Content Menu

● Introduction to the Personalized Micro Powder Center

● What is a Personalized Micro Powder Center?

>> Definition and Core Functions

>> Importance in the Powder Industry

● Key Technologies in a Personalized Micro Powder Center

>> Micronization and Particle Size Reduction

>> Advanced Screening and Classification

>> Quality Control and Analytical Characterization

● Applications of Personalized Micro Powder

>> Cosmetics and Personal Care

>> Pharmaceuticals

>> Industrial Coatings and Additives

● Advantages of Partnering with a Chinese OEM Personalized Micro Powder Center

>> Cost Efficiency and Scalability

>> Advanced Manufacturing Facilities

>> Customized Solutions and Technical Support

● Challenges and Solutions in Personalized Micro Powder Production

>> Maintaining Consistency Across Batches

>> Regulatory Compliance

>> Innovation and Sustainability

● Future Trends in Personalized Micro Powder Centers

>> Integration of AI and Automation

>> Expansion into New Markets

>> Focus on Green Technologies

● Frequently Asked Questions (FAQs)

● Conclusion

Introduction to the Personalized Micro Powder Center

In today's dynamic industrial landscape, the demand for precision, customization, and high-quality powder materials has never been greater. A Personalized Micro Powder Center serves as a pivotal hub for the development, processing, and manufacturing of micro powders tailored to meet the specific needs of international powder management brand owners, wholesalers, and manufacturers. This article explores the comprehensive capabilities, technological innovations, and strategic advantages of such centers, particularly from the perspective of a Chinese OEM factory providing specialized services to global clients.

What is a Personalized Micro Powder Center?

Definition and Core Functions

A Personalized Micro Powder Center is a specialized facility that focuses on the custom production and management of micro powders — ultra-fine particles used across a variety of industries including cosmetics, pharmaceuticals, coatings, and more. These centers combine advanced micronization technologies, quality control, and tailored formulation expertise to deliver powders that meet stringent client specifications.

Importance in the Powder Industry

The micro powder industry demands not only particle size precision but also consistency in chemical and physical properties. A Personalized Micro Powder Center ensures that each batch is customized to optimize performance in end-use applications, whether it be enhancing bioavailability in pharmaceuticals or improving texture and aesthetics in personal care products[1][3][5].

Key Technologies in a Personalized Micro Powder Center

Micronization and Particle Size Reduction

Micronization is a core technology used to reduce particle size to the micro or nano scale, significantly enhancing the powder's surface area and reactivity. This process is crucial for improving dissolution rates in pharmaceuticals and achieving uniform dispersion in coatings and cosmetics[3].

Advanced Screening and Classification

To ensure particle uniformity, sophisticated screening technologies classify powders by size and morphology. This precision is vital for maintaining quality standards and achieving desired product performance[3].

Quality Control and Analytical Characterization

State-of-the-art analytical tools such as laser diffraction and morphology analysis are employed to monitor particle size distribution, shape, and surface properties, ensuring every batch meets client requirements[3].

Applications of Personalized Micro Powder

Cosmetics and Personal Care

In cosmetics, a Personalized Micro Powder Center produces powders that enhance product aesthetics and functionality. These include spherical exfoliants, ultrafine powders for smooth texture, and natural or synthetic additives that improve product stability and sensory appeal[5].

Pharmaceuticals

Pharmaceutical applications benefit from micronized powders that improve drug bioavailability and dissolution rates, enabling more effective and consistent therapeutic outcomes. Customized powders also support controlled release formulations and high-potency drug handling[3].

Industrial Coatings and Additives

Micro powders serve as additives in coatings to provide unique surface effects such as gloss reduction, abrasion resistance, and improved durability. Customized powders help manufacturers meet specific industrial performance criteria[1][7].

Advantages of Partnering with a Chinese OEM Personalized Micro Powder Center

Cost Efficiency and Scalability

Chinese OEM factories offering Personalized Micro Powder Center services provide competitive pricing without compromising quality. Their large-scale production capabilities allow for flexible order volumes, from small batches to multi-ton shipments[9][10].

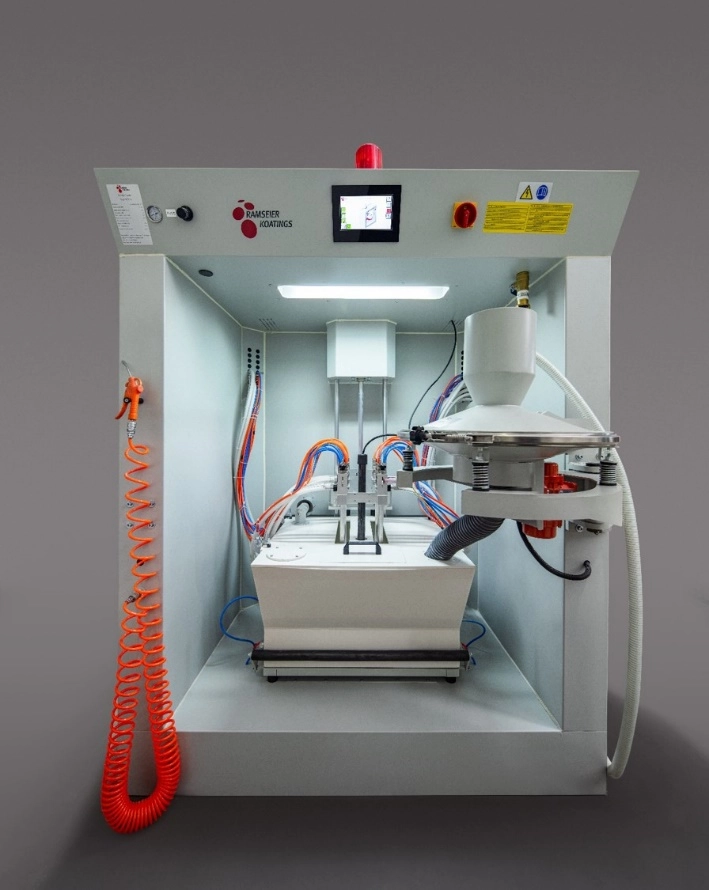

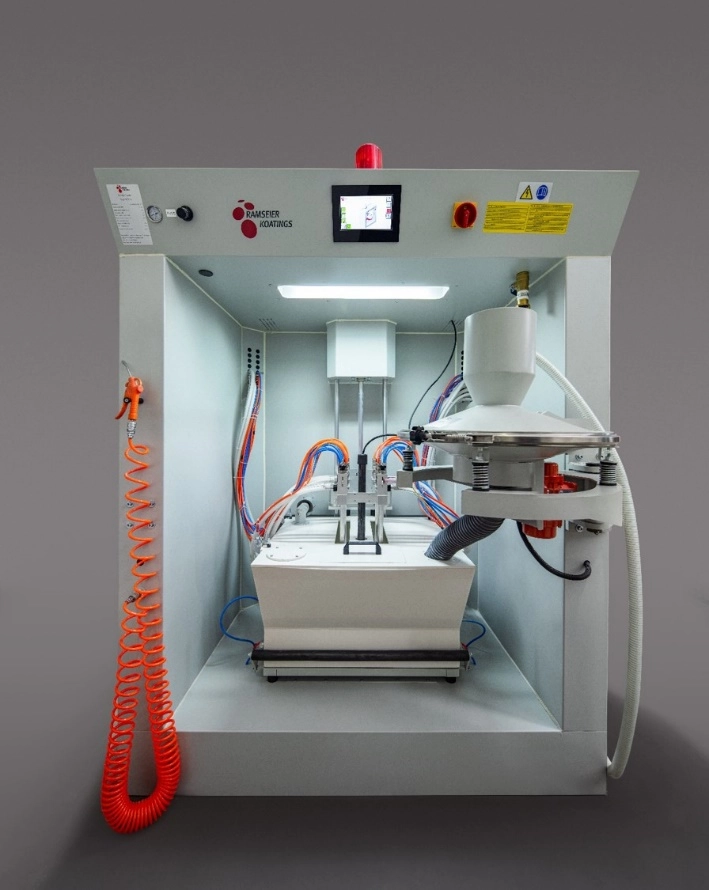

Advanced Manufacturing Facilities

Equipped with modern production lines and cleanroom environments, these centers ensure compliance with international quality standards such as GMP and ISO certifications, critical for pharmaceutical and cosmetic applications[6][9].

Customized Solutions and Technical Support

OEM centers in China offer tailored formulations and technical support, collaborating closely with foreign brand owners and manufacturers to develop powders that align perfectly with their product goals[9][10].

Challenges and Solutions in Personalized Micro Powder Production

Maintaining Consistency Across Batches

Ensuring uniformity in particle size and quality is challenging but addressed through rigorous quality control systems and real-time monitoring technologies[3].

Regulatory Compliance

Meeting diverse international regulatory requirements necessitates thorough documentation and adherence to standards such as FDA, CE, and ISO, which many Chinese OEM centers are equipped to handle[6][9].

Innovation and Sustainability

There is a growing emphasis on developing biodegradable and environmentally friendly powders. Leading Personalized Micro Powder Centers are innovating with natural materials and nanocomposite technologies to meet these demands[1][7].

Future Trends in Personalized Micro Powder Centers

Integration of AI and Automation

Automation and AI-driven process controls are expected to enhance precision, reduce production times, and improve scalability in micro powder manufacturing.

Expansion into New Markets

With rising demand in emerging sectors such as nutraceuticals and advanced materials, Personalized Micro Powder Centers will expand their product portfolios and geographic reach.

Focus on Green Technologies

Sustainable production methods and eco-friendly powder materials will become standard offerings, aligning with global environmental goals[1][7].

Frequently Asked Questions (FAQs)

Q1: What industries benefit most from a Personalized Micro Powder Center?

A1: Key industries include cosmetics, pharmaceuticals, coatings, agriculture, and personal care, all of which require customized micro powders for enhanced product performance[1][3][5].

Q2: How does micronization improve powder properties?

A2: Micronization reduces particle size, increasing surface area and improving dissolution rates, bioavailability, and uniformity in formulations[3].

Q3: What quality certifications do Chinese OEM Personalized Micro Powder Centers typically have?

A3: They often hold GMP, ISO, FDA registration, and CE certifications to meet international standards for pharmaceutical and cosmetic production[6][9].

Q4: Can a Personalized Micro Powder Center handle both natural and synthetic powders?

A4: Yes, these centers produce a wide range of powders including natural, synthetic, biodegradable, and nanocomposite materials tailored to client needs[1][7].

Q5: What are the environmental considerations in micro powder production?

A5: Leading centers focus on sustainable sourcing, biodegradable powders, and reducing waste through advanced manufacturing technologies[1][7].

Conclusion

A Personalized Micro Powder Center plays a critical role in the global powder management ecosystem by providing customized, high-quality micro powders that meet the exacting standards of international brand owners, wholesalers, and manufacturers. Chinese OEM factories excel in delivering scalable, cost-effective, and innovative solutions backed by advanced technology and stringent quality control. As industries evolve, these centers will continue to drive innovation, sustainability, and excellence in powder production.

[1] https://www.micropowders.com

[2] https://www.etsy.com/market/micro_powder

[3] https://microsize.com

[4] https://www.micromatic.com/en-us/capabilities/custom-towers-design

[5] https://www.micropowders.com/personal-care.html

[6] http://www2.mfa.gr/infofiles/%E4%B8%8A%E6%B5%B7%E9%98%B2%E7%96%AB%E5%B1%95%E4%BC%9A%E5%88%8ASEPMEF%20Catalog%20cn.pdf

[7] https://www.pcimag.com/directories/2169-buyers-guide/listing/1925-micro-powders-inc

[8] https://www.scribd.com/document/787859150/2024%E6%B4%81%E5%87%80%E4%BC%9A%E5%88%8A%E7%94%B5%E5%AD%90%E7%89%88-Vn

[9] language.english_writing.cosmetics

[10] work.powder_coating_equipment

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.