Content Menu

● Introduction to Powder Coating Equipment Florida Market

● What Is Powder Coating Equipment?

>> H2: Understanding Powder Coating Equipment

>> H3: Importance of Quality Equipment in Florida's Industrial Sector

● Why Choose a Chinese OEM Manufacturer for Powder Coating Equipment Florida?

>> H2: Advantages of Chinese OEM Services

>> H3: Supporting Florida Businesses with Expert OEM Solutions

● Key Features of Our Powder Coating Equipment for Florida Clients

>> H2: State-of-the-Art Powder Coating Systems

>> H3: Durability and Efficiency

● Powder Coating Equipment Florida Market Trends and Opportunities

>> H2: Growing Demand for Eco-Friendly Finishing Solutions

>> H3: Expansion of Industrial Coating Services in Florida

● How Our OEM Services Enhance Your Powder Coating Business in Florida

>> H2: Comprehensive Support from Design to Delivery

>> H3: Seamless Integration with Your Production Line

● Frequently Asked Questions About Powder Coating Equipment Florida

● Conclusion

Introduction to Powder Coating Equipment Florida Market

Powder coating is a highly durable and environmentally friendly finishing process widely used in various industries. For businesses in Florida seeking reliable powder coating equipment, partnering with an experienced OEM manufacturer can provide customized, high-quality solutions. As a prominent Chinese powder coating equipment manufacturer, supplier, and OEM service provider, we specialize in delivering advanced powder coating systems tailored for Florida's industrial needs.

What Is Powder Coating Equipment?

H2: Understanding Powder Coating Equipment

Powder coating equipment includes the machinery and tools used to apply powder coating finishes to metal and other substrates. This equipment typically consists of:

- Powder spray guns

- Curing ovens

- Pretreatment washers

- Conveyors and handling systems

These components work together to ensure a uniform, durable finish that resists corrosion, chemicals, and UV damage.

H3: Importance of Quality Equipment in Florida's Industrial Sector

Florida's diverse industries, from automotive to construction, demand powder coating equipment that can withstand humid and corrosive environments. High-quality powder coating equipment Florida providers ensure that coatings are applied efficiently and consistently, meeting strict industry standards.

Why Choose a Chinese OEM Manufacturer for Powder Coating Equipment Florida?

H2: Advantages of Chinese OEM Services

Our factory offers comprehensive OEM services for powder coating equipment, catering to Florida-based brands, wholesalers, and manufacturers. The benefits include:

- Customization: Tailored equipment designs to meet specific production requirements.

- Cost Efficiency: Competitive pricing without compromising quality.

- Advanced Technology: Incorporation of the latest powder coating innovations.

- Reliable Supply Chain: Steady production capacity and timely delivery.

H3: Supporting Florida Businesses with Expert OEM Solutions

We collaborate closely with Florida companies, providing not just equipment but also design and production expertise. This partnership approach ensures that powder coating equipment Florida customers receive is optimized for local market demands and environmental conditions.

Key Features of Our Powder Coating Equipment for Florida Clients

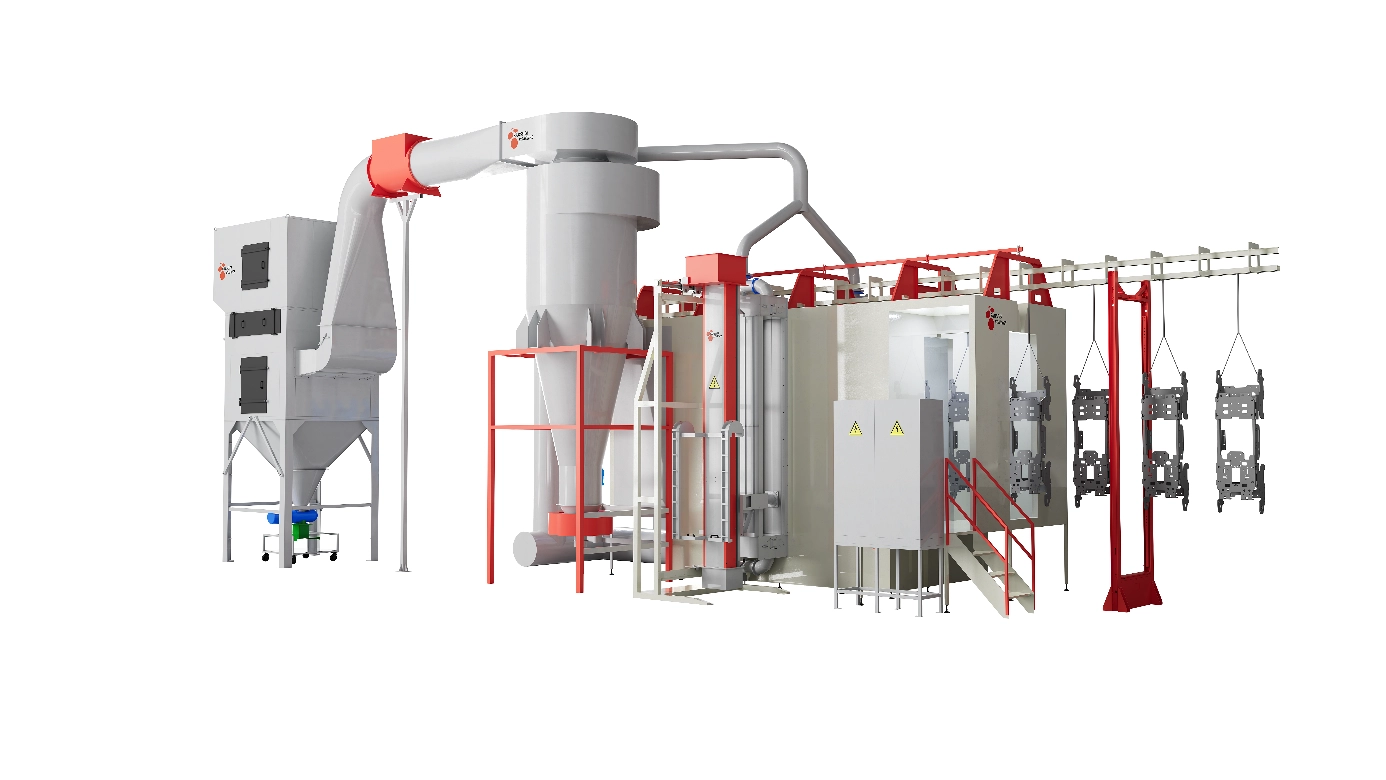

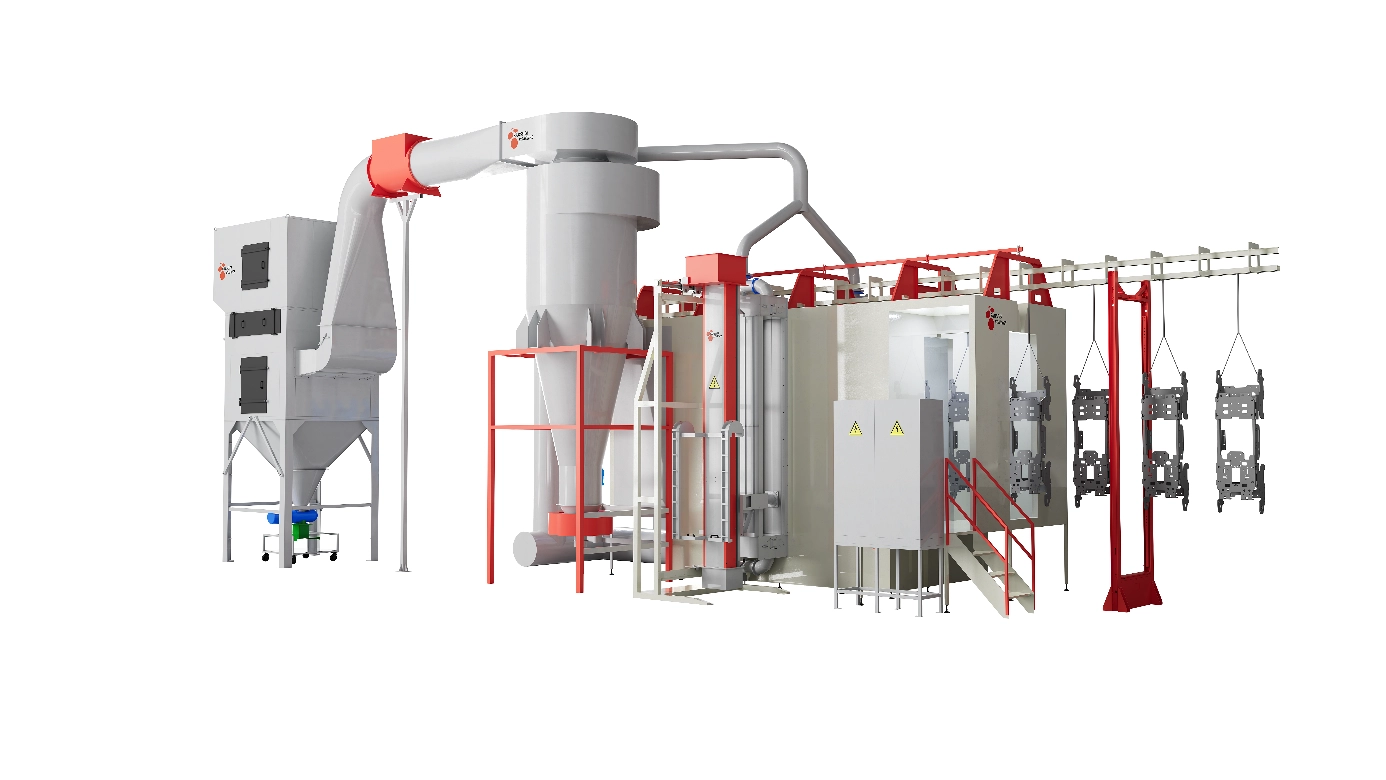

H2: State-of-the-Art Powder Coating Systems

Our equipment lineup includes:

- Automatic Powder Coating Systems: For fast color changes and uniform application, ideal for high-volume production.

- Batch Powder Coating Equipment: Suitable for smaller runs or specialized products, offering flexibility and precision.

- Large Capacity Ovens: Capable of curing parts up to 45 feet in length, meeting the needs of Florida's large-scale industrial projects.

H3: Durability and Efficiency

Designed to resist Florida's humid climate and corrosive salt air, our powder coating equipment ensures long-lasting performance and minimal maintenance.

Powder Coating Equipment Florida Market Trends and Opportunities

H2: Growing Demand for Eco-Friendly Finishing Solutions

Florida's industries increasingly prioritize environmentally sustainable processes. Powder coating, being solvent-free and producing minimal waste, aligns perfectly with this trend, driving demand for advanced powder coating equipment.

H3: Expansion of Industrial Coating Services in Florida

With companies like Patriot Powder Coating offering large-scale coating services, the need for reliable OEM equipment partners grows. Our factory supports these businesses by supplying equipment that enhances their operational efficiency and coating quality.

How Our OEM Services Enhance Your Powder Coating Business in Florida

H2: Comprehensive Support from Design to Delivery

We provide end-to-end OEM services including:

- Equipment design tailored to your product specifications

- Manufacturing with strict quality control

- After-sales technical support and training

H3: Seamless Integration with Your Production Line

Our equipment is designed for easy integration into existing Florida production environments, minimizing downtime and maximizing productivity.

Frequently Asked Questions About Powder Coating Equipment Florida

1. What types of powder coating equipment are best suited for Florida's climate?

Equipment with corrosion-resistant materials and robust curing ovens designed to handle humid and salty air conditions is ideal for Florida.

2. Can Chinese OEM manufacturers customize powder coating equipment for specific industrial needs?

Yes, customization is a core service, allowing equipment to be tailored for size, capacity, and process requirements.

3. What is the typical lead time for OEM powder coating equipment delivery to Florida?

Lead times vary but generally range from 8 to 16 weeks, depending on customization and order volume.

4. How does powder coating equipment improve production efficiency?

Automated systems ensure consistent coating thickness, reduce material waste, and speed up the curing process.

5. Are there local service options available for powder coating equipment in Florida?

Many OEM providers, including our factory, offer remote support and can coordinate with local service partners for maintenance.

Conclusion

For Florida powder coating brands, wholesalers, and manufacturers, partnering with a reputable Chinese OEM powder coating equipment supplier offers unmatched advantages in customization, technology, and cost-effectiveness. Our factory's expertise and comprehensive OEM services empower Florida businesses to enhance their coating capabilities and meet growing market demands with confidence.

[1] https://www.indcoating.com

[2] https://www.thomasnet.com/florida/powder-coating-equipment-62441282-1.html

[3] https://www.nordson.com/en/divisions/industrial-coating-systems

[4] https://www.patriotpowdercoating.net

[5] https://www.southernspring.com/powder-coating-additional-services

[6] https://kjc.tust.edu.cn/docs/20181012095635354040.xlsx

[7] https://www.powdercoatingonline.com/powder-coating-batch-equipment/

[8] https://www.dlhitech.gov.cn/resources/news/newsConstantImages/20200825172656759.pdf

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.