Content Menu

● Introduction to Personalized Powder Management Center

● What is a Personalized Powder Management Center?

>> Key Features of a Personalized Powder Management Center

● Why Choose a Personalized Powder Management Center for OEM Services?

>> Enhanced Efficiency and Productivity

>> Superior Powder Quality and Consistency

>> Cost Savings and Waste Reduction

>> Flexibility for Diverse Client Needs

● Core Technologies in a Personalized Powder Management Center

>> Automated Powder Coating and Handling Lines

>> Fluidized Hoppers and Injectors

>> Modular Powder Supply Systems

>> Custom Powder Processing Techniques

● Implementing a Personalized Powder Management Center in Your OEM Factory

>> Step 1: Assess Client Requirements

>> Step 2: Design Customized Solutions

>> Step 3: Integrate Quality Control Measures

>> Step 4: Train Staff and Optimize Operations

● Case Study: Benefits Realized by a Leading OEM Powder Factory

● Frequently Asked Questions (FAQs)

● Conclusion

Introduction to Personalized Powder Management Center

In today's competitive manufacturing landscape, precision and customization are key drivers of success. For powder management, especially in OEM services catering to international powder management brands, wholesalers, and producers, a Personalized Powder Management Center is a game-changer. This article explores the concept, benefits, and technological advancements of such centers, emphasizing their role in enhancing efficiency, quality, and customer satisfaction.

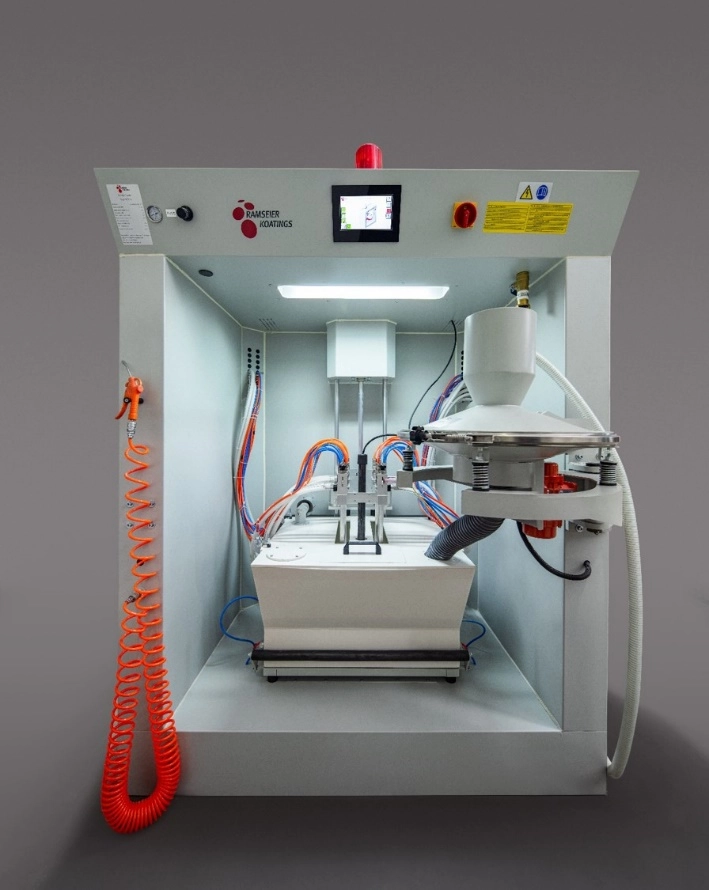

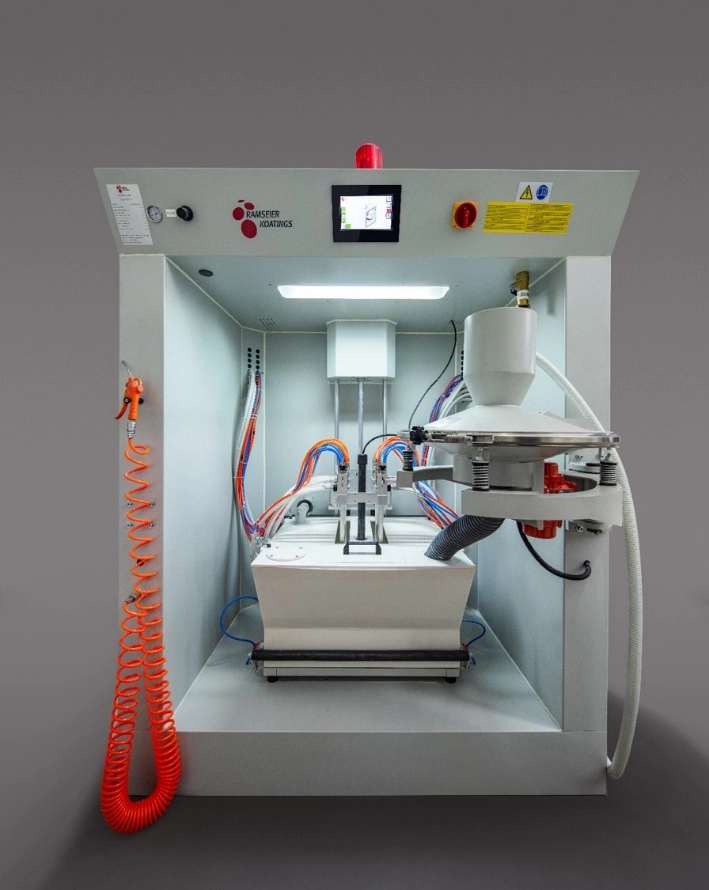

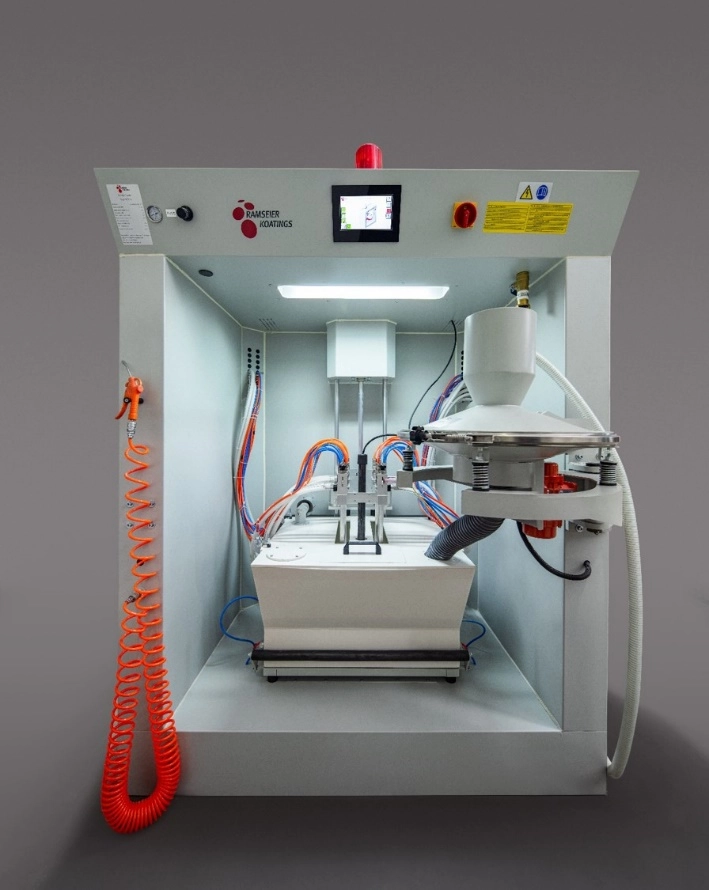

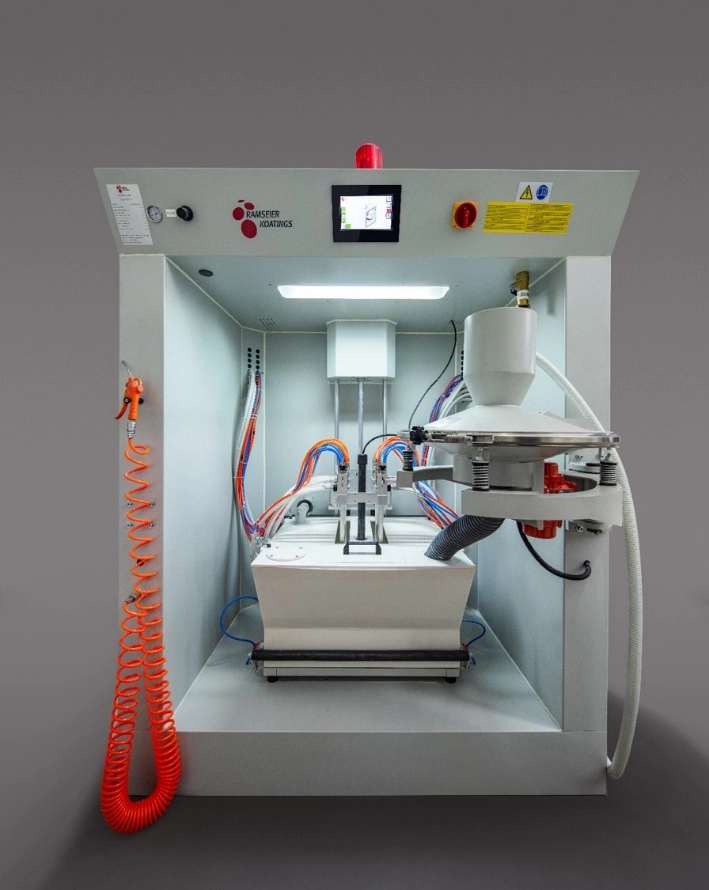

What is a Personalized Powder Management Center?

A Personalized Powder Management Center is a specialized facility or system designed to handle, process, and manage powders with tailored solutions that meet specific client needs. Unlike generic powder handling systems, these centers focus on customization, ensuring that powder management aligns perfectly with the production requirements of various brands and manufacturers.

Key Features of a Personalized Powder Management Center

- Tailored Powder Handling Solutions: Customization in blending, transferring, and conditioning powders to suit client specifications[2].

- Efficient Color Change and Powder Recovery: Fast color change capabilities reduce downtime and enhance productivity while recovering up to 99% of powder[4].

- Modular and Scalable Design: Adaptable to different production scales and needs, allowing for expansion and integration with existing systems[4][7].

- Advanced Automation: Incorporation of automatic cleaning, powder feeding, and process control to minimize manual intervention and errors[1][7].

Why Choose a Personalized Powder Management Center for OEM Services?

OEM powder management requires precision, reliability, and flexibility. A Personalized Powder Management Center offers several advantages:

Enhanced Efficiency and Productivity

By utilizing automated systems and fast color change technology, these centers minimize downtime during production shifts, which is crucial for OEM factories serving multiple brands or product lines[1][4][7].

Superior Powder Quality and Consistency

Custom powder processing ensures that powders meet exact specifications, improving the final product quality. This includes controlled blending, conditioning, and fluidization techniques[2][5].

Cost Savings and Waste Reduction

Efficient powder recovery systems and optimized powder usage reduce material waste, lowering operational costs and environmental impact[4].

Flexibility for Diverse Client Needs

Personalization allows OEM factories to cater to various international clients with different powder formulations and handling requirements, enhancing market competitiveness[2][4].

Core Technologies in a Personalized Powder Management Center

Automated Powder Coating and Handling Lines

Modern centers integrate automatic powder coating lines with cleaning and color change automation, streamlining the entire powder application process[1].

Fluidized Hoppers and Injectors

Fluidized hoppers provide perfect powder fluidization, ensuring stable and consistent powder flow to application guns or processing units. This technology supports quick and efficient color changes[3][4].

Modular Powder Supply Systems

Systems like the PXM powder center offer modular configurations with manual or automatic powder supply, supporting up to 34 injectors and enabling flexible production setups[7].

Custom Powder Processing Techniques

Services such as spray drying, rotary calcining, grinding, and blending are tailored to client needs, ensuring powders meet stringent quality and performance standards[5].

Implementing a Personalized Powder Management Center in Your OEM Factory

Step 1: Assess Client Requirements

Understand the specific powder types, batch sizes, and color change frequency required by your clients.

Step 2: Design Customized Solutions

Develop modular systems that can be scaled and adapted, incorporating advanced automation and fluidization technologies.

Step 3: Integrate Quality Control Measures

Implement analytical capabilities and process monitoring to maintain powder consistency and quality throughout production[5].

Step 4: Train Staff and Optimize Operations

Ensure operators are skilled in managing the personalized systems and maintaining efficiency during production runs.

Case Study: Benefits Realized by a Leading OEM Powder Factory

A Chinese powder management factory serving international brands implemented a Personalized Powder Management Center featuring fast color change systems and modular powder supply units. The results included:

- 30% reduction in downtime during color changes

- 25% powder savings due to improved recovery rates

- Enhanced client satisfaction through customized powder handling solutions

Frequently Asked Questions (FAQs)

Q1: What industries benefit most from a Personalized Powder Management Center?

A1: Industries such as automotive, electronics, cosmetics, and pharmaceuticals that require precise powder handling and coating benefit greatly from personalized centers[2][5].

Q2: How does fast color change technology improve OEM powder processing?

A2: It reduces production downtime, allowing quick shifts between different powder colors or formulations, enhancing productivity and flexibility[4][7].

Q3: Can a Personalized Powder Management Center handle small batch production efficiently?

A3: Yes, modular designs and fluidized hopper technologies enable efficient handling of small batches without compromising quality[4].

Q4: What role does automation play in these centers?

A4: Automation ensures consistent powder supply, cleaning, and process control, reducing manual errors and improving operational efficiency[1][7].

Q5: How does customization in powder management impact product quality?

A5: Tailored powder processing and handling ensure powders meet exact client specifications, resulting in higher quality and consistency in finished products[2][5].

Conclusion

A Personalized Powder Management Center is essential for OEM powder factories aiming to serve global powder management brands with high-quality, efficient, and flexible solutions. By embracing advanced technologies, modular designs, and tailored services, these centers drive productivity, reduce costs, and elevate product standards, positioning OEM providers as preferred partners in the international market.

[1] https://www.colo-group.com/powder-management-center-15917754950208390.html

[2] https://custom-powder.com

[3] https://www.gemapowdercoating.com/en/products/powder-management-centers-and-hoppers

[4] https://dewa.sames.com/poland-east-europe/en/product-inocenter.html

[5] https://www.pptechnology.com/powder-processing

[6] https://www.dlhitech.gov.cn/resources/news/newsConstantImages/20230908114507486.xlsx

[7] https://www.wagner-group.com/en/industry/products/powder-coating/product/pxm-powder-center/

[8] http://www2.mfa.gr/infofiles/%E4%B8%8A%E6%B5%B7%E9%98%B2%E7%96%AB%E5%B1%95%E4%BC%9A%E5%88%8ASEPMEF%20Catalog%20cn.pdf

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.