Content Menu

● Introduction to Powder Coating and the Role of Powder Hoppers

● What Is a Powder Hopper?

>> Definition and Basic Function

>> Types of Powder Hoppers

● How Does a Powder Hopper Work?

>> Fluidization Mechanism

>> Powder Delivery

● Why Is a Powder Hopper Crucial in Powder Coating Systems?

>> Ensures Consistent Powder Flow

>> Improves Finish Quality

>> Reduces Downtime and Maintenance

>> Supports Large-Scale and High-Volume Production

● Advantages of Fluidized Hopper Systems Compared to Other Feeding Systems

● Applications and Suitability of Powder Hoppers

>> When to Choose a Hopper Feed System

>> Limitations to Consider

● Key Components of a Powder Hopper System

>> Hopper Drum or Container

>> Fluidizing Membrane and Air Supply System

>> Powder Pump and Dosing Air

● Installation and Maintenance Considerations

>> Installation

>> Maintenance

● Conclusion

● Related Questions and Answers

Introduction to Powder Coating and the Role of Powder Hoppers

Powder coating is a widely used finishing technique that involves applying a dry powder to a surface, which is then cured under heat to form a smooth, durable coating. It offers benefits such as environmental friendliness, efficiency, and a high-quality finish compared to traditional liquid paints. One key component that plays a critical role in the effectiveness of powder coating systems is the powder hopper.

What Is a Powder Hopper?

Definition and Basic Function

A powder hopper is a container or reservoir used in powder coating systems to hold and feed the powder coating material consistently to the coating gun. It acts as an intermediate storage and delivery unit designed to ensure the powder is supplied smoothly and evenly during the coating process.

Types of Powder Hoppers

Powder hoppers come in various designs, with the most common being:

- Fluidized Hoppers: These hoppers have a membrane at the base that vibrates or is supplied with air, causing the powder to become suspended and behave almost like a fluid. This fluidization allows for more uniform feeding and reduces powder clumping.

- Box Feed Systems: These are simpler vibratory boxes that agitate the powder to feed it, less sophisticated than fluidized hoppers but more suited for rapid color changes.

How Does a Powder Hopper Work?

Fluidization Mechanism

In a fluidized powder hopper, a thin membrane at the base of a steel drum is supplied with air. This air causes the powder to suspend and become fluid-like inside the container. The powder then flows steadily to the powder gun, ensuring a consistent and smooth coating application.

Powder Delivery

The hopper feeds the powder directly to the coating gun, where an electrostatic charge is applied to the powder particles to adhere them uniformly to the target surface. The fluidized state inside the hopper allows the powder particles to be evenly suspended, minimizing clumps and improving feeding consistency.

Why Is a Powder Hopper Crucial in Powder Coating Systems?

Ensures Consistent Powder Flow

A powder hopper's fluidizing mechanism ensures a steady and uniform flow of powder to the spray gun, which eliminates powder surges or uneven sprays. This consistent delivery improves the quality of the coating and reduces waste.

Improves Finish Quality

The ability of the hopper to keep the powder fluidized leads to finer and more even powder particle distribution, contributing to a smoother, more appealing finish on the coated parts.

Reduces Downtime and Maintenance

Hoppers reduce the frequency of powder clogging at the coating gun, which means less downtime for cleaning and maintenance. This increases production efficiency and lowers operational costs.

Supports Large-Scale and High-Volume Production

With capacities that can hold larger amounts of powder (e.g., 5 pounds or more), hoppers enable coating of large or numerous parts without frequent refilling, enhancing productivity in industrial settings.

Advantages of Fluidized Hopper Systems Compared to Other Feeding Systems

| Feature | Fluidized Hopper | Box Feed System |

| Powder Flow Consistency | High – powder fluidized for smooth feeding | Moderate – mechanical agitation, less fluid |

| Finish Quality | Superior due to uniform powder suspension | Good but less consistent finish |

| Ease of Color Change | Limited – multiple hoppers required for different colors | Easy and quick change of powder boxes |

| Equipment Weight | Heavier due to steel drum and air supply system | Lighter and simpler setup |

| Powder Recovery and Blending | Efficient for powders with special characteristics or reclaimed powder | Less efficient |

Applications and Suitability of Powder Hoppers

When to Choose a Hopper Feed System

Hopper feed powder coating systems are ideal for:

- Powder coatings with special characteristics, such as metallic particles requiring thorough blending.

- Operations with limited color changes, focusing on high-quality finishes for specific colors.

- Situations where powder recovery and reuse is practiced to blend virgin and reclaimed powder for cost-effectiveness.

- High-volume or large-size production runs where steady and reliable feeding is critical.

Limitations to Consider

- Hopper systems are less effective for rapid color changes since swapping powder colors requires multiple hoppers.

- They tend to be heavier and more complex compared to simpler box feed systems.

- Initial investment and setup may be higher due to the air supply and fluidizing components.

Key Components of a Powder Hopper System

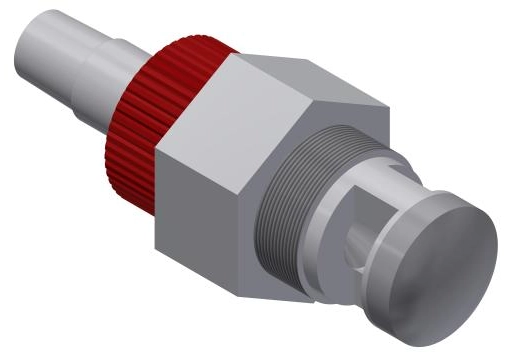

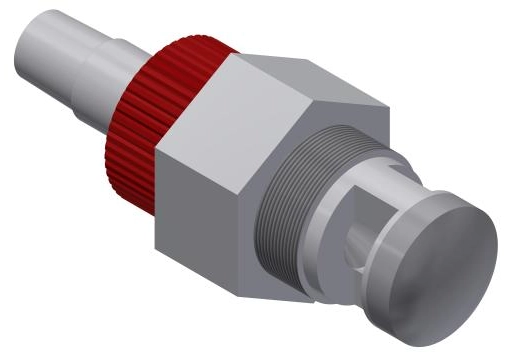

Hopper Drum or Container

Typically made of stainless steel or aluminum, the container must be durable, easy to clean, and resistant to contamination. It stores the powder and allows fluidization.

Fluidizing Membrane and Air Supply System

The membrane, usually at the base, receives a controlled supply of air to suspend the powder. This component is critical for creating the fluidized bed effect.

Powder Pump and Dosing Air

Some hoppers include a powder pump to maintain a steady flow and dosing air injection to enhance powder delivery consistency to the spray gun nozzle.

Installation and Maintenance Considerations

Installation

Powder hoppers are integrated into the powder coating system with connections for powder hoses and air supply lines. Proper installation ensures reliable powder flow and system efficiency.

Maintenance

Regular cleaning of the hopper, especially the membrane and drum interior, is important to prevent contamination and buildup. Checking the air supply and pump system helps maintain consistent fluidization and flow.

Conclusion

In powder coating systems, a powder hopper is a fundamental component that significantly affects the quality and efficiency of the coating process. By fluidizing powder coatings and ensuring consistent delivery, hoppers enable higher-quality finishes, reduced downtime, and cost-effective, large-scale production. Choosing the right hopper system depends on factors like powder type, production volume, and color change frequency. Proper use and maintenance of powder hoppers can thus optimize powder coating operations for both industrial and specialized applications.

Related Questions and Answers

1. What is the main benefit of using a fluidized powder hopper?

The main benefit is the consistent and uniform powder flow it provides by suspending the powder particles in air, which reduces clumping and improves the finish quality.

2. Can powder hoppers be used for multiple powder colors?

While possible, fluidized hoppers are less suited to rapid color changes since cleaning between colors requires significant effort, and multiple hoppers may be needed for different powders.

3. How does a powder hopper improve production efficiency?

By holding larger quantities of powder and ensuring steady supply, hoppers reduce refilling frequency and minimize system downtime from clogging or irregular powder flow.

4. Are powder hoppers heavier than other feeding systems?

Yes, due to the steel drum and air supply equipment, fluidized powder hoppers tend to be heavier than simpler vibratory box feed systems.

5. What maintenance is required for powder hoppers?

Regular cleaning of the hopper interior, fluidizing membrane, and checking air supply and pumps are essential to maintaining optimal powder flow and system performance.

[1] https://www.oemoven.com/post/hopper-fed-powder-coating-systems-how-they-work-pros-cons

[2] https://patents.google.com/patent/WO2014154668A1/zh

[3] https://pittsburghsprayequip.com/blogs/pittsburgh-spray-equipment-company/powder-coating-feeding-systems-box-vs-hopper-feed-systems

[4] https://patents.google.com/patent/CN109675732B/zh

[5] https://www.youtube.com/watch?v=p3AKv3NbJ58

[6] https://patents.google.com/patent/CN113042284B/zh

[7] https://www.royalcoatspowdercoating.com/product-page/powder-coat-hopper-2-0

[8] https://dictionary.cambridge.org/zhs/%E8%AF%8D%E5%85%B8/%E8%8B%B1%E8%AF%AD/powder-coating

[9] https://www.parkerionics.com/powder-coating-equipment/powder-coating-hoppers.html

[10] https://www.wordreference.com/enzh/powder%20coating

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.