Content Menu

● Introduction

● What Influences Powder Coating Equipment Cost?

>> H2: Major Components Affecting Equipment Cost

● H2: Types of Powder Coating Equipment and Their Costs

>> H3: Small-Scale vs. Industrial Systems

>> H3: Recovery vs. Non-Recovery Powder Coating Booths

● H2: Cost Breakdown for Starting a Powder Coating Business

● H2: Tips to Optimize Powder Coating Equipment Cost

>> H3: Choosing the Right Equipment

>> H3: OEM and Custom Solutions

>> H3: Energy Efficiency and Automation

● H2: The Role of OEM Manufacturers in Powder Coating Equipment Cost

● Frequently Asked Questions (FAQs)

Introduction

In the competitive world of powder coating, understanding the powder coating equipment cost is crucial for manufacturers, OEM suppliers, and brand owners aiming to optimize production and quality while controlling expenses. This article explores the various factors influencing powder coating equipment costs, types of equipment, and tips for cost-effective procurement and operation. Whether you are a powder coating equipment manufacturer or a brand looking for OEM services, this guide provides detailed insights to help you make informed decisions.

What Influences Powder Coating Equipment Cost?

H2: Major Components Affecting Equipment Cost

The total powder coating equipment cost depends on several key components:

- Powder Coating Booths: These booths filter powder during application to ensure safety and compliance. Booth prices vary by size and type, with non-recovery booths generally costing around $8,500 to $9,000 for an 8x10 size[4].

- Powder Coating Ovens: Ovens are typically the most expensive part of the setup. Batch convection ovens suitable for a variety of products cost about $30,000, while infrared ovens may be faster but more costly[4].

- Powder Coating Guns and Delivery Systems: A quality powder coating gun system, such as the Wagner Sprint unit, costs approximately $4,250 and is essential for effective powder application[4].

- Compressed Air Systems: Compressed air is vital for spraying and sandblasting. A suitable compressor can cost upwards of $25,000 depending on capacity requirements[4].

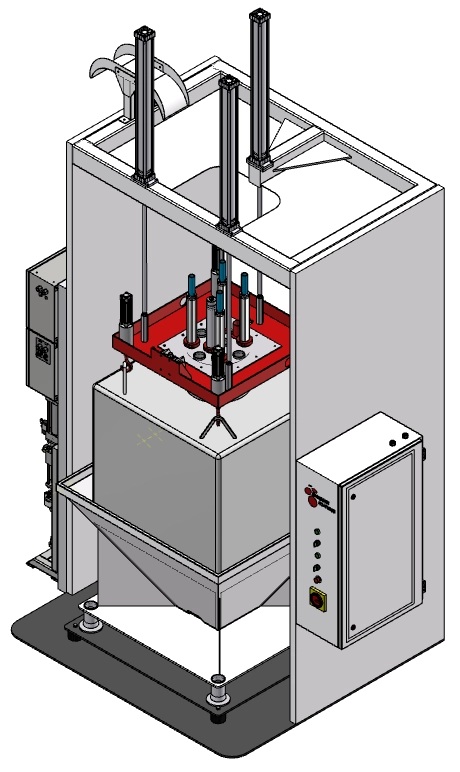

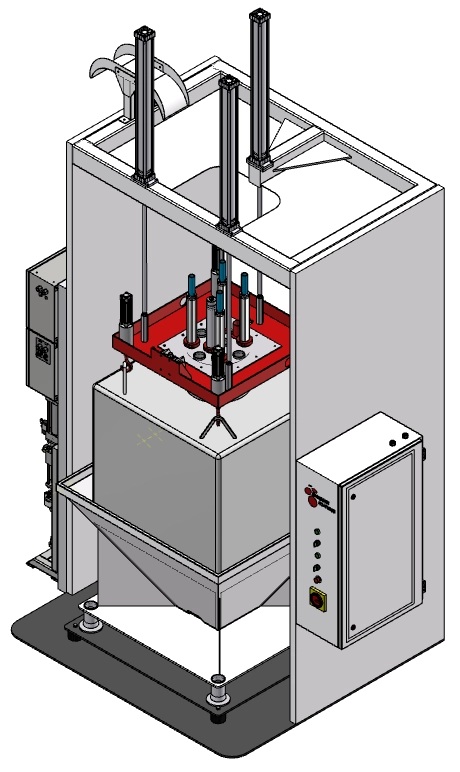

- Automation and Conveyor Systems: For industrial-scale operations, automated coating lines with conveyors can significantly increase costs, ranging from $200,000 to over $2 million installed, depending on size and complexity[5].

H2: Types of Powder Coating Equipment and Their Costs

H3: Small-Scale vs. Industrial Systems

- Small-Scale Equipment: Ideal for startups or smaller batch production, costs can be kept lower by choosing non-recovery booths and smaller ovens. A basic setup might range from $20,000 to $50,000, including booth, oven, gun, and compressor[4][7].

- Industrial-Scale Systems: Larger operations require automated lines, bigger ovens, and advanced recovery booths. These systems can cost from $200,000 to several million dollars, depending on throughput and automation level[5].

H3: Recovery vs. Non-Recovery Powder Coating Booths

- Non-Recovery Booths: More economical, costing around $8,500 to $9,000, but they do not reclaim overspray powder[4].

- Recovery Booths: More expensive but reduce powder waste and improve efficiency, suitable for high-volume production.

H2: Cost Breakdown for Starting a Powder Coating Business

Starting a powder coating business involves several cost factors beyond equipment:

- Facility Preparation: Building or modifying space to accommodate ovens, booths, and compressed air systems.

- Utilities and Installation: Electrical, ventilation, and compressed air connections add to initial costs[5].

- Consumables and Maintenance: Powder materials, gun parts, filters, and regular maintenance must be budgeted.

- Labor and Training: Skilled operators are needed to ensure quality and efficient use of equipment.

H2: Tips to Optimize Powder Coating Equipment Cost

H3: Choosing the Right Equipment

- Assess production volume and product size to select appropriately sized booths and ovens.

- Consider starting with batch ovens and non-recovery booths for cost savings if volume is moderate.

H3: OEM and Custom Solutions

- Partnering with experienced OEM manufacturers, especially those offering customized equipment, can optimize cost-performance balance.

- Chinese manufacturers often provide OEM services with competitive pricing and customization options, ideal for brands and wholesalers seeking tailored solutions[11].

H3: Energy Efficiency and Automation

- Investing in energy-efficient ovens and automated powder recovery systems can reduce long-term operational costs.

- Automation increases upfront cost but improves throughput and consistency.

H2: The Role of OEM Manufacturers in Powder Coating Equipment Cost

OEM manufacturers specializing in powder coating equipment play a pivotal role in controlling costs while delivering quality. They provide:

- Design and Customization: Tailoring equipment to specific product and process requirements.

- Bulk Production and Wholesale Pricing: Reducing unit costs for brand owners and distributors.

- After-Sales Support and Upgrades: Ensuring longevity and adaptability of equipment.

As a Chinese powder coating equipment OEM supplier, offering comprehensive manufacturing, design, and processing services helps international brand owners and wholesalers reduce costs and improve production efficiency[11].

Frequently Asked Questions (FAQs)

1. What is the average powder coating equipment cost for a startup?

The average cost ranges from $20,000 to $50,000 for a basic setup including booth, oven, gun, and compressor[4][7].

2. How much does an industrial powder coating system cost?

Industrial systems typically cost between $200,000 and $2 million installed, depending on automation and size[5].

3. What is the most expensive component in powder coating equipment?

The powder coating oven is generally the most expensive, costing around $30,000 or more for batch convection ovens[4].

4. Are recovery booths worth the extra cost?

Yes, recovery booths reduce powder waste and improve efficiency, which can save money in high-volume operations[4].

5. Can OEM manufacturers help reduce powder coating equipment costs?

Yes, OEM manufacturers can provide customized, cost-effective solutions and bulk pricing for brand owners and wholesalers[11].

[1] https://qualitypowdercoatingsandiego.com/powder-coat-pricing/

[2] https://powdercoatingproducts.com/products/powder-coating-equipment-start-up-package

[3] https://www.eptexcoatings.com/powder_coating_packages/

[4] https://pittsburghsprayequip.com/blogs/pittsburgh-spray-equipment-company/much-costs-start-powder-coating-guide

[5] https://reliantfinishingsystems.com/how-much-does-an-industrial-sized-powder-coating-system-cost/

[6] http://www.sse.com.cn/disclosure/listedinfo/announcement/c/new/2025-04-29/688128_20250429_IZYA.pdf

[7] https://www.reddit.com/r/Powdercoating/comments/8ylj8n/how_much_to_a_start_a_powder_coating_business_and/

[8] https://www.dlhitech.gov.cn/resources/news/newsConstantImages/20200825172656759.pdf

[9] http://www.vietchina.org/hyml/3041.html

[10] https://pdf.dfcfw.com/pdf/H3_AP202405061632470726_1.pdf

[11] work.powder_coating_equipment

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.