Content Menu

● What is a Reciprocator?

>> Types of Reciprocators

● The Importance of Motion Profiles

>> 1. Coating Uniformity

>> 2. Material Efficiency

>> 3. Surface Coverage

● Key Components of Motion Profiles

>> 1. Speed

>> 2. Stroke Length

>> 3. Acceleration and Deceleration

>> 4. Dwell Time

● Optimizing Motion Profiles for Superior Coating Results

>> 1. Analyze Coating Requirements

>> 2. Utilize Advanced Control Systems

>> 3. Conduct Regular Maintenance

>> 4. Implement Testing and Feedback Loops

>> 5. Train Operators

● Challenges in Reciprocator Motion Profiles

>> 1. Variability in Coating Materials

>> 2. Environmental Factors

>> 3. Equipment Limitations

● Future Trends in Reciprocator Technology

>> 1. Automation and Robotics

>> 2. Smart Coating Technologies

>> 3. Data-Driven Decision Making

● Conclusion

>> Frequently Asked Questions

In the world of industrial coating, achieving a superior finish is paramount. One of the critical factors influencing the quality of coatings is the motion profile of the reciprocator used in the application process. This article delves into the intricacies of reciprocator motion profiles, their impact on coating results, and best practices for optimizing these profiles to enhance the quality of coatings.

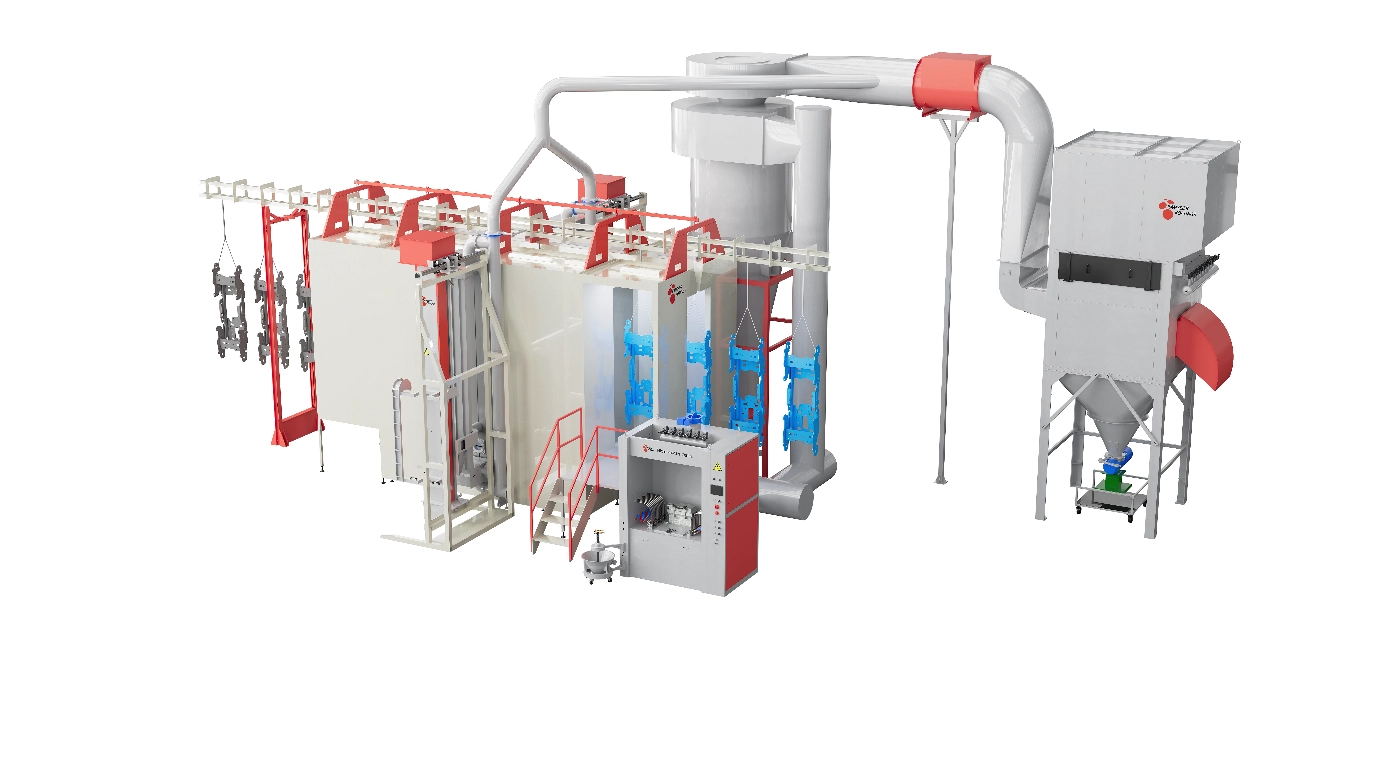

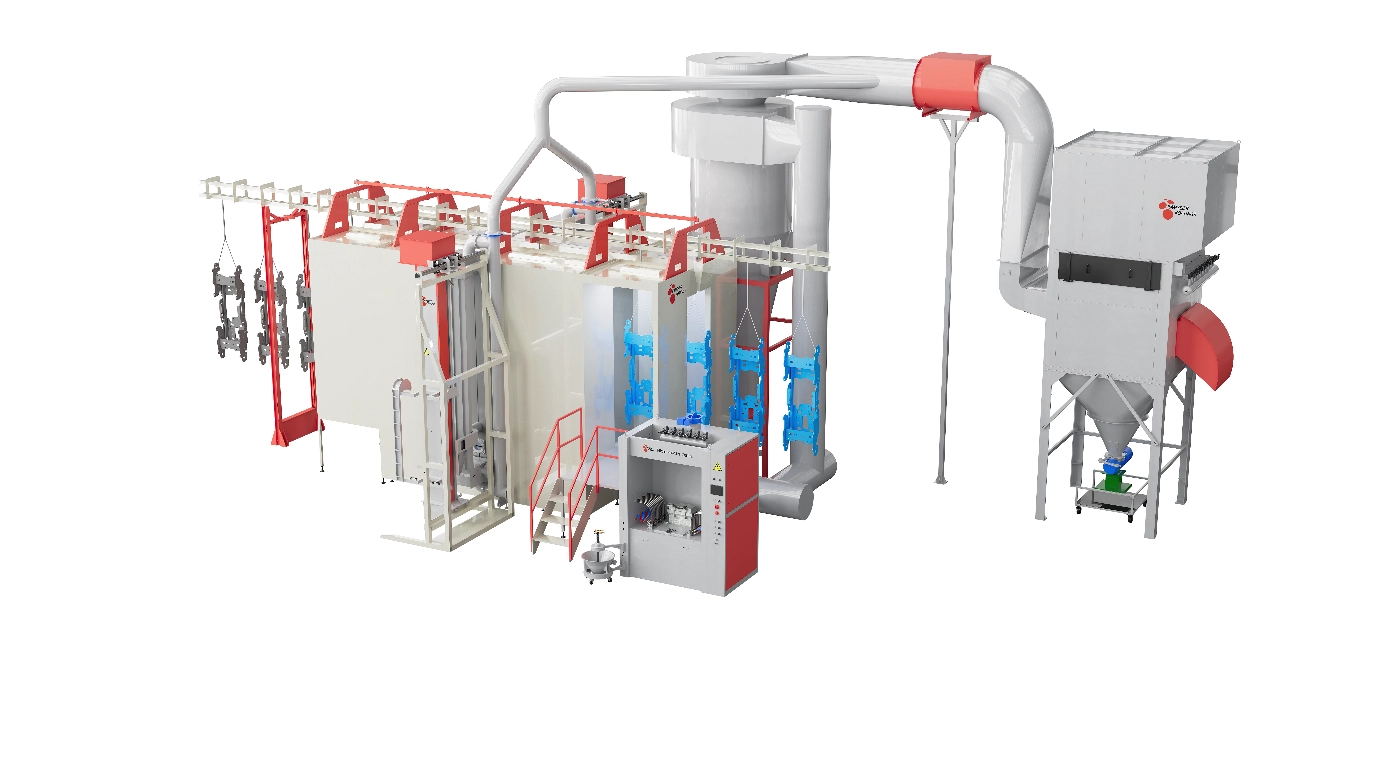

What is a Reciprocator?

A reciprocator is a mechanical device that moves a spray gun or other coating applicator back and forth in a linear motion. This motion is essential in various coating applications, including painting, powder coating, and other surface treatments. The design and operation of the reciprocator can significantly affect the uniformity, thickness, and overall quality of the coating applied to a surface.

Types of Reciprocators

Reciprocators can be classified into several types based on their design and operational mechanisms:

1. Electric Reciprocators: These use electric motors to drive the motion. They are known for their precision and control, making them suitable for applications requiring high accuracy.

2. Pneumatic Reciprocators: Utilizing compressed air, these reciprocators are often more robust and can handle heavier loads. They are commonly used in environments where electric devices may pose a risk.

3. Hydraulic Reciprocators: These are powered by hydraulic fluid and are capable of delivering high force and speed. They are ideal for heavy-duty applications.

The Importance of Motion Profiles

The motion profile of a reciprocator refers to the specific path and speed at which the applicator moves during the coating process. Understanding and optimizing these profiles is crucial for several reasons:

1. Coating Uniformity

A well-defined motion profile ensures that the coating is applied uniformly across the surface. Variations in speed or direction can lead to uneven thickness, which can affect the performance and appearance of the final product.

2. Material Efficiency

Optimizing the motion profile can lead to better material usage. By ensuring that the coating is applied only where needed and in the right amounts, manufacturers can reduce waste and lower costs.

3. Surface Coverage

Different surfaces require different approaches. A tailored motion profile can enhance coverage on complex geometries, ensuring that all areas receive adequate coating.

Key Components of Motion Profiles

To fully understand reciprocator motion profiles, it is essential to consider the key components that define them:

1. Speed

The speed of the reciprocator affects the amount of coating applied and the finish quality. Higher speeds can lead to overspray and reduced coating thickness, while lower speeds may improve coverage but increase application time.

2. Stroke Length

The stroke length is the distance the applicator travels in one complete cycle. Longer strokes can cover more area but may require more precise control to avoid overspray.

3. Acceleration and Deceleration

The rate at which the reciprocator accelerates and decelerates can impact the coating quality. Smooth transitions are essential to prevent defects such as runs or sags in the coating.

4. Dwell Time

Dwell time refers to the period the applicator spends at each end of the stroke. Properly managing dwell time can enhance coating thickness and uniformity, particularly in areas requiring more material.

Optimizing Motion Profiles for Superior Coating Results

To achieve superior coating results, manufacturers must focus on optimizing their reciprocator motion profiles. Here are some strategies to consider:

1. Analyze Coating Requirements

Understanding the specific requirements of the coating material and the surface being coated is the first step in optimizing motion profiles. Different materials may require different application techniques.

2. Utilize Advanced Control Systems

Modern reciprocators often come equipped with advanced control systems that allow for precise adjustments to motion profiles. Utilizing these systems can help achieve the desired coating results more consistently.

3. Conduct Regular Maintenance

Regular maintenance of the reciprocator is essential to ensure it operates smoothly and accurately. Any wear and tear can affect the motion profile and, consequently, the coating quality.

4. Implement Testing and Feedback Loops

Establishing a testing protocol to evaluate the effectiveness of different motion profiles can provide valuable insights. Feedback loops allow for continuous improvement based on real-world results.

5. Train Operators

Proper training for operators on how to adjust and optimize motion profiles can lead to significant improvements in coating quality. Knowledgeable operators can make real-time adjustments based on observed results.

Challenges in Reciprocator Motion Profiles

While optimizing motion profiles can lead to superior coating results, several challenges may arise:

1. Variability in Coating Materials

Different coating materials have unique properties that can affect how they behave during application. Understanding these properties is crucial for adjusting motion profiles accordingly.

2. Environmental Factors

Temperature, humidity, and other environmental factors can influence coating performance. Reciprocators must be adjusted to account for these variables to maintain consistent results.

3. Equipment Limitations

Not all reciprocators are created equal. Some may have limitations in terms of speed, stroke length, or control capabilities. Understanding these limitations is essential for setting realistic expectations.

Future Trends in Reciprocator Technology

As technology continues to advance, several trends are emerging in the field of reciprocator motion profiles:

1. Automation and Robotics

The integration of automation and robotics in coating processes is on the rise. Automated systems can optimize motion profiles in real-time, leading to improved efficiency and consistency.

2. Smart Coating Technologies

Smart coatings that respond to environmental changes are becoming more prevalent. Reciprocators will need to adapt their motion profiles to accommodate these new materials.

3. Data-Driven Decision Making

The use of data analytics to inform motion profile adjustments is gaining traction. By analyzing performance data, manufacturers can make informed decisions to enhance coating quality.

Conclusion

Understanding reciprocator motion profiles is essential for achieving superior coating results. By focusing on key components such as speed, stroke length, and dwell time, manufacturers can optimize their processes for better efficiency and quality. As technology continues to evolve, staying informed about advancements in reciprocator technology will be crucial for maintaining a competitive edge in the coating industry.

Frequently Asked Questions

1. What is the primary function of a reciprocator in coating applications?

The primary function of a reciprocator is to move a spray gun or coating applicator back and forth to ensure even and consistent application of coatings on surfaces.

2. How does speed affect coating quality?

Speed affects the amount of coating applied; higher speeds can lead to overspray and uneven thickness, while lower speeds may improve coverage but increase application time.

3. What role does dwell time play in coating applications?

Dwell time is the period the applicator spends at each end of the stroke, and managing it properly can enhance coating thickness and uniformity.

4. What are some common challenges in optimizing motion profiles?

Common challenges include variability in coating materials, environmental factors like temperature and humidity, and equipment limitations.

5. How can manufacturers improve their reciprocator motion profiles?

Manufacturers can improve their motion profiles by analyzing coating requirements, utilizing advanced control systems, conducting regular maintenance, implementing testing protocols, and training operators.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.