Content Menu

● Understanding Powder Flow Challenges

● Key Features of Efficient Powder Hoppers

● Types of Best Powder Hoppers for Consistent Flow

>> 1. Fluidizing Powder Hoppers

>>> How They Work

>>> Advantages

>>> Example Application

>> 2. Tilted Plane Hoppers

>>> How They Work

>>> Advantages

>>> Applications

>> 3. Gravity Hoppers

>>> How They Work

>>> Advantages

>>> Limitations

>> 4. Force-Feed and Vacuum Hoppers

>>> How They Work

>>> Advantages

>>> Applications

● Innovations and Design Considerations for Best Powder Hoppers

>> Material and Shape of Hopper Surface

>> Hopper Capacity and Accessibility

>> Powder Handling Safety and Environmental Factors

● Practical Tips for Optimizing Powder Hopper Performance

>> Proper Aeration and Fluidization

>> Use of Vibratory Assistance

>> Regular Maintenance and Cleaning

>> Customize Hopper Design for Your Powder

● Frequently Asked Questions (FAQs)

>> Q1: What is the main advantage of using a fluidizing powder hopper?

>> Q2: How does a tilted plane hopper improve powder flow consistency?

>> Q3: Can gravity hoppers work with all powder types?

>> Q4: What role do vibratory systems play in powder hoppers?

>> Q5: How can dust generation be controlled in powder hopper systems?

Powder hoppers are essential components in many industrial processes, ranging from pharmaceutical manufacturing and powder coating to food production and chemical processing. The efficiency and consistency of powder flow through a hopper can significantly influence the quality of the end product, the speed of production, and operational costs. This article explores the best powder hoppers designed for efficient and consistent powder flow, detailing their types, features, and innovations that make them ideal for various applications.

Understanding Powder Flow Challenges

Before diving into the types of powder hoppers, it's important to understand common challenges associated with powder flow in industrial settings:

- Cohesive Powders: Powders that tend to clump together, causing blockages or inconsistent flow.

- Segregation: Separation of different-sized particles, leading to uneven mixing and product quality issues.

- Bridging and Rat-Holing: Formation of arch-like blockages or channels inside the hopper, halting flow.

- Dust Generation: Free-falling powders can create dust, leading to safety and health concerns.

- Flow Rate Control: Precise control is necessary for consistent dosing and quality assurance.

The choice of the hopper and its design plays a critical role in overcoming these issues for reliable, steady delivery of powders.

Key Features of Efficient Powder Hoppers

To achieve smooth, consistent flow, powder hoppers typically incorporate:

- Fluidizing Systems: Using aeration or low-pressure air to suspend powder particles to reduce clumping.

- Vibratory Mechanisms: To encourage powder movement and prevent sticking.

- Tilted or Angled Design: Promotes gravity-assisted flow while minimizing segregation.

- Adjustable Gates: Control discharge rate and powder volume.

- Smooth Surfaces: Reduce material hang-ups inside the hopper.

- Sealing and Dust Control: Minimize dust escape and material loss.

Types of Best Powder Hoppers for Consistent Flow

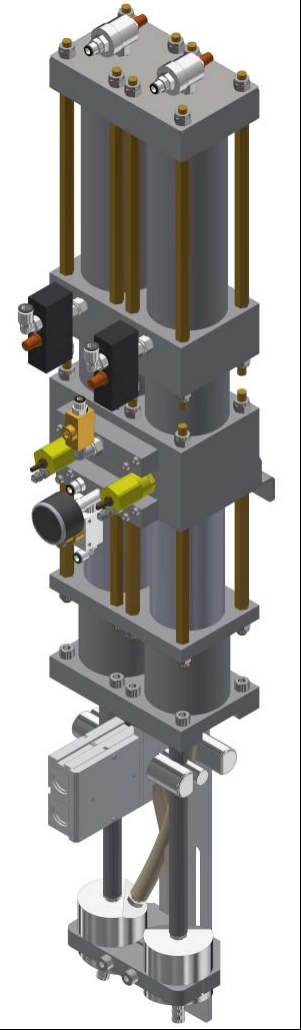

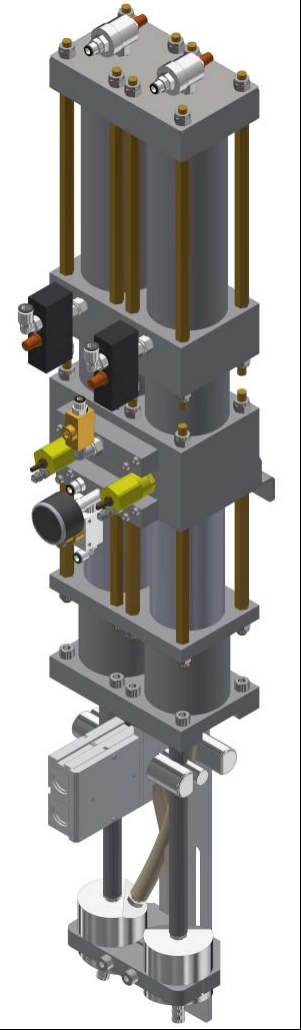

1. Fluidizing Powder Hoppers

How They Work

Fluidizing hoppers incorporate a perforated plate at the hopper base, through which low-pressure air is blown. This air suspends the powder particles, creating a fluid-like state that allows powders to flow freely without clumping or bridging.

Advantages

- Provides smooth and consistent powder flow without surges or interruptions.

- Ideal for fine and cohesive powders that tend to stick.

- Reduces waste by minimizing powder buildup and inconsistent dosing.

Example Application

The Eastwood HotCoat 5 lb Fluidizing Hopper is a high-capacity hopper engineered for powder coating operations. It includes an integral fluidizing plate, a powder pump for steady feed, and dosing air injection to enhance powder flow and reduce surging. Its design helps achieve uniform coating thickness and reduces downtime thanks to a larger powder capacity.[1]

2. Tilted Plane Hoppers

How They Work

Tilting the hopper body at an angle (usually 10-45 degrees) lets powders glide down steadily under gravity. This design reduces the risk of dead zones and stagnation by encouraging a consistent avalanche of material towards the outlet.

Advantages

- Significantly improves flow consistency compared to vertical hoppers.

- Minimizes segregation and maintains uniform powder distribution.

- Often equipped with adjustable gates for precise flow control.

- Can include vibratory features for even better discharge regulation.

Applications

These hoppers fit well in pharmaceutical tablet pressing and other industries requiring highly accurate fill weights and low weight variation in products. They also reduce dust formation during feeding by managing the powder flow rate more effectively.[3]

3. Gravity Hoppers

How They Work

Relying solely on gravity, these hoppers have a traditional vertical design where powder falls freely into downstream equipment.

Advantages

- Simple design with minimal maintenance.

- Fully open design helps with dust evacuation.

- Cost-effective for free-flowing powders with little cohesion.

Limitations

- Prone to flow interruptions with cohesive or sticky powders.

- Can generate dust and lead to uneven flow rates.

- Not ideal for powders sensitive to segregation or with irregular particle sizes.

4. Force-Feed and Vacuum Hoppers

How They Work

Force-feed hoppers utilize mechanical augers or feeders to push the powder, ensuring steady delivery without free fall. Vacuum hoppers maintain negative pressure to extract dust and deliver powder smoothly.

Advantages

- Excellent for dust control and minimizing free-fall related problems.

- Ensures continuous and uniform feeding even for difficult powders.

- Vacuum hoppers improve environmental safety by containing dust.

Applications

Common in pharmaceutical and chemical industries, particularly where dust hazard is a concern and precise dosing is mandatory.[3]

Innovations and Design Considerations for Best Powder Hoppers

Material and Shape of Hopper Surface

Smooth, polished surfaces prevent powder from sticking and building up inside the hopper. This is especially vital for sticky or hygroscopic powders.

Hopper Capacity and Accessibility

Larger capacity hoppers reduce the frequency of refilling, enhancing production efficiency. Quick-release or modular designs facilitate fast cleaning and powder changeovers to minimize downtime.[8]

Powder Handling Safety and Environmental Factors

Features such as sealed chambers, dust extraction, and inert gas blanketing are incorporated in high-end hoppers to ensure operator safety and reduce environmental contamination.

***

Practical Tips for Optimizing Powder Hopper Performance

Proper Aeration and Fluidization

Adjust aeration air pressure carefully to create a fluidized bed without blowing powder out of the hopper. Consistent air distribution ensures uninterrupted flow.

Use of Vibratory Assistance

Vibrators attached to the hopper walls or base help overcome cohesive forces and prevent material hang-up.

Regular Maintenance and Cleaning

Routine cleaning prevents cross-contamination and buildup inside the hopper, which can affect flow consistency.

Customize Hopper Design for Your Powder

Considering the powder's properties such as particle size, shape, moisture content, and cohesiveness guides the selection or customization of hopper type and design.

Frequently Asked Questions (FAQs)

Q1: What is the main advantage of using a fluidizing powder hopper?

A1: Fluidizing hoppers use low-pressure air to suspend powder, which prevents clumping and ensures a consistent, smooth flow ideal for fine and cohesive powders.

Q2: How does a tilted plane hopper improve powder flow consistency?

A2: Its angled design promotes steady gravity flow while reducing powder segregation and stagnant zones, resulting in uniform product feed.

Q3: Can gravity hoppers work with all powder types?

A3: Gravity hoppers are best suited for free-flowing powders. They may not work well with cohesive or sticky powders prone to clumping.

Q4: What role do vibratory systems play in powder hoppers?

A4: Vibrators help dislodge powder stuck to hopper walls and facilitate continuous powder flow, reducing blockages and bridging.

Q5: How can dust generation be controlled in powder hopper systems?

A5: Using enclosed or vacuum hoppers, minimizing free fall, incorporating dust extraction systems, and maintaining proper air pressure all help reduce dust emissions.

[1] https://www.youtube.com/watch?v=p3AKv3NbJ58

[2] https://patents.google.com/patent/CN203551072U/zh

[3] https://pharmamanual.com/unlocking-the-power-of-your-tablet-press-a-guide-to-hopper-types-and-design/

[4] https://patents.google.com/patent/CN101360565A/zh

[5] https://jenike.com/improve-powder-flowability/

[6] https://patents.google.com/patent/CN1109583C

[7] https://www.azocleantech.com/article.aspx?ArticleID=1927

[8] https://www.oerlikon.com/ecoma/files/DSE-0044_Twin-Single_Hoppers_ZH.pdf?download=true

[9] https://www.sciencedirect.com/science/article/pii/S2405844023037052

[10] https://patents.google.com/patent/CN105600501B/pt-PT

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.