Content Menu

● Introduction

● Understanding Powder Coating

>> What is Powder Coating?

>> Environmental Benefits of Powder Coating

● The Role of Smart Control Systems

>> What are Smart Control Systems?

>> Key Features of Smart Control Systems

● Enhancing Sustainability through Smart Control Systems

>> Reducing Energy Consumption

>> Minimizing Material Waste

>> Improving Quality Control

● Applications of Smart Control Systems in Various Industries

>> Automotive Industry

>> Appliance Manufacturing

>> Furniture Production

● Future Trends in Smart Control Systems and Powder Coating

>> Integration with Industry 4.0

>> Development of Eco-Friendly Powder Formulations

>> Enhanced Automation and Robotics

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using smart control systems in powder coating?

>> 2. How do smart control systems improve quality in powder coating?

>> 3. What industries benefit most from smart control systems in powder coating?

>> 4. What challenges do manufacturers face when implementing smart control systems?

>> 5. How do smart control systems contribute to sustainability in powder coating?

Introduction

In recent years, the manufacturing industry has increasingly focused on sustainability, driven by both regulatory pressures and consumer demand for environmentally friendly practices. One area where significant advancements have been made is in powder coating, a popular finishing process known for its durability and aesthetic appeal. Smart control systems are revolutionizing this sector by enhancing efficiency, reducing waste, and promoting sustainable practices. This article explores how these technologies support sustainability in powder coating, detailing their applications, benefits, and future potential.

Understanding Powder Coating

What is Powder Coating?

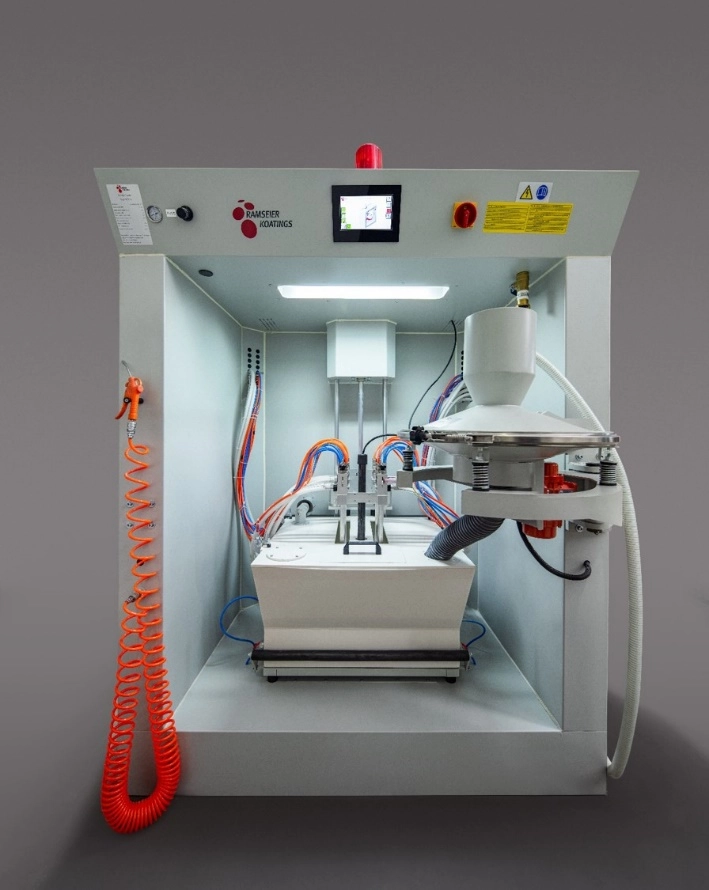

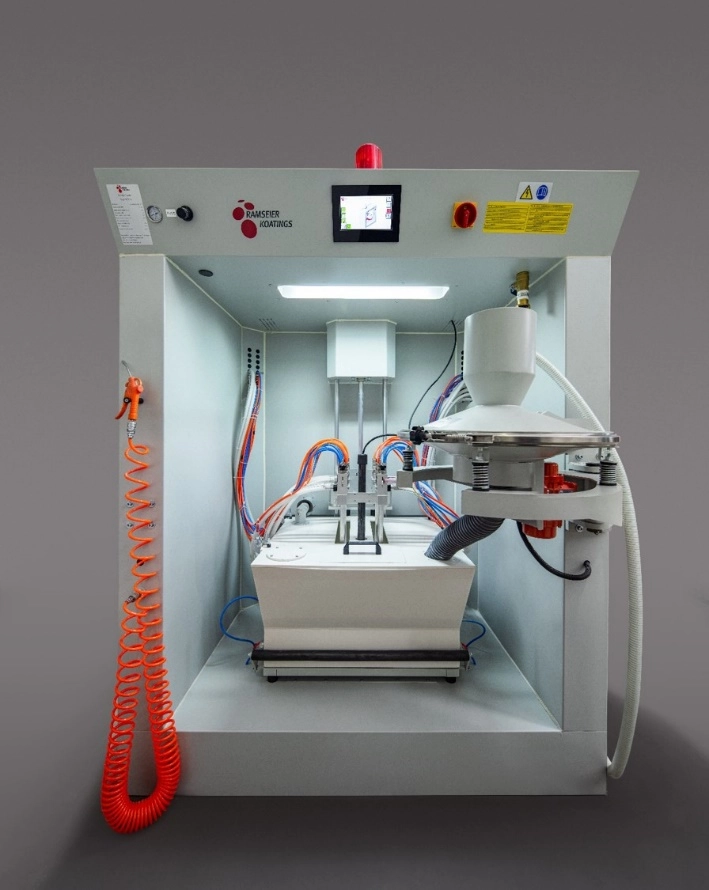

Powder coating is a dry finishing process that uses finely ground particles of pigment and resin, which are electrostatically charged and sprayed onto a surface. The coated object is then heated in an oven, where the powder melts and forms a hard, protective layer. This method is widely used in various industries, including automotive, appliances, and furniture, due to its superior finish and environmental benefits compared to traditional liquid coatings.

Environmental Benefits of Powder Coating

Powder coating is inherently more sustainable than conventional liquid coatings. It produces minimal volatile organic compounds (VOCs), which are harmful to both health and the environment. Additionally, any overspray can be collected and reused, leading to less waste. However, the integration of smart control systems takes these benefits to the next level.

The Role of Smart Control Systems

What are Smart Control Systems?

Smart control systems in powder coating involve the use of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and real-time data analytics. These systems monitor and optimize the coating process, ensuring that every aspect—from powder application to curing—is as efficient as possible.

Key Features of Smart Control Systems

1. Real-Time Monitoring: Sensors track various parameters such as temperature, humidity, and powder flow, allowing for immediate adjustments to maintain optimal conditions.

2. Automated Adjustments: AI algorithms analyze data and make real-time adjustments to the coating process, reducing the likelihood of defects and waste.

3. Predictive Maintenance: Smart systems can predict equipment failures before they occur, minimizing downtime and extending the lifespan of machinery.

Enhancing Sustainability through Smart Control Systems

Reducing Energy Consumption

One of the most significant contributions of smart control systems to sustainability is their ability to reduce energy consumption. By optimizing the curing process and adjusting conveyor speeds based on real-time data, these systems can significantly lower energy usage. For instance, AI-driven energy management systems can fine-tune the operation of curing ovens, ensuring they operate at the most efficient temperatures and times.

Minimizing Material Waste

Smart control systems also play a crucial role in minimizing material waste. Traditional powder coating processes often result in overspray, which can lead to significant material loss. However, with precise control over powder application, smart systems can reduce overspray and allow for the recycling of excess material. This not only conserves resources but also lowers costs for manufacturers.

Improving Quality Control

Quality control is essential in powder coating, as defects can lead to costly rework and waste. Smart control systems enhance quality assurance by using AI-powered cameras and sensors to detect defects in real-time. This capability allows for immediate corrections, ensuring that every coated item meets the required standards without unnecessary waste.

Applications of Smart Control Systems in Various Industries

Automotive Industry

The automotive sector is one of the largest users of powder coating, and smart control systems are transforming how manufacturers approach this process. By implementing automated powder coating lines equipped with robotics and advanced controls, companies can achieve high-volume production while maintaining consistent quality. Features such as rapid color change capabilities streamline operations, reducing downtime and improving efficiency.

Appliance Manufacturing

In the appliance industry, smart control systems help manufacturers meet stringent environmental regulations while enhancing product quality. Automated systems ensure that coatings are applied evenly and efficiently, reducing the risk of defects and waste. Additionally, the ability to recycle overspray powder contributes to a more sustainable manufacturing process.

Furniture Production

Furniture manufacturers are also benefiting from smart control systems in powder coating. These systems allow for customization and flexibility in production, enabling companies to offer a wider range of finishes while maintaining sustainability. By optimizing the coating process, manufacturers can reduce energy consumption and material waste, aligning with consumer preferences for eco-friendly products.

Future Trends in Smart Control Systems and Powder Coating

Integration with Industry 4.0

The future of powder coating lies in its integration with Industry 4.0 technologies. As manufacturers increasingly adopt smart manufacturing practices, the role of smart control systems will expand. This integration will enable more sophisticated data analytics, allowing for even greater efficiencies and sustainability in the coating process.

Development of Eco-Friendly Powder Formulations

As sustainability becomes a priority, the development of eco-friendly powder formulations is gaining traction. Low-temperature curing powders, for example, require less energy during the curing process, further enhancing the sustainability of powder coating. Smart control systems will play a crucial role in optimizing the application of these new materials.

Enhanced Automation and Robotics

The continued advancement of automation and robotics in powder coating will further improve efficiency and sustainability. Automated systems can operate with precision and consistency, reducing human error and ensuring that every product meets quality standards. As these technologies evolve, they will enable manufacturers to achieve higher production rates with lower environmental impact.

Conclusion

Smart control systems are revolutionizing the powder coating industry by enhancing sustainability through improved efficiency, reduced waste, and better quality control. As these technologies continue to evolve, they will play an increasingly vital role in helping manufacturers meet their sustainability goals. By integrating smart systems into their operations, companies can not only improve their bottom line but also contribute to a more sustainable future.

Frequently Asked Questions

1. What are the main advantages of using smart control systems in powder coating?

Smart control systems enhance efficiency, improve quality control, reduce costs, and promote sustainability.

2. How do smart control systems improve quality in powder coating?

They ensure consistent application through real-time monitoring and automated adjustments, minimizing defects.

3. What industries benefit most from smart control systems in powder coating?

The automotive, appliance, and furniture industries are among the primary beneficiaries.

4. What challenges do manufacturers face when implementing smart control systems?

Initial investment costs, the need for workforce training, and ongoing technology updates can pose challenges.

5. How do smart control systems contribute to sustainability in powder coating?

They optimize energy usage and reduce material waste, leading to more environmentally friendly manufacturing practices.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.