Content Menu

● Understanding Data Management Systems in Powder Coating

● Key Benefits of Integrating a Data Management System

>> 1. Enhanced Production Efficiency

>>> Real-time Process Visibility

>>> Automated Scheduling and Resource Optimization

>> 2. Improved Inventory and Material Management

>>> Accurate Inventory Tracking

>>> Waste Reduction and Cost Control

>> 3. Superior Quality Control and Compliance

>>> Consistent Quality Monitoring

>>> Traceability and Audit Readiness

>> 4. Streamlined Reporting and Analytics

>>> Automated Reporting

>>> Data-Driven Decision Making

>> 5. Enhanced Customer Service and Communication

>>> Faster and More Accurate Quotes

>>> Improved Order Tracking and Documentation

● How Data Management Systems Work in Powder Coating Lines

>> Integration with Production Equipment

>> Cloud-Based Platforms for Accessibility

● Case Study: Benefits Realized in a Powder Coating Plant

● Best Practices for Implementing a Data Management System

● Frequently Asked Questions (FAQs)

In today's competitive manufacturing environment, powder coating operations face increasing pressure to improve efficiency, quality, and traceability while controlling costs and reducing waste. Integrating a robust data management system into your powder coating line is no longer a luxury but a necessity to stay ahead. This article explores the top benefits of implementing such a system, highlighting how it transforms operations, enhances decision-making, and drives profitability.

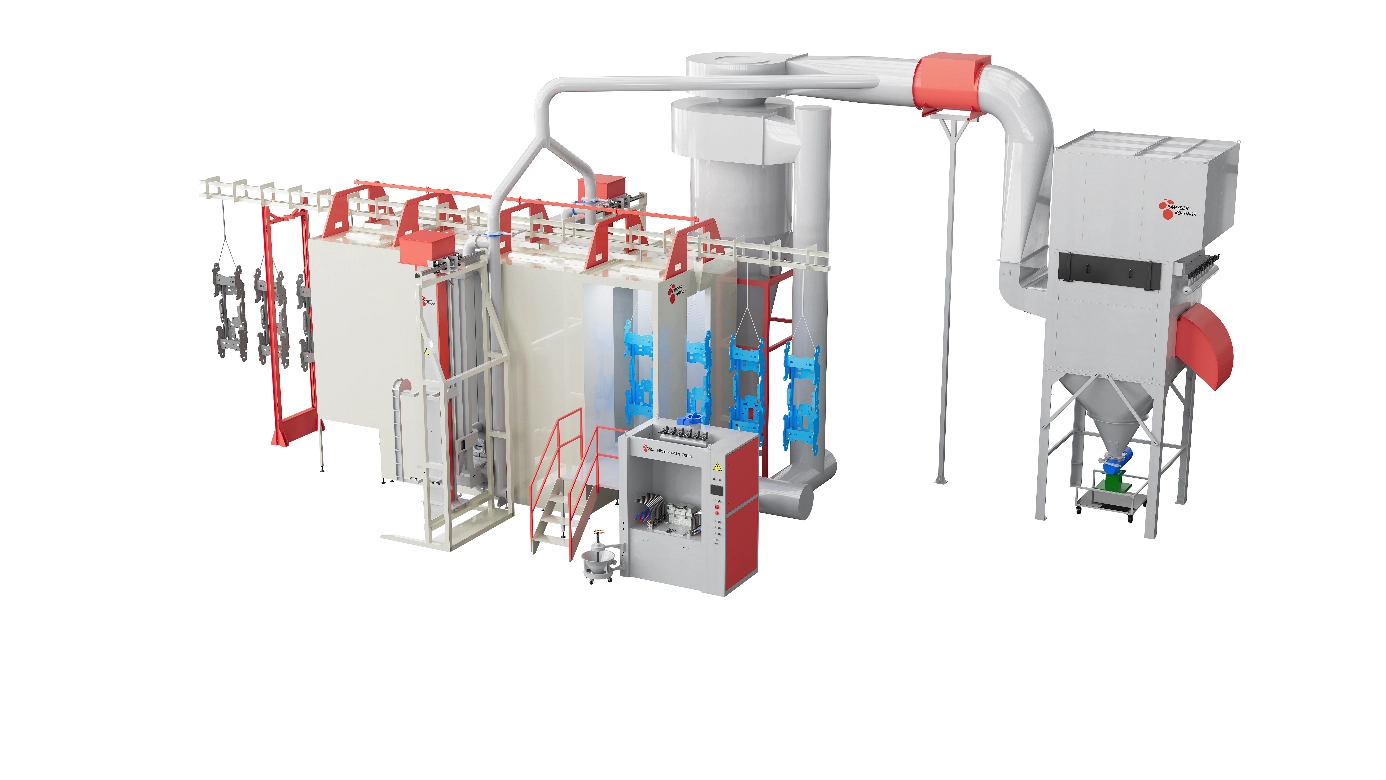

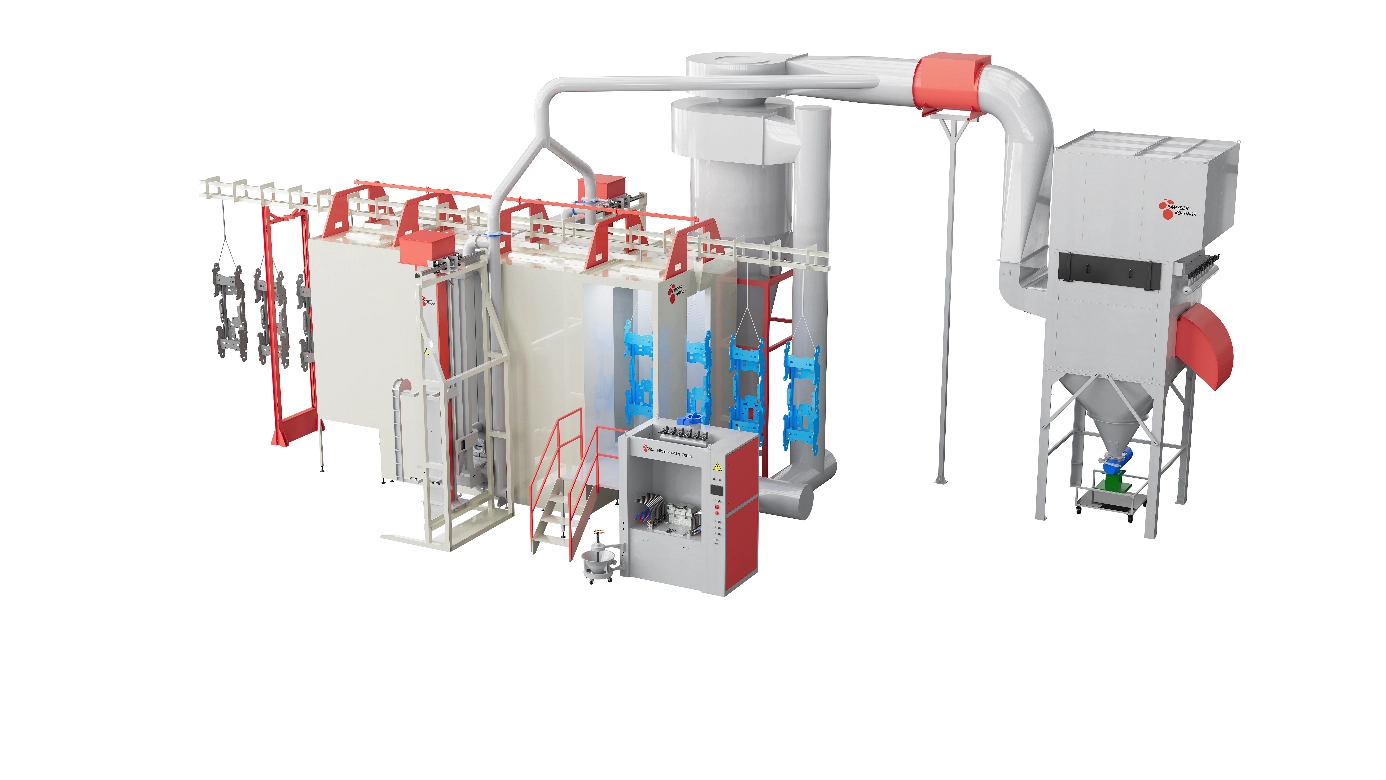

Understanding Data Management Systems in Powder Coating

A data management system in powder coating refers to software and digital tools designed to collect, organize, analyze, and report data generated throughout the coating process. This includes inventory tracking, production scheduling, quality control, and customer order management. Modern systems often integrate with ERP (Enterprise Resource Planning), MES (Manufacturing Execution Systems), and SCADA (Supervisory Control and Data Acquisition) platforms to provide seamless visibility and control.

Key Benefits of Integrating a Data Management System

1. Enhanced Production Efficiency

Real-time Process Visibility

A data management system provides real-time tracking of every stage in the powder coating process—from pre-treatment to curing. Managers can monitor job progress, machine performance, and material usage instantly, enabling quick identification and resolution of bottlenecks or delays. This visibility ensures smoother workflows and reduces downtime.

Automated Scheduling and Resource Optimization

With integrated scheduling tools, manufacturers can create dynamic production plans that consider order priorities, machine availability, and workforce capacity. Automated scheduling reduces manual errors and overloading, ensuring jobs are completed on time and resources are optimally utilized.

2. Improved Inventory and Material Management

Accurate Inventory Tracking

Inventory management is critical in powder coating, where raw materials like powders and chemicals must be carefully controlled. A data management system maintains a live, cloud-based inventory that updates in real time as materials are used or replenished. This prevents stockouts and overstocking, reducing carrying costs.

Waste Reduction and Cost Control

By tracking powder usage per job and monitoring chemical consumption, the system helps identify inefficiencies and prevent over-application. This leads to significant waste reduction, lowering material costs and minimizing environmental impact.

3. Superior Quality Control and Compliance

Consistent Quality Monitoring

Data management systems automate quality control by capturing inspection data at every stage, ensuring adherence to standards and specifications. This reduces human error and helps maintain consistent finish quality.

Traceability and Audit Readiness

All process data, including batch records, inspection results, and operator actions, are logged and easily retrievable. This comprehensive traceability simplifies compliance with industry regulations and customer audits, enhancing credibility and customer trust.

4. Streamlined Reporting and Analytics

Automated Reporting

Generating production, inventory, and profitability reports becomes effortless with a data management system. Reports are produced automatically based on live data, eliminating time-consuming manual compilation.

Data-Driven Decision Making

Advanced analytics provide insights into operational trends, cost drivers, and quality issues. Manufacturers can leverage this information to optimize processes, adjust pricing strategies, and implement continuous improvements.

5. Enhanced Customer Service and Communication

Faster and More Accurate Quotes

Integrated systems link inventory and production data to quoting tools, enabling rapid and accurate price estimates based on current material costs and capacity.

Improved Order Tracking and Documentation

Customers can receive timely updates, invoices, and shipping documents generated directly from the system, improving transparency and satisfaction.

How Data Management Systems Work in Powder Coating Lines

Integration with Production Equipment

Modern powder coating lines often include automated application robots, machine vision systems for defect detection, and parameter control software managing temperature and voltage. Data management systems integrate with these technologies to collect and analyze operational data continuously.

Cloud-Based Platforms for Accessibility

Cloud integration allows stakeholders to access dashboards and reports from anywhere, facilitating remote monitoring and collaboration across departments.

Case Study: Benefits Realized in a Powder Coating Plant

A powder coating manufacturer implemented an ERP-integrated data management system tailored for surface finishing. The results included:

- 30% reduction in material waste through precise powder tracking and automated reordering.

- Improved on-time delivery rates by optimizing scheduling based on real-time production data.

- Enhanced product quality via automated inspection data capture and analysis.

- Reduced administrative workload with automated reporting and customer communication.

- Better inventory turnover by maintaining optimal stock levels and minimizing excess.

Best Practices for Implementing a Data Management System

- Assess Your Needs: Identify pain points in your current process and define clear goals for the system.

- Choose Industry-Specific Software: Select solutions designed for powder coating or surface finishing to benefit from tailored features.

- Train Your Team: Ensure operators and managers understand how to use the system effectively.

- Integrate Gradually: Start with critical modules like inventory and scheduling before expanding to full production and quality control.

- Leverage Analytics: Use data insights to continuously refine your process and reduce costs.

Frequently Asked Questions (FAQs)

Q1: How does a data management system reduce powder waste?

A1: By tracking powder usage per job and monitoring chemical consumption, the system identifies over-application and inefficiencies, enabling adjustments that minimize waste.

Q2: Can a data management system improve scheduling accuracy?

A2: Yes, it automates scheduling by considering real-time production capacity, machine availability, and order priorities, ensuring efficient job sequencing.

Q3: Is it difficult to integrate data management software with existing equipment?

A3: Most modern systems are designed for integration with common powder coating line equipment and can be customized to fit existing workflows.

Q4: How does the system help with quality control?

A4: It automates data capture during inspections, tracks compliance with standards, and maintains detailed records for traceability and audits.

Q5: What kind of reports can the system generate?

A5: Reports on inventory levels, production efficiency, material usage, profitability, and quality metrics can be generated automatically and customized as needed.

[1] https://gosteelhead.com/powder-coating-software

[2] https://docs.dhis2.org/zh/full/use/user-guides/dhis-core-version-master/dhis2-user-manual.html

[3] https://proplate.pro/how-powder-coating-manufacturers-can-boost-erp-efficiency/

[4] https://patents.google.com/patent/CN107526766A/zh

[5] https://inspenet.com/en/articulo/batch-powder-coating-system-fundamentals/

[6] https://patents.google.com/patent/CN111566648B/zh

[7] https://www.ramseierkoatings.com/what-makes-a-good-data-management-system-in-powder-coating-applications.html

[8] https://developer.mozilla.org/zh-CN/docs/MDN/Writing_guidelines/Writing_style_guide

[9] https://finishingandcoating.com/index.php/powder-coat/2307-the-next-decade-how-ai-and-robotics-will-transform-the-powder-coating-industry

[10] https://d1.awsstatic.com/whitepapers/awsdeloitte-data-driven-whitepaper.pdf

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.