Content Menu

● What Is a Vibrating Sieve?

>> How Does a Vibrating Sieve Work?

>> Common Types of Vibrating Sieves

● Key Benefits of Vibrating Sieves in Powder Applications

● Important Considerations for Choosing the Right Vibrating Sieve

>> 1. Powder Characteristics

>> 2. Type of Vibration and Motion

>> 3. Number of Sieve Decks (Layers)

>> 4. Material and Build Quality

>> 5. Cleaning and Maintenance Features

>> 6. Throughput and Capacity

>> 7. Integration and Footprint

● Typical Applications of Vibrating Sieves for Powders

● Steps to Ensure Optimal Vibrating Sieve Selection

● Additional Tips

● Related Questions and Answers

When working with powders in industries such as food processing, pharmaceuticals, chemicals, metallurgy, or recycling, achieving precise and efficient particle separation is critical. A vibrating sieve is a common and effective tool for screening powders, ensuring product quality, and removing impurities. However, selecting the right vibrating sieve for your specific powder application requires careful consideration of various factors to optimize performance and cost-effectiveness. This article guides you through understanding vibrating sieves and the key criteria for choosing the best one to suit your powder handling needs.

What Is a Vibrating Sieve?

A vibrating sieve, also known as a vibrating screen or vibratory sifter, is a mechanical device that separates materials based on particle size through vibration. It consists mainly of a motor or electromagnetic source that generates vibration forces transmitted to a mesh screen surface. Powder or granular material is fed onto the screen, and vibration causes smaller particles to pass through the mesh while larger particles remain on top, allowing classification or impurity removal.

How Does a Vibrating Sieve Work?

The operation relies on vibration intensity, frequency, and screen mesh size. The vibration agitates the powder to prevent clogging and promote efficient separation. Multiple sieve decks can be used for multi-level classification, and some machines feature cleaning mechanisms like ultrasonic or ball cleaning systems to maintain screen efficiency.

Common Types of Vibrating Sieves

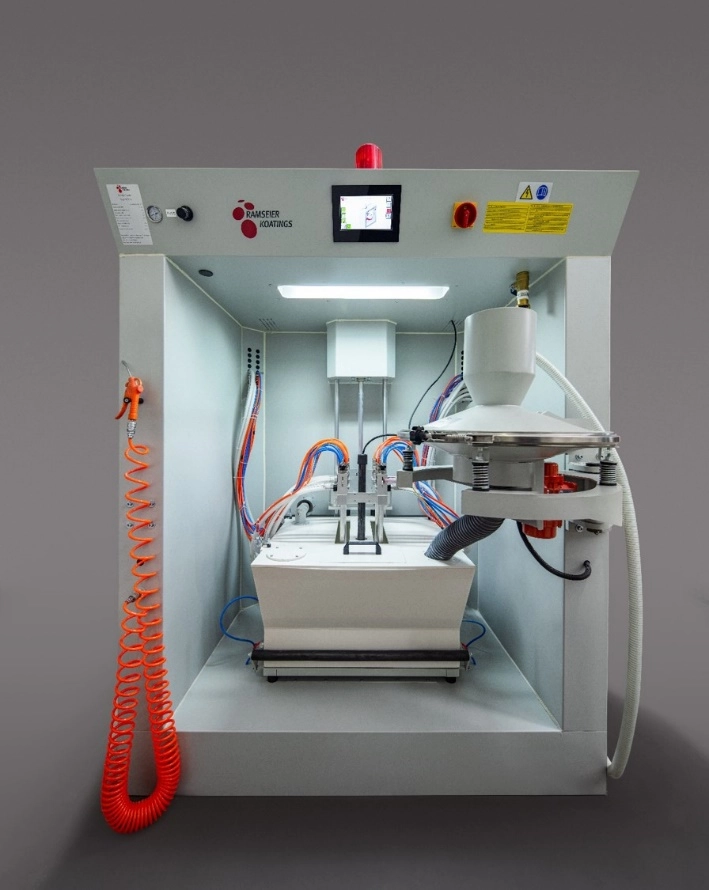

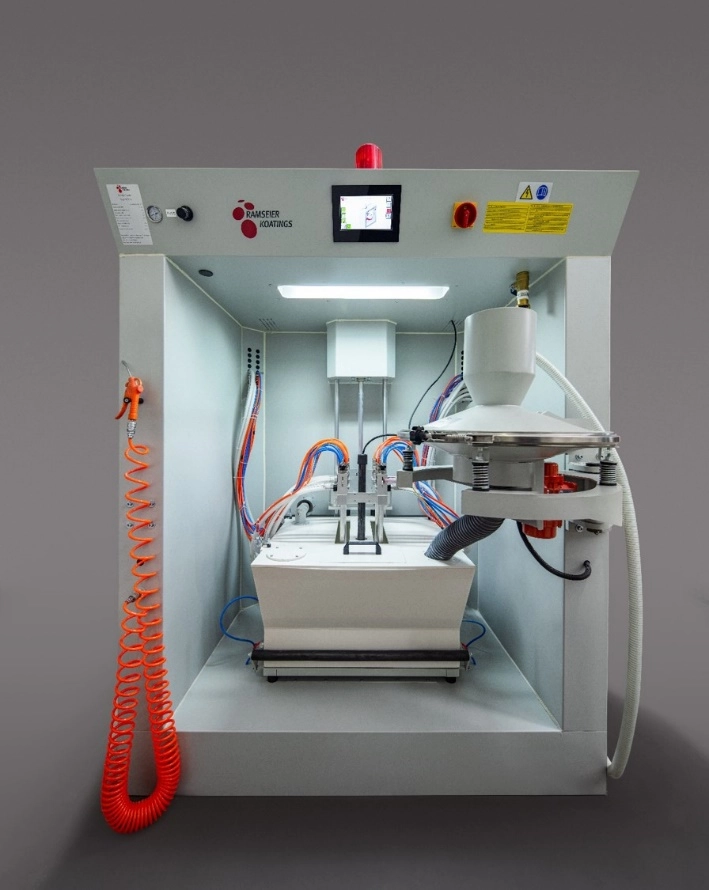

- Rotary Vibrating Sieves: Utilize motor-driven rotary motion transformed into three-dimensional vibration, effective for powders, granules, and even mucus-like materials.

- Linear Vibrating Sieves: Have a horizontal screen surface and vibrate in a linear motion, suitable primarily for dry powders.

- Electromagnetic Vibrating Sieves: Use electromagnetic pulses for precise and high-frequency sieving, ideal for fine powders requiring accuracy.

- Sieve Shaker Machines: Vibrate vertically for very precise particle size distribution testing and classification.

Key Benefits of Vibrating Sieves in Powder Applications

- High Efficiency: Capable of continuous operation at high throughput rates to meet large production demands.

- Precision: Provide stable and repeatable screening results, ensuring consistency in particle size distribution.

- Versatility: Suitable for a wide range of powders including food ingredients, chemical powders, pharmaceuticals, metal powders, and recycled materials.

- Ease of Maintenance: Features such as quick screen removal, anti-blinding mechanisms, and easy cleaning reduce downtime.

Important Considerations for Choosing the Right Vibrating Sieve

Selecting the right vibrating sieve depends on understanding your specific powder characteristics, process requirements, and operational constraints.

1. Powder Characteristics

- Particle Size Distribution: Identify the size range you need to separate or classify. The mesh size and number of sieve layers will depend on this.

- Moisture Content: Wet powders or those with sticky properties may require sieves designed to handle moisture without clogging.

- Abrasiveness: Powders that cause wear may need sieves made of durable materials such as stainless steel or polyurethane coating.

- Flow Properties: Consider how freely your powder flows; poorly flowing powders may need a vibration type that agitates well to prevent bridging.

2. Type of Vibration and Motion

- Amplitude and Frequency: Higher amplitude and frequency can improve separation efficiency but may cause excessive wear or require more power.

- Vibration Direction: Circular motion is common for general sieving, linear motion suits wet or sticky materials better by enhancing material flow.

- Motor Type: Electromagnetic motors provide high-frequency vibrations and precise control; mechanical motors are robust and good for large volumes.

3. Number of Sieve Decks (Layers)

- Single Deck: Suitable for simple separation between two size ranges.

- Multi-Deck (2-3 layers): Enable simultaneous separation into several fractions, useful for classification or grading.

4. Material and Build Quality

- Contact Parts: Should be made from food-grade stainless steel (e.g., AISI 304 or 316) if handling consumables.

- Structure: Durable construction such as carbon or alloy steel frames ensures longevity in industrial environments.

- Seals and Joints: Proper sealing avoids powder leakage and contamination, vital for pharmaceuticals or food powders.

5. Cleaning and Maintenance Features

- Screen Cleaning Systems: Ultrasonic or ball cleaning can prevent clogging or blinding of the screen mesh, maintaining steady throughput.

- Tool-Free Disassembly: Quick-release clamps and modular designs reduce downtime during screen changes.

- Sanitary Design: Smooth surfaces and minimal crevices help comply with hygiene standards and simplify cleaning.

6. Throughput and Capacity

Estimate the volume of powder to be processed per hour to select a sieve with appropriate capacity. Oversized machines can waste energy and space; undersized units can bottleneck production.

7. Integration and Footprint

- Consider how the vibrating sieve fits into your process line. Features like adjustable height, mounting options (fixed base, wheels), and compatibility with feeding or bagging stations are important.

- Space constraints may favor compact designs.

Typical Applications of Vibrating Sieves for Powders

- Food Processing: Screening flour, sugar, spices, coffee powders for safety and quality control.

- Pharmaceuticals: Precise particle size distribution for drug formulation and capsule filling.

- Chemical Industry: Separation of pigments, coating materials, fine chemicals.

- Metal Powders: Powder metallurgy applications requiring uniform granule sizes.

- Recycling: Dedusting, sorting crushed materials to prepare for reuse.

Steps to Ensure Optimal Vibrating Sieve Selection

1. Define Your Requirements: Particle sizes, powder properties, production capacity, and product quality goals.

2. Evaluate Available Models: Look for sieves designed specifically for powders with relevant features.

3. Ask About Cleaning and Maintenance: Downtime is costly, so machines with easy cleaning options are preferred.

4. Request Demonstrations or Samples: Testing powder samples can confirm sieve suitability.

5. Consider After-Sales Support: Reliable service and parts availability during installation and operation are crucial.

Additional Tips

- Avoid Over-Specifying: Choose a sieve that meets, not exceeds requirements, to optimize cost.

- Consider Automation: Some vibrating sieves include automated controls for feed rate, vibration settings, and self-cleaning.

- Safety Compliance: Ensure the sieve adheres to industry-specific safety and hygiene regulations.

Related Questions and Answers

Q1: What types of powders can vibrating sieves handle?

A1: Vibrating sieves can process a wide range of powders, from food-grade flours and spices to pharmaceuticals, chemical powders, metal powders, and recycled materials.

Q2: How do I prevent screen clogging in powder sieving?

A2: Use sieves with ultrasonic or ball cleaning systems, select appropriate vibration frequency, and consider mesh materials or coatings designed to reduce blinding.

Q3: Can vibrating sieves handle wet powders?

A3: Yes, certain types like linear vibrating sieves are better suited for wet or sticky powders thanks to their vibration motion that promotes flow and separation.

Q4: How important is the number of sieve decks?

A4: Number of decks affects classification detail. Single decks provide simple separation, while multiple decks allow simultaneous grading into several size groups.

Q5: What materials are vibrating sieves made from?

A5: Common materials include stainless steel (AISI 304 or 316) for food and pharmaceutical applications, carbon or alloy steel for structural components, and sometimes polyurethane coatings to resist wear.

[1] https://www.sollau.com/the-vpb-vpm-vibrating-sieve-for-powders-and-bulk-materials

[2] https://www.made-in-china.com/products-search/hot-china-products/Vibratory_Powder_Sieve.html

[3] https://kindle-tech.com/faqs/what-is-a-vibrating-sieve

[4] https://www.alibaba.com/showroom/sieve-vibration-sieve-device.html

[5] https://elcanindustries.com/vibrating-sieve/

[6] https://ejje.weblio.jp/content/vibrating+sieve

[7] https://www.dahanmachine.com/news-center/Application-of-Vibrating-Sieve-in-Reduced-Iron-Powder.html

[8] https://www.gea.com/zh/products/product-handling-systems/vibrating-sifters/sifters-for-powders/

[9] https://reegermachinery.com/metal-powder-sieving-application/

[10] https://patents.google.com/patent/CN113477512B/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.