Content Menu

● Understanding the role of a powder hopper system

● What makes an advanced system different from a standard one

● Financial considerations and return on investment

● Impact on safety and regulatory compliance

● Operational efficiency and throughput

● Integration with existing equipment and controls

● Potential challenges and how to mitigate them

● Selecting the right specifications for your operation

● Maintenance philosophy: proactive versus reactive

● Manufacturing philosophy and scalability

● Decision framework: should you upgrade?

● Implementation best practices

● FAQ

● Summary

Upgrade decisions in manufacturing lines often hinge on clarity about returns, downtime, and long-term costs. If your operation relies on precise powder handling—whether in food processing, pharmaceuticals, or chemical production—the choice to upgrade to an advanced powder hopper system deserves careful consideration. This article outlines the core advantages, potential pitfalls, and practical steps to evaluate whether this upgrade aligns with your goals.

Understanding the role of a powder hopper system

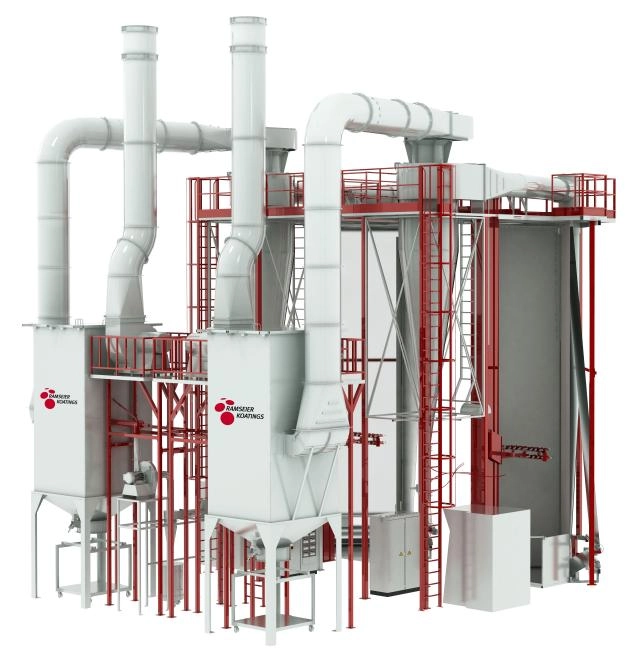

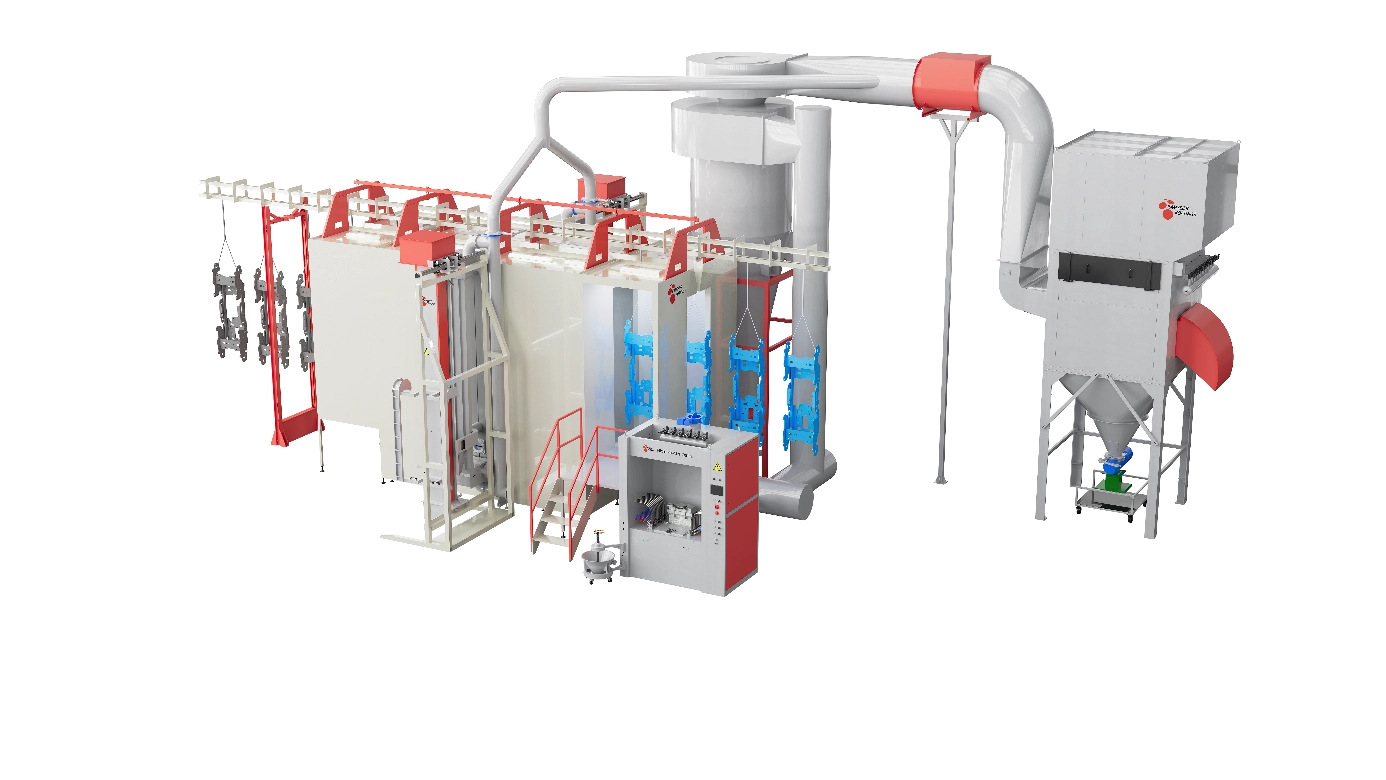

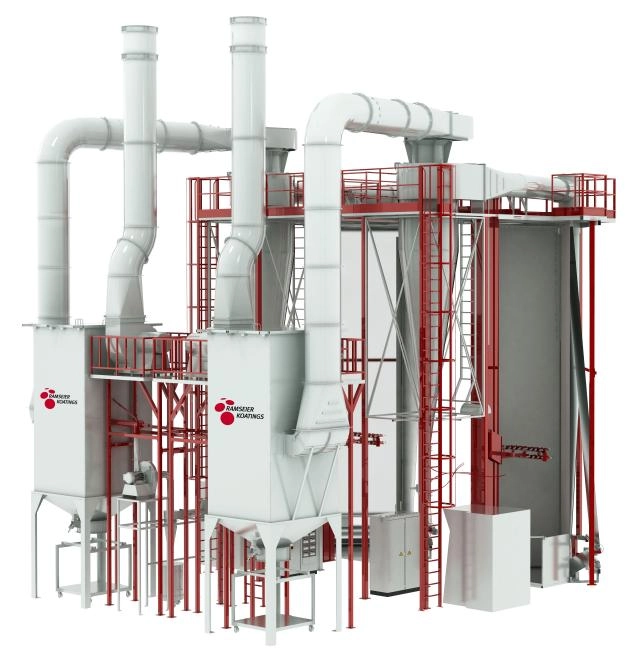

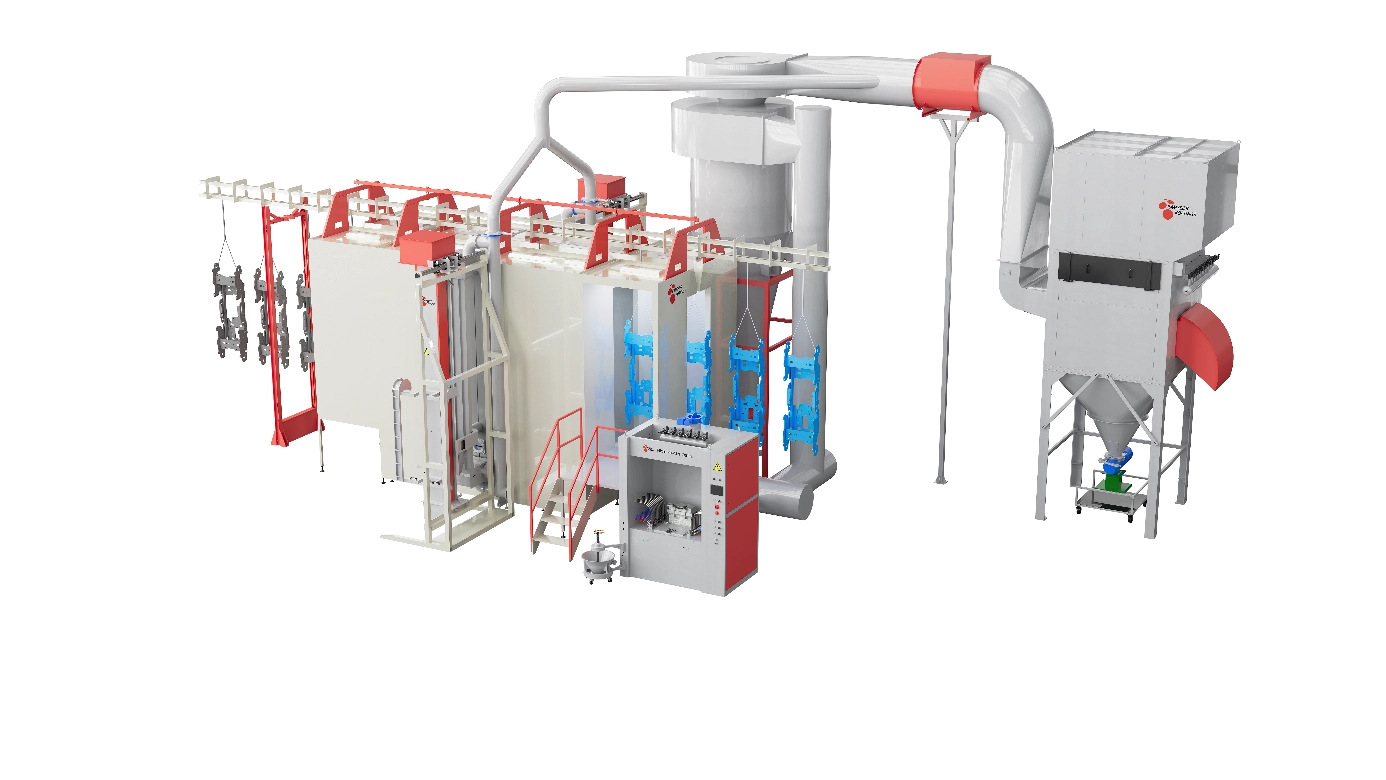

Powder hopper systems are the conduits through which bulk solids are stored, metered, and fed into downstream processes. An advanced system typically enhances accuracy, consistency, and cleanliness compared with traditional hoppers. Key features often include improved agitation or vibration control, automated level sensing, closed transfer paths, dust collection, and integration with supervisory control and data acquisition systems.

What makes an advanced system different from a standard one

An upgraded hopper system usually stands out in four areas: control sophistication, containment and dust management, cleanliness and ease of maintenance, and data-driven operability. Enhanced control algorithms regulate feed rate with fine granularity, while improved seals and closed piping reduce airborne particulates. Modular design and accessible components shorten maintenance cycles, and built-in sensors provide visibility into material behavior, enabling proactive adjustments.

Financial considerations and return on investment

Upfront cost is only part of the picture. When evaluating a potential upgrade, consider the total cost of ownership over the system's lifecycle. Savings opportunities often arise from reduced waste, longer drum or silo life, less downtime during changeovers, and lower housekeeping costs due to better containment. Quantifying these factors helps determine payback period and overall value.

Impact on safety and regulatory compliance

Better containment minimizes dust exposure, which is a critical safety and regulatory concern in many industries. An advanced hopper can lower the risk of cross-contamination and help maintain clean processing environments. Compliance benefits may also come from traceability features, such as integrated flow metering and data logging, which support quality assurance and audits.

Operational efficiency and throughput

A modern hopper system can stabilize feed consistency even with variable powder characteristics such as flowability and cohesiveness. This stability translates to fewer process disturbances, more reliable throughput, and smoother scaling when production volumes increase. Automated level control and interlocks further reduce operator intervention, enabling teams to focus on higher-value tasks.

Integration with existing equipment and controls

Before upgrading, map how the new hopper system will fit with your current line equipment and control architecture. Compatibility with PLCs, SCADA systems, and your current recipe management software is essential. If the upgrade introduces new communication protocols or requires firmware updates, plan for integration testing and staff training.

Potential challenges and how to mitigate them

Transitioning to an advanced system can introduce temporary disruption as operators acclimate to new controls and workflows. Common challenges include calibration of feeders, achieving the desired dust-tight performance, and ensuring the system remains accessible for maintenance. Mitigation strategies include phased implementation, comprehensive commissioning, and robust standard operating procedures.

Selecting the right specifications for your operation

To choose effectively, document the powder's properties, including particle size distribution, bulk density, moisture content, and flow behavior. Desired outcomes should cover accuracy, repeatability, dust control, cleaning time, and maintenance intervals. Use these inputs to guide specifications for hopper capacity, agitation method, lid design, material compatibility, and sensor types.

Maintenance philosophy: proactive versus reactive

An advanced system benefits from a maintenance plan that emphasizes proactive care. Regular calibration of sensors, inspection of seals, and routine dust collection efficiency checks help sustain performance. Establishing a schedule for part replacement and a clear escalation path for faults reduces unplanned downtime.

Manufacturing philosophy and scalability

If growth is on the horizon, consider how the hopper system will scale with demand. Features such as modular expansion, parallel feed lines, and compatible accessory options (e.g., inline weighing or batching modules) support future production plans. Evaluating scalability now avoids costly retrofits later.

Decision framework: should you upgrade?

- Assess current performance gaps: Are routine downtime, inconsistent feed rates, or excessive dust causing issues?

- Quantify benefits: What is the expected reduction in waste, downtime, or cleaning time?

- Check compatibility: Will the new system integrate with existing controls and recipes?

- Plan a staged implementation: Can you pilot the upgrade on a single line before full deployment?

- Budget realistically: Include installation, validation, training, and potential downtime during transition.

Implementation best practices

- Define clear success criteria and measurable targets for the upgrade.

- Conduct a thorough risk assessment covering safety, quality, and operational continuity.

- Develop comprehensive commissioning and validation protocols.

- Train operators and maintenance staff with hands-on sessions and written procedures.

- Establish a post-implementation review to capture lessons learned and refine settings.

FAQ

Q1: What indicators suggest an advanced hopper system would deliver value?

A: Persistent issues with inconsistent feed rates, high dust levels, frequent cleaning, and planned downtime due to material handling problems often indicate value from an upgrade.

Q2: How long does a typical upgrade project take?

A: Project duration varies with scope, but planning, installation, and commissioning can range from a few weeks to a few months for a full line integration.

Q3: Will the upgrade affect product quality or batch consistency?

A: Yes, improved feed accuracy and dust control typically enhance batch consistency and reduce variability in processed products.

Q4: How does an advanced system help with regulatory audits?

A: Enhanced data logging, traceability, and controlled material handling support compliance efforts and simplify audit reviews.

Q5: What maintenance practices maximize the system's life?

A: Regular sensor calibration, seal inspections, filter and dust collector maintenance, and scheduled part replacements align with sustained performance.

Q6: Can I retrofit an advanced hopper onto an existing line?

A: Retrofitting is possible in many cases, but it requires careful planning to ensure mechanical fit, control integration, and process compatibility.

Q7: What training resources should be planned?

A: Operator training on new controls, maintenance staff training on diagnostics, and updated standard operating procedures are essential.

Q8: How do I estimate the return on investment?

A: Compare baseline performance metrics with projected improvements in waste reduction, downtime savings, and labor efficiency to estimate payback.

Q9: Are there safety implications during the upgrade?

A: Yes, plan for lockout/tagout procedures, dust control during transition, and ensuring all safety interlocks function with the new equipment.

Q10: What role does data play in ongoing optimization?

A: Continuous data collection enables trend analysis, proactive maintenance, and recipe optimization over time.

Summary

Upgrading to an advanced powder hopper system can yield meaningful gains in control, safety, and efficiency, but it requires careful evaluation of powder properties, system compatibility, and long-term costs. A phased approach with clear success metrics, thorough commissioning, and ongoing training maximizes the chances of a successful, value-driven upgrade.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.