Content Menu

● Introduction

● Why Choose Wholesale Automatic Spray Booth Systems?

>> Enhanced Efficiency and Productivity

>> Consistency and Superior Finish Quality

>> Cost Savings and Resource Optimization

>> Enhanced Workplace Safety

>> Scalability for Growing Operations

● Key Features of Wholesale Automatic Spray Booth Systems

>> Advanced Automation and Controls

>> Customizable Configurations

>> Robust Material Handling Solutions

>> Environmental and Safety Compliance

>> Comprehensive Support and Aftermarket Services

● Applications of Wholesale Automatic Spray Booth Systems

>> Automotive Industry

>> Furniture and Woodworking

>> Metal Fabrication and Industrial Equipment

>> Electronics and Plastics

● How to Select the Right Wholesale Automatic Spray Booth System

>> Assess Your Production Needs

>> Evaluate Supplier Credentials

>> Prioritize Customization and Integration

>> Consider Total Cost of Ownership

>> Plan for Future Growth

● Frequently Asked Questions (FAQs)

● Citations:

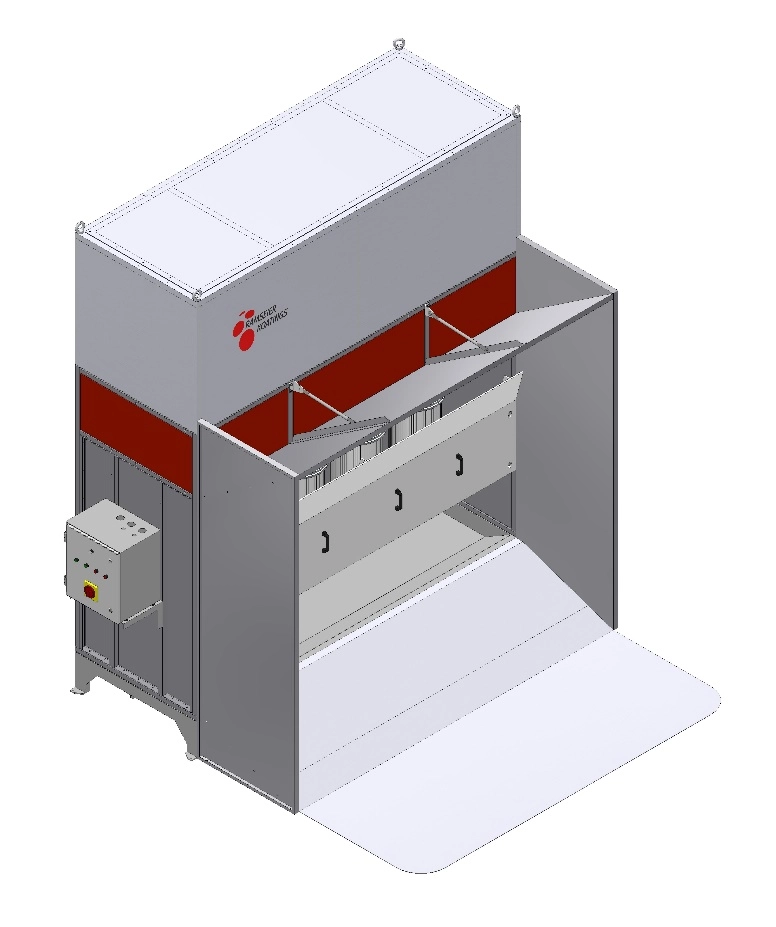

Introduction

In today's competitive manufacturing landscape, *Wholesale Automatic Spray Booth Systems* have become a cornerstone for businesses seeking efficiency, consistency, and scalability in their finishing operations. As a leading Chinese OEM manufacturer, supplier, and designer, we specialize in custom automatic spray booth systems tailored for international brands, wholesalers, and production facilities. This comprehensive article explores the advantages, key features, applications, and selection strategies for wholesale automatic spray booth systems, empowering global partners to elevate their finishing processes.

Why Choose Wholesale Automatic Spray Booth Systems?

Enhanced Efficiency and Productivity

Wholesale automatic spray booth systems revolutionize the finishing process by automating paint application, which drastically increases throughput and reduces labor costs. Automation enables continuous operation, minimizes human error, and ensures every product receives a uniform finish, regardless of batch size[2][5].

Consistency and Superior Finish Quality

One of the primary benefits of automatic spray booth systems is their ability to deliver consistent, high-quality finishes. Machine-guided applicators maintain precise spray patterns and coating thickness, reducing the risk of defects and rework. This consistency is especially crucial for OEM brands that demand strict adherence to quality standards[2][5].

Cost Savings and Resource Optimization

Investing in wholesale automatic spray booth systems leads to significant cost savings over time. Automation reduces paint and solvent waste, lowers energy consumption, and decreases the need for expensive manual labor. Bulk purchasing from a trusted supplier further enhances cost efficiency through volume discounts and tailored solutions[2][4][5].

Enhanced Workplace Safety

Automatic spray booth systems minimize worker exposure to hazardous fumes and chemicals, creating a safer production environment. Advanced safety features, such as emergency shutoffs and real-time monitoring, further reduce the risk of accidents and health issues[2][5].

Scalability for Growing Operations

As businesses expand, wholesale automatic spray booth systems can be easily scaled or customized to accommodate increased production demands. Modular designs and flexible configurations ensure that your finishing line grows with your business, future-proofing your investment[2][5].

Key Features of Wholesale Automatic Spray Booth Systems

Advanced Automation and Controls

Modern automatic spray booth systems are equipped with programmable logic controllers (PLCs), touch-screen interfaces, and cloud-based monitoring. These technologies allow for precise control over spray parameters, real-time diagnostics, and seamless integration with other production equipment[5].

Customizable Configurations

Wholesale automatic spray booth systems can be tailored to specific product sizes, shapes, and production rates. Options include:

- Cross draft, down draft, and semi-down draft airflow designs

- Water wash, dry filter, or powder coating booths

- Integrated conveyors and robotic applicators for continuous or batch processing[3][4][5]

Robust Material Handling Solutions

Efficient material handling is vital for maximizing throughput. Automatic spray booth systems often include:

- Overhead or in-floor conveyors

- Specialized part fixtures and carriers

- Automated loading and unloading stations[3]

Environmental and Safety Compliance

Wholesale automatic spray booth systems are designed to meet stringent environmental and safety regulations. Features such as advanced filtration, dust collection, and explosion-proof components ensure compliance and protect both workers and the environment[3][5].

Comprehensive Support and Aftermarket Services

Leading suppliers offer end-to-end support, including system design, installation, training, and ongoing maintenance. This ensures optimal system performance and minimizes downtime throughout the system's lifecycle[3].

Applications of Wholesale Automatic Spray Booth Systems

Automotive Industry

Automatic spray booth systems are essential for automotive manufacturers and body shops, providing flawless finishes for vehicles, parts, and accessories. High throughput and consistent quality are critical in this sector[1][4].

Furniture and Woodworking

Custom spray booths are widely used in the furniture industry for painting, staining, and finishing wood products. Automated systems ensure even coverage and reduce overspray, improving both quality and efficiency[3][4].

Metal Fabrication and Industrial Equipment

Manufacturers of metal components and industrial machinery rely on automatic spray booth systems for corrosion protection and aesthetic finishes. Automation accommodates large parts and high production volumes[3][4].

Electronics and Plastics

Precision is paramount in electronics and plastics finishing. Automatic spray booths provide controlled environments for applying coatings to delicate components, ensuring product reliability and appearance[3][4].

How to Select the Right Wholesale Automatic Spray Booth System

Assess Your Production Needs

Begin by evaluating your product types, production volumes, and desired finish quality. Consider factors such as part size, coating materials, and cycle times to determine the optimal booth configuration[5].

Evaluate Supplier Credentials

Choose a supplier with a proven track record, relevant certifications, and positive customer feedback. Reputable manufacturers offer customization, technical support, and compliance with international standards[4].

Prioritize Customization and Integration

Work with suppliers who can tailor the system to your unique requirements, including integration with existing production lines and automation infrastructure[3][5].

Consider Total Cost of Ownership

Beyond the initial investment, factor in operating costs, maintenance, energy consumption, and potential savings from reduced waste and labor. Wholesale purchasing often provides substantial long-term value[2][4][5].

Plan for Future Growth

Select a system that can scale with your business. Modular designs and flexible automation options ensure your spray booth system remains an asset as production demands evolve[2][5].

Frequently Asked Questions (FAQs)

Q1: What are the main advantages of purchasing wholesale automatic spray booth systems?

A1: Wholesale purchasing offers cost savings, bulk customization, and tailored solutions, making it ideal for brands and manufacturers seeking efficiency and scalability[4].

Q2: What industries can benefit from automatic spray booth systems?

A2: Automotive, furniture, metal fabrication, electronics, plastics, and many other industries utilize these systems for high-quality, consistent finishes[1][3][4].

Q3: How do automatic spray booth systems improve workplace safety?

A3: Automation reduces worker exposure to hazardous chemicals and incorporates advanced safety features, minimizing health risks and accidents[2][5].

Q4: What key components are included in a typical automatic spray booth system?

A4: Core components include pumps, nozzles, control systems, conveyors, filtration units, and safety features, all working together for efficient, precise spraying[3][4].

Q5: How do I identify reputable suppliers of wholesale automatic spray booth systems?

A5: Look for suppliers with industry certifications, strong customer reviews, and a history of delivering customized solutions for global clients[4].

Citations:

[1] https://www.fenderbender.com/running-a-shop/operations/article/33020016/spraybooth-lighting-theory-and-practice

[2] https://pfsspraybooths.com/advantages-of-using-automated-spray-booths-in-your-operation

[3] https://productionsystems-usa.com

[4] https://www.made-in-china.com/products-search/hot-china-products/Automatic_Spray_Booth.html

[5] https://www.spraysystems.com/how-automated-spray-booth-systems-can-save-you-time-and-money/

[6] https://www.asminternational.org/tss/wp-content/uploads/sites/38/files/content/safety5.pdf

[7] https://www.hppneumatics.com/spray-booth-benefits/

[8] https://www.gzguangli.com/products

[9] https://www.alibaba.com/showroom/automatic-spray-booth.html

[10] https://www.saif.com/Documents/SafetyandHealth/OperationalHazards/S849_spray_finishing.pdf

[11] https://arnoldmachine.com/resources/automated-spray-systems-key-to-increased-efficiency/

[12] https://paintfinishingequipment.com/spray-booths/

[13] https://www.made-in-china.com/manufacturers/wholesale-automatic-spray-booth.html

[14] https://blog.qrfs.com/221-fire-protection-for-paint-spray-booths-in-auto-body-shops/

[15] https://arnoldmachine.com/expertise/coating-systems/

[16] https://paint-booth.en.made-in-china.com/product/jywnCfjLMDWH/China-Factory-OEM-ODM-Services-Bulk-Price-Auto-Paint-Booth-for-Sale.html

[17] https://www.alibaba.com/showroom/automated-spray-booth.html

[18] https://www.alibaba.com/product-detail/Wholesale-Vehicle-room-HC-ZD300-Auto-62317248776.html

[19] https://www.fenderbender.com/home/article/33035666/latest-paint-booths-expand-capabilities-improve-efficiency

[20] https://www.ecotechsystems.net/3-key-components-of-paint-booth-design

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.