Content Menu

● Understanding Powder Coating

>> The Powder Coating Process

● Types of Powder Coating Systems

>> Application Methods

>>> Electrostatic Spray Deposition (ESD)

>>> Fluidized Bed Coating

>>> Electrostatic Fluidized Bed Coating

>>> Electrostatic Magnetic Brush (EMB) Coating

>> Types of Powder Used

>>> Epoxy Powder Coatings

>>> Polyester Powder Coatings

>>> Hybrid Powder Coatings

>>> Specialty Powders

>> System Configurations

>>> Batch Systems

>>> Conveyorized Systems

● Components of a Powder Coating System

● Advantages of Powder Coating Systems

>> Durability and Performance

>> Environmental Benefits

>> Efficiency and Cost-Effectiveness

>> Versatility

● Selecting the Right Powder Coating System

● Innovations and Trends in Powder Coating

● Common Challenges and Solutions

>> Achieving Uniform Coverage

>> Powder Recovery and Waste Reduction

>> Curing Consistency

● Maintenance and Safety Considerations

● Frequently Asked Questions

● Citations:

Powder coating has revolutionized the world of surface finishing, offering a durable, environmentally friendly, and versatile alternative to traditional liquid paints. But with the variety of powder coating systems available, how do you determine which is right for your needs? This comprehensive guide explores what a powder coating system is, how it works, the different types and technologies, and how to select the best system for your application.

Understanding Powder Coating

Powder coating is a dry finishing process in which fine, electrostatically charged powder particles are applied to a substrate, typically metal, and then cured under heat to form a hard, protective layer. Unlike traditional liquid paints, powder coating does not require solvents and emits negligible volatile organic compounds (VOCs), making it an environmentally responsible choice.

The Powder Coating Process

The powder coating process generally involves three main steps:

- Pre-treatment: The substrate is cleaned and prepared to ensure optimal adhesion. This may involve chemical cleaning, mechanical abrasion, or both.

- Powder Application: The powder is applied using an electrostatic spray gun or other specialized methods. The powder particles are charged and adhere to the grounded substrate.

- Curing: The coated part is heated in an oven, causing the powder to melt, flow, and chemically react to form a tough, uniform coating.

Types of Powder Coating Systems

Powder coating systems can be categorized based on the application method, the type of powder used, and the level of automation.

Application Methods

Electrostatic Spray Deposition (ESD)

The most common method, ESD uses a spray gun to apply charged powder particles onto a grounded substrate. The electrostatic attraction ensures even coverage, while the subsequent curing process creates a durable finish. ESD is suitable for a wide range of part sizes and shapes.

Fluidized Bed Coating

In this method, parts are preheated and then dipped into a bed of fluidized powder. The powder melts and adheres to the hot surface, forming a uniform coating. Fluidized bed coating is particularly effective for thick, even layers and is often used for items requiring heavy-duty protection.

Electrostatic Fluidized Bed Coating

This approach combines fluidized bed technology with electrostatic charging, allowing for more controlled and efficient powder application, particularly on complex geometries.

Electrostatic Magnetic Brush (EMB) Coating

EMB coating is designed for flat materials, using a roller to apply powder at high speeds and with precise thickness control. This method is ideal for sheet-to-sheet or roll-to-roll processes and is gaining traction in commercial applications.

Types of Powder Used

Epoxy Powder Coatings

Epoxy powders offer excellent chemical resistance and corrosion protection, making them ideal for indoor applications. However, they are not UV-stable and are unsuitable for prolonged outdoor exposure.

Polyester Powder Coatings

Polyester powders are highly durable and UV-resistant, making them suitable for outdoor applications. They are commonly used in automotive, architectural, and outdoor furniture industries.

Hybrid Powder Coatings

Hybrid powders combine epoxy and polyester resins, balancing chemical resistance and application ease. While they offer good corrosion resistance, they are less suitable for outdoor use due to limited UV stability.

Specialty Powders

Other powder types include polyurethane, acrylic, and fluoropolymer powders, each designed for specific performance requirements such as enhanced weatherability, gloss retention, or chemical resistance.

System Configurations

Batch Systems

Batch systems are ideal for low to medium production volumes and offer flexibility for coating parts of various sizes. In these systems, parts are loaded onto racks or carts and manually moved through the pre-treatment, coating, and curing stages.

Conveyorized Systems

Conveyorized systems are designed for high-volume production. Parts move continuously through each stage on a conveyor, with options for manual or fully automated operation. These systems maximize throughput and consistency.

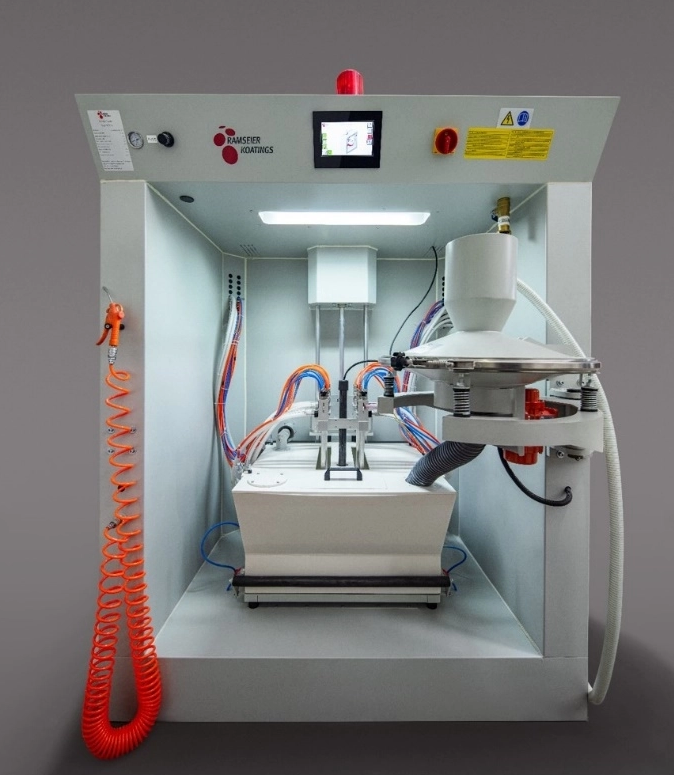

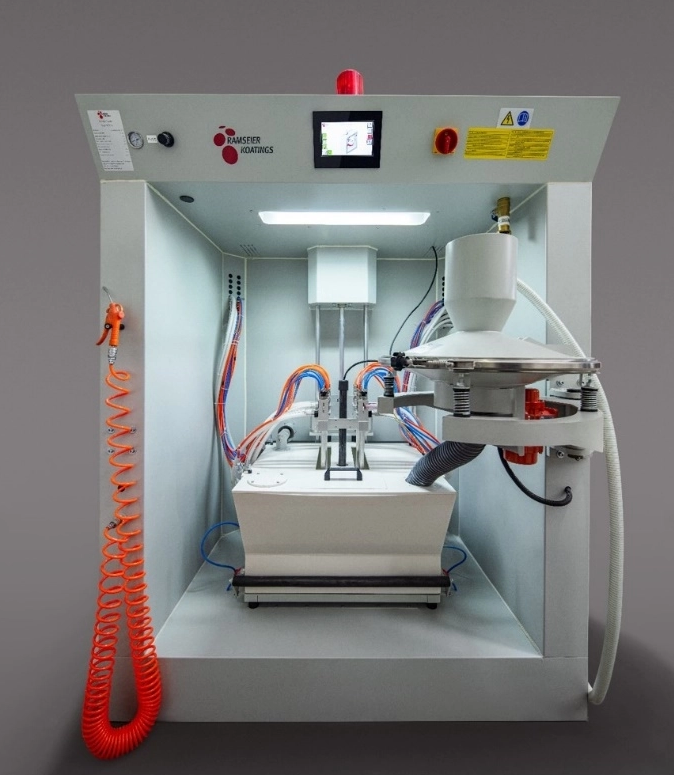

Components of a Powder Coating System

A complete powder coating system typically includes the following components:

- Pre-treatment Equipment: Washers, blast cabinets, or chemical treatment stations to clean and prepare parts.

- Powder Application Booth: Enclosed area with ventilation and recovery systems to contain and recycle overspray.

- Powder Feed System: Hoppers and pumps to deliver powder to the application gun.

- Application Guns: Electrostatic spray guns or other applicators, often with control units for adjusting voltage, flow, and spray patterns.

- Curing Oven: Gas or electric ovens to heat parts and cure the powder.

- Material Handling Equipment: Racks, carts, or conveyors for moving parts through the process.

Advantages of Powder Coating Systems

Durability and Performance

Powder coatings create a tough, resilient finish that resists chipping, scratching, and fading. The thermosetting process results in a molecularly cross-linked film, providing long-lasting protection.

Environmental Benefits

Powder coating is free from solvents and emits little to no VOCs, making it a greener alternative to traditional painting. Overspray can often be collected and reused, reducing waste.

Efficiency and Cost-Effectiveness

While the initial investment in equipment may be higher, powder coating systems offer long-term savings through reduced maintenance, lower material costs, and compliance with environmental regulations.

Versatility

Powder coating can be applied to a wide range of substrates, including metals, plastics, and composites. It accommodates various colors, textures, and gloss levels, enabling both functional and decorative finishes.

Selecting the Right Powder Coating System

Choosing the optimal powder coating system depends on several factors:

- Production Volume: Batch systems suit low to medium volumes; conveyorized systems are best for high-volume operations.

- Part Size and Geometry: Large or complex parts may require specialized booths or application methods.

- Performance Requirements: Consider the environment (indoor vs. outdoor), desired durability, and chemical resistance.

- Budget and Space: Evaluate equipment costs, installation space, and operational expenses.

- Environmental Regulations: Ensure compliance with local and national environmental standards.

Innovations and Trends in Powder Coating

The powder coating industry continues to evolve, with advancements such as:

- Low-Temperature Curing Powders: Allow coating of heat-sensitive substrates.

- Automated Application Systems: Improve consistency and reduce labor costs.

- Smart Control Units: Enable precise adjustment and monitoring of application parameters.

- Special Effect Powders: Expand design possibilities with metallic, textured, and multi-color finishes.

- Sustainable Practices: Enhanced powder recovery and recycling systems minimize waste.

Common Challenges and Solutions

Achieving Uniform Coverage

Complex part geometries can result in uneven coating or "Faraday cage" effects. Using advanced spray guns and optimizing application parameters can help ensure uniform coverage.

Powder Recovery and Waste Reduction

Efficient booth design and recovery systems can capture overspray for reuse, minimizing material waste and operating costs.

Curing Consistency

Proper oven calibration and part spacing are essential to achieve consistent curing and optimal coating performance.

Maintenance and Safety Considerations

Regular maintenance of equipment, including cleaning booths, guns, and ovens, ensures reliable operation and high-quality results. Safety measures, such as adequate ventilation and personal protective equipment, protect operators from powder inhalation and other hazards.

Frequently Asked Questions

1. What are the main differences between batch and conveyorized powder coating systems?

Batch systems are flexible and suitable for small to medium production runs, allowing manual handling of parts. Conveyorized systems are designed for high-volume, continuous processing and can be automated for greater efficiency.

2. Can powder coating be applied to materials other than metal?

Yes, while metals are the most common substrates, certain powder coatings can be formulated for plastics, composites, and even wood, provided the substrate can withstand the curing temperatures.

3. How does powder coating compare to traditional liquid painting in terms of durability?

Powder coating generally offers superior durability, with better resistance to chipping, scratching, and fading. The thermosetting process creates a tougher, more resilient finish.

4. What are the environmental benefits of powder coating systems?

Powder coating emits little to no VOCs, contains no solvents, and allows for the recycling of overspray, making it a more environmentally friendly option than traditional painting methods.

5. What factors should be considered when selecting a powder coating system?

Key factors include production volume, part size and complexity, required performance characteristics, budget, available space, and environmental compliance requirements.

Citations:

[1] https://www.tiger-coatings.com/us-en/blog/powder-coating-process

[2] https://advancedplatingtech.com/blog/types-of-powder-coating/

[3] https://www.valencesurfacetech.com/the-news/advantages-of-powder-coating-over-traditional-paint/

[4] https://www.keystonekoating.com/blog/guide-to-powder-coating/

[5] https://www.youtube.com/watch?v=l3VF6C1_RGg

[6] https://www.thefabricator.com/thefabricator/article/finishing/an-overview-of-a-powder-coating-line-for-fabricators

[7] https://en.wikipedia.org/wiki/Powder_coating

[8] https://advancedplatingtech.com/wp-content/uploads/2013/10/Characteristics-of-Powder-Coating-Materials.pdf

[9] https://www.nordson.com/en/about-us/newsroom/industrial-coating-systems-news/complete-guide-to-powder-coating

[10] https://e-ims.com/different-types-of-powder-coating/

[11] https://www.youtube.com/watch?v=JXokJQFAlFU

[12] https://abitl.com/why-powder-coating-10-pros-and-cons/

[13] https://arpowdercoating.com/3309/

[14] https://ampp.org/technical-research/what-is-corrosion/types-of-powder-coatings-systems

[15] https://www.paintbooth.com/the-6-types-of-powder-coating/

[16] https://www.youtube.com/watch?v=-SS8XBk3MP0

[17] https://www.keystonekoating.com/blog/powder-coating-benefits/

[18] https://www.ulprospector.com/knowledge/11788/pc-the-basics-of-powder-coatings/

[19] https://www.tiger-coatings.com/us-en/blog/how-to-powder-coat-an-extensive-overview

[20] https://metaltech.us/blog/powder-coating-101-how-does-it-work/

---

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.