Content Menu

● Understanding Powder Hoppers

>> What is a Powder Hopper?

>> Importance of Powder Hoppers in Coating Systems

● The Evolution of Powder Hoppers

>> Historical Context

>> Technological Advancements

● Smart Coating Systems: A New Paradigm

>> What are Smart Coating Systems?

>> Benefits of Smart Coating Systems

● The Future of Powder Hoppers

>> Innovations on the Horizon

>> Challenges Ahead

● Case Studies: Successful Implementations

>> Automotive Industry

>> Industrial Applications

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using smart powder hoppers?

>> 2. How do smart powder hoppers contribute to sustainability?

>> 3. What challenges do manufacturers face when implementing smart powder hoppers?

>> 4. In which industries are smart powder hoppers most commonly used?

>> 5. What future innovations can we expect in powder hopper technology?

The powder coating industry is undergoing a significant transformation, driven by advancements in technology and automation. At the heart of this evolution are powder hoppers, which play a crucial role in the efficiency and effectiveness of smart coating systems. This article explores the future of powder hoppers, their integration into smart coating systems, and the implications for manufacturers and end-users alike.

Understanding Powder Hoppers

What is a Powder Hopper?

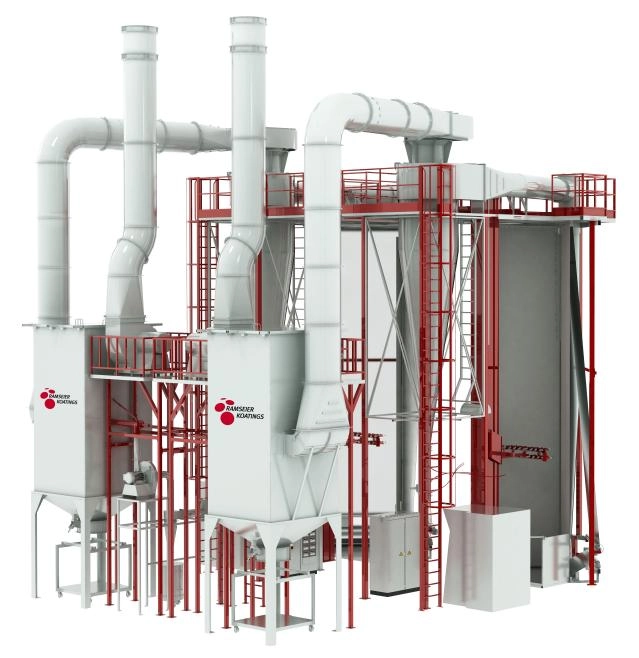

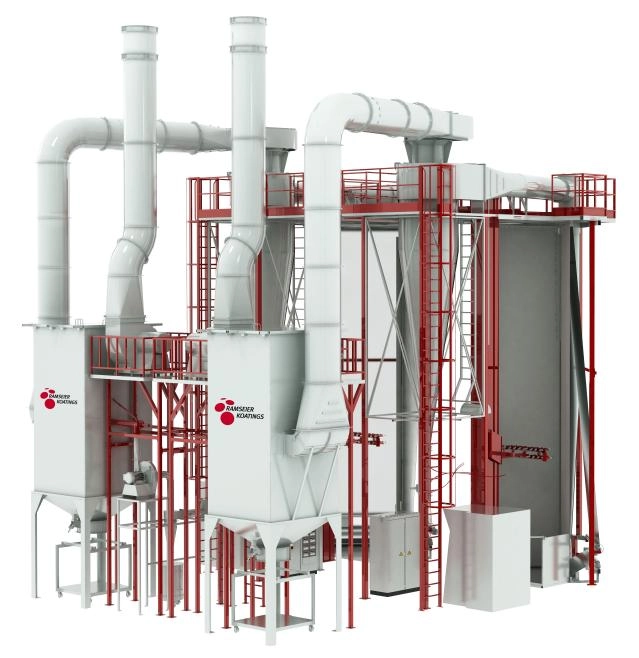

A powder hopper is a storage and dispensing unit designed to hold powder coating materials. It ensures a consistent and controlled flow of powder to the application equipment, such as spray guns. The design and functionality of powder hoppers are critical for achieving high-quality finishes in various applications, from automotive to industrial coatings.

Importance of Powder Hoppers in Coating Systems

Powder hoppers are essential for maintaining the efficiency of powder coating processes. They help minimize waste, ensure uniform application, and enhance the overall quality of the coating. As manufacturers strive for greater efficiency and sustainability, the role of powder hoppers becomes even more significant.

The Evolution of Powder Hoppers

Historical Context

Traditionally, powder hoppers were simple containers that relied on gravity to dispense powder. However, as the demand for precision and efficiency increased, manufacturers began to innovate. Modern powder hoppers are equipped with advanced features such as vibration systems, automated controls, and real-time monitoring capabilities.

Technological Advancements

Recent advancements in technology have led to the development of smart powder hoppers. These hoppers are integrated with sensors and IoT (Internet of Things) technology, allowing for real-time data collection and analysis. This integration enables manufacturers to monitor powder levels, flow rates, and application consistency, leading to improved operational efficiency.

Smart Coating Systems: A New Paradigm

What are Smart Coating Systems?

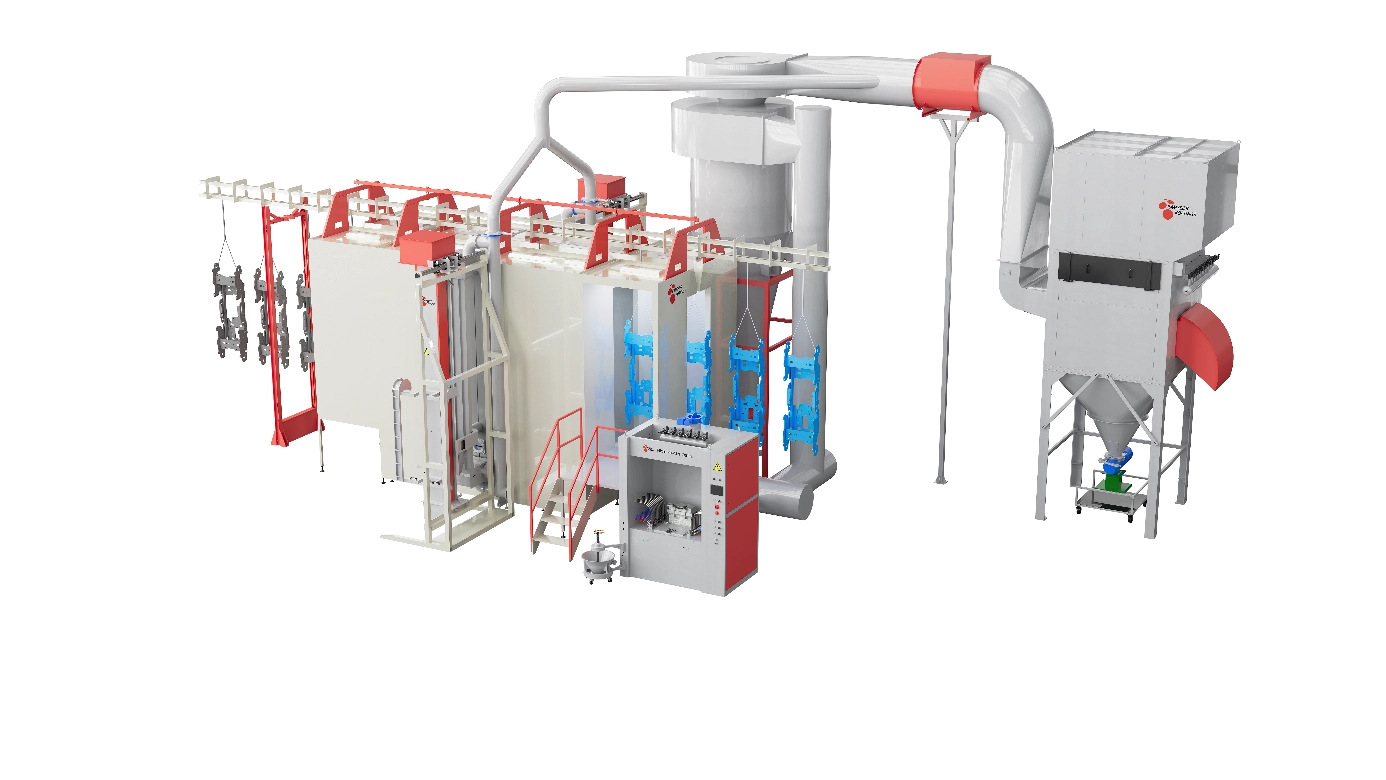

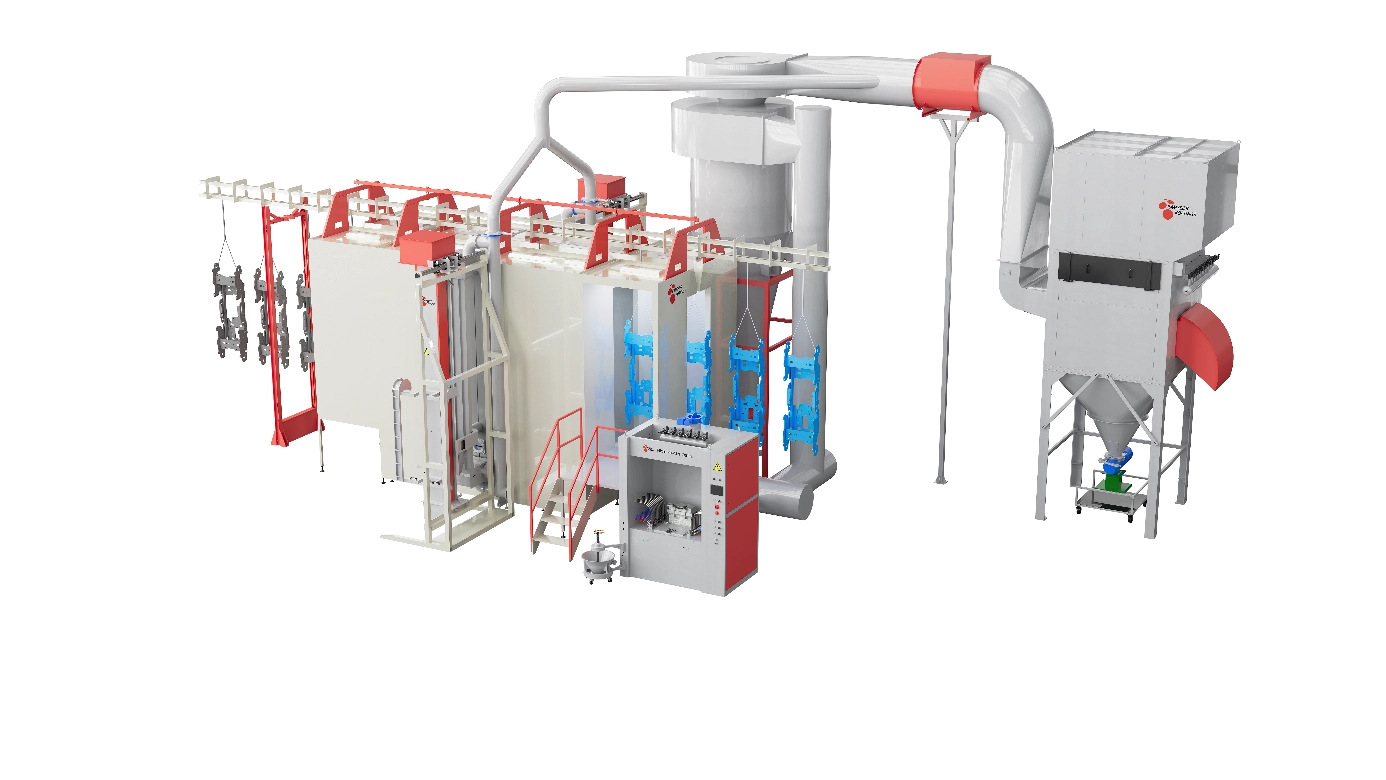

Smart coating systems utilize advanced technologies to enhance the powder coating process. These systems incorporate automation, data analytics, and connectivity to optimize performance and reduce waste. The integration of smart powder hoppers is a key component of these systems, enabling precise control over powder delivery.

Benefits of Smart Coating Systems

1. Increased Efficiency: Smart coating systems streamline operations, reducing downtime and increasing throughput.

2. Enhanced Quality: With precise control over powder application, manufacturers can achieve consistent and high-quality finishes.

3. Reduced Waste: By optimizing powder usage, smart systems minimize material waste, contributing to sustainability efforts.

4. Real-Time Monitoring: Continuous data collection allows for immediate adjustments, ensuring optimal performance.

The Future of Powder Hoppers

Innovations on the Horizon

The future of powder hoppers is bright, with several innovations expected to shape their development:

1. Advanced Materials: The use of lightweight and durable materials will enhance the design and functionality of powder hoppers.

2. AI Integration: Artificial intelligence will play a significant role in optimizing powder delivery and application processes, allowing for predictive maintenance and improved performance.

3. Sustainability Features: As environmental concerns grow, powder hoppers will increasingly incorporate features that reduce energy consumption and material waste.

Challenges Ahead

Despite the promising future, several challenges remain:

1. Cost of Implementation: The initial investment in smart technology can be high, which may deter some manufacturers from upgrading their systems.

2. Training and Adaptation: Employees will need training to effectively use new technologies, which can be a barrier to adoption.

3. Integration with Existing Systems: Ensuring compatibility with legacy systems can pose technical challenges.

Case Studies: Successful Implementations

Automotive Industry

In the automotive sector, manufacturers have successfully integrated smart powder hoppers into their coating lines. By utilizing real-time data analytics, they have improved powder application consistency and reduced waste, leading to significant cost savings.

Industrial Applications

Industrial manufacturers are also reaping the benefits of smart powder hoppers. By automating the powder delivery process, they have enhanced operational efficiency and reduced the risk of human error, resulting in higher quality finishes.

Conclusion

The future of powder hoppers in smart coating systems is poised for significant advancements. As technology continues to evolve, manufacturers will benefit from increased efficiency, enhanced quality, and reduced waste. By embracing these innovations, the powder coating industry can meet the growing demands for sustainability and performance.

Frequently Asked Questions

1. What are the main advantages of using smart powder hoppers?

Smart powder hoppers offer increased efficiency, enhanced quality, reduced waste, and real-time monitoring capabilities, leading to improved operational performance.

2. How do smart powder hoppers contribute to sustainability?

By optimizing powder usage and minimizing waste, smart powder hoppers help manufacturers reduce their environmental impact and promote sustainable practices.

3. What challenges do manufacturers face when implementing smart powder hoppers?

Manufacturers may encounter challenges such as high implementation costs, the need for employee training, and integration issues with existing systems.

4. In which industries are smart powder hoppers most commonly used?

Smart powder hoppers are commonly used in the automotive, industrial, and consumer goods sectors, where precision and efficiency are critical.

5. What future innovations can we expect in powder hopper technology?

Future innovations may include advanced materials, AI integration for predictive maintenance, and features designed to enhance sustainability and energy efficiency.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.