Content Menu

● Understanding Vibrating Sieves for Powder Processing

>> What Makes Vibrating Sieves Essential for Powder Processing?

● Key Features of Ramseierkoatings Vibrating Sieves in 2025

>> High Frequency Vibration Technology

>> Multi-layer Screening Systems

>> Ultrasonic-assisted Sieving (H3)

>> Robust Construction and Easy Maintenance

>> Customization for Various Powders and Industries

● Advantages of Using Ramseierkoatings Vibrating Sieves for Powder Processing

>> Superior Screening Efficiency

>> Enhanced Product Quality and Consistency

>> Increased Processing Capacity and Throughput

>> Reduced Material Wastage and Operational Costs

>> Versatility Across Powder Types

● Selecting the Best Vibrating Sieve for Your Powder Processing Needs

>> Particle Size and Mesh Selection

>> Powder Properties

>> Production Throughput Needs

>> Material Compatibility

>> Footprint and Integration

● Practical Applications of Ramseierkoatings Vibrating Sieves in Powder Processing

>> Powder Coating Industry

>> Chemical and Pharmaceutical Processing

>> Food Industry

>> Metal Powder Processing

● Maintenance and Operational Tips for Maximum Performance

● Addressing Common Challenges in Powder Sieving

● Frequently Asked Questions (FAQs)

Powder processing industries increasingly rely on advanced sieving technologies to ensure product quality, consistency, and efficiency. Among the available solutions, vibrating sieves stand out as a critical component in the processing line for fine powders. In 2025, industry leaders like ramseierkoatings offer cutting-edge vibrating sieve systems tailored to evolve with the demands of powder coating and other powder processing applications. This article provides a comprehensive overview of the best vibrating sieves for powder processing in 2025, detailing their features, advantages, and ideal applications to guide users in making informed decisions.

Understanding Vibrating Sieves for Powder Processing

Vibrating sieves, also known as vibrating screens or vibratory sifters, are mechanical devices designed to separate materials based on particle size using vibration and mesh screens. They are widely used to ensure uniform particle size distributions in powders, remove contaminants, and improve product quality.

What Makes Vibrating Sieves Essential for Powder Processing?

Powder processing industries demand high precision in particle size control to maintain consistent coating thickness, flowability, and aesthetic properties in finished products. Vibrating sieves help achieve these goals by:

- Effectively separating fine powder particles with high screening accuracy.

- Preventing mesh clogging and material buildup through vibration-induced agitation.

- Enhancing screening capacity and efficiency.

- Providing versatility in screening multiple powders and particle sizes.

Such capabilities make vibrating sieves indispensable in sectors like powder coatings, pharmaceuticals, chemicals, food processing, and metallurgy.

Key Features of Ramseierkoatings Vibrating Sieves in 2025

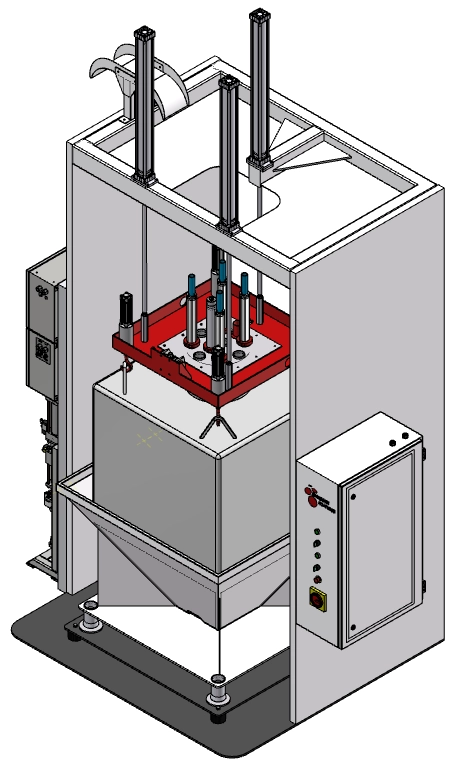

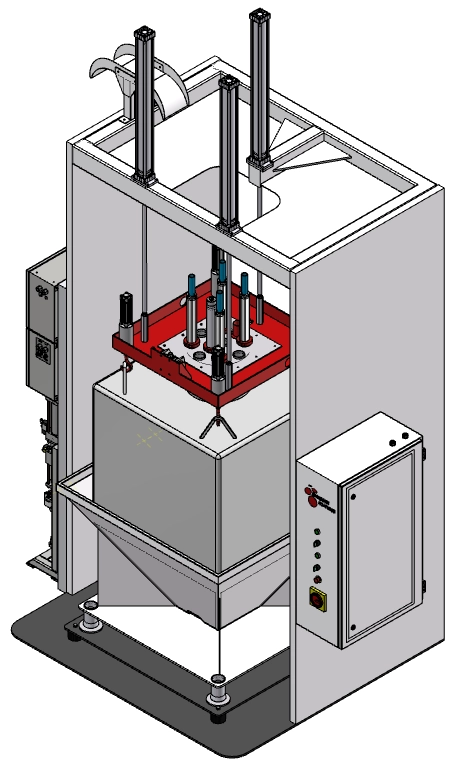

Ramseierkoatings, a leader in powder coating technology, offers vibrating sieve solutions optimized for the latest industry needs. Their systems incorporate several advanced features that set them apart in 2025.

High Frequency Vibration Technology

Ramseierkoatings vibrating sieves utilize high-frequency motors that can reach speeds up to 3000 revolutions per minute. This high-frequency vibration empowers the sieve to process materials rapidly with greater throughput—up to several tons per hour—while maintaining exceptional screening precision.

Multi-layer Screening Systems

These sieves support single to multi-layer mesh deck configurations, enabling simultaneous classification into multiple particle size ranges. This feature enhances separation accuracy and reduces the need for downstream processing steps.

Ultrasonic-assisted Sieving (H3)

For particularly challenging powder materials prone to agglomeration or static buildup, ramseierkoatings incorporates ultrasonic vibrating sieve technology. Ultrasonic waves are applied directly to the mesh, breaking up particle clusters and preventing clogging. This ensures uninterrupted processing and higher product quality.

Robust Construction and Easy Maintenance

Manufactured from high-grade stainless steel with hygienic design standards, ramseierkoatings vibrating sieves meet stringent industrial hygiene requirements while offering durability. They feature quick mesh replacement systems and are easy to clean, reducing downtime and maintenance effort.

Customization for Various Powders and Industries

Ramseierkoatings offers customization options tailored to specific powder characteristics and industry demands. Whether processing metal powders like aluminum or copper, chemicals such as resins and coatings, or fine food powders, their sieves can be configured with appropriate mesh sizes, vibration amplitudes, and screening angles.

Advantages of Using Ramseierkoatings Vibrating Sieves for Powder Processing

Superior Screening Efficiency

Combining high-frequency vibrations with ultrasonic technology allows ramseierkoatings sieves to achieve screening efficiencies upwards of 96%. This precise separation reduces off-spec product and waste, improving yield and profitability.

Enhanced Product Quality and Consistency

Consistent particle size distribution helps powder coatings achieve flawless surface finishes with minimal defects. Vibrating sieves provided by ramseierkoatings ensure that only properly sized particles proceed, contributing to high-gloss, smooth powder coating applications.

Increased Processing Capacity and Throughput

The high-speed motors and multi-layer configurations allow large volumes of powder to be processed continuously, meeting industrial-scale demand. This capability supports automated production lines and reduces bottlenecks.

Reduced Material Wastage and Operational Costs

Efficient sieving minimizes material loss and contamination. Additionally, features like ultrasonic cleaning reduce manual cleaning frequency and extend mesh life, lowering operating expenses over time.

Versatility Across Powder Types

Ramseierkoatings vibrating sieves are capable of handling a wide array of powder materials including chemical powders, food powders, metal powders, and specialty coatings. This versatility benefits manufacturers with diverse product lines.

Selecting the Best Vibrating Sieve for Your Powder Processing Needs

Choosing the optimal vibrating sieve involves evaluating several critical factors aligned with your powder characteristics and process requirements.

Particle Size and Mesh Selection

The mesh size must correspond to the smallest particle size you need to separate. Ramseierkoatings offers sieve meshes ranging typically from coarse (several millimeters) to ultra-fine (8-600 mesh).

Powder Properties

Powders with high viscosity, tendency to agglomerate, or static electricity challenge standard sieves. Consider ultrasonic vibrating sieve options to maintain continuous screening.

Production Throughput Needs

Estimate your powder processing volume to select a vibrating sieve with appropriate capacity. Ramseierkoatings sieves support outputs from hundreds of kilograms to multiple tons per hour.

Material Compatibility

Ensure the sieve materials are compatible with your powders, especially corrosive or abrasive substances. Stainless steel and hygienic designs are advisable for chemical and food-grade applications.

Footprint and Integration

Consider the space available and the need for integration into existing production lines. Ramseierkoatings offers compact and mobile units with universal wheels for flexibility.

Practical Applications of Ramseierkoatings Vibrating Sieves in Powder Processing

Powder Coating Industry

The powder coating process demands uniform particle sizes for smooth application and defect-free finishes. Ramseierkoatings vibrating sieves aid in removing oversized particles and contaminants from powder batches before application, safeguarding finish quality.

Chemical and Pharmaceutical Processing

Precise particle size control ensures efficacy and consistency in chemical powders and pharmaceuticals. Vibrating sieves engineered by ramseierkoatings facilitate high-precision screening essential for these regulated industries.

Food Industry

Uniform fine powders such as starch, sugar, and milk powder benefit from sieving to maintain flow characteristics and prevent lumping. Ramseierkoatings sieves comply with food-grade standards, ensuring safety.

Metal Powder Processing

In metallurgy and additive manufacturing, particle size affects sintering and melting behavior. Ramseierkoatings vibrating sieves effectively separate metal powders such as aluminum and copper, supporting quality control.

Maintenance and Operational Tips for Maximum Performance

Proper operation and maintenance prolong the lifespan and efficiency of vibrating sieves.

- Regularly inspect mesh screens and replace worn or damaged ones.

- Clean sieves thoroughly between batches to prevent contamination.

- Monitor vibration motor performance and service as recommended.

- Adjust vibration frequency and amplitude based on powder behavior for optimal screening.

- Utilize ultrasonic functions effectively with powders prone to clogging.

Addressing Common Challenges in Powder Sieving

Even with advanced vibrating sieves, operators may face issues such as mesh blinding, powder build-up, or inconsistent output. Ramseierkoatings offers support and customization to tackle these problems, including:

- Automatic mesh cleaning via ultrasonic waves.

- Adjustable vibration parameters to optimize flow.

- Modular design for quick disassembly and troubleshooting.

Frequently Asked Questions (FAQs)

Q1: Can vibrating sieves handle very fine powders like those under 10 microns?

A1: Yes. Advanced vibrating sieves with high-frequency and ultrasonic capabilities can effectively screen powders down to micro and sub-micro sizes.

Q2: How does ultrasonic vibration improve sieve performance?

A2: Ultrasonic vibrations prevent particles from sticking to the mesh by breaking up agglomerates and reducing static, thus maintaining continuous flow and reducing clogging.

Q3: What industries benefit most from ramseierkoatings vibrating sieves?

A3: Key industries include powder coatings, pharmaceuticals, chemicals, food processing, and metal powder production due to high precision and hygiene requirements.

Q4: How often should the sieve mesh be replaced?

A4: Replacement frequency depends on usage and powder abrasiveness but generally ranges from several months to a year. Regular inspection is essential.

Q5: Are vibrating sieves compatible with automated production lines?

A5: Yes. Ramseierkoatings vibrating sieves can be integrated with automated systems, supporting continuous operation with high throughput.

[1] https://vibratingscreen.en.made-in-china.com/product/MZsfkDIOEHUm/China-60-Mesh-Sifter-Industrial-Powder-Coating-Sieve-Vibrating-Screen-Equipment.html

[2] https://patents.google.com/patent/CN114262791A/zh

[3] https://www.dahanmachine.com/news-center/What-is-The-Cost-of-Vibrating-Sieve-.html

[4] https://ejje.weblio.jp/content/vibrating+sieve

[5] https://www.ramseierkoatings.com/powder-sieve-vs-vibrating-sieve-which-is-best-for-your-powder-coating-process.html

[6] https://patents.google.com/patent/CN202506590U/zh

[7] https://elcanindustries.com/toll-processing/best-industrial-screening-machines-sieving-equipment/

[8] https://www.gea.com/zh/products/product-handling-systems/vibrating-sifters/sifters-for-powders/

[9] https://www.alibaba.com/showroom/detergent-powder-vibration-sieve.html

[10] https://patents.google.com/patent/CN107470140A/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.