Content Menu

● Understanding Powder Hoppers

>> What is a Powder Hopper?

>> Types of Powder Hoppers

● The Importance of Material Selection

>> Durability and Corrosion Resistance

>> Impact on System Longevity

● Factors Influencing Hopper Performance

>> Powder Characteristics

>> Design Considerations

● Maintenance for Longevity

>> Regular Inspections

>> Cleaning Protocols

>> Upgrades and Modifications

● Conclusion

>> Frequently Asked Questions

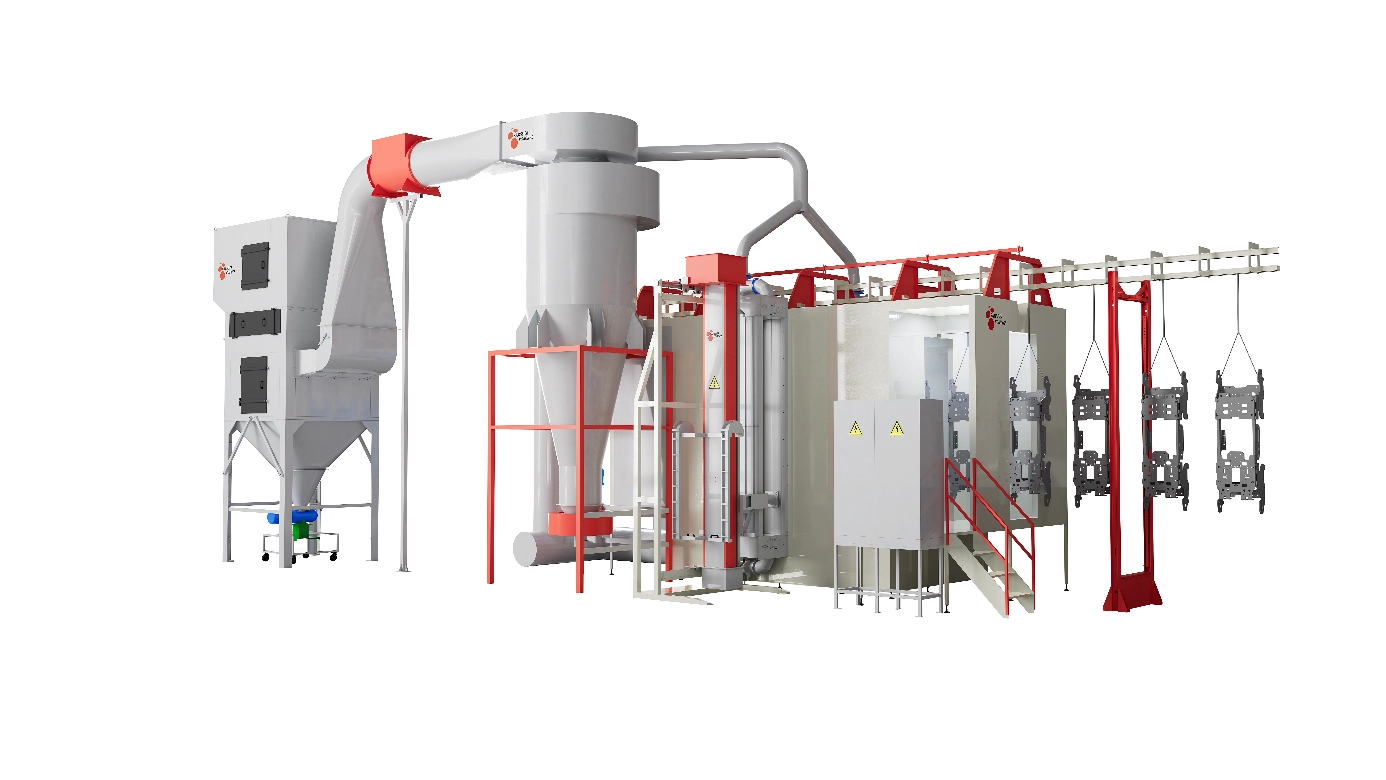

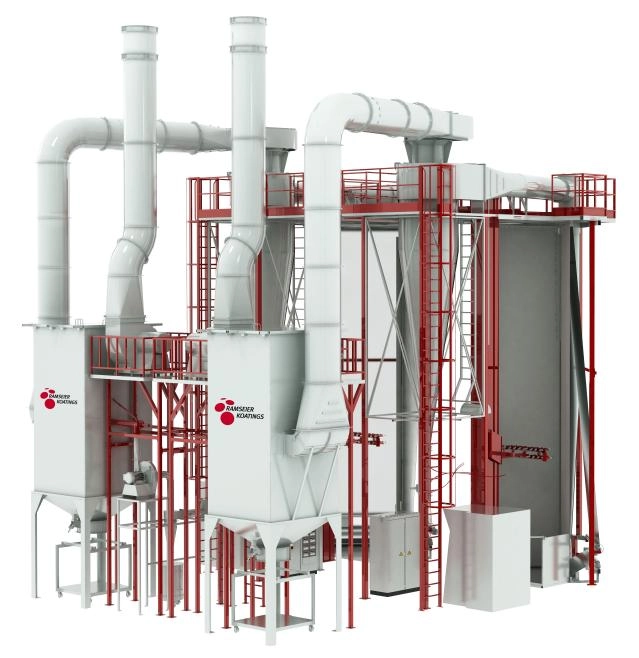

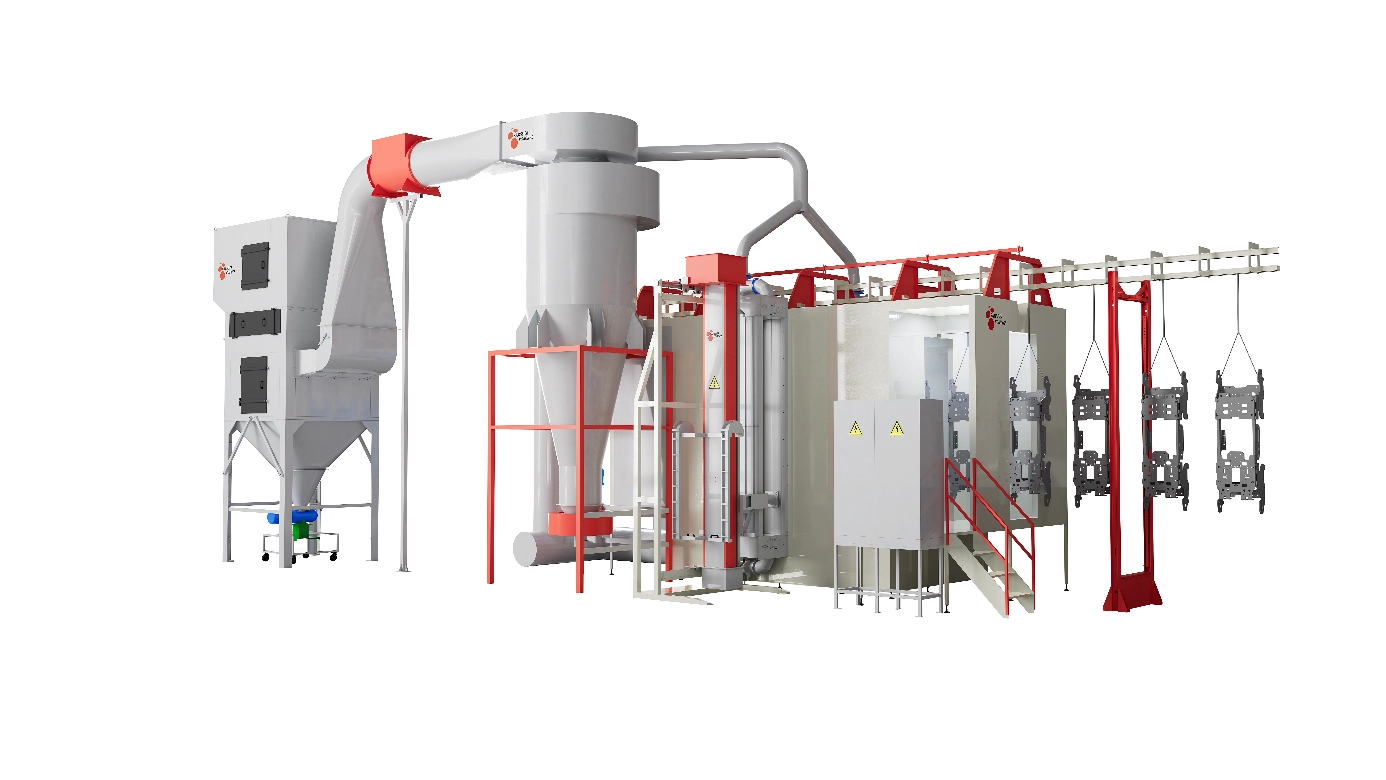

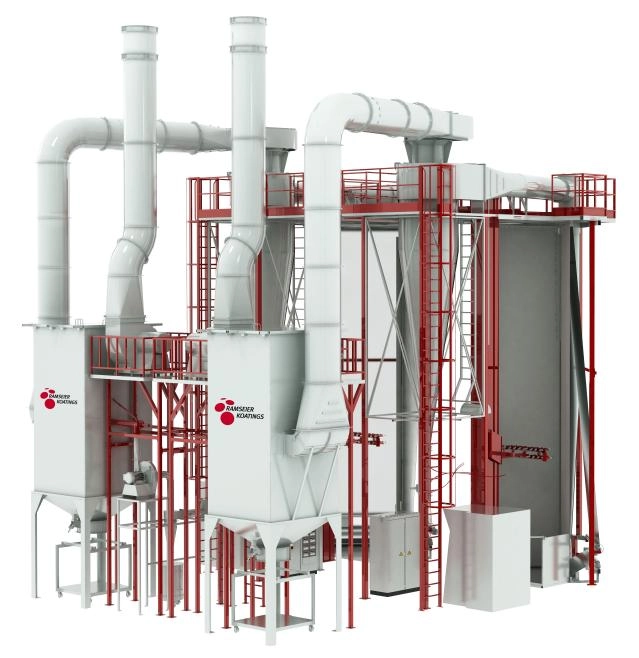

In the world of industrial processing, the materials used in powder hoppers play a crucial role in the longevity and efficiency of the entire system. Powder hoppers are essential components in various industries, including pharmaceuticals, food processing, and manufacturing, where they facilitate the storage and dispensing of powdered materials. This article explores the significance of hopper material selection, its impact on system longevity, and best practices for maintaining optimal performance.

Understanding Powder Hoppers

What is a Powder Hopper?

A powder hopper is a container designed to hold bulk quantities of powdered materials. It serves as a storage unit that feeds powders into processing equipment, ensuring a continuous and controlled flow. The design and material of the hopper can significantly influence the efficiency of powder handling and the overall performance of the system.

Types of Powder Hoppers

There are several types of powder hoppers, each suited for different applications:

- Conical Hoppers: These are designed to promote mass flow, where all material moves together towards the outlet. They are ideal for free-flowing powders.

- Funnel Hoppers: These hoppers allow for gravity flow but can lead to issues like ratholing, where material gets stuck.

- Square or Rectangular Hoppers: These are often used for larger volumes and can be designed to minimize dead zones.

The Importance of Material Selection

Durability and Corrosion Resistance

The material used to construct a powder hopper is critical for its durability and resistance to corrosion. Common materials include:

- Stainless Steel: Known for its strength and resistance to corrosion, stainless steel is often the preferred choice for food and pharmaceutical applications. It is easy to clean and does not react with most powders.

- Carbon Steel: While less expensive, carbon steel is prone to rust and may require protective coatings to enhance its lifespan.

- Plastic and Composite Materials: These materials can be lightweight and resistant to certain chemicals but may not withstand high temperatures or abrasive powders.

Impact on System Longevity

The choice of hopper material directly affects the longevity of the entire system. For instance, using a material that is not compatible with the stored powder can lead to contamination, affecting product quality and necessitating costly cleanups or replacements. Additionally, hoppers made from inferior materials may suffer from wear and tear, leading to leaks and operational inefficiencies.

Factors Influencing Hopper Performance

Powder Characteristics

The properties of the powder being handled significantly influence hopper design and material selection. Key characteristics include:

- Flowability: Powders with poor flowability can cause blockages and require hoppers designed to facilitate smoother flow.

- Particle Size and Shape: Fine powders may compact more easily, while larger particles might require different handling techniques to prevent bridging.

- Moisture Sensitivity: Powders that absorb moisture can clump together, leading to flow issues. Hoppers must be designed to minimize exposure to humidity.

Design Considerations

The design of the hopper itself is crucial for maintaining optimal performance. Important design features include:

- Angle of Repose: The angle at which the powder can rest without sliding affects how the material flows out of the hopper.

- Surface Finish: A smooth interior surface can help reduce friction and promote better flow.

- Flow Control Mechanisms: Incorporating vibrators or agitators can help break up clumps and ensure a consistent flow of powder.

Maintenance for Longevity

Regular Inspections

Routine inspections are essential for identifying wear and tear before they lead to significant issues. Key areas to inspect include:

- Seals and Gaskets: Ensure that all seals are intact to prevent leaks and contamination.

- Structural Integrity: Check for signs of corrosion or damage that could compromise the hopper's performance.

Cleaning Protocols

Maintaining cleanliness is vital, especially in industries where contamination can lead to product recalls or safety issues. Best practices include:

- Scheduled Cleanings: Establish a regular cleaning schedule based on the type of powder being handled.

- Use of Appropriate Cleaning Agents: Ensure that cleaning agents do not react with the materials stored in the hopper.

Upgrades and Modifications

As technology advances, consider upgrading hoppers with modern features such as:

- Smart Sensors: These can monitor conditions like humidity and temperature, providing real-time data to optimize performance.

- Automated Cleaning Systems: These can reduce downtime and ensure consistent cleanliness.

Conclusion

The material and design of powder hoppers are critical factors that influence the longevity and efficiency of powder handling systems. By selecting the appropriate materials, understanding the characteristics of the powders being handled, and implementing regular maintenance protocols, industries can ensure that their systems operate smoothly and efficiently over time. Investing in high-quality hoppers not only enhances operational efficiency but also contributes to the overall success of the manufacturing process.

Frequently Asked Questions

1. What materials are best for powder hoppers?

- Stainless steel is often preferred for its durability and corrosion resistance, while carbon steel and plastics may be used depending on the application.

2. How does powder flowability affect hopper design?

- Powders with poor flowability may require hoppers designed with features like vibrators or specific angles to facilitate smoother flow.

3. What maintenance practices are essential for powder hoppers?

- Regular inspections, cleaning, and prompt repairs are crucial for maintaining hopper performance and longevity.

4. Can the choice of hopper material impact product quality?

- Yes, using incompatible materials can lead to contamination, affecting the quality of the final product.

5. What are the signs that a powder hopper needs maintenance?

- Signs include leaks, unusual noises during operation, and inconsistent powder flow.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.