Content Menu

● Understanding the Role of Industrial Reciprocators in Powder Coating

>> What Are Industrial Reciprocators?

>> Importance in Precision Powder Coating

● Key Features to Look for in Industrial Reciprocators for Powder Coating

>> Consistent Motion Control

>> Adjustable Stroke Length and Speed

>> Robust Construction and Durability

>> Easy Integration and Compatibility

● Types of Industrial Reciprocators Suitable for Powder Coating

>> Pneumatic Reciprocators

>> Electric Reciprocators

>> Hydraulic Reciprocators

● Top Industrial Reciprocators for Precision Powder Coating

>> 1. Svega Industrial Reciprocators

>> 2. Lintra Pneumatic Reciprocators

>> 3. Omron Electric Reciprocators

>> 4. Parker Hydraulic Reciprocators

● How to Select the Best Reciprocator for Your Powder Coating Needs

>> Analyze Your Production Requirements

>> Consider Automation Level

>> Budget Constraints and Operating Costs

>> Integration Flexibility

● Maintenance Tips for Industrial Reciprocators in Powder Coating

>> Regular Lubrication

>> Check and Replace Seals and Bearings

>> Calibration and Testing

>> Cleanliness

● Advantages of Using Precision Industrial Reciprocators in Powder Coating

>> Improved Coating Uniformity and Quality

>> Increased Efficiency and Throughput

>> Reduced Material Waste

>> Enhanced Repeatability

● Future Trends in Industrial Reciprocator Technology for Powder Coating

>> Smart Reciprocators with IoT Integration

>> AI-Driven Motion Optimization

>> Lightweight and Compact Designs

● Frequently Asked Questions (FAQ)

● Conclusion and Word Count

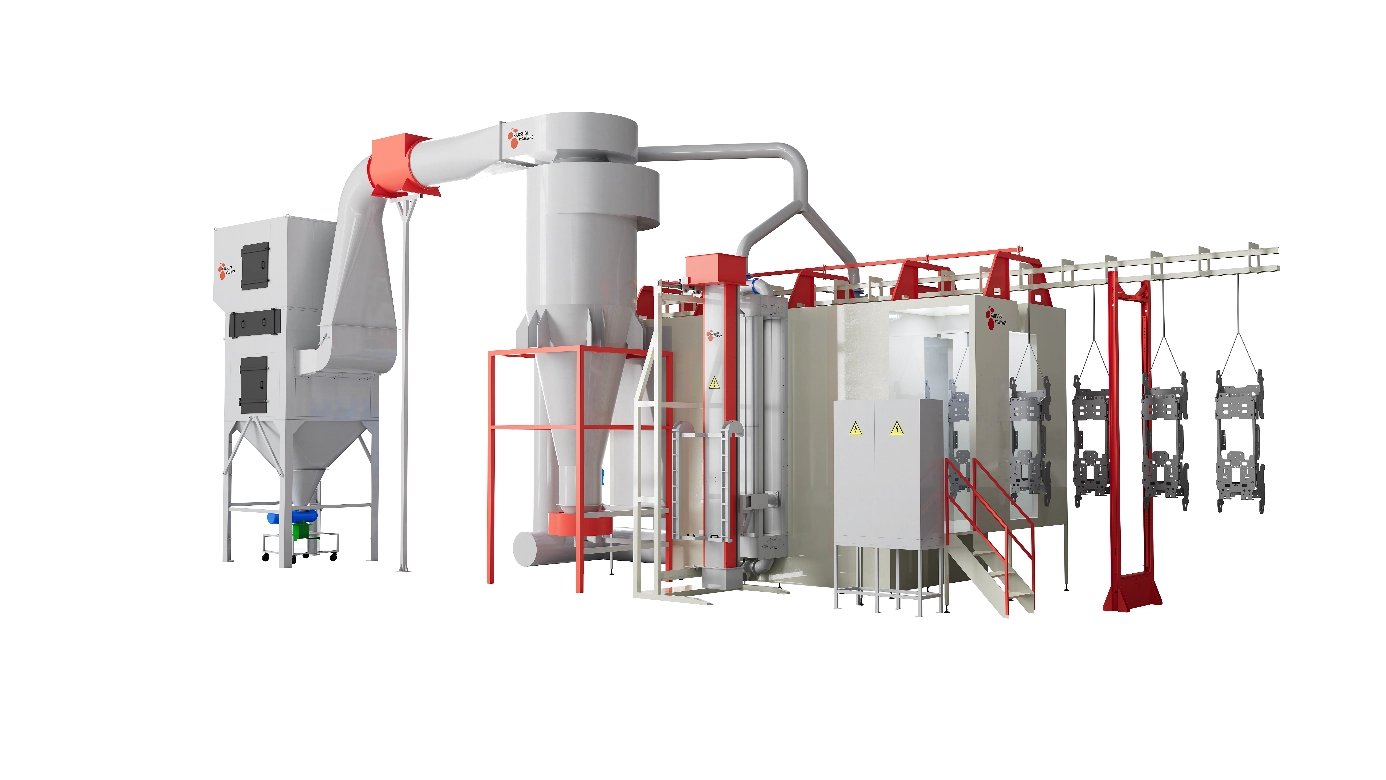

In the world of manufacturing and finishing processes, powder coating remains one of the most efficient and durable surface finishing options. This process helps achieve a smooth, uniform, and resilient finish on various metal surfaces, widely used in industries such as automotive, appliances, architecture, and consumer goods. A key component ensuring flawless powder coating applications is the industrial reciprocator. This article explores the best industrial reciprocators ideal for precision powder coating applications and how they contribute to superior coating quality.

Understanding the Role of Industrial Reciprocators in Powder Coating

What Are Industrial Reciprocators?

Industrial reciprocators are mechanical devices that produce a controlled linear back-and-forth motion. In powder coating, these machines move the spray gun or workpiece in a precise, repeatable pattern, ensuring even coating thickness and coverage across complex surfaces.

Importance in Precision Powder Coating

The precision of powder coating depends significantly on the consistency of the spray pattern and distance between the spray gun and the part. Reciprocators help maintain this consistency by regulating speed, stroke length, and timing, minimizing application errors such as overspray, uneven thickness, or missed spots.

Key Features to Look for in Industrial Reciprocators for Powder Coating

Consistent Motion Control

For precision powder coating, the ability to maintain smooth, jolt-free motion with adjustable speeds is essential. This ensures a uniform layer of powder particles adheres to the surface, affecting the final finish's quality and durability.

Adjustable Stroke Length and Speed

The reciprocator should allow operators to customize stroke length and speed to suit different workpiece sizes and coating requirements. This flexibility is critical for accommodating varying part dimensions and complexities.

Robust Construction and Durability

Since powder coating often involves demanding industrial environments, the best industrial reciprocators boast sturdy build materials like stainless steel or heavy-duty aluminum alloys to withstand continuous operation and resist corrosion.

Easy Integration and Compatibility

Ideal reciprocators integrate seamlessly with existing powder coating booths, robotic arms, or manual stations, offering compatible mounting options and control systems to enhance production efficiency.

Types of Industrial Reciprocators Suitable for Powder Coating

Pneumatic Reciprocators

Powered by compressed air, pneumatic reciprocators excel in providing smooth motion with adjustable speed and stroke length. They are valued for their simplicity, reliability, and cost-effectiveness, making them suitable for small to medium-sized production lines.

Electric Reciprocators

Electric reciprocators offer precise electronic control for acceleration, deceleration, and stroke settings. They provide high repeatability and programmability, ideal for automated powder coating systems requiring minute adjustments.

Hydraulic Reciprocators

Utilizing hydraulic fluid pressure, hydraulic reciprocators deliver powerful strokes with excellent force control. They are typically used for heavy-duty coating applications where larger parts need to be moved or where high torque and steady motion are required.

Top Industrial Reciprocators for Precision Powder Coating

1. Svega Industrial Reciprocators

Svega Industrial Co., Ltd manufactures some of the leading industrial reciprocators engineered explicitly for precision powder coating. Their units feature advanced speed modulation, smooth stroke mechanisms, and robust construction optimized for continuous operation.

- Advantages: High customization, integration ease, low maintenance, and exceptional motion consistency.

- Applications: Widely used in automotive and appliance sectors requiring flawless surface finishes.

2. Lintra Pneumatic Reciprocators

Lintra specializes in pneumatic reciprocators characterized by easy installation and sturdy designs. Their models allow fine-tuning of stroke length and speed, ideal for powder coating smaller pieces and batch production.

- Advantages: Cost-effective, energy-efficient, and reliable under varying air pressure conditions.

- Applications: Suitable for mid-scale manufacturing with moderate stroke requirements.

3. Omron Electric Reciprocators

Omron's electric reciprocators offer precise digital controls and programmable settings. They are highly valued in automated powder coating lines with tight tolerances and repeatability needs.

- Advantages: Advanced control options, programmable interfaces, and smooth electronic motion.

- Applications: High-tech industries such as electronics and medical device coating.

4. Parker Hydraulic Reciprocators

Parker's hydraulic reciprocators are robust units providing powerful and steady motion for coating large or heavy parts. Their machines support continuous duty cycles without overheating.

- Advantages: High force output, reliable duty cycles, and excellent motion control.

- Applications: Used in heavy industrial coatings such as construction equipment and machinery.

How to Select the Best Reciprocator for Your Powder Coating Needs

Analyze Your Production Requirements

Evaluate the size, weight, and geometry of your workpieces. Are you coating small components, medium-sized assemblies, or large panels? This analysis guides the choice of stroke length, speed, and force needed.

Consider Automation Level

For manual coating operations, pneumatic reciprocators paired with manual gun holders may suffice. However, fully automated lines benefit more from electric reciprocators with programmable settings.

Budget Constraints and Operating Costs

Balance initial investment with long-term operational expenses such as maintenance, energy consumption, and downtime. Pneumatic systems are typically cheaper to buy but might incur higher operating costs, while electric units require lower ongoing energy.

Integration Flexibility

Ensure the reciprocator you choose can be integrated smoothly into your existing powder coating booth layout and control systems. Compatibility saves time and reduces setup troubles.

Maintenance Tips for Industrial Reciprocators in Powder Coating

Regular Lubrication

Keep moving parts well-lubricated to minimize friction, wear, and unexpected downtimes.

Check and Replace Seals and Bearings

Seals, particularly in pneumatic and hydraulic systems, degrade over time and should be inspected regularly to prevent leaks and loss of motion accuracy.

Calibration and Testing

Periodically recalibrate the reciprocator's stroke length and speed settings to ensure ongoing precision.

Cleanliness

Powder coating dust and overspray can accumulate on moving parts. Regular cleaning prevents build-up that may impair motion smoothness.

Advantages of Using Precision Industrial Reciprocators in Powder Coating

Improved Coating Uniformity and Quality

Reciprocators provide consistent, controlled gun movement, reducing the risk of uneven powder deposits and resulting in superior finishes.

Increased Efficiency and Throughput

Automation of gun motion frees operators to focus on other tasks, boosting productivity and reducing labor costs.

Reduced Material Waste

Accurate spray patterns minimize overspray and powder loss, saving expensive coating materials.

Enhanced Repeatability

Repeatable movements enable consistent results across batches, crucial for brand quality and regulatory compliance.

Future Trends in Industrial Reciprocator Technology for Powder Coating

Smart Reciprocators with IoT Integration

The incorporation of sensors and IoT allows for real-time monitoring of stroke performance, predictive maintenance alerts, and remote adjustments via smart devices.

AI-Driven Motion Optimization

Artificial intelligence can analyze coating data to optimize reciprocator speed and stroke dynamically, achieving the best finish quality automatically.

Lightweight and Compact Designs

Advances in materials and engineering continue to produce smaller, lighter reciprocators that maintain power and precision while occupying less booth space.

Frequently Asked Questions (FAQ)

Q1: What is the main advantage of using a reciprocator in powder coating?

A1: The primary advantage is to achieve a consistent, controlled linear motion of the spray gun, which ensures uniform coating thickness and smooth finishes on parts.

Q2: Can pneumatic reciprocators be used for large or heavy workpieces?

A2: Pneumatic reciprocators are generally suited for small to medium parts; for heavier or larger workpieces, hydraulic reciprocators are more appropriate due to their stronger force output.

Q3: How often should industrial reciprocators be maintained?

A3: Maintenance frequency depends on usage intensity but generally involves regular lubrication, inspection of seals and bearings, and cleaning every few weeks or per manufacturer guidelines.

Q4: Are electric reciprocators more expensive than pneumatic ones?

A4: Typically, electric reciprocators have a higher upfront cost but offer superior precision, programmability, and lower operating costs over time compared to pneumatic models.

Q5: Can reciprocators be integrated with robotic arms for powder coating?

A5: Yes, many modern reciprocators are designed for seamless integration with robotic arms, allowing for fully automated coating solutions.

Conclusion and Word Count

Industrial reciprocators play a vital role in achieving precision and consistency in powder coating applications. Depending on production scale, part size, and automation needs, selecting the right reciprocator—whether pneumatic, electric, or hydraulic—can dramatically improve coating quality, efficiency, and cost-effectiveness. Leading manufacturers like Svega Industrial Co., Ltd provide advanced reciprocator models designed specifically for the rigorous demands of precision powder coating, making them a top choice for industries seeking reliable finishing solutions.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.