Content Menu

● Introduction

● The Evolution of Powder Coating Manufacturing

>> From Manual to Digital

>> The Rise of Industry 4.0

● Understanding Smart Data Management Systems

>> What Are Smart Data Management Systems?

>> Key Components

● Why Manufacturers Are Making the Switch

>> Enhanced Operational Efficiency

>> Real-Time Visibility and Decision-Making

>> Improved Quality Control

>> Sustainability and Waste Reduction

>> Competitive Advantage

● Key Benefits of Smart Data Management in Powder Coating

>> Streamlined Inventory Management

>> Predictive Maintenance and Reduced Downtime

>> Advanced Analytics and Continuous Improvement

>> Enhanced Collaboration and Communication

● How Smart Data Management Systems Work in Practice

>> Integration with Existing Processes

>> Real-World Example: Rapid Digital Transformation

>> Remote Monitoring and Control

● Overcoming Challenges in Implementation

>> Data Security and Privacy

>> Change Management and Training

>> Customization and Scalability

● The Future of Powder Coating: AI, Robotics, and Beyond

>> Artificial Intelligence for Smarter Operations

>> Robotics and Automation

>> Sustainability and Environmental Impact

● Frequently Asked Questions (FAQs)

>> 1. What is a smart data management system in powder coating?

>> 2. How does smart data management improve quality control?

>> 3. Can small powder coating businesses benefit from these systems?

>> 4. What are the main challenges in adopting smart data management?

>> 5. How do smart data management systems support sustainability?

Introduction

The powder coating industry is experiencing a transformative shift. As global competition intensifies and customer expectations rise, manufacturers are under pressure to deliver higher quality, improve efficiency, and reduce environmental impact. One of the most significant enablers of this transformation is the adoption of smart data management systems. These digital platforms are revolutionizing how powder coating manufacturers operate, empowering them to make data-driven decisions, streamline processes, and stay ahead in a rapidly evolving market.

The Evolution of Powder Coating Manufacturing

From Manual to Digital

Historically, powder coating operations relied heavily on manual processes and paper-based record-keeping. Operators tracked inventory, job progress, and quality checks by hand, which often led to errors, inefficiencies, and delays. As demand for customization and faster turnaround times increased, these traditional methods became unsustainable.

The Rise of Industry 4.0

The fourth industrial revolution, known as Industry 4.0, introduced advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and automation. These innovations have enabled the creation of smart factories, where machines, sensors, and systems are interconnected to collect and analyze vast amounts of data in real time. For powder coating manufacturers, this means unprecedented visibility and control over every aspect of production.

Understanding Smart Data Management Systems

What Are Smart Data Management Systems?

Smart data management systems are digital platforms designed to collect, store, integrate, and analyze data from various sources within a manufacturing environment. In powder coating, these systems connect equipment, inventory, quality control, and supply chain data into a unified ecosystem.

Key Components

- IoT Sensors: Devices embedded in machinery that monitor parameters like temperature, humidity, and powder flow.

- Cloud Computing: Centralized storage and processing of data, accessible from anywhere.

- Analytics Engines: Software tools that analyze data for trends, anomalies, and predictive insights.

- User Dashboards: Visual interfaces that present real-time data to operators, managers, and executives.

Why Manufacturers Are Making the Switch

Enhanced Operational Efficiency

Smart data management systems automate routine tasks such as inventory tracking, scheduling, and quality checks. By integrating data across the production line, manufacturers can:

- Reduce manual entry errors

- Eliminate redundant processes

- Optimize resource allocation

- Minimize downtime through predictive maintenance

Real-Time Visibility and Decision-Making

With instant access to production data, managers can monitor job progress, machine performance, and material usage in real time. This transparency enables:

- Faster identification of bottlenecks

- Immediate response to issues

- Data-driven decision-making at every level

Improved Quality Control

Quality is paramount in powder coating. Smart systems track every batch, monitor application parameters, and record inspection results automatically. This ensures:

- Consistent product quality

- Traceability for audits and compliance

- Early detection of defects and deviations

Sustainability and Waste Reduction

Environmental regulations and cost pressures demand efficient use of materials and energy. Smart data management enables:

- Precise tracking of powder and chemical usage

- Automated adjustments to minimize overspray and waste

- Optimization of curing ovens and conveyor speeds to reduce energy consumption

Competitive Advantage

Manufacturers that embrace smart data management gain a significant edge. They can offer faster turnaround times, higher quality, and better customer service, positioning themselves as leaders in the market.

Key Benefits of Smart Data Management in Powder Coating

Streamlined Inventory Management

Automated inventory tracking ensures that raw materials and finished products are always at optimal levels. Features such as inventory forecasting and automated reordering prevent shortages and excess stock, leading to cost savings and smoother operations.

Predictive Maintenance and Reduced Downtime

By continuously monitoring equipment health, smart systems predict when maintenance is needed before breakdowns occur. This proactive approach reduces unplanned downtime, extends machine life, and lowers repair costs.

Advanced Analytics and Continuous Improvement

Data collected from every stage of production feeds into analytics engines that uncover patterns and opportunities for improvement. Manufacturers can benchmark performance, set targets, and implement continuous improvement initiatives based on real data.

Enhanced Collaboration and Communication

With centralized data accessible to all stakeholders, teams across departments can collaborate more effectively. Operators, managers, and executives share a single source of truth, fostering alignment and faster problem-solving.

How Smart Data Management Systems Work in Practice

Integration with Existing Processes

Modern data management platforms are designed to integrate seamlessly with existing equipment and workflows. They connect with ERP (Enterprise Resource Planning) systems, accounting software, and even customer portals, creating a unified digital thread throughout the organization.

Real-World Example: Rapid Digital Transformation

A mid-sized powder coating manufacturer recently transitioned from manual processes to a smart data management system. The deployment included:

- A digital twin of the facility, mapping every process step

- Real-time tracking of orders, inventory, and shipments

- Automated data synchronization with accounting and customer management systems

Within weeks, the company achieved:

- Full visibility into operations

- Significantly improved efficiency and reduced errors

- The ability to make informed decisions based on accurate, up-to-date data

Remote Monitoring and Control

Some systems offer cloud-based dashboards, allowing authorized personnel to monitor production from any location. While operational changes typically require on-site action for safety reasons, remote access to data ensures that managers can stay informed and respond quickly, even when offsite.

Overcoming Challenges in Implementation

Data Security and Privacy

As more data moves to the cloud, protecting sensitive information becomes critical. Smart data management platforms employ robust security measures, including encryption, access controls, and compliance with industry standards.

Change Management and Training

Transitioning to a digital system requires investment in training and change management. Successful implementations involve:

- Hands-on training for all staff

- Clear communication of benefits and goals

- Ongoing support to address questions and concerns

Customization and Scalability

Every powder coating operation is unique. Leading platforms offer customizable modules and scalable features to fit businesses of all sizes, from small job shops to large-scale manufacturers.

The Future of Powder Coating: AI, Robotics, and Beyond

Artificial Intelligence for Smarter Operations

AI-powered systems are taking smart data management to the next level. By analyzing data in real time, AI can:

- Optimize coating applications for minimal waste and maximum quality

- Predict maintenance needs with greater accuracy

- Identify root causes of defects and recommend corrective actions

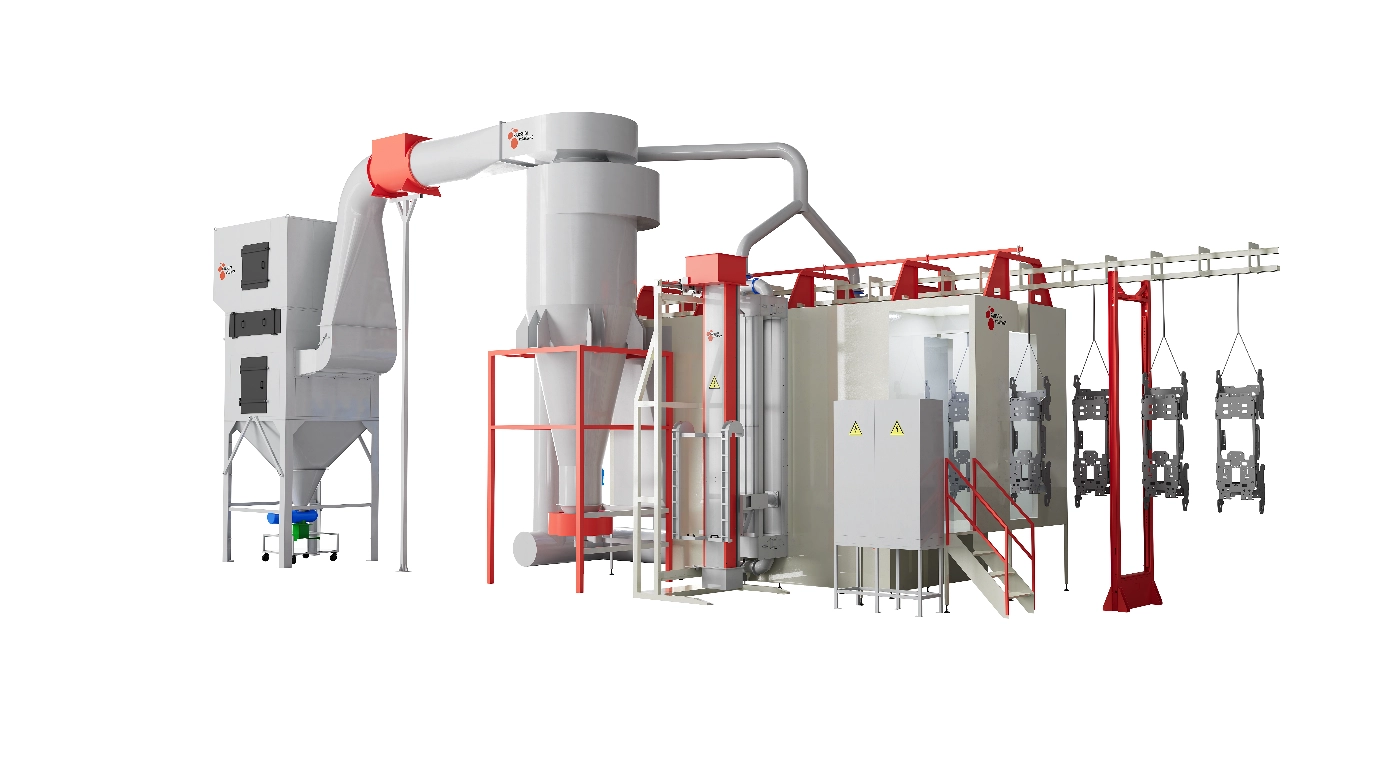

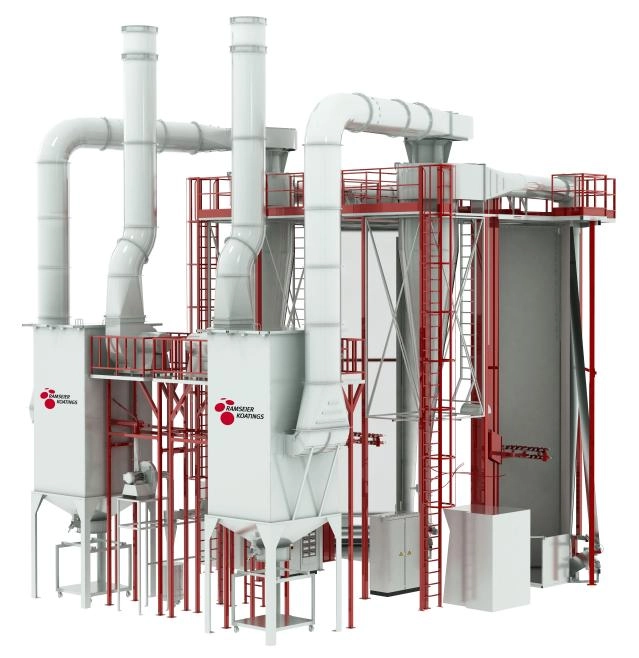

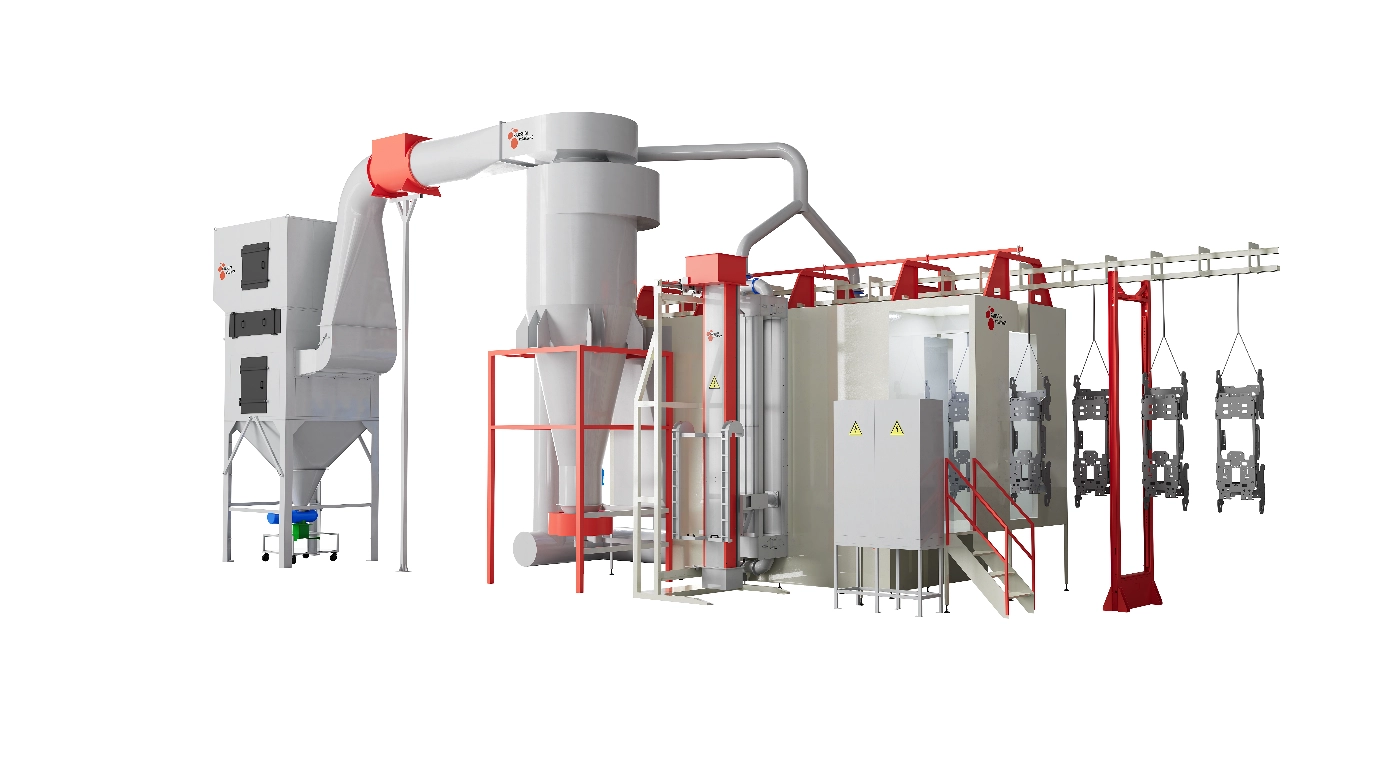

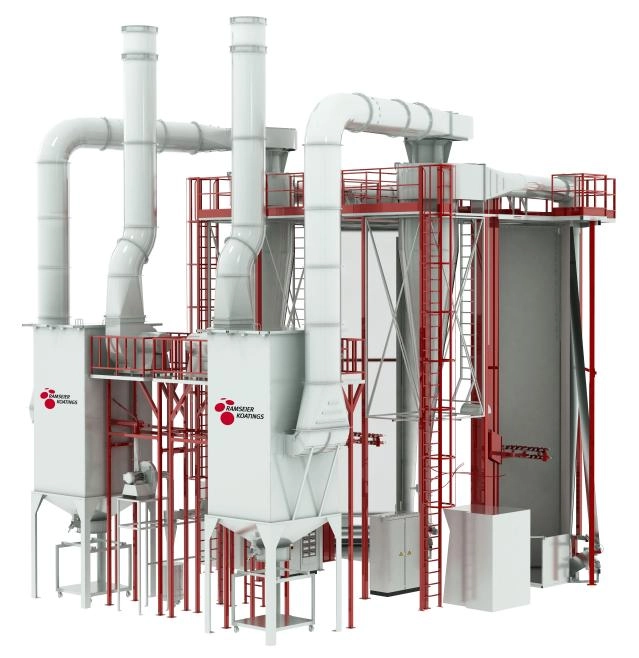

Robotics and Automation

Automated powder coating lines equipped with robotics deliver consistent, high-quality finishes while reducing labor costs and exposure to hazardous materials. Robotics, combined with smart data systems, enable:

- Faster cycle times

- Greater flexibility for high-mix, low-volume production

- Enhanced safety and ergonomics for workers

Sustainability and Environmental Impact

Smart systems help manufacturers meet sustainability goals by:

- Reducing energy consumption through intelligent process control

- Minimizing material waste with precise application and recovery systems

- Supporting compliance with environmental regulations through automated reporting

Frequently Asked Questions (FAQs)

1. What is a smart data management system in powder coating?

A smart data management system is a digital platform that collects, stores, and analyzes data from all aspects of powder coating operations. It integrates information from machines, inventory, quality control, and supply chain to provide real-time insights and enable data-driven decision-making.

2. How does smart data management improve quality control?

By automatically tracking application parameters and inspection results, smart systems ensure consistent quality, traceability, and early detection of defects. This leads to fewer rejects, less rework, and higher customer satisfaction.

3. Can small powder coating businesses benefit from these systems?

Yes. Modern smart data management platforms are scalable and customizable, making them accessible to businesses of all sizes. Even small job shops can achieve significant improvements in efficiency, quality, and cost control.

4. What are the main challenges in adopting smart data management?

Key challenges include data security, change management, and the initial investment in technology and training. However, with proper planning and support, these challenges can be overcome, leading to long-term benefits.

5. How do smart data management systems support sustainability?

These systems optimize material usage, reduce waste, and lower energy consumption through real-time monitoring and automated adjustments. They also facilitate compliance with environmental regulations by automating data collection and reporting.

[1] https://www.pfonline.com/articles/powder-coating-40-smarter-faster-more-efficient-and-connected

[2] https://www.datadynamicsinc.com/blog-empowering-smart-factories-5-data-management-tips-for-ultimate-success/

[3] https://gosteelhead.com/how-starter-package-transformed-powder-coating-technologies

[4] https://www.bolair.ca/blog/smart-technologies-powder-coating/

[5] https://proplate.pro/how-erp-software-can-solve-inventory-management-challenges-in-powder-coating/

[6] https://finishingandcoating.com/index.php/powder-coat/2307-the-next-decade-how-ai-and-robotics-will-transform-the-powder-coating-industry

[7] https://www.hivemq.com/blog/power-of-iot-data-management-in-smart-manufacturing/

[8] https://www.pcimag.com/articles/113350-how-industry-40-technologies-are-revolutionizing-paint-and-coatings-manufacturing

[9] https://www.managingmfg.com/news/integrating-powder-coating-in-smart-manufacturing-a-new-era-for-metal-finishing-services-in-canada-nwid-693.html

[10] https://www.paint.org/coatingstech-magazine/articles/powder-coatings-leaders-see-beyond-todays-challenges/

[11] https://proplate.pro/how-powder-coating-manufacturers-can-boost-erp-efficiency/

[12] https://www.credencys.com/blog/guide-to-manufacturing-data-management/

[13] https://aimetalfinishing.com/industry-news-blog/how-industry-4-0-is-revolutionizing-powder-coating/

[14] https://www.linkedin.com/posts/strong3000_smart-strong3000-liveuptade-activity-7223945451304062976-HU9k

[15] https://cwfinishing.net/continuous-improvement-powder-coating/

[16] https://ems-powdercoating.com/automated-powder-coating-system/

[17] https://www.averna.com/en/products/smart-data-management

[18] https://www.linkedin.com/pulse/pure-epoxy-powder-coatings-market-size-digital-hm2ff/

[19] https://www.paint.org/coatingstech-magazine/articles/market-update-advances-in-powder-coatings/

[20] https://www.powdercoatedtough.com/News/ID/5403/Minimizing-Challenges-When-Building-a-Powder-Coating-System

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.