Content Menu

● Introduction

● What is a Wholesale Manual Spray Booth System?

● Key Components of a Manual Spray Booth System

>> Walls and Doors

>> Air Intake Plenum

>> Exhaust Chamber

>> Filtration System

>> Lighting and Controls

● Types of Manual Spray Booth Systems

● Design Considerations for Wholesale Manual Spray Booth Systems

>> Manual vs. Automatic Application

>> Quality of Finish

>> Multiple Coatings

>> Customization and OEM Services

● Installation and Assembly

● Safety and Compliance

>> Operator Protection

>> Ventilation

>> Regulatory Standards

● Benefits of Choosing a Wholesale Manual Spray Booth System

● Selecting the Right Wholesale Manual Spray Booth System

● Frequently Asked Questions (FAQs)

>> 1. What are the main advantages of a wholesale manual spray booth system?

>> 2. How does airflow design impact the performance of a manual spray booth system?

>> 3. Can a manual spray booth system be customized for different brands and applications?

>> 4. What safety features should a manual spray booth system include?

>> 5. How do I determine the right size and configuration for my spray booth system?

● Citations:

Introduction

In the world of industrial and automotive finishing, the *Wholesale Manual Spray Booth System* stands as a cornerstone solution for businesses seeking high-quality, consistent, and safe paint application. Whether you are an OEM, brand owner, wholesaler, or manufacturer looking to expand your product line or streamline your finishing process, understanding the intricacies of manual spray booth systems is essential. This comprehensive guide delves into the design, function, benefits, and selection criteria for wholesale manual spray booth systems, providing valuable insights for international buyers and industry professionals.

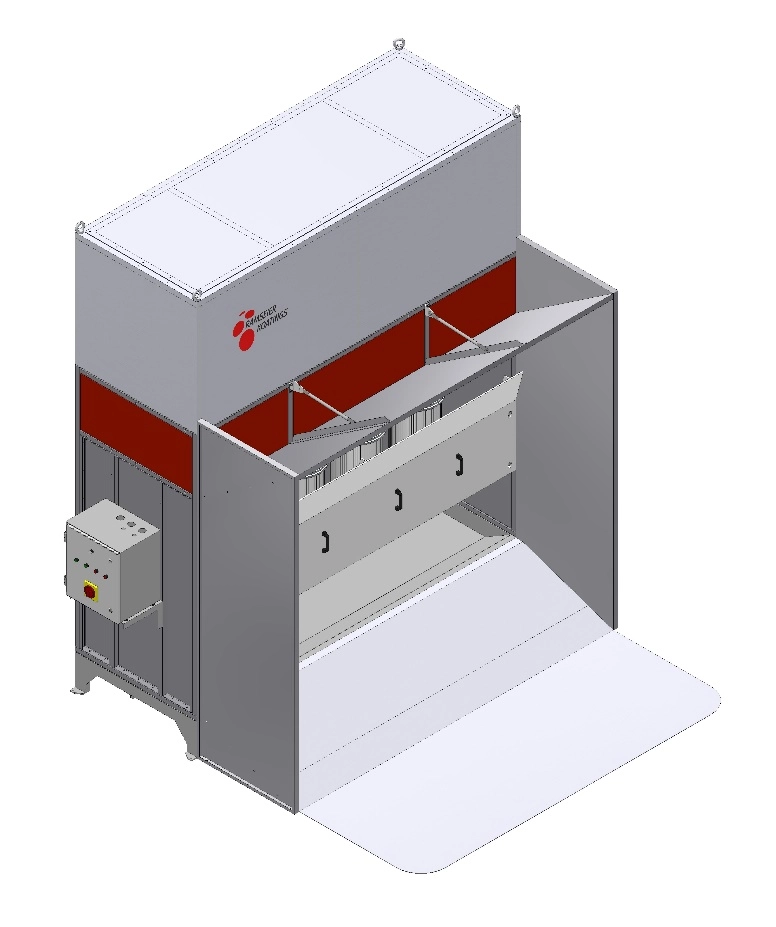

What is a Wholesale Manual Spray Booth System?

A *Wholesale Manual Spray Booth System* is an enclosed workspace designed for the manual application of paints and coatings. These systems are engineered to control environmental variables such as airflow, filtration, and containment of overspray, ensuring both operator safety and high-quality finishes. Wholesale solutions are tailored for bulk buyers, offering cost advantages and customization for different brands and applications.

Key Components of a Manual Spray Booth System

Walls and Doors

- Constructed from durable materials to contain overspray and fumes.

- Doors may be filtered or solid, depending on whether the booth is pressurized or non-pressurized[3].

- Proper design ensures easy access and maintenance while maintaining a controlled environment.

Air Intake Plenum

- Introduces clean, filtered air into the booth, either from the floor or overhead.

- Maintains a dust-free environment essential for quality finishes[3].

Exhaust Chamber

- Removes contaminated air, overspray, and fumes.

- Features various airflow designs such as crossdraft, semi-downdraft, side downdraft, and downdraft, each with unique advantages for different applications[3].

Filtration System

- Captures particulate matter and volatile organic compounds (VOCs) to protect both operators and the environment.

- Multiple stages of filters are often used for maximum efficiency.

Lighting and Controls

- High-intensity, explosion-proof lighting ensures visibility and safety.

- Control panels manage airflow, temperature, and other environmental variables.

Types of Manual Spray Booth Systems

| Type | Airflow Pattern | Key Advantages | Typical Applications |

| Crossdraft | Front-to-back | Economical, easy installation | General automotive, industrial |

| Semi-Downdraft | Angled, diagonal | Improved contaminant removal | Mid-range finishing |

| Side Downdraft | Ceiling to side walls | Even airflow, minimal overspray | High-quality finishes |

| Downdraft | Ceiling to floor | Premium finish, best contaminant control | Automotive, aerospace, luxury |

Design Considerations for Wholesale Manual Spray Booth Systems

Manual vs. Automatic Application

- Manual booths require stringent airflow and filtration to ensure operator safety due to higher paint overspray.

- Automatic systems may allow for simpler filtration since less overspray is generated, but manual booths offer flexibility for custom jobs and lower upfront costs[2].

Quality of Finish

- Functional coatings (e.g., rust inhibitors) can be applied in basic booths.

- High-quality finishes demand advanced airflow, temperature control, and cleanliness[2].

Multiple Coatings

- Some booths are designed to allow for multiple coatings in one cycle, maximizing efficiency and saving floor space[2].

Customization and OEM Services

- Wholesale manual spray booth systems can be customized for brand owners, OEMs, and distributors, including branding, size, and functional features.

Installation and Assembly

Proper installation is critical for optimal performance and safety. Key steps include:

- Site selection and layout planning (considering exhaust stack placement and door locations).

- Assembly of wall and ceiling panels, ensuring all joints are plumb and square[4].

- Installation of intake and exhaust systems, anchoring panels to the floor, and verifying system integrity.

- Final checks for airflow, filtration, and control systems before commissioning[4].

Safety and Compliance

Operator Protection

- Enclosures protect operators from hazardous fumes, overspray, and particulate matter.

- Negative pressure is maintained to prevent contaminants from escaping into the workspace[5].

Ventilation

- Proper ventilation is essential to remove airborne contaminants and maintain air quality.

- Entry timers and interlocks may be used to ensure the booth is safe to enter after spraying[5].

Regulatory Standards

- Compliance with local and international safety standards is mandatory.

- Features such as explosion-proof lighting, emergency shut-off, and proper filtration are standard in quality systems.

Benefits of Choosing a Wholesale Manual Spray Booth System

- Cost Efficiency: Bulk purchasing and OEM customization reduce per-unit costs.

- Flexibility: Manual systems accommodate a wide range of part sizes and coating types.

- Quality Control: Consistent environmental control ensures repeatable, high-quality finishes.

- Brand Customization: OEM services allow for private labeling and tailored features for brand owners and distributors.

Selecting the Right Wholesale Manual Spray Booth System

When sourcing a system, consider:

- Booth Size and Configuration: Match the booth size to your typical workpieces and production volume.

- Airflow Design: Choose the airflow pattern that best suits your finish quality requirements and workspace layout.

- Filtration and Environmental Controls: Ensure the system meets or exceeds regulatory requirements for emissions and operator safety.

- Customization Options: Evaluate the supplier's ability to provide OEM branding, custom sizes, and features.

- After-Sales Support: Reliable technical support and spare parts availability are crucial for long-term operation.

Frequently Asked Questions (FAQs)

1. What are the main advantages of a wholesale manual spray booth system?

A wholesale manual spray booth system offers cost savings through bulk purchasing, customization for different brands, and flexibility for various applications, all while ensuring high-quality finishes and operator safety.

2. How does airflow design impact the performance of a manual spray booth system?

Airflow design determines how effectively contaminants are removed and how evenly coatings are applied. Downdraft and side downdraft systems offer superior contaminant control and finish quality compared to crossdraft designs[3].

3. Can a manual spray booth system be customized for different brands and applications?

Yes, OEM and private label services allow for customization in size, branding, and functional features to meet the specific needs of brand owners, distributors, and manufacturers.

4. What safety features should a manual spray booth system include?

Essential safety features include explosion-proof lighting, proper ventilation, negative pressure maintenance, interlocks, and compliance with local and international safety standards[5].

5. How do I determine the right size and configuration for my spray booth system?

Consider the size of your typical workpieces, production volume, available workspace, and the type of finishes required. Consulting with your supplier can help ensure the optimal configuration for your needs.

Citations:

[1] https://p2infohouse.org/ref/25/24086.pdf

[2] https://www.spraysystems.com/essential-design-elements-of-a-spray-booth-coatings-involved-in-the-finishing-process/

[3] https://www.ecotechsystems.net/3-key-components-of-paint-booth-design

[4] https://www.redlinestands.com/manuals/iDEAL_PSB_Manual_(SDD).pdf

[5] https://www.asminternational.org/tss/wp-content/uploads/sites/38/files/content/safety5.pdf

[6] https://www.blastone.com/product/enclosed-spray-booths/

[7] https://cabinaslagos.com/en/why-should-i-buy-a-spray-booth/

[8] https://www.si.edu/sites/default/files/unit/oshem/ch_21_paint_and_spray_operations.pdf

[9] https://dptcoating.en.made-in-china.com/product/HxhrOMJuOCpE/China-2025-Wholesale-CE-Approved-Manual-Powder-Coating-Equipment-Paint-Spray-Booth.html

[10] https://globalfinishing.com/2018/03/15/buy-paint-booth-7-steps-make-process-easier/

[11] https://www.blastone.com/paint-booth-key-components/

[12] https://www.alibaba.com/product-detail/Wholesale-Price-Electrostatic-Manual-Spray-Painting_1601162020703.html

[13] https://www.ramseierkoatings.com/automatic-vs-manual-spray-booths-which-offers-better-environmental-protection.html

[14] https://www.rwu.edu/sites/default/files/downloads/ehs/Spray%20Booth%20Procedures.pdf

[15] https://www.spraysystems.com

[16] https://airknowledge.gov/ILT/TOXC220/Current/CI/04TOXC220_Handout_Innovative_Spray_Booth_Technology.pdf

[17] https://wflitone.en.made-in-china.com/product/KJbUWdwVyjci/China-Manual-Powder-Coating-Paint-Spray-Booth-System.html

[18] https://globalfinishing.com/wp-content/uploads/2020/07/General_Purpose_Pressurized_Crossdraft_Installation_Manual.pdf

[19] https://www.saif.com/Documents/SafetyandHealth/OperationalHazards/S849_spray_finishing.pdf

[20] https://totalfinishingsupplies.com/products/manual-control-panel-for-tfs-paint-spray-booth-ul-listed

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.