Content Menu

● Understanding Powder Hoppers

>> What is a Powder Hopper?

>> Types of Powder Hoppers

● Manual Powder Hoppers

>> How Manual Powder Hoppers Work

>> Advantages of Manual Powder Hoppers

>> Disadvantages of Manual Powder Hoppers

● Automatic Powder Hoppers

>> How Automatic Powder Hoppers Work

>> Advantages of Automatic Powder Hoppers

>> Disadvantages of Automatic Powder Hoppers

● Comparing Key Factors Between Manual and Automatic Powder Hoppers

● When to Choose a Manual Powder Hopper

● When to Choose an Automatic Powder Hopper

● Practical Tips for Using Powder Hoppers

>> Manual Hopper Tips

>> Automatic Hopper Tips

● Innovations in Powder Hopper Technology

● Frequently Asked Questions (FAQs)

>> 1. Are automatic powder hoppers always more accurate than manual ones?

>> 2. Can I convert my manual powder hopper into an automatic one?

>> 3. How much space does an automatic powder hopper usually require?

>> 4. Is digital calibration necessary for an automatic powder hopper?

>> 5. What are common maintenance requirements for automatic powder hoppers?

Powder hoppers are essential tools for anyone involved in powder handling or ammunition reloading. Choosing between manual and automatic powder hoppers can greatly impact your efficiency, accuracy, and overall experience. This article explores the key differences, advantages, and disadvantages of manual and automatic powder hoppers to help you decide which option suits your needs best.

Understanding Powder Hoppers

What is a Powder Hopper?

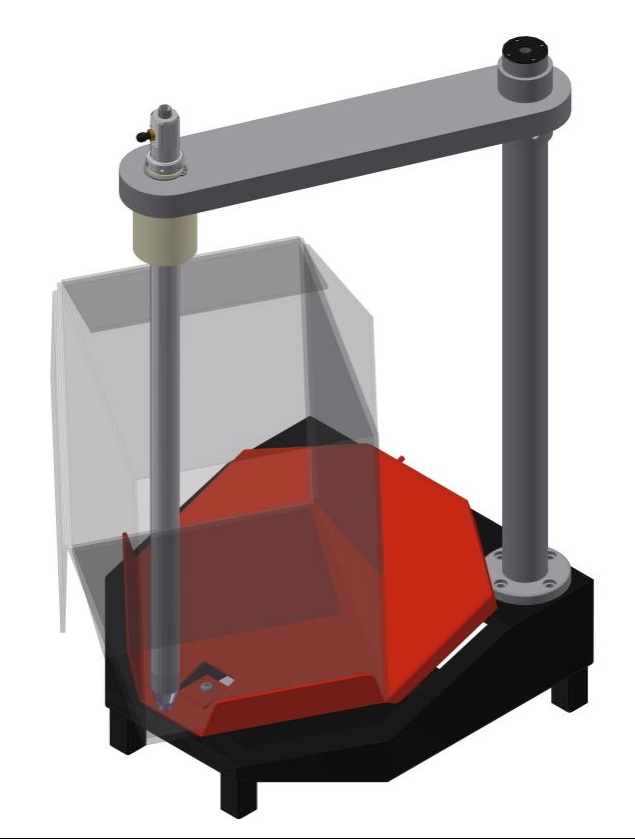

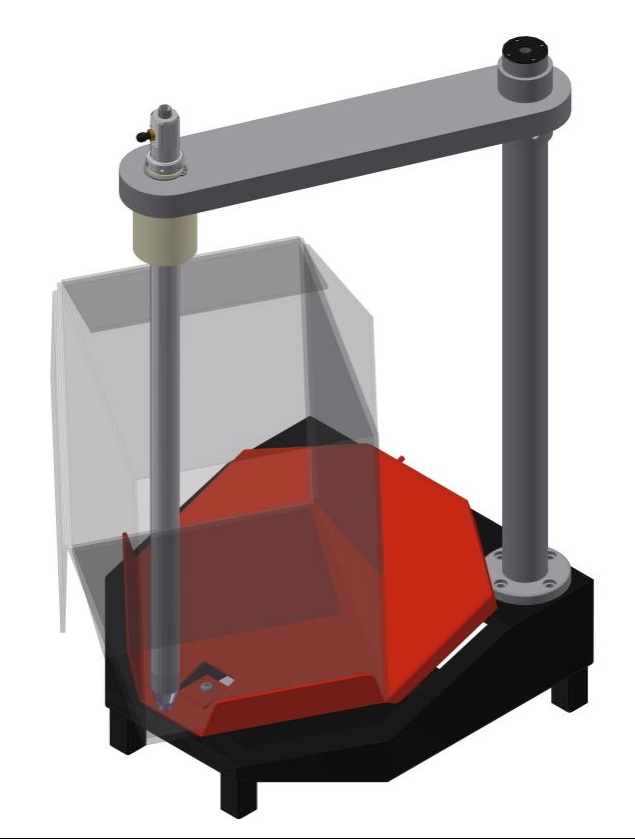

A powder hopper is a container or device that stores powder and releases it in measured quantities for various applications, typically ammunition reloading or industrial powder coating. Accurate powder measurement and consistent dispensing are crucial for safety and quality in these fields.

Types of Powder Hoppers

There are primarily two types of powder hoppers based on their operational method: manual and automatic. Each type varies in technology, ease of use, capacity, and suitable use cases.

Manual Powder Hoppers

How Manual Powder Hoppers Work

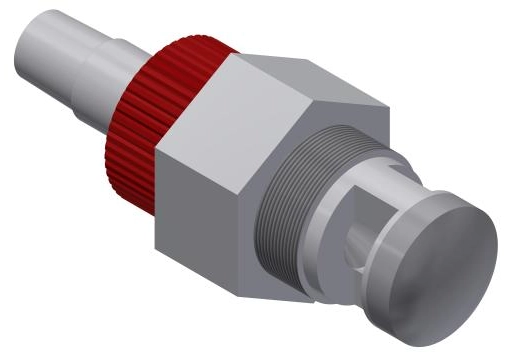

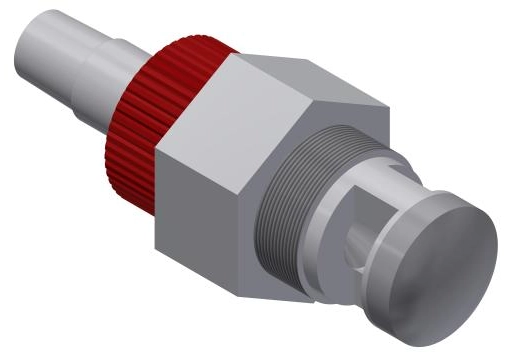

Manual powder hoppers rely on the user to control the dispensing of powder directly. Users typically operate a lever, crank, or use a scoop and trickler method to measure powder incrementally. The process involves careful handling and weighing to ensure each charge meets the required amount.

Advantages of Manual Powder Hoppers

- Cost-Effective: Manual systems are generally more affordable, making them accessible for beginners and hobbyists.

- Full Control: Operators have direct control over powder measurement, useful for load development requiring precise adjustments.

- Portable and Compact: Manual hoppers are smaller and do not require power, suitable for limited workspace or remote locations.

- Simplicity: With fewer mechanical parts, manual hoppers require less maintenance and are less prone to technical failures.

Disadvantages of Manual Powder Hoppers

- Slower Process: Measuring powder manually is time-consuming, especially for large volume reloading.

- Labor Intensive: Requires constant attention and physical operation, which may be tiring over time.

- Accuracy Dependency: Achieving repeatable precision depends heavily on user skill and consistency.

- Limited Capacity: Typically hold less powder, requiring frequent refilling during extended work.

Automatic Powder Hoppers

How Automatic Powder Hoppers Work

Automatic powder hoppers incorporate electronic or mechanical mechanisms that dispense pre-set amounts of powder. Common features include digital scales, programmable memory for different loads, automatic trickling to fine-tune powder charges, and speed control.

Advantages of Automatic Powder Hoppers

- Speed and Efficiency: Automate measurement and dispensing, significantly increasing throughput for high volume tasks.

- Consistency: Less user-dependent, delivering repeatable and precise powder charges.

- Convenience: Programmable settings and automatic functions reduce operator workload.

- Advanced Features: Some models include memory functions to save load data, automatic calibration, and self-learning dispensing rates.

Disadvantages of Automatic Powder Hoppers

- Higher Cost: Typically more expensive, which might be prohibitive for casual or beginner users.

- Power Requirement: Dependence on electricity can be limiting in some environments.

- Complexity and Maintenance: More moving parts and electronics require careful maintenance and occasional troubleshooting.

- Size: Larger footprint on workbenches, requiring more dedicated space.

Comparing Key Factors Between Manual and Automatic Powder Hoppers

| Factor | Manual Powder Hopper | Automatic Powder Hopper |

| Cost | Lower, affordable for beginners | Higher, investment needed for advanced tech |

| Speed | Slower, suited for small batches | Faster, optimized for large-scale reloading |

| Accuracy | Depends on user skill and method | High consistency with electronic calibration |

| Ease of Use | Requires physical operation and attention | User-friendly with programmable features |

| Maintenance | Simple, less prone to breakdowns | Requires regular calibration and servicing |

| Portability | Compact, no power needed | Bulkier, needs stable power supply |

| Suitable For | Precision handloading, hobbyists | High volume loading, production environments |

When to Choose a Manual Powder Hopper

Manual powder hoppers are ideal if you:

- Are a hobbyist or beginner starting with reloading.

- Do small batch powder measurements where speed is less critical.

- Prefer low-cost equipment.

- Have limited workspace or need portability.

- Want full control over manual powder measurement for experimental or customized loads.

When to Choose an Automatic Powder Hopper

Automatic powder hoppers are a better fit if you:

- Reload large volumes of ammunition frequently.

- Require fast, consistent, and repeatable powder charges.

- Need programmable features and automatic calibration.

- Have a dedicated workbench space with reliable power access.

- Value convenience and time savings in your workflow.

Practical Tips for Using Powder Hoppers

Manual Hopper Tips

- Use a mechanical scale for weighing powder charges precisely.

- Be patient and consistent with the trickling process.

- Regularly clean the hopper to avoid powder contamination or clogging.

- Practice careful handling to maintain safety when working with powders.

Automatic Hopper Tips

- Select a hopper with memory and automatic throw functions for efficiency.

- Calibrate regularly to maintain accuracy.

- Avoid electrical interference by positioning the unit away from power lines.

- Consider the hopper size and capacity based on your volume needs.

Innovations in Powder Hopper Technology

Recent advancements include auto-dispensing powder measures featuring digital scales that calibrate dispensing speed to powder type, improving both speed and accuracy. Some high-end models offer multiple speed settings, trickle adjustments, and memory functions to save load data for repeated use, enhancing user convenience and precision.

Frequently Asked Questions (FAQs)

1. Are automatic powder hoppers always more accurate than manual ones?

Not necessarily. While automatic hoppers provide greater consistency by reducing human error, manual powder hoppers can be very accurate for precision loads when used skillfully with proper weighing methods.

2. Can I convert my manual powder hopper into an automatic one?

Manual hoppers generally cannot be converted into automatic hoppers as they rely on different mechanisms, including electronic components found only in automatic models.

3. How much space does an automatic powder hopper usually require?

Automatic powder hoppers tend to be larger than manual ones due to the built-in electronics and larger powder reservoirs, so they require a dedicated workspace with reliable power.

4. Is digital calibration necessary for an automatic powder hopper?

Yes, digital calibration ensures the hopper dispenses the correct charge each time, which is critical for safety and consistency in reloading.

5. What are common maintenance requirements for automatic powder hoppers?

Regular cleaning of the powder channels, calibration checks, and occasional servicing of electronic components are typical maintenance tasks to keep the hopper functioning accurately.

[1] https://accuraoutdoors.com/2019/05/powder-measures-101/

[2] https://patents.google.com/patent/CN209684040U/zh

[3] https://www.reddit.com/r/reloading/comments/umqy5q/auto_dispenser_vs_manual/

[4] https://blog.csdn.net/weixin_45386937/article/details/113763997

[5] https://backfire.tv/best-reloading-powder-dispenser/

[6] https://www.163.com/opencourse/detail/video-QHIGRS7AV-YHIGRSCSB

[7] https://www.all4shooters.com/en/shooting/accessories/rcbs-chargemaster-link-chargemaster-supreme-and-matchmaster-test/

[8] https://patents.google.com/patent/CN1109583C

[9] https://forum.accurateshooter.com/threads/powder-measures-hand-vs-electronic.4005015/

[10] https://patents.google.com/patent/CN101360565A/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.