Content Menu

● What is a Powder Coating Reciprocator?

>> Definition and Purpose

>> How Does it Work?

● Types of Powder Coating Reciprocators

>> Single-Axis Reciprocators

>> Multi-Axis Reciprocators

>> Line Reciprocators

>> Portable Reciprocators

● Key Features to Consider When Buying a Powder Coating Reciprocator

>> Stroke Length

>> Adjustable Speed Control

>> Load Capacity

>> Control and Automation Features

>> Durability and Build Quality

>> Compatibility and Integration

● Benefits of Using a Powder Coating Reciprocator

>> Enhanced Coating Uniformity

>> Increased Productivity

>> Powder Savings and Environmental Advantages

>> Improved Worker Safety

>> Flexibility for Various Applications

● How to Select the Right Powder Coating Reciprocator for Your Business

>> Assess Your Production Needs

>> Evaluate Your Powder Coating System

>> Consider Future Expansion

>> Budget and Maintenance

>> Request Demonstrations and References

● Installation and Maintenance Tips for Powder Coating Reciprocators

>> Installation Best Practices

>> Regular Maintenance Tasks

● Common Challenges and Troubleshooting

>> Uneven Powder Application

>> Motor or Drive Failures

>> Control System Errors

● FAQs About Powder Coating Reciprocators

>> What types of powder coating reciprocators are best for automotive parts?

>> Can powder coating reciprocators be used with liquid paint systems?

>> How often should a reciprocator be maintained?

>> Are powder coating reciprocators customizable?

>> Is it necessary to automate the reciprocator control?

● Conclusion

● Related Questions and Answers

>> 1. What is the typical stroke length range for powder coating reciprocators?

>> 2. How does a reciprocator improve powder transfer efficiency?

>> 3. Can reciprocators handle multiple spray guns simultaneously?

>> 4. What power sources operate powder coating reciprocators?

>> 5. Are there safety precautions when using reciprocators in powder coating?

Powder coating reciprocators are essential components in many industrial powder coating systems, enabling efficient, uniform application of powder coatings on various surfaces. Whether you are setting up a new coating line or upgrading an existing system, understanding the intricacies of powder coating reciprocators can help you make an informed purchasing decision that enhances productivity, quality, and cost-effectiveness. This guide covers everything you need to know about powder coating reciprocators — from their working principles and types to critical specifications, benefits, maintenance tips, and how to select the right model for your needs.

What is a Powder Coating Reciprocator?

Definition and Purpose

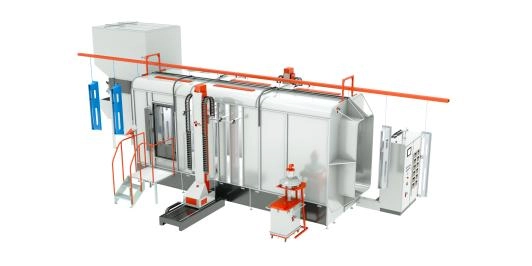

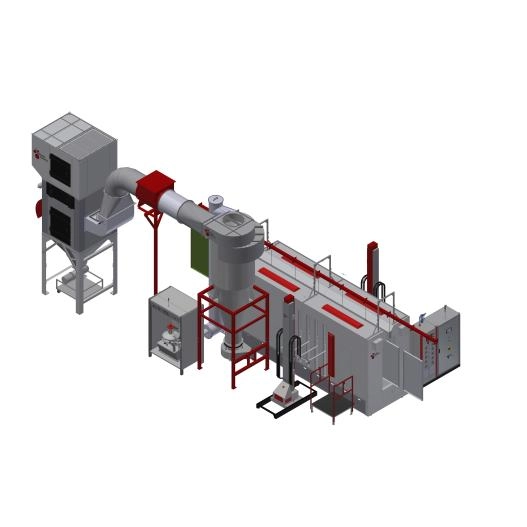

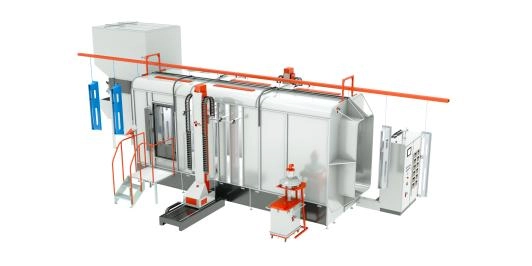

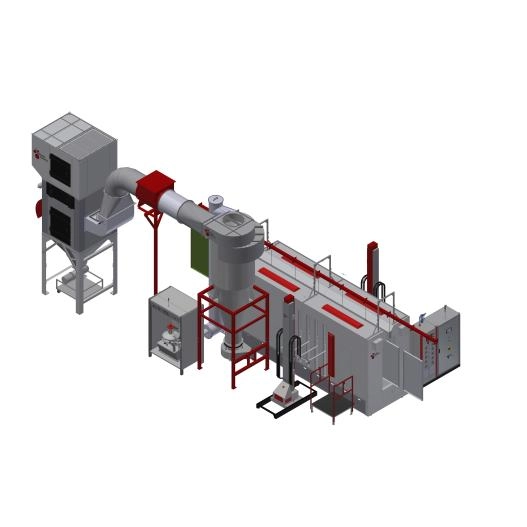

A powder coating reciprocator is a mechanical device designed to move powder coating spray guns back and forth along a preset path. This reciprocating motion allows for consistent and even distribution of the powder across the surface of the workpiece. The device is key in automated or semi-automated powder coating lines, ensuring smooth coverage and superior finish quality.

How Does it Work?

Typically, the powder coating reciprocator is mounted above the conveyor or workpiece. The spray gun(s) attach to the reciprocator's carriage, which moves horizontally in a controlled manner. This back-and-forth motion allows the powder spray to cover a wide area, avoiding underspray or overspray zones, contributing to higher transfer efficiency and reduced powder waste.

The speed, stroke length, and frequency of reciprocation are adjustable to match the size and shape of the products being coated. This flexibility makes the reciprocator integral for various industries such as automotive, appliances, metal furniture, and outdoor equipment manufacturing.

Types of Powder Coating Reciprocators

Single-Axis Reciprocators

Single-axis reciprocators move the spray gun along one straight line — usually horizontally. This simple type is ideal for coating flat or uniformly shaped surfaces, including panels, sheets, and simple profiles. Its straightforward design makes it affordable and easy to maintain, perfect for small to medium production runs.

Multi-Axis Reciprocators

Multi-axis reciprocators provide more complex movements, capable of moving the spray gun along vertical, horizontal, or even diagonal planes. These are used for irregular or large items requiring more precise powder application reach. They often come integrated with robotic arms or gantry systems, providing better control over spray angle and distance.

Line Reciprocators

Line reciprocators are installed inline with conveyor systems, enabling continuous movement synchronized with the workshop's production flow. They typically have adjustable stroke lengths and cycle speeds, suitable for high-volume powder coating processes.

Portable Reciprocators

These compact units are designed for manual setups or small batch applications. They are versatile and easy to transport, making them suitable for workshops that coat oversized or heavy items that are difficult to move through fixed lines.

Key Features to Consider When Buying a Powder Coating Reciprocator

Stroke Length

Stroke length refers to the distance the reciprocator moves the spray gun in each cycle. Choosing the correct stroke length depends on the size of the workpieces and the coverage area needed. A too-short stroke may require multiple passes, decreasing efficiency, while an excessively long stroke can cause uneven coating due to speed variation.

Adjustable Speed Control

Reciprocators come with variable speed controls to accommodate different powder materials and workpiece surfaces. A machine with fine speed adjustments allows safe handling of sensitive coatings and reduces powder consumption while improving surface finish.

Load Capacity

The carriage load capacity dictates the weight of the spray gun assembly and additional attachments the reciprocator can carry. Industrial applications using multiple guns or heavy electrostatic equipment require reciprocators with higher load ratings.

Control and Automation Features

Modern powder coating reciprocators often incorporate programmable logic controllers (PLCs) or touchscreen interfaces to set stroke length, speed, and dwell times. Automation capabilities improve repeatability, reduce operator error, and allow integration with broader coating line control systems.

Durability and Build Quality

Since powder coating environments may expose equipment to dust, chemicals, and abrasive powders, durable construction with corrosion-resistant materials is vital. Look for reciprocators built with high-quality steel, wear-resistant coatings, and sealed bearings to ensure robust performance and minimal maintenance.

Compatibility and Integration

Check if the reciprocator is compatible with your existing spray guns, conveyors, or robotic systems. Universal mounting options and flexible connectivity help reduce installation challenges and increase future scalability.

Benefits of Using a Powder Coating Reciprocator

Enhanced Coating Uniformity

The consistent back-and-forth motion ensures powder is applied evenly across surfaces, eliminating common coating issues such as thin spots or thick accumulations. Uniform coating improves the aesthetic quality and corrosion resistance of finished products.

Increased Productivity

Automated reciprocators allow faster coverage compared to manual spraying. Operators can multitask or monitor other processes while the coating is applied automatically, boosting overall line throughput.

Powder Savings and Environmental Advantages

Even powder distribution reduces overspray and wasted powder materials, lowering operating costs. Additionally, less powder waste contributes to a cleaner working environment and easier powder recovery and recycling.

Improved Worker Safety

By mechanizing the spray gun movement, reciprocators reduce direct operator exposure to airborne powder particles and electrostatic fields, enhancing workplace safety.

Flexibility for Various Applications

Reciprocators accommodate diverse shapes and sizes of workpieces, ensuring versatility for multiple product lines without extensive setup changes.

How to Select the Right Powder Coating Reciprocator for Your Business

Assess Your Production Needs

Determine the volume and types of items you will coat regularly. For high-volume production of simple shapes, single-axis or line reciprocators may suffice. For more complex parts or smaller batch sizes, multi-axis or portable options provide greater flexibility.

Evaluate Your Powder Coating System

Consider compatibility with your existing spray guns, control systems, and conveyor lines. Integration ease can reduce upfront costs and installation downtime.

Consider Future Expansion

Investing in a reciprocator with scalable automation and programmable features can accommodate future workflow increases and technology upgrades.

Budget and Maintenance

Balance upfront purchase price with long-term maintenance and operating costs. Choose machines with durable components, accessible parts, and support from reputable manufacturers.

Request Demonstrations and References

Ask suppliers for live demos or case studies showcasing their reciprocator performance in real production settings. Feedback from other buyers can provide valuable insights.

Installation and Maintenance Tips for Powder Coating Reciprocators

Installation Best Practices

- Ensure the reciprocator is securely mounted and aligned with the coating line conveyor.

- Verify electrical and pneumatic connections comply with manufacturer specifications.

- Calibrate stroke lengths and speeds based on test runs for optimal coverage.

Regular Maintenance Tasks

- Lubricate moving parts according to manufacturer recommendations.

- Inspect bearings and belts frequently for wear or damage.

- Clean spray gun mountings and carriage to prevent powder buildup.

- Check control system software updates or calibrations periodically.

- Replace worn or damaged components promptly to avoid unscheduled downtime.

Common Challenges and Troubleshooting

Uneven Powder Application

- Check reciprocator stroke length and speed settings.

- Verify spray gun alignment and mounting stability.

- Inspect for mechanical obstructions or worn parts restricting smooth movement.

Motor or Drive Failures

- Confirm power supply consistency.

- Regularly lubricate mechanical parts to prevent overheating.

- Replace worn belts and gears before failure occurs.

Control System Errors

- Update PLC or software firmware as recommended.

- Recalibrate stroke and timing parameters if coating uniformity issues arise.

- Contact technical support for complex fault diagnosis.

FAQs About Powder Coating Reciprocators

What types of powder coating reciprocators are best for automotive parts?

Multi-axis reciprocators with programmable controls are preferred due to the complex shapes of automotive components, ensuring thorough and uniform powder coverage.

Can powder coating reciprocators be used with liquid paint systems?

They are primarily designed for powder coating spray guns. Using them with liquid paint requires specialized equipment and may not be compatible due to different application mechanics.

How often should a reciprocator be maintained?

Routine maintenance like lubrication and part inspections should be conducted weekly or monthly based on usage intensity, with more comprehensive servicing annually.

Are powder coating reciprocators customizable?

Yes, many manufacturers offer customization options such as stroke length, speed, load capacity, and control systems to fit specific operational needs.

Is it necessary to automate the reciprocator control?

Automation improves accuracy, repeatability, and efficiency but manual control options are also available for smaller or less complex operations.

Conclusion

Choosing the right powder coating reciprocator can greatly impact the quality, efficiency, and cost-effectiveness of your powder coating operations. Understanding the types available, key features, and associated benefits, alongside proper installation and maintenance, will help you optimize your coating process and achieve outstanding finish results. Evaluate your production requirements carefully, considering the scale of your operations and integration needs, to select a reciprocator that delivers consistent, reliable performance now and for future growth.

Related Questions and Answers

1. What is the typical stroke length range for powder coating reciprocators?

Stroke lengths commonly range from 0.5 meters to 3 meters, adaptable to various workpiece sizes.

2. How does a reciprocator improve powder transfer efficiency?

By moving the spray gun evenly over the surface, it reduces overspray and ensures uniform coverage, thus improving transfer efficiency.

3. Can reciprocators handle multiple spray guns simultaneously?

Yes, many reciprocators can carry multiple guns to speed up coating large surfaces.

4. What power sources operate powder coating reciprocators?

Most use electric motors, sometimes combined with pneumatic components for drive and control.

5. Are there safety precautions when using reciprocators in powder coating?

Operators should ensure proper grounding of equipment, use PPE, and maintain clean working environments to prevent ignition risks.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.