Content Menu

● Understanding Powder Coating Systems

>> What Is Powder Coating?

>> Traditional Powder Coating Systems

>> Swinger Powder Coating Systems

● Key Differences Between Swinger and Traditional Systems

● Advantages of Swinger Powder Coating Systems

>> Enhanced Coating Uniformity and Quality

>> Increased Efficiency and Productivity

>> Powder Recycling and Environmental Benefits

>> Consistent Performance in High-Demand Environments

● Benefits of Traditional Powder Coating Systems

>> Cost-Effectiveness for Small-Scale Operations

>> Simplicity and Ease of Use

>> Versatility Across Varying Production Volumes

● Performance Comparison: Swinger vs Traditional Powder Coating

>> Durability and Finish Quality

>> Impact on Production Workflow

>> Environmental Considerations

● Which System Fits Your Needs?

>> For High-Volume Manufacturing:

>> For Custom or Small Batch Jobs:

>> For Complex-Shaped Parts:

>> Budget and Space Constraints:

>> Environmental and Sustainability Goals:

● Frequently Asked Questions (FAQ)

When it comes to achieving superior surface finishes in manufacturing, automotive, aerospace, or decorative industries, powder coating has long been favored for its durability and aesthetic appeal. However, within the realm of powder coating technologies, choosing the *right system* is crucial for ensuring efficiency, cost-effectiveness, and meeting specific production demands. Two systems to consider are the Swinger powder coating systems and Traditional powder coating systems. This article explores the distinctions, advantages, and ideal applications of each, helping you decide which system best fits your operational needs.

Understanding Powder Coating Systems

What Is Powder Coating?

Powder coating is a finishing process that applies dry powder particles electrostatically onto a surface, which are then cured under heat to form a tough, protective layer. Unlike traditional wet paint, powder coatings produce a thicker, more uniform, and durable finish without runs or drips.

Traditional Powder Coating Systems

Traditional powder coating systems typically involve manual or semi-automatic spray guns applying powder to parts in a spray booth. These systems rely on electrostatic charges to attract powder to the grounded object. After application, coated items enter curing ovens where heat melts and fuses the powder into a continuous film.

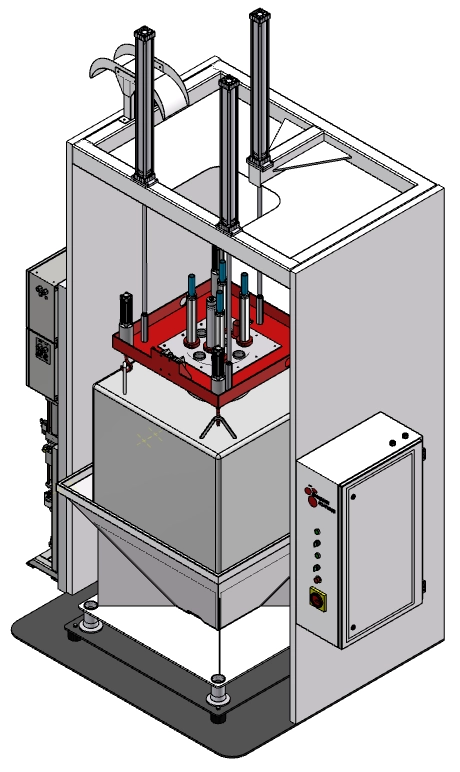

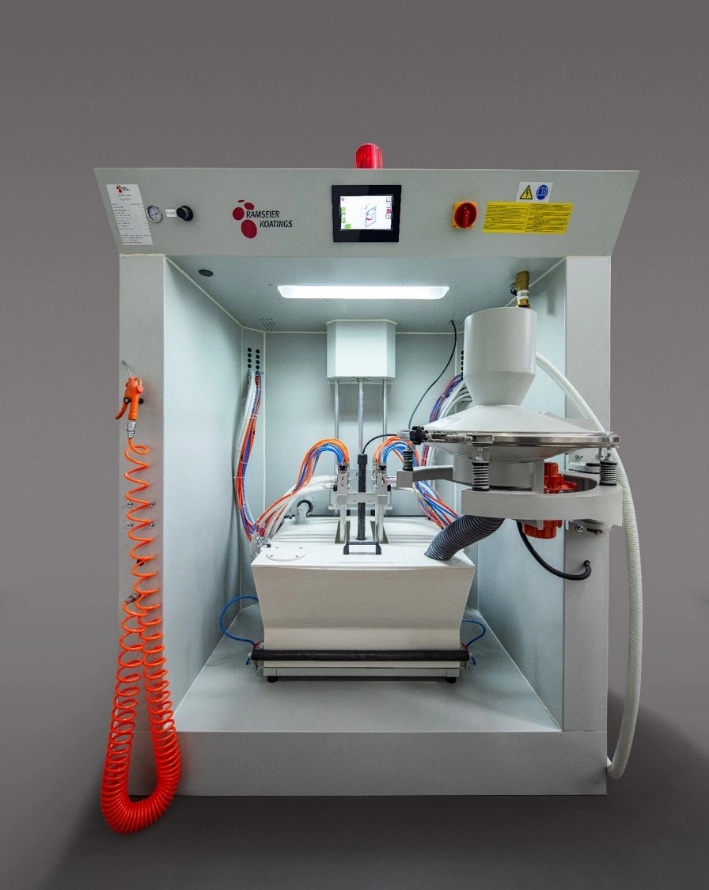

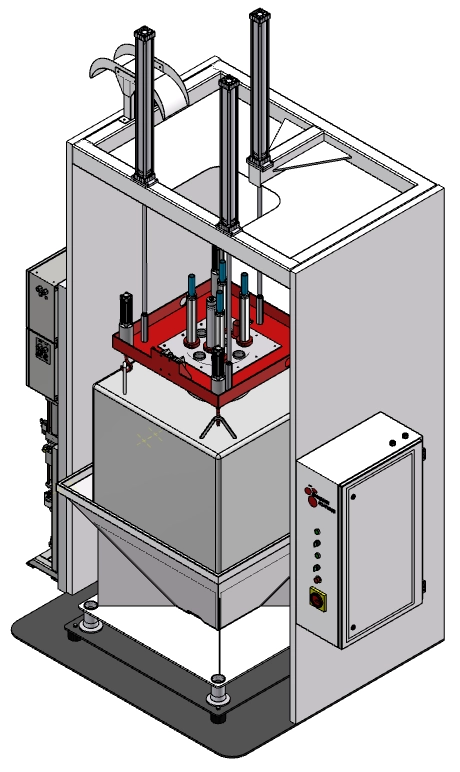

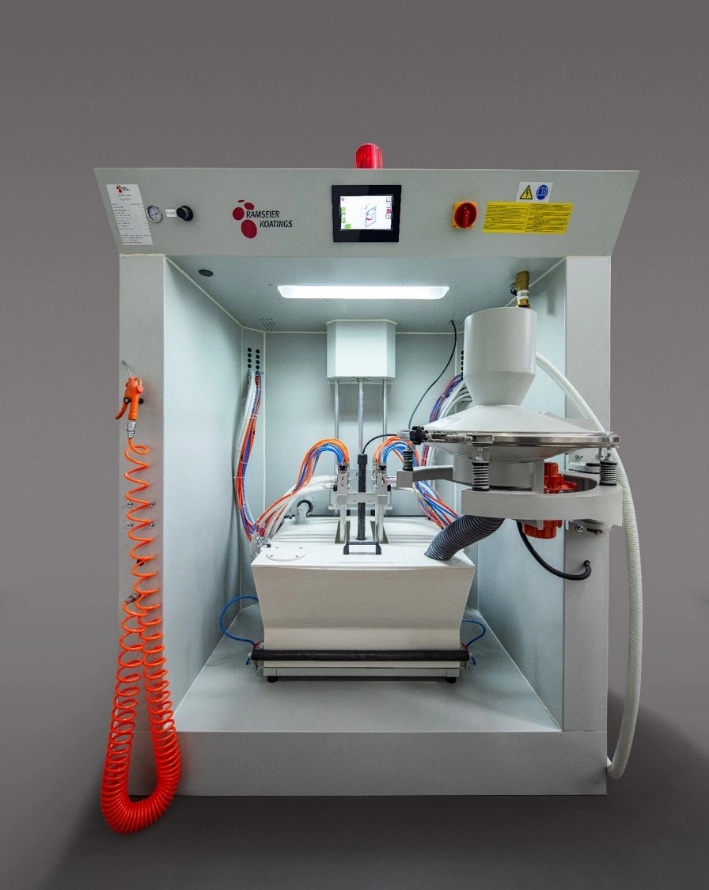

Swinger Powder Coating Systems

Swinger powder coating systems are an evolution in coating line technology. They usually feature automated or robotic arms that "swing" or oscillate to cover complex-shaped parts evenly and efficiently. This mechanism can improve coating consistency and throughput by reducing overspray and coating time. Swinger systems integrate powder delivery, precise control of spray parameters, and often incorporate reclamation technology for unused powder.

Key Differences Between Swinger and Traditional Systems

| Aspect | Swinger Powder Coating Systems | Traditional Powder Coating Systems |

| Application Method | Automated swinging robotic arms for uniform coverage | Manual or semi-automatic spray guns with operator control |

| Coating Consistency | High consistency especially on complex shapes | Variable, dependent on operator skill and part geometry |

| Throughput and Speed | Higher due to automation and multi-axis coverage | Moderate; dependent on manual application speed |

| Powder Overspray | Reduced overspray through controlled application and recovery systems | Typically higher overspray, more powder wastage |

| Initial Investment | Generally higher due to advanced automation and robotics | Lower; suitable for small to medium operations |

| Maintenance | Advanced systems require specialized maintenance | Simpler system maintenance, easier troubleshooting |

Advantages of Swinger Powder Coating Systems

Enhanced Coating Uniformity and Quality

The swinging robotic arms can reach hard-to-access areas on intricate parts, ensuring an even layer of powder is applied. This uniformity reduces defects like thin spots or excessive buildup, improving the overall finish quality.

Increased Efficiency and Productivity

Automation accelerates the coating process by moving parts through with precise timing and reducing manual labor. Swinger systems often support continuous production lines, which is beneficial for high-volume manufacturing.

Powder Recycling and Environmental Benefits

Many swinger powder systems use enclosed spraying environments combined with powder recovery units. Reclaiming unused powder minimizes waste, lowers material costs, and reduces environmental impact compared to traditional open-spray booths.

Consistent Performance in High-Demand Environments

Because swinger technology provides repeatable, automated processes, it is preferred in industries where reliability and finish durability matter — for example, aerospace or automotive manufacturing with strict quality standards.

Benefits of Traditional Powder Coating Systems

Cost-Effectiveness for Small-Scale Operations

With lower initial capital expenditure, traditional systems are accessible for smaller shops or businesses new to powder coating. They offer flexibility to manually adjust application based on part size or customer requirements.

Simplicity and Ease of Use

Operators can quickly learn traditional techniques, and the systems have straightforward components that simplify maintenance. This makes traditional powder coating practical in settings without sophisticated automation expertise.

Versatility Across Varying Production Volumes

Traditional systems allow quick changes between different product types or coating colors without complex programming or setup, ideal for shops with diverse coating jobs or smaller batch sizes.

Performance Comparison: Swinger vs Traditional Powder Coating

Durability and Finish Quality

Both systems deliver the inherent advantages of powder coating—excellent chip resistance, corrosion protection, and a vibrant finish that lasts much longer than traditional paints. Swinger systems, however, enhance these qualities through superior application control and cure consistency.

Impact on Production Workflow

Swinger systems integrate well into automated production lines, reducing labor costs and increasing throughput. Traditional powder coating demands more manual involvement, which may slow production but allows flexibility in handling irregular or custom orders.

Environmental Considerations

Powder coating, in general, is more environmentally friendly than liquid paint due to low volatile organic compound (VOC) emissions. Swinger systems amplify this benefit by efficiently reclaiming unused powder, thus reducing waste and air pollution further.

Which System Fits Your Needs?

For High-Volume Manufacturing:

If your operation handles large quantities requiring consistent, high-quality finishes with minimal labor input, swinger powder coating systems provide an excellent return on investment through automation and efficiency.

For Custom or Small Batch Jobs:

Shops processing a variety of parts or smaller production runs might lean toward traditional powder coating systems, which offer operational flexibility and lower upfront costs.

For Complex-Shaped Parts:

Swinger systems, with their robotic arms, excel at coating items with intricate geometries uniformly, something traditional spray guns might struggle to achieve consistently.

Budget and Space Constraints:

Traditional powder coating equipment often requires less initial investment and may fit better in limited spaces.

Environmental and Sustainability Goals:

If minimal environmental impact is a priority, swinger systems' superior powder recycling capabilities make them the preferred choice.

Frequently Asked Questions (FAQ)

Q1: What is the main advantage of swinger powder coating systems over traditional ones?

A1: Swinger systems provide automated, uniform coating with less overspray and higher efficiency, reducing waste and labor costs.

Q2: Can traditional powder coating achieve the same durability as swinger systems?

A2: Yes, both use the same powder curing process, so durability is similar; however, swinger systems often deliver more uniform coverage.

Q3: Are swinger powder coating systems more expensive to maintain?

A3: They generally require more specialized maintenance due to their automation and robotics but offer long-term savings through efficiency.

Q4: Which system is better for small workshops?

A4: Traditional powder coating systems are often better suited for small-scale or custom jobs because of lower initial costs and versatility.

Q5: How does powder coating compare environmentally to traditional liquid paint?

A5: Powder coating produces negligible VOC emissions and enables powder reclamation, making it far more environmentally friendly.

[1] https://www.highlandmachine.com/powder-coating-versus-traditional-painting-which-is-better/

[2] https://ia800600.us.archive.org/5/items/ittushu-2470/%E6%B8%85%E5%8D%8E%E5%A4%A7%E5%AD%A6%E5%9B%BE%E4%B9%A6%E9%A6%86-%E6%88%98%E7%96%AB%E7%89%88/H_%E8%AF%AD%E8%A8%80%E3%80%81%E6%96%87%E5%AD%97/12133_%E5%9B%BD%E9%99%85%E4%BA%A4%E6%B5%81%E8%8B%B1%E8%AF%AD%E9%98%85%E8%AF%BB%E8%BF%9B%E9%98%B6%E6%95%99%E7%A8%8B_text.pdf

[3] https://www.valencesurfacetech.com/the-news/advantages-of-powder-coating-over-traditional-paint/

[4] https://www.scribd.com/document/648139562/%E9%AB%98%E7%BA%A7%E8%8B%B1%E8%AF%AD1-%E7%AC%AC3%E7%89%88-%E5%AD%A6%E4%B9%A0%E6%8C%87%E5%8D%97

[5] https://www.yellowgate.com/blog/powder-coating-vs-traditional-paint-powder-coating-best-choice

[6] https://studylib.net/doc/25825671/%E6%96%87%E5%AD%97%E9%81%8A%E6%88%B2%E3%80%81%E8%AC%8E%E8%AA%9E%E5%92%8C%E9%82%8F%E8%BC%AF%E6%B8%AC%E8%A9%A6-%E5%BE%B5%E7%A8%85%E4%BD%A0%E7%9A%84%E5%A4%A7%E8%85%A6%EF%BC%8C%E6%8F%90%E9%AB%98%E4%BD%A0%E7%9A%84%E8%8B%B1%E8%AA%9E%E6%B0%B4%E6%BA%96%EF%BC%88pdfdrive%EF%BC%89-1-

[7] https://www.saferack.com/powder-coated-fall-protection/

[8] https://huggingface.co/openbmb/cpm-bee-1b/commit/bd72a61dd7a59086ed7456f1dfcaa995c8ec58a3.diff

[9] https://www.ramseierkoatings.com/manual-spray-booths-vs-powder-coating-systems-which-is-more-versatile.html

[10] https://huggingface.co/facebook/xm_transformer_unity_hk-en/commit/e37fd5ab9c6faf7a9547972cf6dace1c144c49c8.diff?file=en_zh_spm.dict

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.