise control over the coating process, minimizing human error and ensuring that every part receives an even application. The typical operation involves the following steps:

1. Initialization: The system is programmed with specific parameters for the coating process, including the type of coating, desired thickness, and movement speed.

2. Movement: The reciprocator moves the spray gun along a predetermined path, applying the coating as it travels.

3. Feedback Loop: Many advanced systems incorporate sensors that provide real-time feedback, allowing for adjustments to be made on-the-fly to maintain quality.

The Importance of Reciprocators in Coating Facilities

Enhanced Efficiency and Productivity

One of the primary advantages of using reciprocators in automated coating facilities is the significant increase in efficiency and productivity. Unlike manual spraying, which is limited by human capabilities, reciprocators can operate continuously and at high speeds. This capability allows manufacturers to coat a larger number of parts in a shorter time frame, ultimately leading to increased output and reduced labor costs.

Consistency and Quality Control

Reciprocators ensure a consistent application of coatings, which is critical for maintaining quality standards. The automated nature of these devices eliminates variations that can occur with manual application, such as uneven thickness or missed spots. This consistency not only improves the aesthetic quality of the finished product but also enhances its durability and performance.

Reduction of Material Waste

Another significant benefit of reciprocators is their ability to minimize material waste. Automated systems are designed to optimize spray patterns and reduce overspray, which is a common issue in manual coating processes. By capturing excess powder or liquid that does not adhere to the workpiece, these systems help manufacturers save on material costs and reduce environmental impact.

Improved Worker Safety

The use of reciprocators also contributes to a safer working environment. By automating the spraying process, operators are less exposed to potentially harmful substances, such as volatile organic compounds (VOCs) found in many coatings. This reduction in exposure not only protects workers' health but also complies with increasingly stringent safety regulations.

Types of Reciprocators

Pneumatic Reciprocators

Pneumatic reciprocators utilize compressed air to drive the movement of the spray guns. They are known for their simplicity and reliability, making them a popular choice in many coating applications. However, they may not offer the same level of precision as electric models.

Electric Reciprocators

Electric reciprocators provide greater control and precision compared to their pneumatic counterparts. They are often equipped with advanced features such as programmable logic controllers (PLCs) that allow for complex movement patterns and adjustments based on real-time feedback. This makes them ideal for applications requiring high accuracy and repeatability.

Hydraulic Reciprocators

Hydraulic reciprocators are designed for heavy-duty applications where high force and speed are required. They are typically used in industries that demand robust performance, such as automotive manufacturing. While they can be more expensive to operate and maintain, their power and efficiency make them suitable for specific applications.

Key Benefits of Reciprocators in Automated Coating

1. Increased Throughput

The automation provided by reciprocators allows for a continuous flow of production, significantly increasing throughput. This is particularly beneficial in industries where time is of the essence, such as automotive and electronics manufacturing.

2. Customization and Flexibility

Modern reciprocators can be programmed to accommodate various part sizes and shapes, providing manufacturers with the flexibility to adapt to changing production needs. This adaptability is crucial in today's fast-paced manufacturing environment, where customization is often required.

3. Cost-Effectiveness

While the initial investment in automated coating systems may be substantial, the long-term savings achieved through reduced labor costs, minimized material waste, and increased efficiency make reciprocators a cost-effective solution for many manufacturers.

4. Enhanced Coating Quality

The precision of reciprocators ensures that coatings are applied uniformly, resulting in superior finishes. This quality is essential for products that require aesthetic appeal and functional performance, such as consumer electronics and automotive parts.

5. Simplified Maintenance

Automated systems, including reciprocators, often come with built-in diagnostics and maintenance alerts, simplifying the upkeep process. This proactive approach to maintenance helps prevent downtime and extends the lifespan of the equipment.

Future Trends in Automated Coating Technologies

Integration of AI and Machine Learning

As technology continues to evolve, the integration of artificial intelligence (AI) and machine learning into coating processes is becoming more prevalent. These advancements can enhance the capabilities of reciprocators by enabling predictive maintenance, optimizing spray patterns, and improving overall efficiency.

Increased Use of Robotics

The future of automated coating facilities will likely see an increased reliance on robotics, including advanced reciprocators that can perform complex tasks with minimal human intervention. This shift will further enhance productivity and quality while reducing labor costs.

Sustainability Initiatives

With growing concerns about environmental impact, manufacturers are increasingly focusing on sustainable practices. Reciprocators that minimize waste and energy consumption will play a crucial role in achieving these sustainability goals.

Conclusion

Reciprocators are indispensable components in fully automated coating facilities, offering numerous benefits that enhance efficiency, quality, and safety. As technology continues to advance, the role of reciprocators will only become more critical in meeting the demands of modern manufacturing. By investing in these automated systems, manufacturers can ensure they remain competitive in an ever-evolving market.

Frequently Asked Questions

1. What is the primary function of a reciprocator in coating applications?

A reciprocator moves spray guns in a controlled manner to ensure uniform coating application across surfaces.

2. How do reciprocators improve safety in coating facilities?

By automating the spraying process, reciprocators reduce human exposure to harmful substances, enhancing worker safety.

3. What types of reciprocators are commonly used in automated coating?

The most common types are pneumatic, electric, and hydraulic reciprocators, each suited for different applications.

4. How do reciprocators contribute to cost savings?

They minimize material waste, reduce labor costs, and increase production efficiency, leading to overall cost savings.

5. What future trends are expected in automated coating technologies?

Expect to see more integration of AI, increased use of robotics, and a focus on sustainability in coating processes.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.