Content Menu

● Introduction to Automatic Spray Booths

● Key Features of Automatic Spray Booths

>> Programmable Controllers

>> Robotic Arms

>> Advanced Ventilation Systems

>> Real-Time Monitoring and Diagnostics

● Benefits of Automated Spray Booths

>> Increased Safety

>> Scalability

>> Consistency and Quality

● Choosing the Right Automatic Spray Booth System

● Maintenance and Safety Considerations

● Conclusion

● Frequently Asked Questions

● Citations:

When it comes to selecting an automatic spray booth system, there are several key features to consider. These features not only enhance the efficiency and quality of the painting process but also ensure safety and compliance with industry standards. In this article, we will delve into the essential components and considerations for choosing the right automatic spray booth system for your operations.

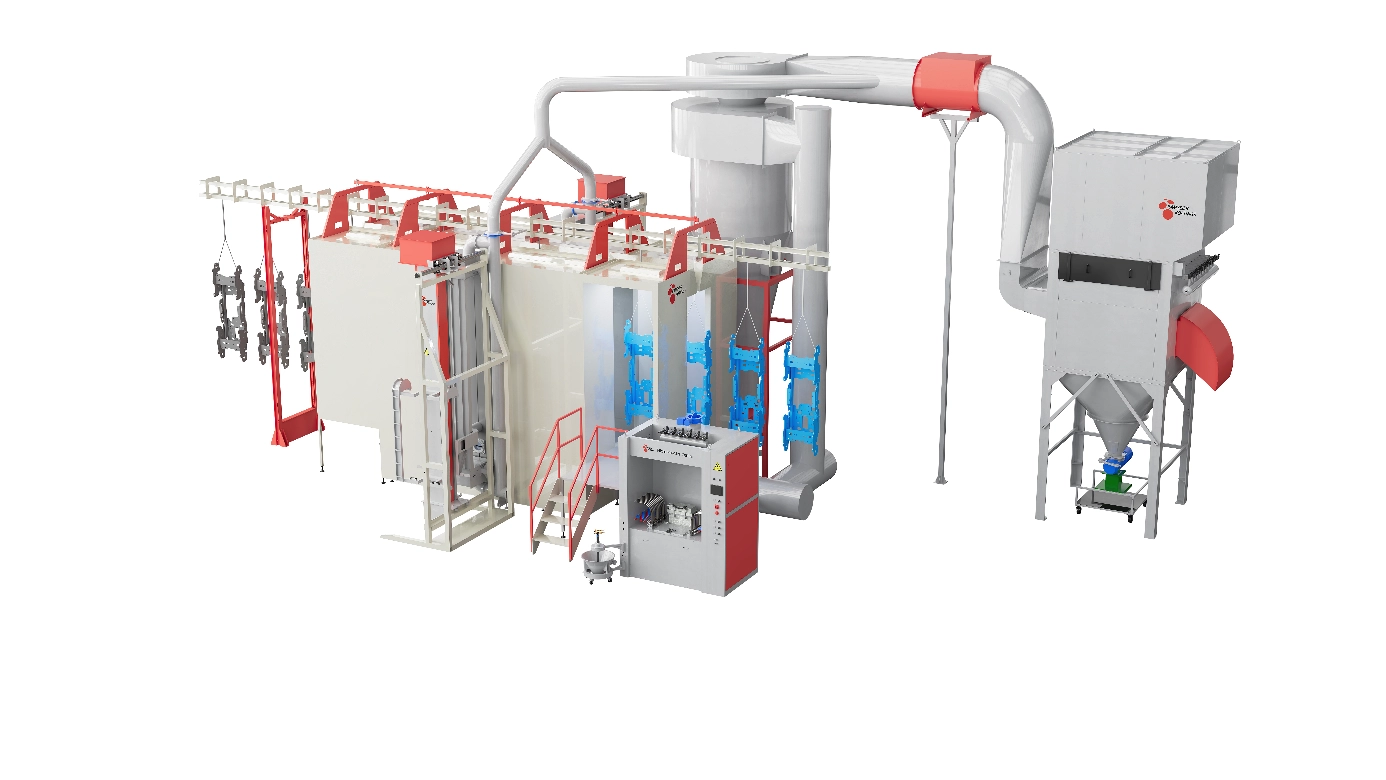

Introduction to Automatic Spray Booths

Automatic spray booths are designed to streamline the painting process by integrating advanced technology that controls various aspects such as airflow, temperature, and paint application. These systems are programmable, allowing for precise control over environmental conditions, which is crucial for achieving consistent and high-quality finishes. By automating the painting process, businesses can significantly reduce manual labor, minimize errors, and enhance productivity.

Key Features of Automatic Spray Booths

Programmable Controllers

Programmable controllers are a fundamental feature of automatic spray booths. They allow for precise control over airflow, temperature, and paint application, ensuring that the system can be customized to meet specific requirements. This level of control is essential for maintaining consistent environmental conditions, which is critical for achieving uniform paint finishes.

Robotic Arms

Robotic arms are used in automated spray booths to apply paint with precision and consistency. These arms can be programmed to follow specific paths, ensuring uniform paint coverage and reducing overspray. The use of robotic arms not only improves the quality of the finish but also enhances repeatability, making them ideal for complex painting tasks.

Advanced Ventilation Systems

Advanced ventilation systems are another critical feature of automatic spray booths. These systems maintain optimal air quality by ensuring the safe removal of fumes and overspray. High-efficiency filters capture contaminants, maintaining clean air and preventing the buildup of hazardous materials. Proper ventilation is essential for both safety and quality, as it helps prevent accidents and ensures a clean workspace.

Real-Time Monitoring and Diagnostics

Real-time monitoring systems track the performance of the spray booth, identifying potential issues before they become serious problems. This capability allows for proactive maintenance, reducing downtime and ensuring optimal performance. Diagnostic alerts notify operators of maintenance needs or system errors, enabling prompt action to be taken.

Benefits of Automated Spray Booths

Increased Safety

Automated spray booths enhance safety by reducing the need for manual labor in hazardous environments. Workers are less exposed to harmful fumes and chemicals, and the risk of accidents is minimized. Advanced safety features such as emergency shutoffs and real-time monitoring further enhance safety.

Scalability

Automated spray booths can be easily scaled to accommodate increased production demands. As businesses grow, automation systems can be adjusted to handle higher volumes without sacrificing quality or efficiency. This flexibility makes automated systems future-proof, ensuring that operations are prepared for future growth.

Consistency and Quality

Automated spray booths ensure consistent and high-quality finishes by maintaining precise control over environmental conditions and paint application. This consistency reduces the need for rework, saving time and resources.

Choosing the Right Automatic Spray Booth System

When selecting an automatic spray booth system, several factors must be considered:

- Size and Space: The size of the booth should be appropriate for the workpieces being painted, and there should be sufficient space for installation.

- Type of Paint: The booth should be compatible with the type of paint or coating being used.

- Airflow Type: Different airflow systems, such as crossdraft or downdraft, offer varying levels of efficiency and suitability for different painting processes.

- Maintenance Requirements: Regular maintenance is crucial for maintaining efficiency and safety. Consider the ease of maintenance and the availability of spare parts.

Maintenance and Safety Considerations

Regular maintenance is essential for ensuring the longevity and efficiency of the spray booth. This includes daily tasks such as sweeping floors and inspecting air filters, as well as more infrequent tasks like cleaning exhaust ducts and replacing filters. Safety protocols should also be implemented, including the use of personal protective equipment and regular safety training for operators.

Conclusion

In conclusion, selecting the right automatic spray booth system involves considering a range of features and factors. By understanding the key components and benefits of automated spray booths, businesses can enhance their painting operations, improve safety, and increase productivity.

---

Frequently Asked Questions

1. What are the primary benefits of using automated spray booths?

- The primary benefits include increased safety, improved consistency and quality of finishes, enhanced efficiency, and scalability.

2. How do robotic arms improve the painting process in automated spray booths?

- Robotic arms ensure precise and consistent paint application, reducing overspray and improving the quality of the finish.

3. What types of airflow systems are commonly used in spray booths?

- Common types include crossdraft, downdraft, and semi-downdraft systems, each offering different advantages depending on the specific painting needs.

4. Why is regular maintenance important for spray booths?

- Regular maintenance ensures optimal performance, prolongs equipment lifespan, and prevents accidents by identifying potential issues early.

5. What safety features should be considered when choosing an automated spray booth?

- Key safety features include advanced ventilation systems, emergency shutoffs, and real-time monitoring systems.

---

Citations:

[1] https://pfsspraybooths.com/advantages-of-using-automated-spray-booths-in-your-operation

[2] https://www.codinter.com/en/spray-booths-a-complete-guide/

[3] https://www.godnfinishing.com/Products/automatic-spray-paint-booth/

[4] https://marathonspraybooths.com/industrial-spray-booth-maintenance-guide/

[5] https://relyonusa.com/how-to-choose-commercial-spray-booths/

[6] https://productionsystems-usa.com/paint-spray-booth-cleaning-and-maintenance-tips-preserving-your-investment-while-maximizing-job-results/

[7] https://www.spraysystems.com/how-automated-spray-booth-systems-can-save-you-time-and-money/

[8] https://www.betagroupltd.com/news/factors-to-consider-when-choosing-a-new-spray-booth/

[9] https://www.ultrimaxstore.com/blogs/news/top-6-paint-spray-booth-design-considerations

[10] https://www.spraysystems.com/spray-paint-booth-repairs-and-maintenance/

[11] http://saicozero.com/how-to-choose-the-right-spray-booth/

[12] https://pfsspraybooths.com/ensuring-safety-in-your-spray-booth-best-practices-and-tips

[13] https://relyonusa.com/proper-spray-booth-maintenance/

[14] https://www.ecotechsystems.net/choosing-the-right-paint-booth-for-you

[15] https://globalfinishing.com/2020/04/07/which-airflow-style-is-best-for-my-paint-booth/

[16] https://www.spraysystems.com/questions-to-address-when-purchasing-a-spray-booth/

[17] https://pfsspraybooths.com/analyzing-paint-booth-air-flow-which-is-best

[18] https://www.spraysystems.com/safety-features/

[19] https://www.practicalmachinist.com/forum/threads/paint-booth-recommendations.337503/

[20] https://alliedcleanrooms.com/paint-booths-types-and-benefits/

[21] https://www.iqsdirectory.com/articles/paint-finishing-equipment/paint-spray-booths.html

[22] https://www.youtube.com/watch?v=vaCfdEH528c

[23] https://jmcautomotiveequipment.com/pages/buyers-guide/automotive-paint-booth-guide.html

[24] https://www.linkedin.com/pulse/key-features-look-spray-paint-booth-gelengg-gzwxf

[25] https://www.stateauto.com/content/make-your-auto-body-paint-spray-booth-smooth-operation

[26] https://www.aiacanada.com/news/key-considerations-to-select-the-right-spray-booth/

[27] https://www.spraysystems.com/nfpa-33-a-guide-to-fire-safety-compliance-for-paint-spray-booths/

[28] https://relyonusa.com/five-essential-tips-paint-booth-maintenance/

[29] https://pfsspraybooths.com/the-ultimate-paint-booth-usage-guide-for-perfect-results

[30] https://www.paint-booths.com/blog/paint-booth-maintenance-how-to-clean-your-booth/

[31] https://roboticpaint.com/how-to-select-a-suitable-paint-booth/

[32] https://www.spraysystems.com/nfpa-33/

[33] https://globalfinishing.com/2020/03/25/spring-paint-booth-cleaning-checklist/

[34] https://pchrome.com/how-to/paint-booth-basics-choosing-right-paint-booth/

[35] https://www.reddit.com/r/Luthier/comments/13y27dn/tips_on_optimizing_paint_booth_setup/

[36] https://www.youtube.com/watch?v=LufX7tj_v8E

[37] https://globalfinishing.com/2021/01/26/understanding-the-4-modes-of-heated-automotive-paint-booths/

[38] https://vocal.media/journal/the-science-behind-spray-booths-how-they-work

---

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.