Content Menu

● Introduction

● What Is Professional Powder Coating Equipment?

>> Definition and Scope

>> Core Components of a Professional Powder Coating System

● Why Choose Professional Powder Coating Equipment?

>> Key Advantages

● Types of Professional Powder Coating Equipment

>> Powder Coating Guns

>> Powder Coating Booths

>> Curing Ovens

>> Surface Preparation and Recovery Systems

● Selecting the Right Professional Powder Coating Equipment

>> Factors to Consider

>> Customization and OEM/ODM Services

● Setting Up a Professional Powder Coating Line

>> Step-by-Step Workflow

>> Maintenance and Safety

● Trends and Innovations in Professional Powder Coating Equipment

>> Automation and Digital Control

>> Energy Efficiency

>> Sustainability

● Frequently Asked Questions (FAQ) About Professional Powder Coating Equipment

>> 1. What is the main difference between professional powder coating equipment and hobbyist systems?

>> 2. How do I choose between a batch oven and a conveyor oven?

>> 3. Can professional powder coating equipment be customized for my specific products?

>> 4. What are the key maintenance tasks for powder coating equipment?

>> 5. Is powder coating environmentally friendly?

● Conclusion

● Citations:

Introduction

In today's competitive manufacturing landscape, the demand for *professional powder coating equipment* is soaring among global brands, wholesalers, and OEM partners. Whether you are a distributor, system integrator, or production manager, investing in advanced powder coating technology is key to delivering flawless finishes, maximizing productivity, and staying ahead in the market. This comprehensive guide explores everything you need to know about professional powder coating equipment—from system components and technology trends to OEM/ODM solutions and maintenance—empowering you to make informed decisions for your business.

What Is Professional Powder Coating Equipment?

Definition and Scope

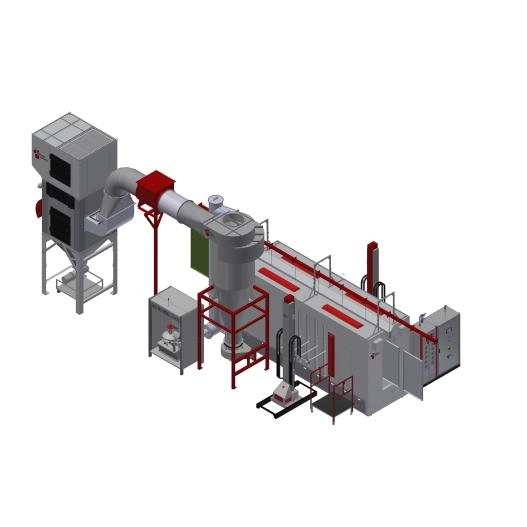

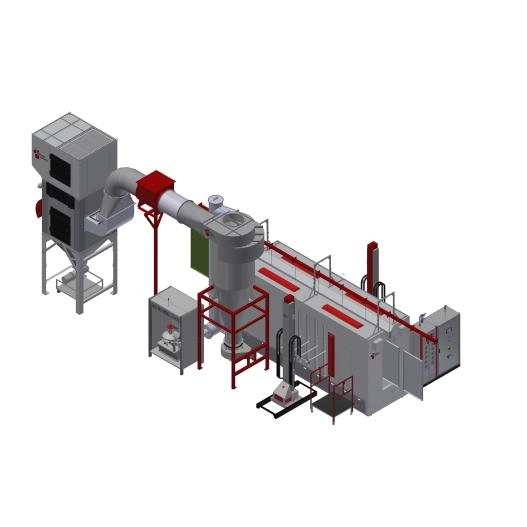

Professional powder coating equipment refers to a complete set of machinery and tools designed for the industrial application of powder coatings onto metal or other substrates. This equipment ensures high transfer efficiency, uniform coverage, and durable finishes, meeting the stringent requirements of automotive, appliance, architectural, and general manufacturing sectors[4][6][11].

Core Components of a Professional Powder Coating System

- Powder Coating Guns: Electrostatic or tribo guns that atomize and charge powder particles for efficient adhesion[4][6].

- Powder Coating Booths: Enclosed, ventilated spaces that contain overspray and maintain a clean working environment[4][6].

- Powder Curing Ovens: Batch or conveyor ovens that cure the applied powder at controlled temperatures for a robust finish[4][6].

- Surface Preparation Equipment: Washers, abrasives, and degreasers for optimal substrate preparation[4].

- Powder Recovery Systems: Capture and recycle overspray to reduce waste and improve cost-effectiveness[6].

- Material Handling Systems: Conveyors, carts, and trolleys for efficient workflow between process stages[4][6].

Why Choose Professional Powder Coating Equipment?

Key Advantages

- Superior Finish Quality: Achieve smooth, uniform, and defect-free coatings that enhance product aesthetics and durability[4][6].

- Operational Efficiency: Automated and high-throughput systems support large-scale production with minimal labor[4][6].

- Cost Savings: Powder recovery and high transfer efficiency reduce material waste and operational costs[6].

- Environmental Compliance: Modern systems minimize air pollution and powder waste, supporting sustainable manufacturing[4][6].

- Versatility: Suitable for a wide range of substrates, part sizes, and custom color requirements[6].

Types of Professional Powder Coating Equipment

Powder Coating Guns

- Electrostatic Guns: Use high voltage to charge powder particles, ensuring strong adhesion to grounded parts[4][6].

- Tribo Guns: Rely on friction charging, offering flexibility for different powder types and applications[6].

- Manual vs. Automatic Guns: Manual guns provide flexibility for small batches, while automatic guns ensure consistency in high-volume production[4][6].

Powder Coating Booths

- Open-Faced Booths: Ideal for small parts and low-volume jobs.

- Enclosed Booths: Feature advanced filtration and airflow control for large-scale, continuous operations[4][6].

Curing Ovens

| Oven Type | Best For | Features |

| Batch Ovens | Small/medium production | Flexibility, handles varied part sizes |

| Conveyor Ovens | Large-scale, continuous | High throughput, automated workflow |

| Infrared Ovens | Fast curing, energy saving | Targeted heating, reduced cycle times |

Surface Preparation and Recovery Systems

- Pre-Treatment Lines: Ensure surfaces are clean and ready for coating[4].

- Recovery Systems: Use filtration or mechanical separation to reclaim overspray powder for reuse[6].

Selecting the Right Professional Powder Coating Equipment

Factors to Consider

- Production Scale: Choose between batch and conveyor systems based on your throughput needs[4][6].

- Part Size and Geometry: Ensure booth and oven dimensions accommodate your largest parts[4][6].

- Automation Level: Determine whether manual or fully automated systems fit your workflow and labor resources[4][6].

- Powder Type Compatibility: Confirm that guns and recovery systems handle your preferred powder chemistries[6].

- Budget and ROI: Balance initial investment with long-term efficiency and operational savings[4].

Customization and OEM/ODM Services

As a leading Chinese manufacturer and supplier, we offer complete OEM/ODM solutions for professional powder coating equipment. Our services include:

- Custom System Design: Tailored layouts and configurations to match your facility and production goals.

- Branding and Packaging: Private label and custom branding for global partners.

- Technical Support: Installation, training, and after-sales service for seamless integration and operation[12][13][11].

Setting Up a Professional Powder Coating Line

Step-by-Step Workflow

1. Surface Preparation: Clean, degrease, and abrade parts for optimal coating adhesion[4].

2. Powder Application: Use professional powder coating guns in a controlled booth environment[4][6].

3. Curing: Transfer coated parts to ovens for precise temperature and time-controlled curing[4][6].

4. Quality Inspection: Check for uniformity, adhesion, and finish quality.

5. Powder Recovery: Collect and recycle overspray to maximize efficiency[6].

Maintenance and Safety

- Regularly inspect and clean all equipment.

- Train staff on safe handling and operational procedures.

- Adhere to local and international safety standards[4][6].

Trends and Innovations in Professional Powder Coating Equipment

Automation and Digital Control

Modern systems feature programmable logic controllers (PLCs), touch-screen interfaces, and recipe management for precise process control and repeatability[4][6].

Energy Efficiency

Infrared and hybrid ovens, improved insulation, and smart airflow systems reduce energy consumption and operational costs[6].

Sustainability

Advanced recovery systems and eco-friendly powder formulations help manufacturers meet environmental regulations and sustainability goals[4][6].

Frequently Asked Questions (FAQ) About Professional Powder Coating Equipment

1. What is the main difference between professional powder coating equipment and hobbyist systems?

Professional powder coating equipment is designed for high throughput, consistent quality, and industrial durability, while hobbyist systems are typically less robust and suitable for small-scale or occasional use[1][3][4].

2. How do I choose between a batch oven and a conveyor oven?

Batch ovens are ideal for flexible, small-to-medium production runs with varied part sizes, while conveyor ovens are best for continuous, high-volume operations[4][6].

3. Can professional powder coating equipment be customized for my specific products?

Yes, OEM/ODM services allow for custom system design, branding, and technical adaptations to meet unique production requirements[12][13][11].

4. What are the key maintenance tasks for powder coating equipment?

Regular cleaning of guns, booths, and ovens; checking filters and airflow; and routine calibration of control systems ensure optimal performance and longevity[4][6].

5. Is powder coating environmentally friendly?

Modern powder coating systems are eco-friendly, producing minimal VOC emissions and enabling powder recovery and recycling, which reduces waste[4][6].

Conclusion

Investing in *professional powder coating equipment* is essential for businesses aiming to deliver high-quality, durable, and aesthetically pleasing finishes on a global scale. By understanding system components, selecting the right equipment, and leveraging OEM/ODM solutions, you can optimize your production, enhance your brand, and meet the evolving needs of your customers. Whether you are a wholesaler, manufacturer, or brand owner, partnering with a trusted supplier ensures you stay at the forefront of the powder coating industry.

Citations:

[1] https://www.powdercoatguide.com/2012/11/getting-into-powder-coating-equipment.html

[2] https://advertisingnews.com/powder-coating-slogans/

[3] https://www.columbiacoatings.com/store/c/568-Equipment.aspx

[4] https://ems-powdercoating.com/professional-powder-coating-system/

[5] https://namefatso.com/blog/powder-coating-slogan-ideas

[6] https://tncoating.com/blog/powder-coat-machine/

[7] https://www.rontar.com/blog/powder-coating-business-name-ideas/

[8] https://www.seair.co.in/powder-coating-machine-hs-code.aspx

[9] https://reliantfinishingsystems.com/want-to-start-powder-coating-succeed-by-avoiding-these-4-common-pitfalls/

[10] https://blog.boon.so/powder-coatings-industry-business-ideas-2024/

[11] language.english_writing.coating_equipment

[12] language.english_writing.cosmetics

[13] language.english_writing.pharmaceutical

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.