Content Menu

● Understanding the Role of Vibrating Sieves in Powder Processing

>> Importance of Particle Size Uniformity

>> Contaminant Removal

● Key Characteristics of a High-Quality Vibrating Sieve for Powder

>> Robust Construction and Materials

>> Precision Mesh Screens

>> Effective Vibrating Mechanism

>> Efficient Design for Material Flow

>> Ease of Cleaning and Maintenance

>> Compliance with Industry Standards

● Operational Parameters Impacting Vibrating Sieve Performance

>> Vibration Frequency and Amplitude

>> Screen Mesh Selection

>> Feed Rate Control

>> Environmental Conditions

● Innovative Features in High-Quality Vibrating Sieves

>> Ultrasonic Vibration Technology

>> Modular and Customizable Designs

>> Automated Monitoring Systems

● Applications Benefiting from High-Quality Vibrating Sieves

● Common Challenges and How a High-Quality Vibrating Sieve Addresses Them

● Frequently Asked Questions (FAQs)

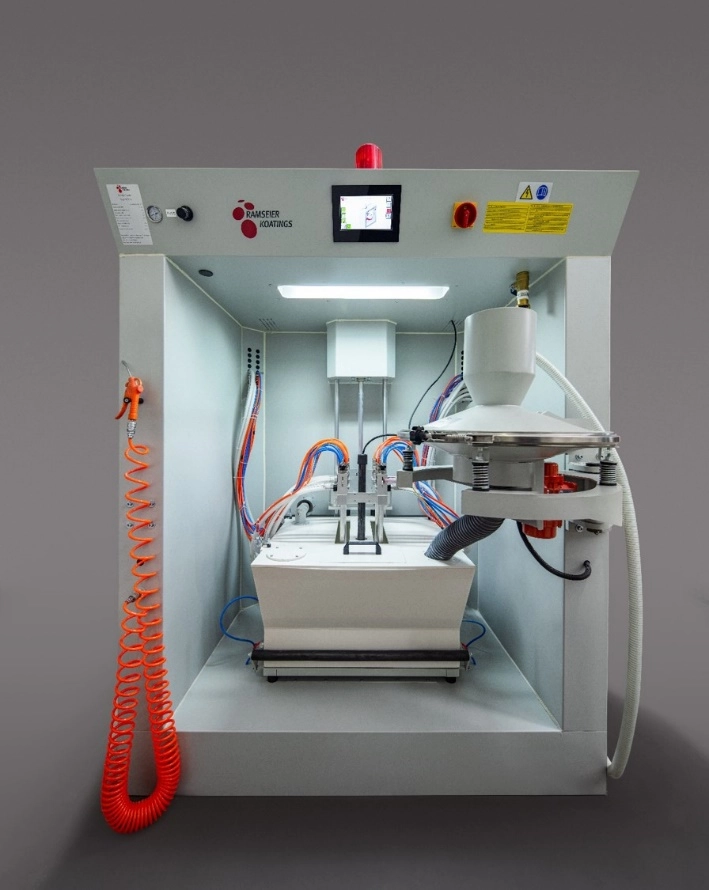

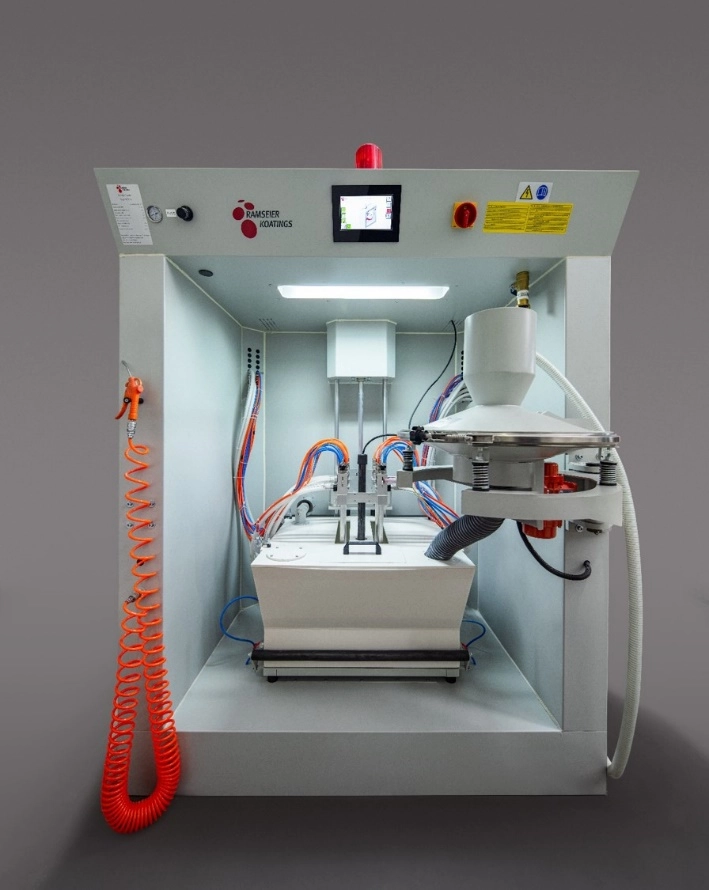

In industries dealing with powder materials, achieving uniform particle size and purity is essential for product quality, consistency, and process efficiency. Vibrating sieves are key equipment used to classify, separate, and filter powders by particle size through vibration-based screening. To ensure optimal performance, it is critical to recognize the qualities that make a vibrating sieve high-quality for powder applications. This article explores the features, components, design considerations, and operational parameters that define a superior vibrating sieve for powder.

Understanding the Role of Vibrating Sieves in Powder Processing

Before delving into the characteristics of a high-quality sieve, it is important to understand why vibrating sieves are indispensable in powder processing.

Importance of Particle Size Uniformity

Powder materials often require strict control over particle size distribution to ensure consistency in performance and quality. For example, in welding powders, uniform sizing enhances flowability and compressibility, leading to better welds. Similarly, in food additives, consistent particle size improves texture and mixing uniformity. Vibrating sieves efficiently separate powders into defined size ranges, eliminating oversized or undersized particles.

Contaminant Removal

Foreign particles, impurities, or agglomerates in powders can degrade product quality and damage downstream equipment. Vibrating sieves help remove contaminants such as metal shavings, dust, and lumps to maintain the purity of the powder. This function is especially critical in sensitive applications like pharmaceuticals, food processing, and high-tech manufacturing.

Key Characteristics of a High-Quality Vibrating Sieve for Powder

Robust Construction and Materials

A high-quality vibrating sieve must be built to withstand rigorous industrial use while preserving product integrity.

- Durable Materials: Stainless steel (often food-grade 304 or 316) is typically used for sieve frames and mesh to resist corrosion, wear, and contamination. High-quality mesh screens with precise aperture sizes ensure longevity and reliable separation.

- Solid Frame Design: The frame should be rigid to minimize unwanted vibrations and maintain stable operation. It should also be designed for ease of cleaning to comply with hygiene standards if used in food or pharmaceutical powders.

Precision Mesh Screens

The mesh screen is the heart of the vibrating sieve, performing the actual separation.

- Accurate Aperture Size: High-quality sieves use precision-engineered meshes that match the target particle size distribution. This accuracy is essential for consistent classification.

- Multiple Mesh Options: Offering a range of mesh sizes tailored to different powder applications allows customization to specific processing needs.

- Tight Tensioning: The mesh must be tightly secured without slack to prevent particle clogging and maintain efficient screening.

Effective Vibrating Mechanism

The vibrating mechanism is responsible for generating motion to facilitate particle stratification and passage through the mesh.

- Powerful, Adjustable Exciters: A top-quality sieve uses vibrators or exciters (often eccentric weights or motor-driven) that provide adjustable vibration amplitude and frequency to optimize screening for diverse powders.

- Balanced Vibrations: The vibration should be balanced and controlled to avoid damage to powder particles and to ensure uniform sieving without material buildup.

- Stable Mounting: The sieve unit should have anti-vibration mounts or springs to isolate vibrations from the surrounding structure, enhancing operator safety and machine stability.

Efficient Design for Material Flow

The sieve's design influences powder flow and separation efficiency.

- Inclined Screen Surfaces: Inclined or sloped screens help powders flow smoothly, preventing clogging or buildup.

- Multiple Deck Configurations: High-quality sieves often offer one or multiple decks allowing simultaneous separation into several size fractions.

- Optimized Discharge Ports: Properly positioned discharge ports reduce particle retention and facilitate continuous operation.

Ease of Cleaning and Maintenance

Regular cleaning is essential to prevent contamination and maintain screening quality.

- Quick-Release Screens: Facilitates fast mesh replacement and cleaning.

- Smooth Surfaces and Rounded Corners: Avoid powder trapping and ease sanitation.

- Accessible Design: Simple to disassemble and reassemble reduces downtime.

Compliance with Industry Standards

For applications in food, pharmaceuticals, and chemicals, compliance with regulatory standards ensures safety and quality.

- Certifications: FDA, GMP, CE, and ATEX certifications guarantee the sieve meets hygiene, safety, and operational requirements.

- Material Traceability: Documentation of materials used in construction helps maintain quality control.

Operational Parameters Impacting Vibrating Sieve Performance

Vibration Frequency and Amplitude

Adjusting vibration frequency and amplitude is paramount to achieving efficient powder separation. Low frequency with high amplitude works well for coarse powders, while fine powders require high-frequency low-amplitude vibration to prevent mesh blinding.

Screen Mesh Selection

Selecting the appropriate mesh size depends on the target powder particle size distribution. Using too coarse a mesh results in poor separation, whereas too fine a mesh reduces throughput and increases clogging risks.

Feed Rate Control

Maintaining the optimum feed rate avoids overloading the sieve. Overfeeding causes inefficient screening and material buildup, while underfeeding reduces productivity.

Environmental Conditions

Temperature, humidity, and dust control within the sieving environment impact efficiency. High humidity can cause powder agglomeration, requiring special sieve designs or ultrasonic vibration assistance.

Innovative Features in High-Quality Vibrating Sieves

Ultrasonic Vibration Technology

Some advanced sieves incorporate ultrasonic transducers that impart high-frequency vibrations to the mesh, enhancing the screening of fine powders and reducing mesh blinding.

Modular and Customizable Designs

Modern sieves may include modular decks, quick-change screens, and customizable vibration settings to adapt quickly to varied processing requirements.

Automated Monitoring Systems

Integration of sensors for real-time monitoring of vibration parameters, screen condition, and feed rates allows predictive maintenance and consistent product quality.

Applications Benefiting from High-Quality Vibrating Sieves

- Metal powder industries: For ensuring uniform particle size and removing metallic contaminants.

- Food additives: For grading and purifying ingredients such as spices, powdered sugar, and protein powders.

- Pharmaceutical powders: For precise classification critical to dosage consistency.

- Chemical industries: For removing impurities from raw materials and finished powders.

- Coatings and paints: For screening fine powder pigments and additives.

Common Challenges and How a High-Quality Vibrating Sieve Addresses Them

- Particle Blinding: Fine powders can clog the mesh; ultrasonic vibration or optimized mesh can prevent this.

- Material Buildup: Inclined screens and vibration amplitude adjustments reduce accumulation.

- Contamination: Stainless steel construction and smooth surfaces minimize contamination risks.

- Wear and Tear: High-grade materials and balanced vibrations increase service life.

- Operational Downtime: Easy cleaning designs and modular components reduce maintenance time.

Frequently Asked Questions (FAQs)

Q1: What materials are best for vibrating sieve construction?

A1: Stainless steel (304 or 316 grades) is preferred for its corrosion resistance, cleanliness, and durability, especially in food and pharmaceutical applications.

Q2: How does vibration frequency affect powder sieving?

A2: Higher frequency vibrations are better suited for fine powders to prevent clogging, while lower frequencies with greater amplitude effectively separate coarser particles.

Q3: Can vibrating sieves handle moist or sticky powders?

A3: Moisture can cause clumping, which reduces efficiency. Some high-quality sieves incorporate ultrasonic vibration or special coatings to handle sticky powders better.

Q4: How often should sieve mesh screens be replaced?

A4: Replacement frequency depends on usage and material abrasiveness but generally ranges from months to a few years. Regular inspection for wear and damage guides replacement timing.

Q5: What maintenance is required for vibrating sieves?

A5: Routine cleaning, inspection of mesh tension, checking vibration motors, and lubricating moving parts are essential to ensure optimal performance and longevity.

[1] https://mahandvibre.com/en/welding-powder-vibrating-sieve-quality-with-mahand-industrial-sieve/

[2] https://patents.google.com/patent/CN107552387A/zh

[3] https://loyal-machine.com/blog/vibrating-sieve/

[4] https://patents.google.com/patent/CN113477512B/zh

[5] https://mahandvibre.com/en/10-key-points-about-food-additives-grading-by-vibrating-sieve/

[6] https://ejje.weblio.jp/content/vibrating+sieve

[7] https://www.ramseierkoatings.com/how-to-choose-the-right-powder-sieve-for-high-efficiency-coating.html

[8] https://patents.google.com/patent/CN109952159A/zh

[9] https://www.globalgilson.com/blog/an-expert-guide-to-selecting-a-sieve-shaker

[10] https://patents.google.com/patent/CN107470140A/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.