Content Menu

● Introduction

● What Is Powder Coating Equipment Harbor Freight?

>> Overview of Harbor Freight Powder Coating Systems

>> Key Components

● Advantages of Harbor Freight Powder Coating Equipment

>> Cost-Effectiveness

>> Ease of Use for OEM Production

>> Versatility in Applications

● Limitations and Considerations

>> Quality and Consistency

>> Additional Equipment Needs

>> Safety and Setup

● How OEM Manufacturers Can Leverage Harbor Freight Equipment

>> Integrating Into Production Lines

>> Customization and Branding

>> Cost Control and Scalability

● Practical Tips for Using Harbor Freight Powder Coating Equipment

>> Preparing the Surface

>> Powder Selection

>> Application Techniques

>> Curing Process

● Frequently Asked Questions (FAQs)

● Conclusion

Introduction

As a leading Chinese manufacturer, wholesaler, and OEM service provider specializing in powder coating equipment, we understand the importance of reliable, cost-effective solutions for powder coating applications. Among the options available in the market, the keyword "powder coating equipment Harbor Freight" has gained significant attention for its affordability and accessibility. This article explores the features, advantages, and practical insights of Harbor Freight powder coating equipment, targeting overseas brands, wholesalers, and manufacturers seeking OEM partnerships.

What Is Powder Coating Equipment Harbor Freight?

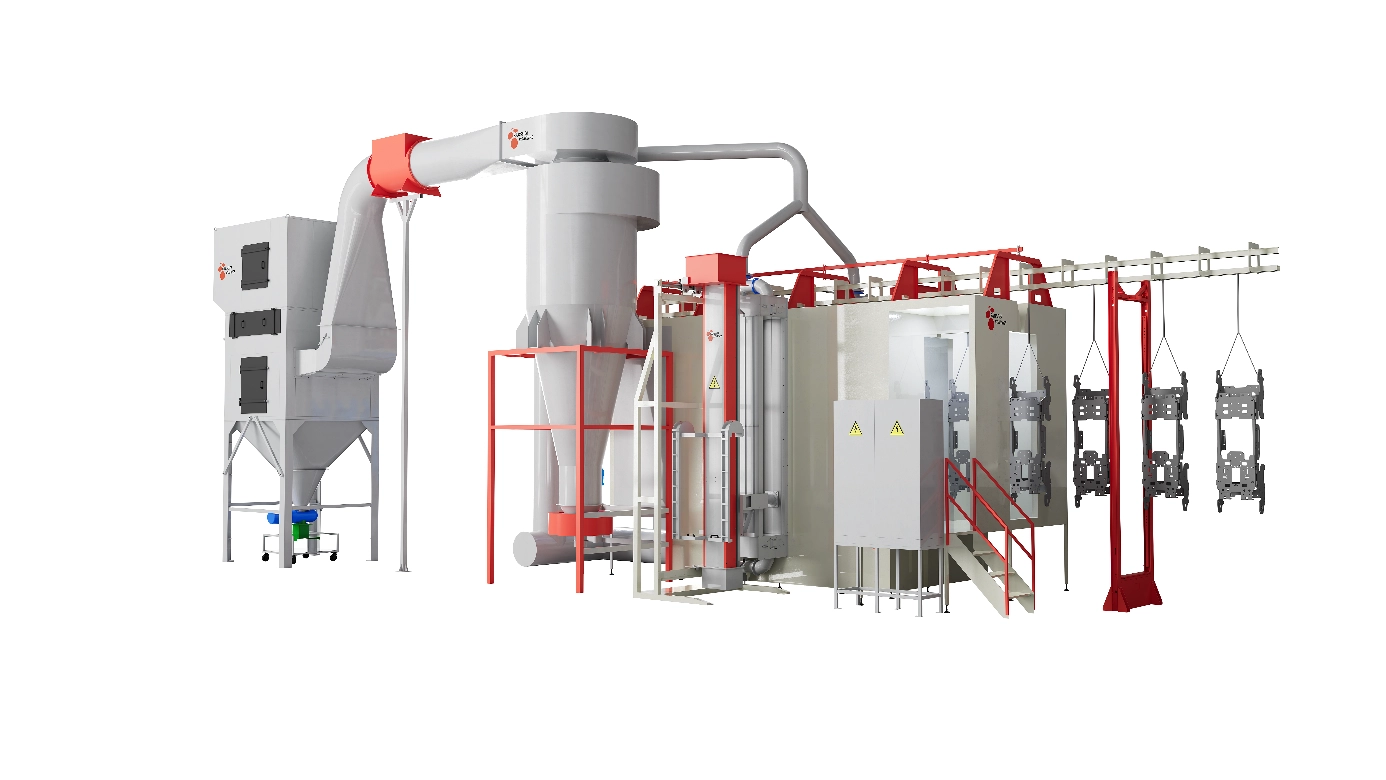

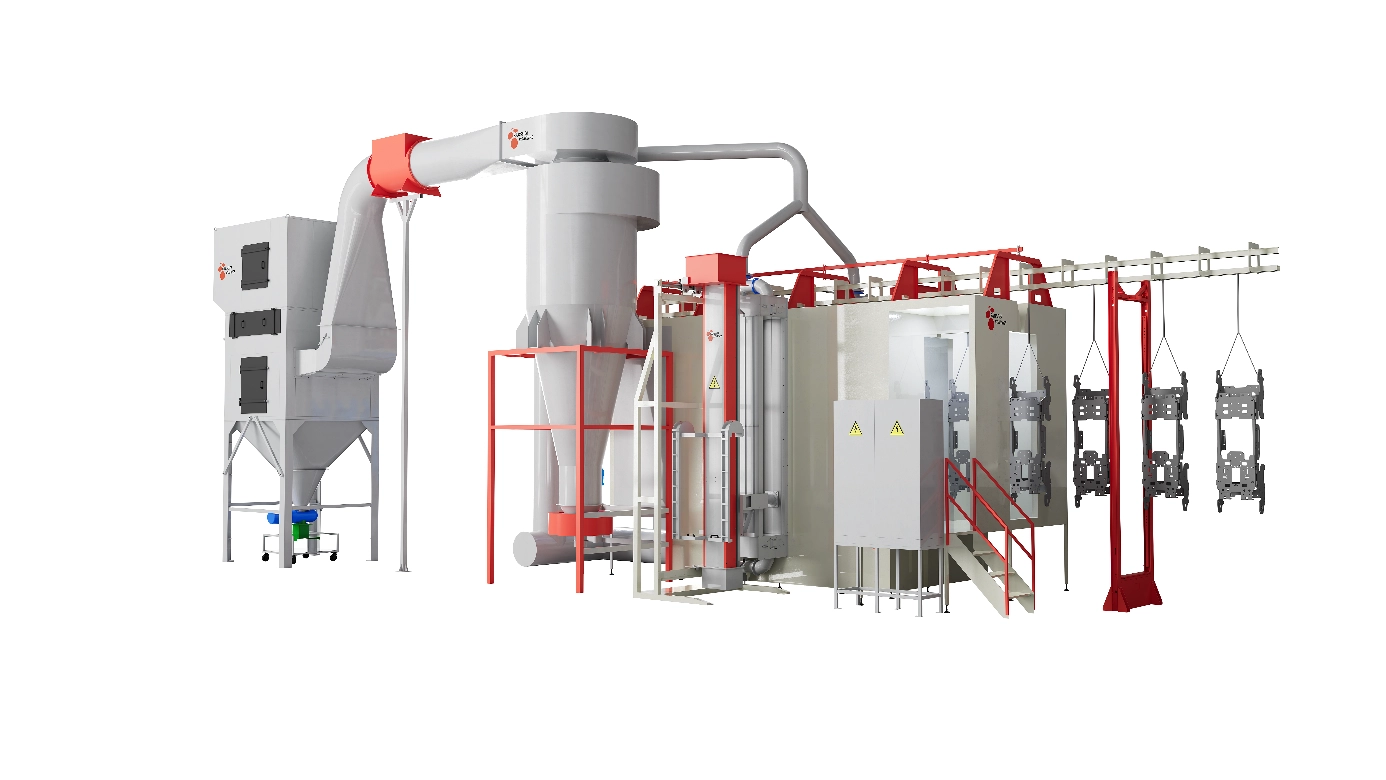

Overview of Harbor Freight Powder Coating Systems

Harbor Freight offers entry-level powder coating kits that are popular among hobbyists and small-scale manufacturers due to their low price point, typically around $60 to $75. These kits usually include a powder coating gun, control unit, and powder containers, requiring an external air compressor to operate. The system works by electrostatically charging powder particles that adhere to grounded metal parts, which are then cured in an oven to form a durable finish[5][1].

Key Components

- Powder coating gun with adjustable diffusers for spray patterns

- Control unit to regulate powder feed

- Powder containers for storing coating materials

- Requires an air compressor with 7-10 psi pressure for operation[5]

Advantages of Harbor Freight Powder Coating Equipment

Cost-Effectiveness

The most compelling advantage of Harbor Freight powder coating equipment is its affordability. For a modest investment, manufacturers and wholesalers can access powder coating capabilities without the high capital expenditure associated with professional-grade systems[4][5].

Ease of Use for OEM Production

The simplicity of the Harbor Freight system makes it suitable for OEM manufacturers who want to provide powder coating as a value-added service. It allows for quick setup and operation, enabling efficient processing of metal parts for various industries[1][5].

Versatility in Applications

Despite being a budget option, Harbor Freight powder coating equipment can handle diverse projects, from automotive parts to industrial components, delivering a durable and attractive finish when used correctly[5].

Limitations and Considerations

Quality and Consistency

Users report that Harbor Freight powder coating guns can be inconsistent, with powder feed sometimes coming out unevenly. The spring mechanism inside the gun may require frequent shaking to maintain powder flow[4]. Compared to higher-end systems like Eastwood, Harbor Freight's finish may be less glossy and smooth[6].

Additional Equipment Needs

While the powder coating kit itself is inexpensive, a proper curing oven is essential for achieving a durable finish. Many users repurpose electric smokers or small ovens for this purpose. Additionally, a reliable air compressor and ventilation setup are necessary to maintain safety and quality[2][5].

Safety and Setup

Proper ventilation and dust control are crucial since powder coating can generate airborne particles. A dedicated spray booth or well-ventilated area is recommended, especially for larger production runs[2].

How OEM Manufacturers Can Leverage Harbor Freight Equipment

Integrating Into Production Lines

OEM manufacturers can incorporate Harbor Freight powder coating equipment into their production processes by powder coating individual parts before assembly or coating sub-assemblies. This flexibility helps optimize workflow and maintain quality control[2].

Customization and Branding

By offering OEM powder coating services using Harbor Freight equipment, manufacturers can provide customized finishes for clients' products, enhancing brand value and meeting specific color or durability requirements[11][12].

Cost Control and Scalability

Starting with Harbor Freight equipment allows small to medium-sized OEM factories to enter the powder coating market with minimal upfront costs. As demand grows, they can scale up or upgrade to more advanced systems while maintaining competitive pricing[11].

Practical Tips for Using Harbor Freight Powder Coating Equipment

Preparing the Surface

Proper surface preparation, including cleaning and sandblasting, is critical for adhesion and finish quality. OEMs should ensure parts are free of oils, rust, and contaminants before coating[5].

Powder Selection

Harbor Freight offers basic powder colors, but for higher quality or specialty finishes, sourcing powders from reputable suppliers is advisable. This can improve the durability and appearance of the coated parts[5].

Application Techniques

- Use different diffuser sizes to control spray pattern

- Keep the powder coating gun steady and maintain a consistent distance from the part

- Shake the gun regularly to prevent clogs[4][6]

Curing Process

Bake coated parts in an oven at temperatures and durations specified by the powder manufacturer, typically around 350°F for 10-20 minutes. Proper curing ensures a hard, durable finish[5].

Frequently Asked Questions (FAQs)

Q1: Is Harbor Freight powder coating equipment suitable for professional OEM manufacturing?

A1: It is best suited for small to medium-scale OEM operations or prototyping due to its affordability. For high-volume or precision work, more advanced systems may be preferable[4][6].

Q2: What air compressor specifications are needed for Harbor Freight powder coating guns?

A2: An air compressor capable of delivering 7-10 psi with adequate CFM (cubic feet per minute) is required. A small 3.5 to 4-gallon compressor is often sufficient[5].

Q3: Can Harbor Freight powder coating kits handle multi-color or clear coat applications?

A3: Yes, but it requires careful technique and multiple coating passes. The system's simplicity may limit the ease of complex finishes compared to professional equipment[6].

Q4: How do I ensure safety when using powder coating equipment?

A4: Use proper ventilation, wear protective gear, and maintain a clean workspace to control dust and powder particles[2].

Q5: What is the typical lifespan of a powder coating finish applied with Harbor Freight equipment?

A5: When properly applied and cured, the finish can be durable and long-lasting, suitable for many industrial and automotive applications, though it may not match the longevity of high-end powder coatings[5].

Conclusion

For OEM manufacturers, wholesalers, and brands seeking cost-effective powder coating solutions, powder coating equipment Harbor Freight offers an accessible entry point. While it has limitations in consistency and finish quality compared to premium systems, its affordability and ease of use make it a valuable tool for expanding manufacturing capabilities and offering OEM services. Proper setup, surface preparation, and curing are key to maximizing results with this equipment.

[1] https://www.youtube.com/watch?v=3deKJVrZcOU

[2] https://www.chiefdelphi.com/t/powder-coating-and-anodizing/407845

[3] https://finishingandcoating.com/index.php/powder-coat/1731-powder-coatings-and-aama-how-to-meet-the-specifications

[4] https://www.youtube.com/watch?v=qbM4h9r7SHk

[5] https://www.youtube.com/watch?v=BuWWY7xiO7g

[6] https://www.youtube.com/watch?v=1VzEHynYP2A

[7] https://www.harborfreight.com/10-30-psi-powder-coating-system-94244.html

[8] https://www.harborfreight.com/painting/paints-sealants-adhesives/powder-coat-paints/powder-coating-systems.html

[9] https://www.harborfreight.com/painting/paints-sealants-adhesives/10-30-psi-powder-coating-system-94244.html

[10] https://go.harborfreight.com/coupons/2022/02/178470-94244/

[11] language.english_writing.pharmaceutical

[12] language.english_writing.coating_equipment

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.