Content Menu

● Introduction

● What Are Powder Coating Equipment Auctions?

>> H2: Defining Powder Coating Equipment Auctions

>> H3: Types of Equipment Typically Found at Auctions

● Why OEM Manufacturers and Wholesalers Should Consider Powder Coating Equipment Auctions

>> H2: Cost Efficiency and Value Acquisition

>> H3: Access to High-Quality and Diverse Equipment

>> H3: Opportunities for Upgrading and Expansion

● How to Participate Successfully in Powder Coating Equipment Auctions

>> H2: Preparing for the Auction

>> H3: Bidding Strategies

● Key Considerations When Buying Powder Coating Equipment at Auctions

>> H2: Equipment Condition and Warranty

>> H3: Shipping and Installation

>> H3: Compatibility and Integration

● Trends and Insights in the Powder Coating Equipment Auction Market

>> H2: Increasing Popularity of Online Auctions

>> H3: Growing Demand for Sustainable and Efficient Equipment

● Conclusion

● Frequently Asked Questions (FAQs)

Introduction

In the competitive world of powder coating equipment manufacturing and supply, finding cost-effective and high-quality machinery is crucial. For OEM manufacturers, wholesalers, and brand owners, "powder coating equipment auctions" represent a strategic opportunity to acquire advanced equipment at competitive prices. This comprehensive guide explores the benefits, processes, and tips for engaging in powder coating equipment auctions, helping you leverage these events to enhance your production capabilities and market competitiveness.

What Are Powder Coating Equipment Auctions?

H2: Defining Powder Coating Equipment Auctions

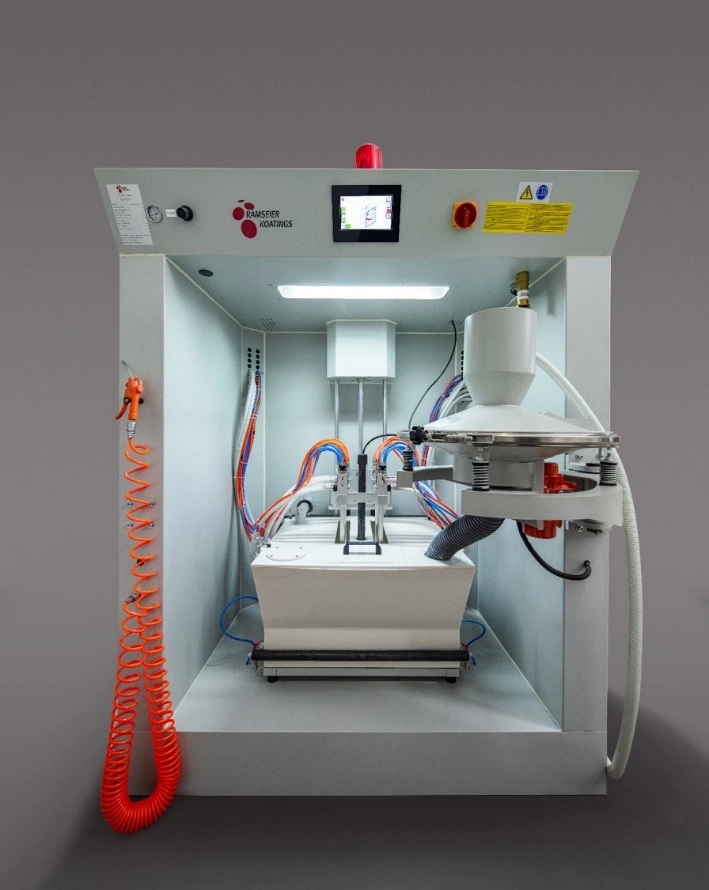

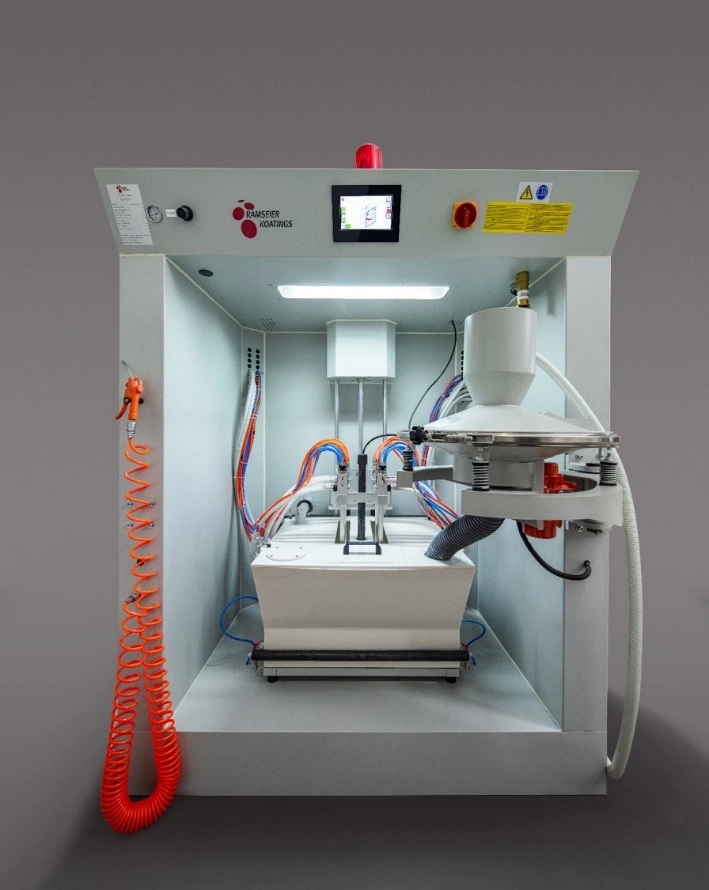

Powder coating equipment auctions are specialized sales events where new and used powder coating machinery and related industrial finishing equipment are sold to the highest bidder. These auctions can be held online or onsite and often feature a wide range of equipment including powder spray guns, curing ovens, washers, conveyor systems, and complete powder coating lines[1][7].

H3: Types of Equipment Typically Found at Auctions

- Powder spray booths and guns

- Pretreatment washers and drying ovens

- Powder coating lines with conveyors

- Color reclaim modules and cyclone collection systems

- Industrial ovens for curing powder coatings

These auctions provide access to equipment from reputable brands such as Nordson, Wagner, Gema, and others[2][5][7].

Why OEM Manufacturers and Wholesalers Should Consider Powder Coating Equipment Auctions

H2: Cost Efficiency and Value Acquisition

For manufacturers and wholesalers, purchasing equipment through powder coating equipment auctions can significantly reduce capital expenditure. Auctioned equipment often includes well-maintained used machines or surplus new equipment offered below market value, enabling buyers to optimize their production costs[1][7].

H3: Access to High-Quality and Diverse Equipment

Auctions frequently feature a variety of equipment models and configurations, allowing buyers to select machines that best fit their specific production requirements. This diversity supports customization and flexibility in manufacturing processes.

H3: Opportunities for Upgrading and Expansion

OEMs can use auctions to upgrade aging equipment or expand production lines without the long lead times associated with new equipment orders. This agility is vital in responding to market demands and maintaining competitive advantage.

How to Participate Successfully in Powder Coating Equipment Auctions

H2: Preparing for the Auction

- Research: Understand the types of equipment available and their market values.

- Inspection: Whenever possible, inspect equipment physically or request detailed condition reports.

- Budgeting: Set a clear bidding limit to avoid overspending.

- Registration: Register early for the auction platform or onsite event.

H3: Bidding Strategies

- Start with lower bids to gauge competition.

- Monitor auction pacing, especially in online staggered close formats where lots close every few seconds[3].

- Be ready to make quick decisions but avoid impulsive overbidding.

Key Considerations When Buying Powder Coating Equipment at Auctions

H2: Equipment Condition and Warranty

Auctioned equipment is often sold "as-is," so understanding the condition and any available warranties is essential. Buyers should inquire about maintenance history and potential refurbishment needs[7].

H3: Shipping and Installation

Consider logistics such as delivery costs and installation services. Some auction platforms offer delivery options, which can simplify the acquisition process[1][4].

H3: Compatibility and Integration

Ensure the purchased equipment integrates smoothly with existing production lines and meets your technical specifications.

Trends and Insights in the Powder Coating Equipment Auction Market

H2: Increasing Popularity of Online Auctions

The shift towards online auctions has broadened access for international buyers, including OEM manufacturers and wholesalers looking to source equipment from global markets[3][7].

H3: Growing Demand for Sustainable and Efficient Equipment

Buyers are increasingly seeking equipment that supports environmental regulations and energy efficiency, influencing auction offerings and buyer preferences.

Conclusion

Powder coating equipment auctions present a valuable avenue for OEM manufacturers, wholesalers, and brand owners to acquire high-quality equipment cost-effectively. By understanding the auction process, preparing adequately, and applying strategic bidding, businesses can enhance their production capabilities and competitiveness in the powder coating industry.

Frequently Asked Questions (FAQs)

Q1: What types of powder coating equipment are commonly available at auctions?

A1: Common equipment includes powder spray guns, curing ovens, washers, conveyor systems, and complete powder coating lines from brands like Nordson and Wagner[2][7].

Q2: Are auctioned powder coating machines sold with warranties?

A2: Most auctioned equipment is sold "as-is" without warranties, so buyers should carefully inspect or request condition reports before bidding[7].

Q3: Can international buyers participate in powder coating equipment auctions?

A3: Yes, many auctions are online and open to international buyers, with some offering delivery services worldwide[3][7].

Q4: How can OEM manufacturers ensure the equipment fits their production needs?

A4: By researching equipment specifications, inspecting condition, and verifying compatibility with existing systems before bidding[7].

Q5: What are the advantages of buying powder coating equipment at auctions versus new purchases?

A5: Auctions often offer lower prices, quicker availability, and access to a variety of equipment models, helping reduce capital costs and upgrade production lines faster[1][7].

[1] https://www.bid-on-equipment.com/coating-equipment

[2] https://www.machinio.com/model/powder-coating-line

[3] https://murphyauction.hibid.com/catalog/455476/rmc-powder-coatingonline-auction

[4] https://machinerymax.com/Browse/C311876-C15543438/Arbor-Powder-Coating?viewstyle=list&statusfilter=completed_only&sortfilteroptions=0

[5] https://surplusrecord.com/machinery-equipment/paint-and-powder-systems/

[6] https://www.dlhitech.gov.cn/resources/news/newsConstantImages/20200825172656759.pdf

[7] https://www.powdercoatingonline.com/powder-coating-used-equipment/

[8] http://www.vietchina.org/hyml/3041.html

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.