Content Menu

● Overview of Powder Hopper Function and Design

>> Basic Components of Powder Hoppers

>> Traditional Challenges with Powder Hoppers

● Key Innovations Driving 2025 Powder Hopper Technology

>> Smart Sensors and IoT Integration

>> Advanced Anti-Clogging Mechanisms

>> Hygienic and Contamination-Resistant Designs

>> Modular and Flexible Hopper Systems

>> Energy Efficiency and Sustainability Features

● Industry Applications Benefiting from 2025 Innovations

>> Food and Beverage Industry

>> Pharmaceutical Manufacturing

>> Chemical and Materials Industry

● Future Outlook and Emerging Trends in Powder Hoppers

>> AI-Driven Predictive Maintenance

>> Multifunctional Hybrid Hopper Systems

>> Biodegradable and Smart Material Use

● Frequently Asked Questions (FAQs)

Powder hoppers are essential components in a wide range of industries such as food processing, pharmaceuticals, chemicals, and manufacturing. Their role in facilitating the smooth transportation, dosing, and storage of powdered materials cannot be overstated. The year 2025 has brought about a wave of technological advancements and design innovations that are shaping the future of powder hopper technology. This article explores these new developments in detail, focusing on how they improve efficiency, reduce contamination, and support sustainability.

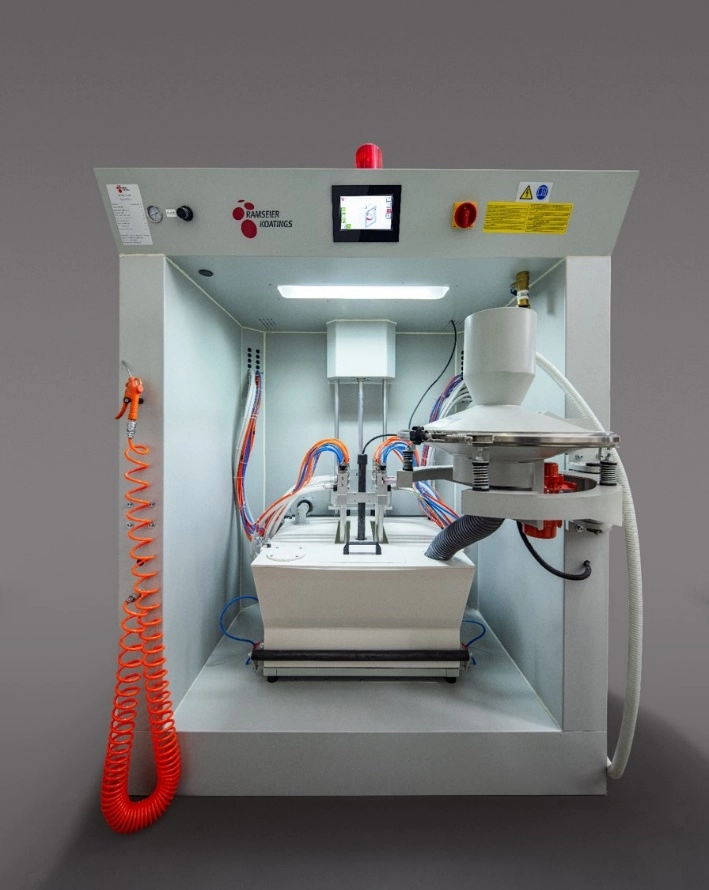

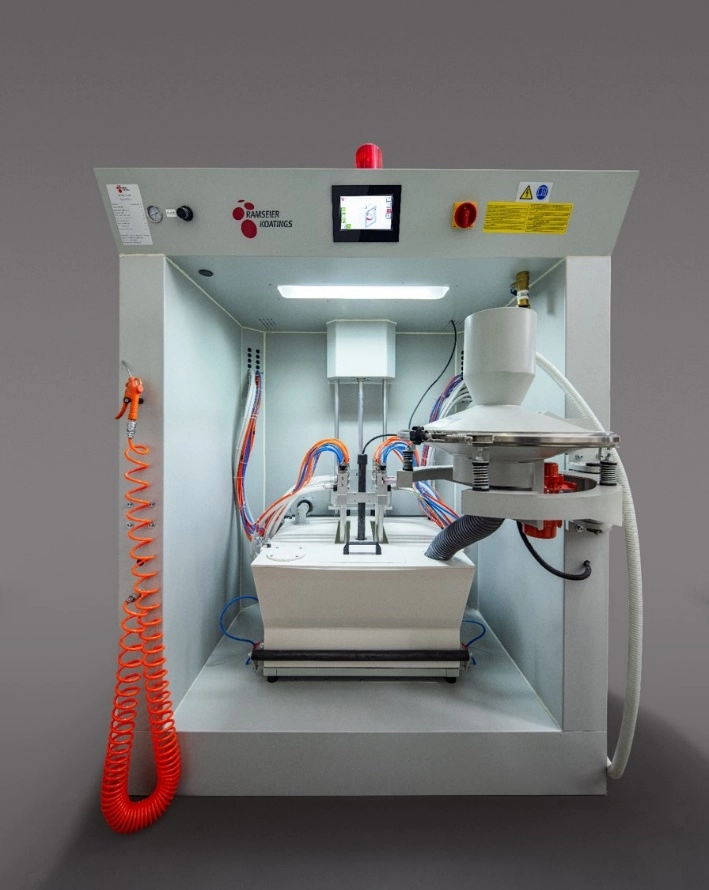

Overview of Powder Hopper Function and Design

Powder hoppers are designed to hold and control the flow of powdered or granular materials. Their design traditionally includes a funnel-shaped container that feeds powders to packaging machines, blenders, or conveyors. The innovations in 2025 have enhanced these core functions, making powder handling more precise and hygienic.

Basic Components of Powder Hoppers

- Storage Chamber: Holds the powder securely until it needs to be dispensed.

- Discharge Outlet: Controls the release rate of the powder.

- Feeding Mechanism: Moves powder through the hopper, often assisted by vibrators or screws.

- Sensors and Controls: Monitor powder levels and flow rate to maintain continuous production.

Traditional Challenges with Powder Hoppers

- Powder clogging and bridging

- Inconsistent flow rates affecting product quality

- Contamination risks

- Material wastage and cleanup difficulties

- Energy inefficiency in continuous operations

Key Innovations Driving 2025 Powder Hopper Technology

Many manufacturers have introduced breakthroughs using automation, materials science, and environmental consciousness to upgrade powder hoppers.

Smart Sensors and IoT Integration

One of the most significant innovations is the integration of Internet of Things (IoT) capabilities into powder hoppers. These sensors provide real-time data on powder levels, flow status, humidity, and temperature within the hopper.

- Automated alerts notify operators of blockages or low powder levels.

- Data analytics optimize batch consistency by adjusting flow rates dynamically.

- Wireless connectivity enables remote hopper monitoring and predictive maintenance.

Advanced Anti-Clogging Mechanisms

New anti-clogging solutions have been developed utilizing ultrasonic vibration systems and adaptive flow controls:

- Ultrasonic transducers emit vibrations that dislodge clumps without damaging powder quality.

- Variable frequency drives adjust vibration intensity based on powder properties.

- Improved internal hopper coatings reduce adhesion, minimizing bridging.

Hygienic and Contamination-Resistant Designs

Industry 4.0 standards have pushed for improved hygiene in powder handling. Powder hoppers now feature:

- Seamless stainless steel interiors that prevent powder residue traps.

- CIP (Clean-in-Place) systems integrated directly into hopper designs for automated sanitation.

- FDA-approved coatings resistant to microbial growth.

- Designs that minimize dead zones where powders can accumulate.

Modular and Flexible Hopper Systems

2025 has also seen the rise of modular powder hopper designs that can be reconfigured quickly to handle different powders or production lines.

- Quick-change hopper modules reduce downtime.

- Adjustable outlet sizes to customize flow for various powders.

- Lightweight, durable materials allow easy relocation.

Energy Efficiency and Sustainability Features

With global emphasis on environmental sustainability, new powder hoppers have been engineered to reduce energy consumption:

- Low-power vibrators and servo motors for feeding mechanisms.

- Integration of recyclable material options in hopper manufacturing.

- Optimized hopper shapes for minimal powder wastage.

- Systems designed to support closed-loop powder recycling within production.

Industry Applications Benefiting from 2025 Innovations

The advancements in powder hopper technology are impacting multiple sectors by enhancing precision, safety, and cost efficiencies.

Food and Beverage Industry

In food manufacturing, controlling powder flow is critical for product consistency and safety.

- Improved hopper designs reduce contamination by allergens or foreign materials.

- Real-time flow monitoring supports automated batching for powdered ingredients.

- Hygienic designs facilitate faster changeovers between product lines.

Pharmaceutical Manufacturing

Pharmaceutical powders require precise dosing and sterile handling.

- High-sensitivity sensors enable exact measurement for tablet and capsule production.

- Clean-in-place features prevent cross-contamination.

- Data logging supports regulatory compliance.

Chemical and Materials Industry

Handling abrasive or hazardous powders demands durable, adaptable hopper solutions.

- Coatings resistant to chemical wear extend hopper lifetime.

- Modular designs allow safe switching between different chemical powders.

- Enhanced flow control minimizes dust emissions.

Future Outlook and Emerging Trends in Powder Hoppers

As 2025 advances, several emerging trends are likely to influence powder hopper design and functionality further.

AI-Driven Predictive Maintenance

Artificial Intelligence (AI) algorithms will increasingly analyze hopper data to predict maintenance needs, reducing unplanned downtime and extending equipment life.

Multifunctional Hybrid Hopper Systems

Hybrid systems combining storage, weighing, mixing, and dispensing in one unit will streamline production workflows.

Biodegradable and Smart Material Use

Research into eco-friendly hopper materials that can self-clean or self-repair will gain traction, aligning with green manufacturing goals.

Frequently Asked Questions (FAQs)

Q1: How does IoT integration improve powder hopper operations?

A1: IoT sensors provide real-time monitoring of powder levels, flow rates, and environmental conditions, enabling automated alerts and optimized flow control, which reduces downtime and enhances product consistency.

Q2: What are ultrasonic vibration systems in powder hoppers?

A2: Ultrasonic vibration systems emit high-frequency vibrations to prevent powder clumping and bridging inside the hopper, ensuring smooth and continuous powder flow without mechanical wear.

Q3: Why are hygienic designs critical for powder hoppers in food and pharmaceutical industries?

A3: Hygienic designs prevent powder contamination, reduce microbial growth, and allow easy cleaning, which is essential for meeting health and safety regulations in these industries.

Q4: What benefits do modular hopper systems offer?

A4: Modular systems allow quick reconfiguration for different powders and processes, leading to reduced downtime, increased production flexibility, and cost savings.

Q5: How do powder hoppers contribute to sustainability goals?

A5: Modern powder hoppers use energy-efficient motors, recyclable materials, and designs that minimize powder wastage, supporting sustainable manufacturing practices.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.