Content Menu

● Understanding Powder Coating Systems

>> What is a Powder Coating System?

>> Why Invest in a Powder Coating System?

● Where to Buy a Powder Coating System

>> Specialized Equipment Manufacturers and Distributors

>>> 1. Columbia Coatings

>>> 2. Powder-X Coating Systems

>>> 3. Reliant Finishing Systems

>>> 4. Eastwood

>>> 5. Powder Buy The Pound

>>> 6. Surplus Equipment Marketplaces

>> Online Retailers and E-Commerce Platforms

● Factors to Consider Before Buying

>> 1. Scale of Operation

>> 2. Equipment Quality and Reliability

>> 3. Space Requirements

>> 4. Budget

>> 5. Customer Support and Training

>> 6. Compliance and Safety

● Types of Powder Coating Systems

>> Manual vs. Automatic Systems

>> Batch vs. Continuous Systems

>> Key Equipment Components

>>> Powder Coating Gun

>>> Spray Booth

>>> Curing Oven

>>> Pretreatment Equipment

● How to Choose the Right Supplier

>> Evaluate Experience and Reputation

>> Assess Product Range

>> Check for Certifications

>> Review Support Services

● Steps to Purchasing a Powder Coating System

>> 1. Define Your Requirements

>> 2. Research Suppliers

>> 3. Request Quotes and Demonstrations

>> 4. Plan for Installation

>> 5. Arrange Training

● Frequently Asked Questions

>> 1. What is the difference between powder coating and traditional painting?

>> 2. Can I powder coat materials other than metal?

>> 3. How do I choose the right powder for my application?

>> 4. What maintenance is required for a powder coating system?

>> 5. Is powder coating safe and environmentally friendly?

>> 6. How much does a powder coating system cost?

>> 7. Can I buy used powder coating equipment?

>> 8. What training is necessary to operate a powder coating system?

>> 9. How do I ensure my powder coating system meets safety standards?

>> 10. Can I upgrade my system as my business grows?

● Citations:

Powder coating is a popular finishing technique used across industries for its durability, environmental friendliness, and attractive finish. Whether you are a hobbyist, a small business owner, or managing a large-scale manufacturing operation, finding the right powder coating system is essential for achieving professional results. This comprehensive guide explores where to buy powder coating systems, what to consider before purchasing, and how to choose the best equipment for your needs.

Understanding Powder Coating Systems

What is a Powder Coating System?

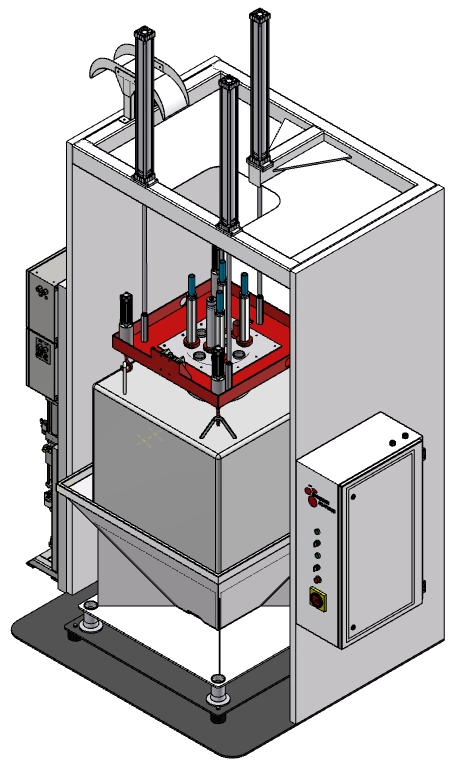

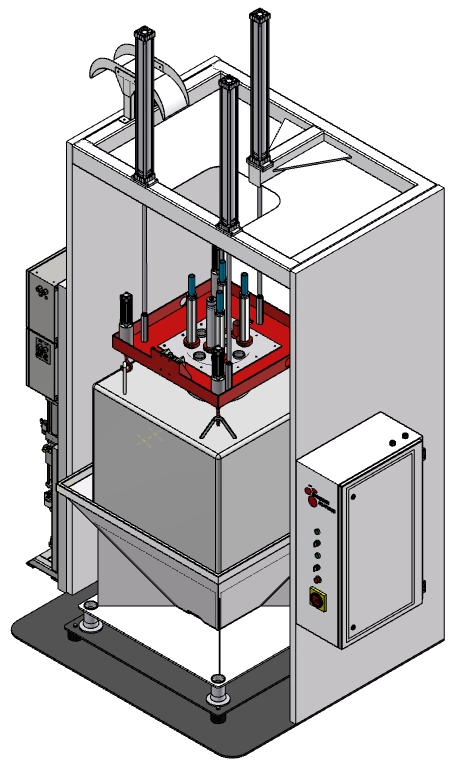

A powder coating system is a collection of equipment and tools designed to apply a dry, free-flowing powder onto a substrate-usually metal-which is then cured under heat to form a hard, protective finish. The system typically includes:

- Powder coating gun (manual or automatic)

- Powder feed system

- Spray booth

- Curing oven

- Pretreatment equipment (for cleaning and preparing the surface)

Why Invest in a Powder Coating System?

Powder coating offers several advantages over traditional liquid paint:

- Durability: Resistant to chipping, scratching, and fading.

- Environmental Benefits: Contains no solvents or VOCs.

- Cost-Effective: Reduces waste and provides long-lasting protection.

- Aesthetic Flexibility: Wide range of colors, textures, and finishes.

Where to Buy a Powder Coating System

Specialized Equipment Manufacturers and Distributors

The most reliable sources for powder coating systems are specialized manufacturers and distributors. These companies offer a range of solutions, from entry-level kits for hobbyists to fully automated systems for industrial applications.

1. Columbia Coatings

Columbia Coatings offers turn-key powder coating systems, including bench-top ovens and booths suitable for small-scale operations or those just starting out. Their systems are built to order, ensuring you get equipment tailored to your requirements.

2. Powder-X Coating Systems

Powder-X is a leader in the powder coating industry, providing both equipment and hands-on training. They offer batch systems for small to medium operations and automated systems for high-volume production. Powder-X is known for its customer support and training programs, making it a top choice for those new to powder coating or looking to expand their business.

3. Reliant Finishing Systems

Reliant Finishing Systems manufactures spray booths, curing ovens, and complete powder coating systems. They offer over 500 standard configurations and can build custom solutions for specific needs. Reliant also provides installation, calibration, and training services to ensure optimal performance.

4. Eastwood

Eastwood is popular among hobbyists and small shops, offering professional-grade powder coating kits and supplies. Their HotCoat systems are designed for home use but deliver results comparable to commercial setups.

5. Powder Buy The Pound

Powder Buy The Pound supplies a wide range of powder coating equipment and materials, catering to both enthusiasts and professionals. Their inventory includes powder guns, booths, ovens, and a vast selection of powder colors.

6. Surplus Equipment Marketplaces

For those seeking budget-friendly options, surplus equipment marketplaces like Surplus Record offer new and used powder coating systems from brands such as Nordson, Wagner, and Gema. This can be a cost-effective way to acquire high-end equipment, though buyers should carefully inspect used systems for wear and compatibility.

Online Retailers and E-Commerce Platforms

Many powder coating systems and related supplies are available through online platforms. These include:

- Direct manufacturer websites

- Industrial supply websites

- Specialized e-commerce stores

Online shopping provides convenience and access to a broader selection, but it's crucial to verify the credibility of the seller and check product reviews.

Factors to Consider Before Buying

1. Scale of Operation

Determine whether you need a system for occasional use, regular small-batch production, or continuous industrial-scale output. This will influence the size, automation level, and cost of the system you require.

2. Equipment Quality and Reliability

Invest in equipment from reputable suppliers with a proven track record. High-quality systems ensure consistent results, reduce maintenance needs, and provide better long-term value.

3. Space Requirements

Assess the available space in your facility. Powder coating systems, especially those with curing ovens and spray booths, require adequate room for operation, ventilation, and safety.

4. Budget

Establish your budget, considering not only the initial purchase price but also installation, maintenance, and operating costs. While entry-level systems may be tempting, investing in durable, efficient equipment can save money over time.

5. Customer Support and Training

Choose suppliers that offer comprehensive customer support, including installation, training, and technical assistance. Proper training ensures safe and efficient operation, maximizing your investment.

6. Compliance and Safety

Ensure the equipment meets local and industry safety and environmental standards. Features such as proper ventilation, filtration systems, and safety interlocks are essential for safe operation.

Types of Powder Coating Systems

Manual vs. Automatic Systems

| Feature | Manual Systems | Automatic Systems |

| Operation | Hand-held spray guns | Programmable, robotic application |

| Best For | Small batches, custom work | High-volume, repetitive jobs |

| Cost | Lower upfront investment | Higher initial investment |

| Flexibility | High (easy to switch colors) | Lower (optimized for efficiency) |

Batch vs. Continuous Systems

- Batch Systems: Ideal for small to medium operations; allow for flexibility and easy color changes.

- Continuous Systems: Designed for large-scale production; maximize throughput and consistency.

Key Equipment Components

Powder Coating Gun

The heart of any system, the gun applies the powder using electrostatic charge. Options range from basic manual guns to advanced automatic models with programmable settings.

Spray Booth

The booth contains overspray and ensures a clean application environment. Features to consider include size, airflow, filtration, and lighting.

Curing Oven

Curing ovens bake the powder onto the substrate, creating a durable finish. Oven size, heat distribution, and energy efficiency are critical factors.

Pretreatment Equipment

Proper surface preparation is vital for adhesion and durability. Equipment may include washers, sandblasters, or chemical treatment stations.

How to Choose the Right Supplier

Evaluate Experience and Reputation

Look for suppliers with a strong industry presence and positive customer feedback. Established companies are more likely to provide reliable equipment and ongoing support.

Assess Product Range

A supplier with a broad product range can better meet your specific needs, whether you require a simple kit or a fully integrated system.

Check for Certifications

Ensure the equipment meets relevant industry standards and certifications, indicating quality and safety compliance.

Review Support Services

Suppliers offering installation, training, and maintenance services add significant value, especially for first-time buyers.

Steps to Purchasing a Powder Coating System

1. Define Your Requirements

- What materials will you coat?

- What is the size and volume of your typical workload?

- Do you need manual flexibility or automated efficiency?

2. Research Suppliers

Compare offerings from multiple suppliers, focusing on product features, pricing, and support services.

3. Request Quotes and Demonstrations

Obtain detailed quotes and, if possible, arrange for equipment demonstrations to evaluate performance and ease of use.

4. Plan for Installation

Ensure your facility is prepared for equipment delivery and installation, including necessary utilities and safety measures.

5. Arrange Training

Take advantage of supplier-provided training to ensure your team can operate the system safely and effectively.

Frequently Asked Questions

1. What is the difference between powder coating and traditional painting?

Powder coating uses a dry powder applied electrostatically and cured with heat, resulting in a more durable and environmentally friendly finish compared to liquid paint, which uses solvents and air drying.

2. Can I powder coat materials other than metal?

While powder coating is primarily used on metals, advancements in technology now allow for coating certain plastics, wood, and glass using specialized powders and processes.

3. How do I choose the right powder for my application?

Consider the operational environment (indoor vs. outdoor), required durability, chemical resistance, and desired appearance. Suppliers can help match the powder to your specific needs.

4. What maintenance is required for a powder coating system?

Regular cleaning of the spray booth, filters, and guns is essential. Ovens should be inspected for even heat distribution, and all equipment should be checked for wear and proper operation.

5. Is powder coating safe and environmentally friendly?

Yes, powder coating is one of the safest finishing methods. It contains no VOCs, produces minimal waste, and is non-toxic, making it suitable for a wide range of industries and applications.

6. How much does a powder coating system cost?

Costs vary widely based on system size, automation level, and features. Entry-level kits may start at a few hundred dollars, while industrial systems can cost tens of thousands. Consider both upfront and ongoing expenses.

7. Can I buy used powder coating equipment?

Yes, used systems are available through surplus equipment dealers and online marketplaces. Always inspect used equipment carefully and verify compatibility with your requirements.

8. What training is necessary to operate a powder coating system?

Training should cover equipment operation, safety procedures, maintenance, and troubleshooting. Many suppliers offer in-person or online training to ensure proper use.

9. How do I ensure my powder coating system meets safety standards?

Purchase equipment from reputable suppliers who adhere to industry standards. Ensure proper ventilation, fire safety measures, and regular equipment inspections.

10. Can I upgrade my system as my business grows?

Many systems are modular or can be expanded with additional components, such as larger ovens or automated guns, allowing you to scale up as needed.

---

Citations:

[1] https://www.columbiacoatings.com/products/equipment/turn-key-powder-system

[2] https://www.powdercoatguide.com/2013/08/where-to-buy-powder.html

[3] https://powderx.com

[4] https://www.thermalspray.com/selecting-powder-coating-equipment-an-essential-guide/

[5] https://www.powdercoating.org/page/FAQ

[6] https://coatingsystems.com/powder-coating-faqs/

[7] https://www.temaequipment.co.uk/choosing-the-right-powder-coating-equipment

[8] https://tncoating.com/blog/best-powder-coating-gun/

[9] https://www.eastwood.com/powder-coating.html

[10] https://www.precisiondipcoating.com/powder-coating-faq-answers-to-your-most-common-questions

[11] https://powderbuythepound.com

[12] https://newfinishinc.com/10-frequently-asked-questions-about-powder-coatings-everything-you-need-to-know/

[13] https://surplusrecord.com/machinery-equipment/paint-and-powder-systems/

[14] https://powdervisioninc.com/2022/07/top-6-powder-coating-faqs-the-most-common-questions-answered/

[15] https://reliantfinishingsystems.com

[16] https://www.parkerionics.com/powder-coating-equipment.html

[17] https://www.royalcoatspowdercoating.com/product-page/rc-1-powder-coat-system

[18] https://www.cetinc.com

[19] https://www.wagner-group.com/us/industry/products/powder-coating/complete-systems/

[20] https://www.nordson.com/en/about-us/newsroom/industrial-coating-systems-news/complete-guide-to-powder-coating

[21] https://www.thomasnet.com/north-carolina/powder-coating-equipment-62441282-1.html

[22] https://www.harborfreight.com/10-30-psi-powder-coating-system-94244.html

[23] https://thepowdercoatstore.com

[24] https://www.nordson.com/en/divisions/industrial-coating-systems/application-solutions/powder-coating

[25] https://reliantfinishingsystems.com/a-beginners-guide-to-powder-coating-equipment/

[26] https://www.homedepot.com/p/VEVOR-Powder-Coating-System-50KV-Electrostatic-Output-Powder-Coating-Kit-with-Foot-Switch-Spray-Gun-Nozzles-and-Powder-Cups-JDFMPTJ50KV4SPYOKV1/330011460

[27] https://www.prismaticpowders.com

[28] https://www.airpower-usa.com/wp-content/uploads/2019/08/Powder-Coating-Troubleshoothing-revised-7-10-14.pdf

[29] https://www.powdercoatingforum.net/forum/powder-coating/4735-need-some-powder-coating-knowledge-d

[30] https://powdercoatingproducts.com/pages/faq

[31] https://reliantfinishingsystems.com/buying-new-vs-used-powder-coating-equipment/

[32] https://reliantfinishingsystems.com/how-to-select-a-powder-coating-equipment-supplier/

[33] https://www.tcipowder.com/resources/troubleshooting-guide/chapter-thirteen-tci-troubleshooting-guide/

[34] https://www.keystonekoating.com/about/faq/

[35] https://www.georgiapowdercoating.com/faqs/

[36] https://ems-powdercoating.com/powder-coating-questions-and-answers/

[37] https://greatdanepowdercoating.com/5-great-tips-for-choosing-the-right-powder-coating-service/

[38] https://reliantfinishingsystems.com/troubleshooting-common-issues-with-powder-coating-equipment/

[39] https://www.v-twinforum.com/threads/what-questions-to-ask-powdercoater.75448/

[40] https://www.sccoa.com/forums/threads/powder-coating-questions-answers.111011/

---

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.