Content Menu

● Understanding Powder Transfer Efficiency

>> What is Powder Transfer Efficiency?

>> Importance of Transfer Efficiency

● Factors Affecting Powder Transfer Efficiency

>> Powder Properties

>> Hopper Design

>> Flow Mechanisms

● Selecting the Right Hopper

>> Assessing Your Needs

>> Hopper Types

● Enhancing Powder Transfer Efficiency

>> Implementing Best Practices

>> Training and Education

● Conclusion

>> Frequently Asked Questions

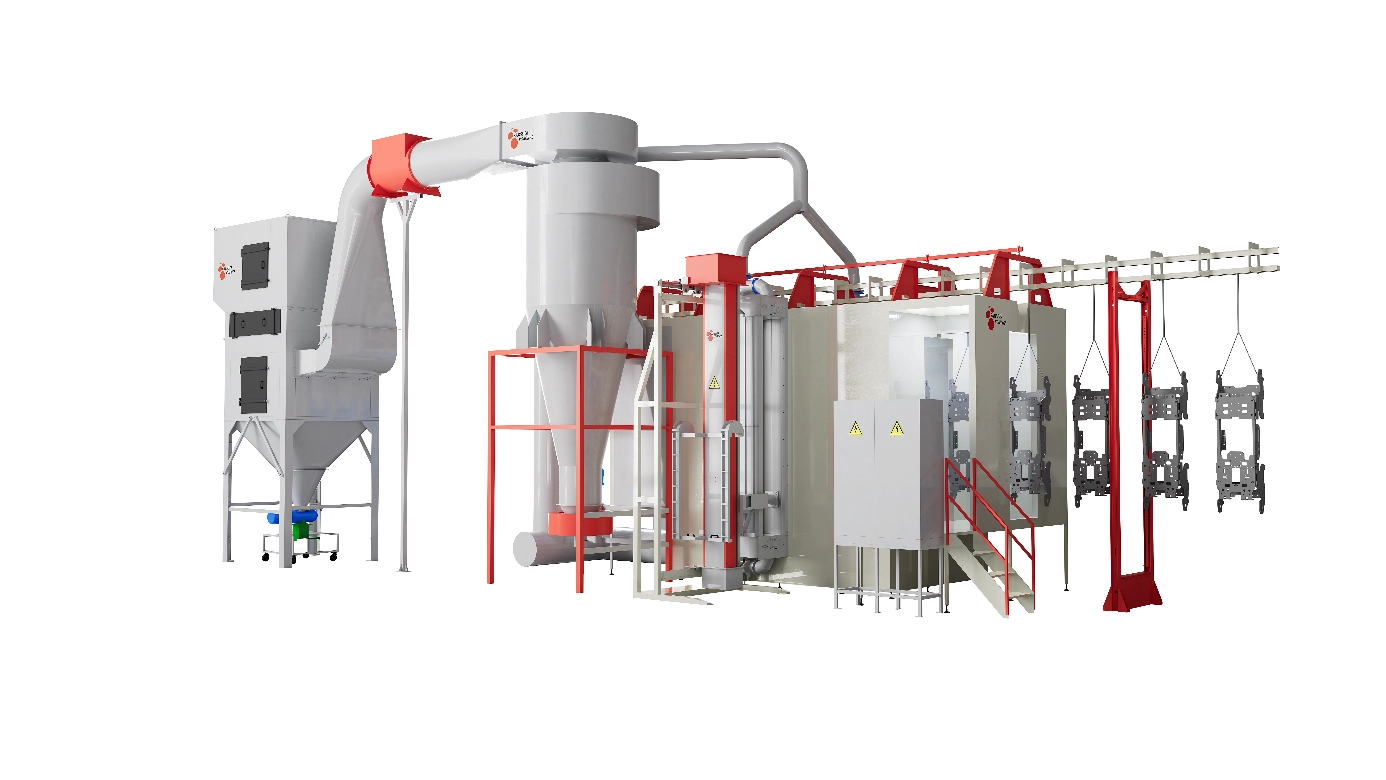

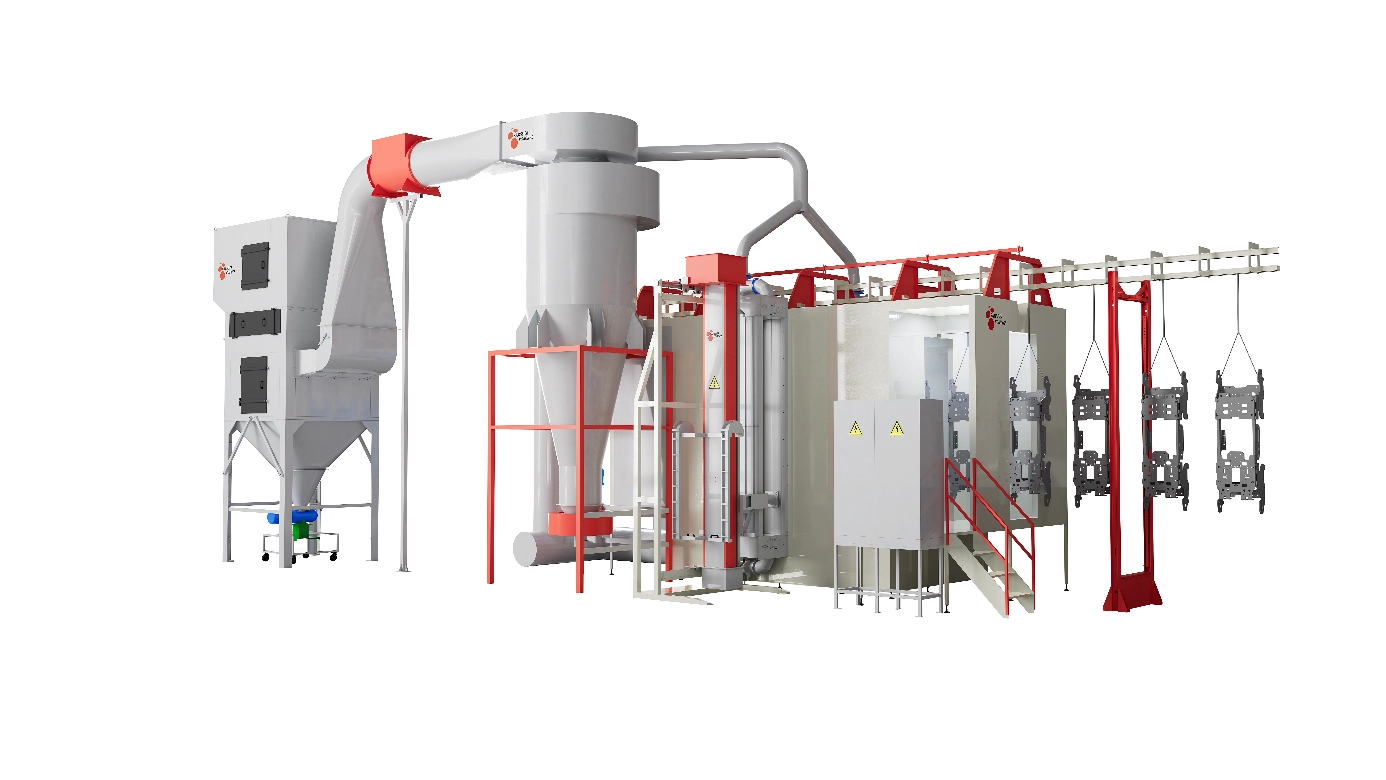

Efficient powder transfer is crucial in various industries, including pharmaceuticals, food processing, and manufacturing. The right hopper design can significantly enhance the transfer efficiency of powders, ensuring consistent flow and minimizing downtime. This article explores the factors influencing powder transfer efficiency and how to select the appropriate hopper for optimal performance.

Understanding Powder Transfer Efficiency

What is Powder Transfer Efficiency?

Powder transfer efficiency refers to the effectiveness of moving powder from one point to another within a processing system. It is typically measured by the ratio of the amount of powder successfully transferred to the amount initially supplied. High transfer efficiency means less waste and better utilization of materials, which is essential for cost-effective operations.

Importance of Transfer Efficiency

Improving powder transfer efficiency can lead to several benefits, including:

- Reduced Material Waste: Efficient transfer minimizes the amount of powder left behind in hoppers and other equipment.

- Increased Production Rates: Higher efficiency allows for faster processing times, leading to increased output.

- Improved Product Quality: Consistent powder flow helps maintain uniformity in product formulation, which is critical in industries like pharmaceuticals and food production.

Factors Affecting Powder Transfer Efficiency

Powder Properties

The characteristics of the powder being transferred play a significant role in determining transfer efficiency. Key properties include:

- Flowability: Powders can be free-flowing or cohesive. Free-flowing powders move easily through hoppers, while cohesive powders may require additional measures to facilitate flow.

- Particle Size and Shape: Smaller particles may flow more easily, but they can also be more prone to clumping. The shape of the particles can affect how they interact with each other and the hopper walls.

- Moisture Content: Powders with high moisture content can clump together, leading to blockages and reduced flow rates.

Hopper Design

The design of the hopper itself is critical for ensuring efficient powder transfer. Important design considerations include:

- Hopper Shape: Conical hoppers are often preferred for their ability to promote mass flow, where all material moves together as a unit. This design minimizes the risk of arching and ratholing, which can occur in poorly designed hoppers.

- Wall Angle: The angle of the hopper walls affects how easily the powder can flow out. Steeper angles generally promote better flow, especially for cohesive powders.

- Surface Finish: Smooth surfaces reduce friction and help prevent powder from sticking to the walls, facilitating better flow.

Flow Mechanisms

Understanding the flow mechanisms within the hopper is essential for optimizing transfer efficiency. Two primary flow patterns are:

- Mass Flow: In mass flow, all the powder moves uniformly towards the outlet, ensuring that the first powder in is the first out. This pattern is ideal for maintaining consistent flow and minimizing stagnation.

- Funnel Flow: In funnel flow, only a portion of the powder moves towards the outlet, while the rest remains stagnant. This can lead to issues such as arching and uneven flow, which negatively impact efficiency.

Selecting the Right Hopper

Assessing Your Needs

When selecting a hopper, consider the following factors:

- Type of Powder: Different powders have unique flow characteristics. Understanding these properties will help you choose a hopper that can handle your specific material effectively.

- Production Volume: High-volume production may require larger hoppers with features that support continuous flow and minimize downtime.

- Space Constraints: The available space in your facility may limit the size and type of hopper you can use. Custom solutions may be necessary to fit your operational needs.

Hopper Types

There are several types of hoppers available, each suited for different applications:

- Fluidized Hoppers: These hoppers use air or vibration to keep the powder suspended, promoting uniform flow. They are particularly effective for fine powders that tend to clump.

- Box Feed Systems: Simpler than fluidized hoppers, these systems use vibration to agitate the powder. They are suitable for applications where rapid color changes are needed.

- Mass Flow Hoppers: Designed to promote mass flow, these hoppers are ideal for cohesive powders and applications requiring consistent discharge.

Enhancing Powder Transfer Efficiency

Implementing Best Practices

To maximize powder transfer efficiency, consider the following best practices:

- Regular Maintenance: Ensure that hoppers and associated equipment are regularly cleaned and maintained to prevent blockages and ensure smooth operation.

- Flow Aids: Use flow aids such as anti-caking agents or surface treatments to improve the flowability of powders, especially those that are cohesive or hygroscopic.

- Monitoring and Control: Implement monitoring systems to track powder flow rates and detect any issues early. This can help prevent downtime and maintain efficiency.

Training and Education

Educating staff on the importance of proper hopper operation and maintenance can significantly impact transfer efficiency. Training should cover:

- Understanding Powder Properties: Staff should be familiar with the characteristics of the powders they are handling and how these affect flow.

- Hopper Operation: Proper operation techniques can help prevent common issues such as bridging and ratholing.

Conclusion

Improving powder transfer efficiency is essential for optimizing production processes in various industries. By understanding the factors that influence transfer efficiency and selecting the right hopper design, businesses can enhance their operations, reduce waste, and improve product quality. Regular maintenance, best practices, and staff training further contribute to achieving high transfer efficiency.

Frequently Asked Questions

1. What is the best hopper design for cohesive powders?

- Mass flow hoppers are typically the best choice for cohesive powders, as they promote uniform flow and minimize the risk of blockages.

2. How can I improve the flowability of my powder?

- Consider using flow aids, adjusting moisture content, and ensuring that the hopper design supports smooth flow.

3. What are the signs of poor powder transfer efficiency?

- Signs include frequent blockages, inconsistent product quality, and increased downtime during production.

4. How often should I clean my hopper?

- Regular cleaning is recommended, especially when switching between different powders or if you notice flow issues.

5. Can I use the same hopper for different types of powders?

- It depends on the powders' properties. Some hoppers can handle multiple powders, but others may require specific designs to accommodate different flow characteristics.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.