Content Menu

● Understanding the Basics of Sieving Technology

>> What Is a Vibrating Sieve?

>> What Is a Rotary Sieve?

● Main Differences Between Vibrating and Rotary Sieves

>> Operating Principle

>> Design and Structure

>> Screening Efficiency and Particle Flow

>> Noise and Maintenance

● Advantages and Limitations

>> Advantages of Vibrating Sieves

>> Limitations of Vibrating Sieves

>> Advantages of Rotary Sieves

>> Limitations of Rotary Sieves

● Typical Applications in Powder Processing

>> Vibrating Sieves

>> Rotary Sieves

● How to Choose Between a Vibrating Sieve and a Rotary Sieve?

>> Consider the Material Characteristics

>> Evaluate the Required Capacity and Throughput

>> Assess Space and Installation Constraints

>> Maintenance and Operating Costs

● Case Study Examples

>> Food Industry

>> Pharmaceutical Industry

>> Spice Processing

● Maintenance Tips for Both Types

>> Vibrating Sieves

>> Rotary Sieves

● Frequently Asked Questions (FAQs)

>> 1. Can I use a vibrating sieve for sticky powders?

>> 2. Which sieve type is quieter in operation?

>> 3. What is the typical throughput difference?

>> 4. Are vibrating sieves easier to clean?

>> 5. Which sieve type is more energy-efficient?

In powder processing industries, sieving plays a crucial role in classifying particles by size to ensure product quality, uniformity, and process efficiency. When choosing between vibrating sieves and rotary sieves for powder applications, understanding their operating principles, advantages, and limitations is essential for selecting the right equipment that fits your production needs. This article explores the key differences, typical applications, and decision criteria between vibrating sieves and rotary sieves for powder handling.

Understanding the Basics of Sieving Technology

What Is a Vibrating Sieve?

A vibrating sieve, also called a vibratory sieve or vibrating screen, uses vibration to separate particles based on size. A motor generates vibrations transmitted to the sieve mesh, causing particles to move and pass through the mesh if they are smaller than the openings. Vibrating sieves rely primarily on gravity and vibration for particle movement and screening. This technology is widely used for powders, granules, and small aggregates where size classification and removal of oversized particles are required.

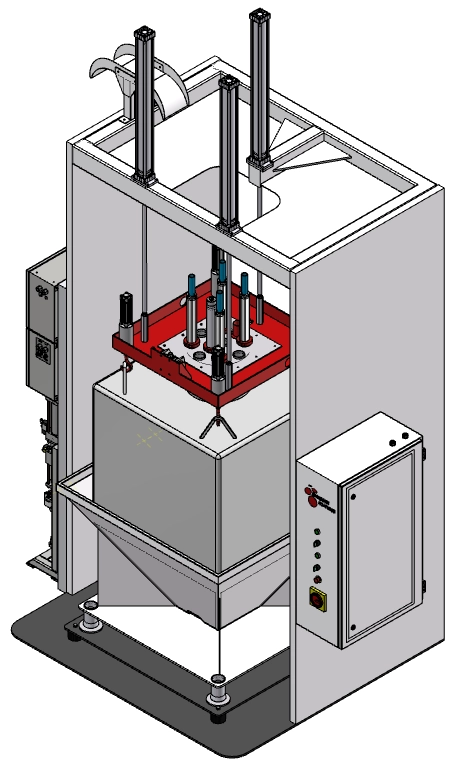

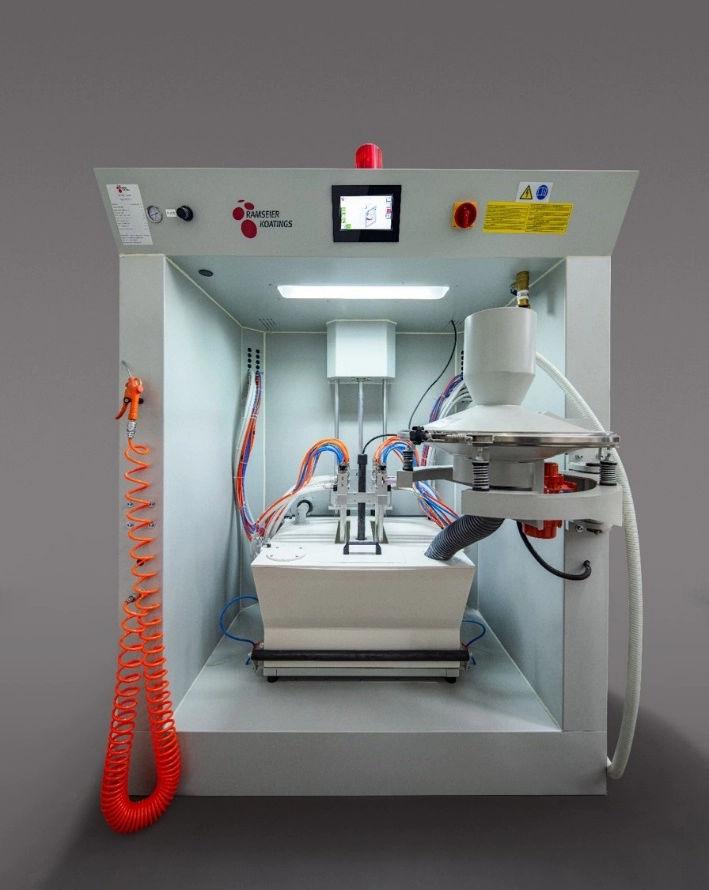

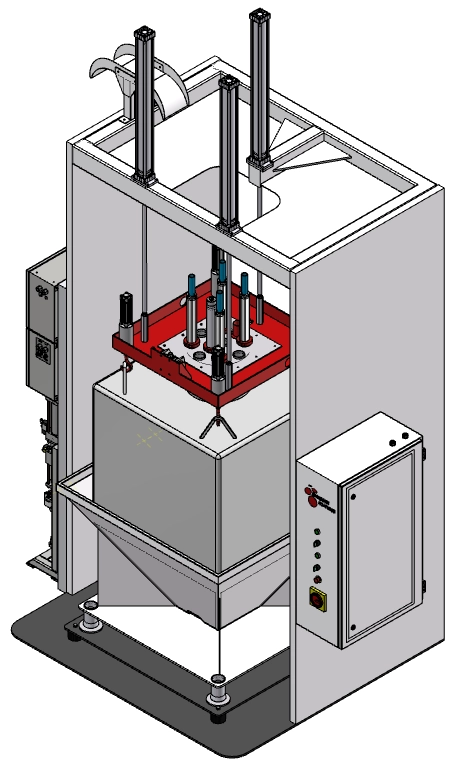

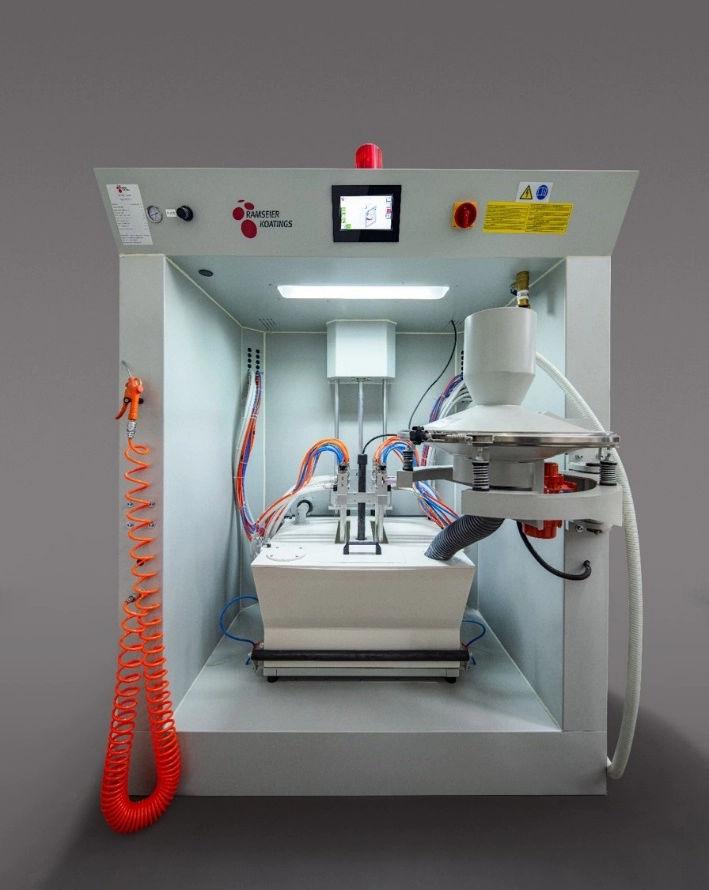

What Is a Rotary Sieve?

A rotary sieve, often known as a rotary sifter or centrifugal sifter, operates on the principle of centrifugal force. It contains a rotating screw conveyor or paddles that push the powder particles against the sieve mesh at high speed. This centrifugal force drives the finer particles through the mesh while oversized materials are excluded. Rotary sieves typically have a cylindrical design and provide continuous screening suitable for processing large volumes and friable materials.

Main Differences Between Vibrating and Rotary Sieves

Operating Principle

- Vibrating Sieve: Uses vibration motor to induce shaking or tumbling motion, helping particles pass through the mesh by gravity assistance.

- Rotary Sieve: Uses rotational force (centrifugal force) generated by spinning paddles or screws to push particles through the mesh.

Design and Structure

- Vibrating Sieve: Usually compact with an external vibration motor. The sieve deck is stationary except for vibration.

- Rotary Sieve: Features a rotating shaft conveyor inside a cylindrical screen. Particles are conveyed axially while being sifted circumferentially.

Screening Efficiency and Particle Flow

- Vibrating Sieve: Particle flow depends on vibration intensity and amplitude, making it suitable for powders that flow freely.

- Rotary Sieve: The centrifugal force ensures consistent pressure on particles against the mesh, leading to higher throughput especially for sticky, lumpy, or agglomerated powders.

Noise and Maintenance

- Vibrating Sieve: May generate significant noise due to vibration; screens are easily accessible for replacement and cleaning.

- Rotary Sieve: Generally quieter; maintenance can be simpler due to fewer parts exposed to vibration, but internal rotating parts require inspection.

Advantages and Limitations

Advantages of Vibrating Sieves

- Capable of processing large volumes with multi-layered screens for multiple-size fraction separation.

- Easier and quicker screen replacement due to external layout.

- Compact and space-saving with smaller height requirements.

- Suitable for powders that do not easily form lumps or have consistent flow properties.

Limitations of Vibrating Sieves

- Particles with high moisture or sticky nature may clog the mesh, reducing effectiveness.

- Vibrations can cause wear and tear on components over time.

- Not suitable for fragile or friable materials that may degrade under vibration.

Advantages of Rotary Sieves

- Excellent for handling agglomerated or moist powders that tend to lump.

- Centrifugal force breaks down lumps, providing more consistent product quality.

- Reduced product loss as lumps are broken down rather than discarded.

- Quieter operation beneficial in noise-sensitive environments.

Limitations of Rotary Sieves

- Typically larger and heavier equipment.

- May require more specialized maintenance for rotating parts.

- Higher initial investment compared to vibrating sieves in some cases.

Typical Applications in Powder Processing

Vibrating Sieves

- Food powders such as flour, sugar, and milk powder that flow freely and require multiple size classifications.

- Pharmaceutical powders with relatively dry and free-flowing characteristics.

- Chemical powders requiring consistent particle sizes for blending or further processing.

Rotary Sieves

- Powders prone to lump formation like spices, coffee, and soy lecithin.

- Sticky or slightly moist materials that need lump breakdown during screening.

- Granulated materials and bulk powders where product loss must be minimized.

How to Choose Between a Vibrating Sieve and a Rotary Sieve?

Consider the Material Characteristics

- If the powder is dry, free-flowing, and less prone to lumping, a vibrating sieve is usually optimal.

- For powders with moisture content or that tend to form lumps, a rotary sieve's centrifugal action offers better performance.

Evaluate the Required Capacity and Throughput

- Vibrating sieves can handle high volumes with multi-layered setups.

- Rotary sieves may provide higher throughput for difficult materials due to centrifugal force facilitating screening.

Assess Space and Installation Constraints

- Vibrating sieves often have smaller footprints and can fit into limited height spaces.

- Rotary sieves tend to require more installation space but can be integrated easily into bulk powder handling lines.

Maintenance and Operating Costs

- Vibrating sieves have simpler maintenance but may require more frequent screen replacements due to vibration wear.

- Rotary sieves generally last longer but need periodic inspection of rotating components; quieter operation may reduce hearing protection costs.

Case Study Examples

Food Industry

A flour milling facility might prefer vibrating sieves for sorting large quantities of flour by particle size. The free-flowing nature of flour suits vibrating motion, and multiple mesh layers can divide the product into several fractions efficiently.

Pharmaceutical Industry

When processing powder blends where tablets or granules vary in size, vibrating laboratory sieves with multiple stacked screens provide detailed particle analysis and sorting.

Spice Processing

Spices containing oils and moisture that create lumps are better sieved with rotary sifters. The centrifugal force breaks lumps, preserving product quality and minimizing product rejection.

Maintenance Tips for Both Types

Vibrating Sieves

- Regularly inspect and tighten bolts to avoid excessive vibration.

- Clean screens after each batch to prevent clogging.

- Replace worn-out or damaged mesh promptly.

Rotary Sieves

- Lubricate rotating parts as per manufacturer's guidelines.

- Inspect screw conveyors and paddles for wear.

- Ensure the motor and bearings are functioning smoothly.

Frequently Asked Questions (FAQs)

1. Can I use a vibrating sieve for sticky powders?

Vibrating sieves are less effective for sticky powders as these can clog the mesh. Rotary sieves, with their centrifugal force, are recommended for such materials.

2. Which sieve type is quieter in operation?

Rotary sieves generally operate more quietly because there is less external vibration compared to vibrating sieves.

3. What is the typical throughput difference?

Throughput depends on the powder and sieve size; however, rotary sieves often achieve higher throughput for challenging materials due to their continuous centrifugal screening action.

4. Are vibrating sieves easier to clean?

Yes, vibrating sieves usually have easier access to screens and components, simplifying cleaning compared to rotary sifters.

5. Which sieve type is more energy-efficient?

Energy efficiency varies, but rotary sieves can be more efficient for sticky or lumpy powders since they require less downtime and fewer reprocessing steps.

[1] https://blog.praterindustries.com/sieving-techniques-industrial-sieves-vs.-rotary-sifters

[2] https://www.alibaba.com/showroom/rotary-pharmaceutical-vibration-sieve.html

[3] https://fzsn.virtogroup.com/how-to-choose-between-a-rotary-sieve-and-a-circular-vibrating-screen/

[4] https://patents.google.com/patent/CN202366872U/en

[5] https://www.galaxysivtek.com/blog/confused-between-choosing-rotary-sifter-round-vibrating-separators/

[6] https://www.youtube.com/watch?v=po2AQdzQgUw

[7] https://www.palamaticprocess.com/en-us/blog/centrifugal-sieve-or-vibrating-sieve-which-one-to-choose

[8] https://www.alibaba.com/showroom/vibrating-mechanical-sieve-shaker.html

[9] https://www.dahanmachine.com/news-center/A-Simple-Guide-To-Vibrating-Sieve-Selection.html

[10] https://patents.google.com/patent/CN203235674U/en

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.