Content Menu

● Introduction

● Understanding the Powder Coating Equipment Market

>> What is Powder Coating Equipment?

>> Market Growth and Trends

● Our Role as a Leading Powder Coating Equipment Company

>> Comprehensive OEM Manufacturing Services

>> Product Range

● Advantages of Choosing Our Powder Coating Equipment Company

>> Quality and Reliability

>> Customization and Flexibility

>> Cost-Effectiveness

>> Global Support and Service

● How to Select the Right Powder Coating Equipment

>> Assess Your Production Needs

>> Consider Equipment Features

>> Evaluate OEM Capabilities

● Frequently Asked Questions (FAQs)

● Conclusion

Introduction

In the rapidly evolving industrial coatings sector, powder coating stands out as an eco-friendly, efficient, and durable finishing solution. As a leading powder coating equipment company based in China, we specialize in manufacturing, designing, and supplying high-quality powder coating machinery. Our factory provides comprehensive OEM services to global brand owners, wholesalers, and manufacturers, enabling them to enhance their production capabilities with customized powder coating equipment. This article explores the powder coating equipment market, the types of machinery available, our OEM service advantages, and answers common questions to guide businesses in selecting the ideal equipment.

Understanding the Powder Coating Equipment Market

What is Powder Coating Equipment?

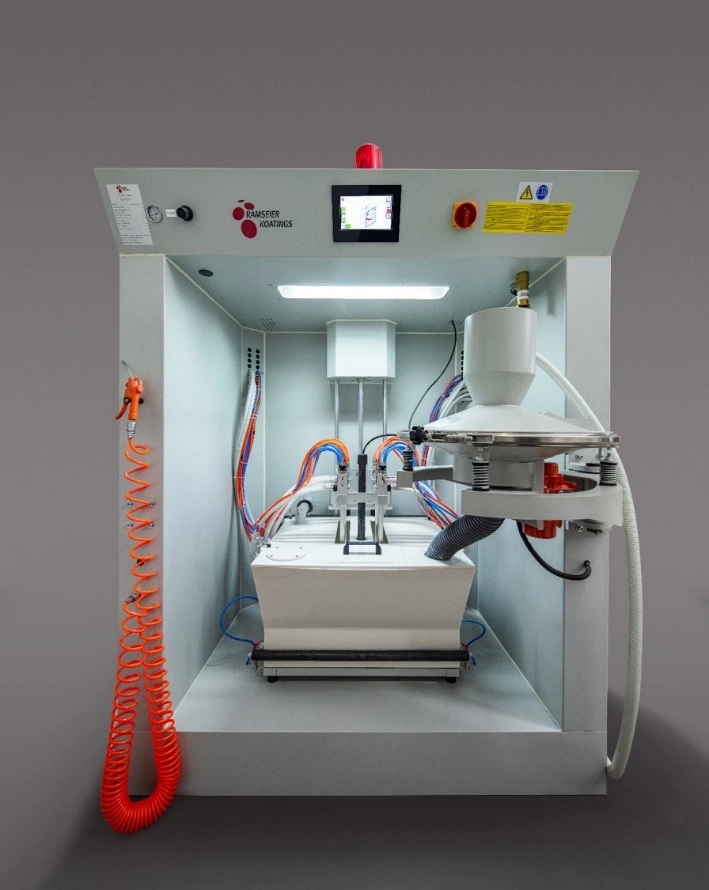

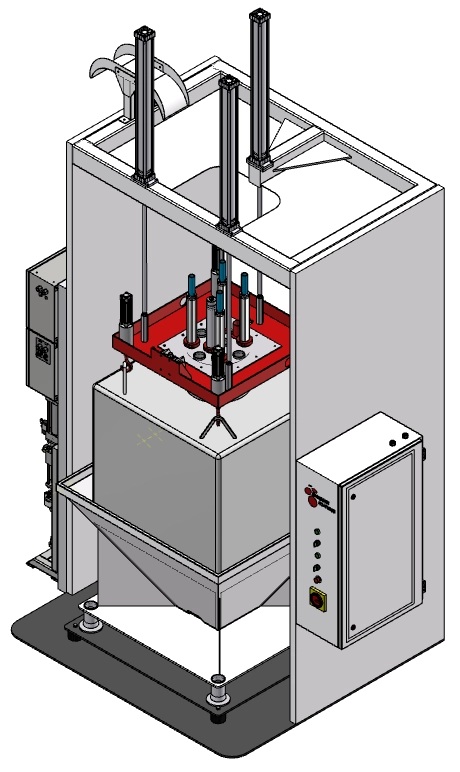

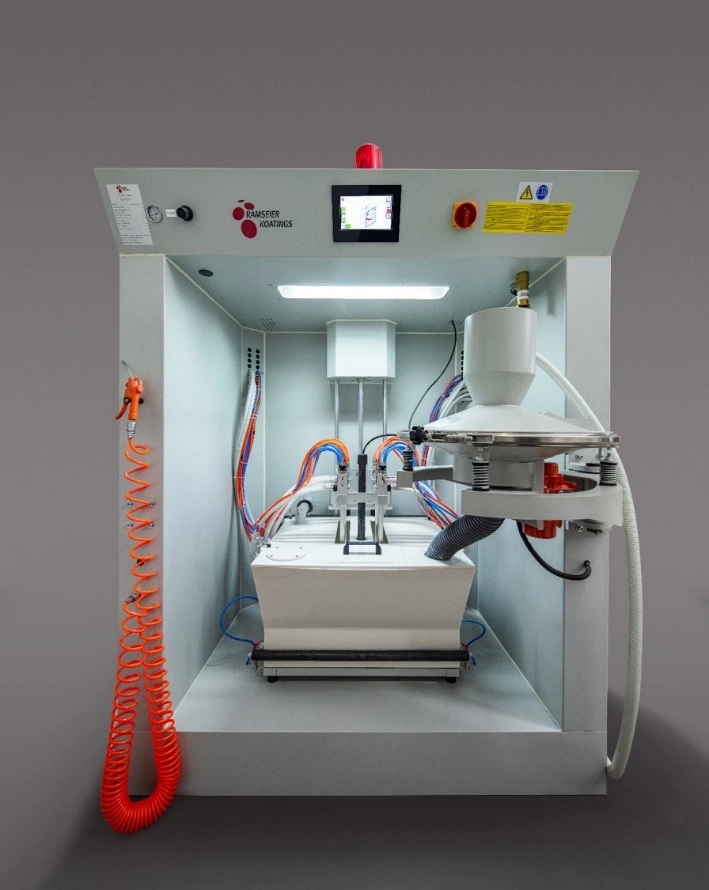

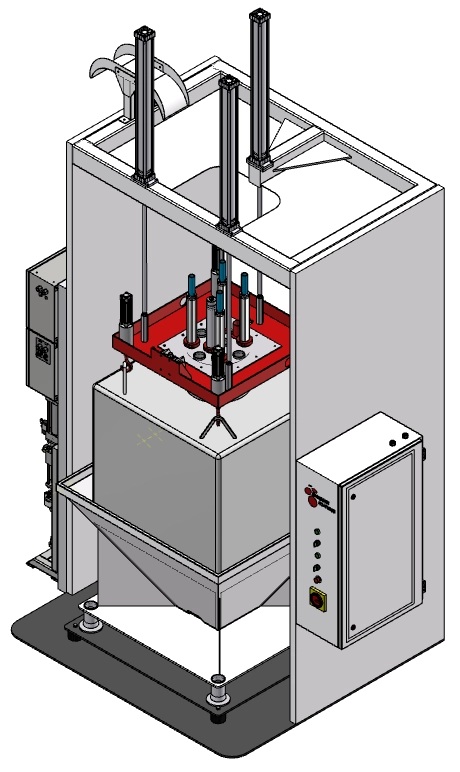

Powder coating equipment refers to the machinery and systems used to apply powder coatings to various surfaces. This equipment typically includes powder coating booths, spray guns, curing ovens, conveyor lines, and filtration systems. The powder coating process involves electrostatically charging powder particles and spraying them onto a grounded surface, followed by curing to form a hard, protective finish.

Market Growth and Trends

The global powder coating equipment market was valued at approximately USD 2.93 billion in 2022 and is projected to grow steadily, driven by increasing demand for environmentally friendly coatings and industrial automation[1][3][10]. The rise in manufacturing activities across automotive, construction, and consumer goods sectors fuels this growth, making powder coating equipment indispensable for modern production lines.

Our Role as a Leading Powder Coating Equipment Company

Comprehensive OEM Manufacturing Services

As an experienced powder coating equipment company, we offer OEM services tailored to the specific needs of foreign platform brand owners, wholesalers, and manufacturers. Our services encompass:

- Custom design and engineering of powder coating booths, guns, ovens, and conveyor systems

- Manufacturing and assembly adhering to international quality standards, including CE certification

- Flexible production volumes from small batch to large-scale manufacturing

- After-sales support including spare parts and maintenance guidance

Our factory leverages advanced manufacturing technologies and over 30 years of industry expertise to deliver durable, efficient, and cost-effective powder coating equipment[5][11].

Product Range

Our product portfolio includes:

- Powder Coating Booths: Both manual and automatic booths designed for optimal powder recovery and operator safety.

- Powder Spray Guns: Electrostatic guns with cartridge or automatic designs for consistent powder application.

- Curing Ovens: Energy-efficient ovens for curing powder coatings, available in various sizes to fit production needs.

- Conveyor Systems: Automated lines to transport parts through coating and curing processes seamlessly.

- Filters and Spare Parts: Essential components to maintain system performance and longevity.

Advantages of Choosing Our Powder Coating Equipment Company

Quality and Reliability

Our equipment is engineered for heavy-duty industrial use, ensuring high throughput and consistent coating quality. We conduct rigorous testing and quality control to meet international standards, providing our clients with reliable machinery that minimizes downtime.

Customization and Flexibility

Understanding that each client's production requirements differ, we offer fully customizable OEM solutions. Whether you need specialized booth dimensions, unique gun configurations, or integrated automation, our design team works closely with you to meet those specifications.

Cost-Effectiveness

By manufacturing in China with optimized production processes, we provide competitively priced powder coating equipment without compromising quality. This allows our clients to maximize their investment and improve their market competitiveness.

Global Support and Service

We support our customers worldwide with technical assistance, training, and spare parts supply to ensure smooth operation of their powder coating lines.

How to Select the Right Powder Coating Equipment

Assess Your Production Needs

- Volume of parts to be coated

- Size and shape of parts

- Desired coating thickness and finish quality

- Automation level required

Consider Equipment Features

- Powder recovery efficiency

- Ease of maintenance

- Energy consumption of curing ovens

- Compatibility with different powder types

Evaluate OEM Capabilities

- Ability to customize equipment

- Compliance with safety and quality standards

- After-sales support and training availability

Frequently Asked Questions (FAQs)

Q1: What is the difference between manual and automatic powder coating booths?

A1: Manual booths require operators to manually spray powder, suitable for low to medium volume production. Automatic booths use robotic or mechanized systems for higher throughput and consistent application[5].

Q2: How does a powder coating gun work?

A2: Powder coating guns electrostatically charge powder particles and spray them onto grounded parts, ensuring even coverage. Guns can be cartridge-type or automatic, depending on application needs[5][10].

Q3: What are the benefits of OEM powder coating equipment?

A3: OEM equipment is customized to client specifications, ensuring better integration with existing processes, improved efficiency, and tailored features that off-the-shelf products may not offer[11].

Q4: How important is the curing oven in powder coating?

A4: The curing oven is critical as it melts and fuses the powder to form a durable finish. Proper oven performance ensures coating quality and adhesion[5].

Q5: Can your company provide training on powder coating equipment operation?

A5: Yes, we offer training and technical support to help clients operate and maintain their powder coating equipment effectively[9][11].

Conclusion

As a dedicated powder coating equipment company, we combine advanced manufacturing capabilities with personalized OEM services to empower global powder coating brand owners, wholesalers, and manufacturers. Our commitment to quality, customization, and support makes us a trusted partner in the powder coating industry. Whether you are launching a new powder coating line or upgrading existing equipment, our solutions are designed to meet your unique production challenges and drive your business success.

[1] https://www.grandviewresearch.com/industry-analysis/powder-coatings-equipment-market

[2] https://www.nordson.com/en/divisions/industrial-coating-systems/application-solutions/powder-coating

[3] https://www.marketsandmarkets.com/Market-Reports/powder-coating-equipment-market-189728086.html

[4] https://www.youtube.com/watch?v=l6jlnjmy5aI

[5] https://ems-powdercoating.com

[6] http://www.sse.com.cn/disclosure/listedinfo/announcement/c/new/2025-04-29/688128_20250429_IZYA.pdf

[7] https://www.cetinc.com

[8] https://www.rd.uestc.edu.cn/__local/C/4A/6F/4509FEC479E23049C115E336875_66CAE54B_2A71B7.pdf?e=.pdf

[9] https://powderx.com

[10] https://www.snsinsider.com/reports/powder-coating-equipment-market-6045

[11] work.powder_coating_equipment

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.