Content Menu

● The Role of Manual Spray Booths in Industrial Manufacturing

>> What Is a Manual Spray Booth?

>> Why Are Spray Booths Essential?

● How Manual Spray Booths Enhance Product Quality

>> Controlled Environment for Superior Finishes

>> Precision and Flexibility

>> Reduction of Contamination and Defects

>> Consistent Airflow and Overspray Management

>> Enhanced Lighting and Visibility

● Safety and Compliance: Indirect Contributors to Quality

>> Worker Protection and Health

>> Regulatory Compliance

>> Fire and Explosion Prevention

● Waste Reduction and Environmental Benefits

>> Minimizing Material Waste

>> Cleaner Workspaces

>> Air Quality Protection

● Manual vs. Automated Spray Booths: A Quality Perspective

● Key Components and Features of Modern Manual Spray Booths

>> Advanced Filtration and Overspray Recovery

>> Adjustable Environmental Controls

>> Energy Efficiency

>> Ergonomic Design

● Maintenance and Best Practices for Sustained Quality

>> Regular Filter Replacement

>> Booth Cleaning and Inspection

>> Operator Training

● Industry Applications and Case Examples

>> Automotive and Aerospace

>> Furniture and Woodworking

>> Metal Fabrication

● Frequently Asked Questions

● Citations:

Manual spray booths are a cornerstone of quality assurance in industrial finishing processes. By providing a controlled environment for the application of paints and coatings, these booths play a vital role in ensuring product consistency, workplace safety, and regulatory compliance. This article explores the mechanisms by which manual spray booths elevate product quality, compares them to automated systems, and addresses common questions about their operation and benefits.

The Role of Manual Spray Booths in Industrial Manufacturing

What Is a Manual Spray Booth?

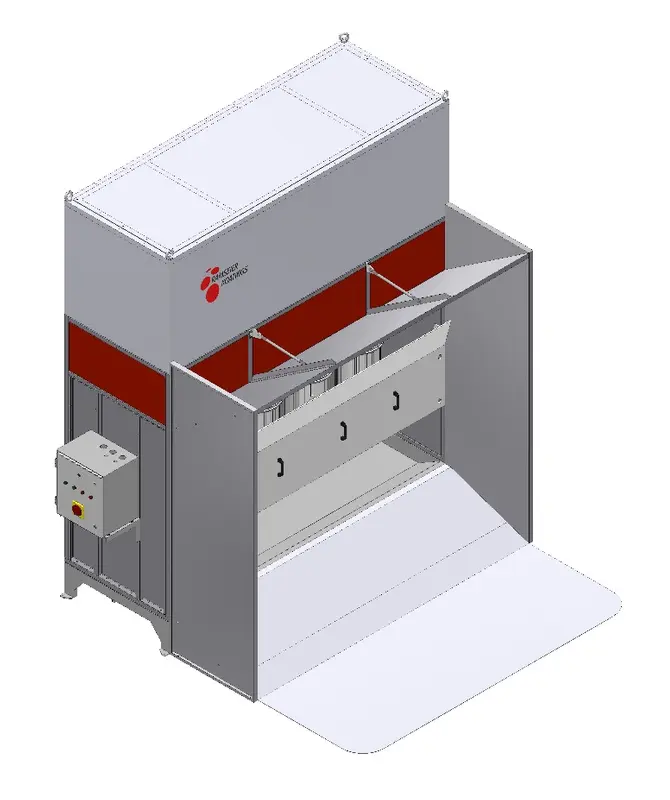

A manual spray booth is an enclosed workspace designed for the hand-application of paints, varnishes, and coatings to industrial products. Operators use spray guns to apply finishes, leveraging their skill for precision and adaptability. The booth's environment is engineered to control airflow, temperature, humidity, and airborne contaminants, all crucial factors in achieving a high-quality finish.

Why Are Spray Booths Essential?

Spray booths are not just a matter of convenience-they are often a legal requirement in manufacturing and finishing operations. They protect both workers and the environment by containing hazardous materials, filtering fumes, and preventing the spread of dust and overspray.

How Manual Spray Booths Enhance Product Quality

Controlled Environment for Superior Finishes

Manual spray booths create a stable environment where temperature, humidity, and airflow are regulated. This minimizes the risk of dust, debris, or moisture compromising the coating. The result is a smoother, more uniform finish with fewer defects such as runs, sags, or orange peel textures. The controlled environment also accelerates drying and curing, reducing production bottlenecks and improving throughput.

Precision and Flexibility

Manual spraying allows skilled operators to adapt to the unique geometry and requirements of each product. This is especially valuable for custom jobs, small batches, or parts with intricate details. Operators can adjust spray patterns, angles, and techniques in real-time, ensuring optimal coverage and finish quality.

Reduction of Contamination and Defects

One of the primary challenges in industrial coating is contamination. Dust, fibers, and airborne particles can settle on wet surfaces, causing imperfections. Manual spray booths are equipped with advanced filtration and ventilation systems that capture contaminants before they reach the workpiece. This leads to a significant reduction in rework and rejects, boosting overall product quality.

Consistent Airflow and Overspray Management

Proper airflow is essential for even coating application and the removal of overspray. Manual spray booths are designed with optimized ventilation systems that direct air in a manner that prevents the accumulation of paint mist and ensures a clean workspace. Overspray is captured by filters or water curtains, preventing it from settling on finished products or other surfaces.

Enhanced Lighting and Visibility

Quality lighting is a critical but often overlooked aspect of finishing. Manual spray booths are fitted with specialized lighting systems that allow operators to clearly see the surface being coated, identify flaws, and ensure even coverage. This attention to detail directly translates into higher-quality results.

Safety and Compliance: Indirect Contributors to Quality

Worker Protection and Health

Manual spray booths safeguard operators from exposure to hazardous fumes, solvents, and particulates. By containing these substances and filtering the air, booths reduce the risk of respiratory problems, skin irritation, and long-term health issues. Healthy workers are more productive, attentive, and capable of maintaining high standards in their work.

Regulatory Compliance

Industrial finishing operations are subject to strict environmental and safety regulations. Manual spray booths are designed to comply with standards set by agencies such as OSHA, NFPA, and the EPA. Compliance not only avoids legal penalties but also ensures that processes are optimized for safety and environmental stewardship, both of which are integral to sustainable quality management.

Fire and Explosion Prevention

Many industrial coatings are flammable or produce volatile organic compounds (VOCs). Manual spray booths control ventilation and exhaust, minimizing the risk of fire or explosion. This secure environment protects both products and personnel, reducing the likelihood of costly accidents that can disrupt production and damage product integrity.

Waste Reduction and Environmental Benefits

Minimizing Material Waste

Manual spray booths are engineered to contain and collect overspray, reducing the amount of paint or coating material wasted. Efficient capture systems mean that more of the applied material ends up on the product, lowering costs and environmental impact.

Cleaner Workspaces

By containing fumes, dust, and overspray, manual spray booths keep the surrounding workspace clean. This not only improves worker morale and safety but also prevents cross-contamination between different production areas, further enhancing product quality.

Air Quality Protection

High-efficiency filtration systems in manual spray booths capture toxins and pollutants, ensuring that emissions meet environmental standards. This protects indoor air quality and reduces the facility's environmental footprint.

Manual vs. Automated Spray Booths: A Quality Perspective

| Feature | Manual Spray Booths | Automated Spray Booths |

| Precision & Flexibility | High (operator skill-dependent) | High for uniform parts, less flexible |

| Customization | Excellent for unique jobs | Limited to programmed routines |

| Consistency | Operator-dependent | Very high for repetitive tasks |

| Labor Requirement | High (skilled labor needed) | Lower (after setup) |

| Throughput | Lower for large batches | High for mass production |

| Initial Investment | Lower | Higher |

| Maintenance | Simpler | More complex |

| Ideal Use Case | Custom, small batch, intricate | Large-scale, repetitive |

Manual spray booths excel in situations where adaptability, craftsmanship, and attention to detail are paramount. Automated systems, while providing unmatched consistency and speed for high-volume production, may struggle with complex shapes or frequent changeovers.

Key Components and Features of Modern Manual Spray Booths

Advanced Filtration and Overspray Recovery

Modern manual spray booths use multi-stage filtration systems to capture both particulate and gaseous contaminants. Water curtain systems and high-efficiency filters ensure that overspray is collected and disposed of properly, minimizing waste and environmental impact.

Adjustable Environmental Controls

Sophisticated control panels allow operators to adjust lighting, humidity, and airflow to suit the specific requirements of each coating process. This level of control is essential for achieving optimal results with different materials and finishes.

Energy Efficiency

Energy-saving devices and inverter-controlled exhaust systems reduce power consumption while maintaining optimal working conditions. This not only lowers operating costs but also contributes to environmental sustainability.

Ergonomic Design

Manual spray booths are designed with operator comfort and safety in mind. Features such as adjustable work platforms, easy-access controls, and ample lighting help reduce fatigue and improve the quality of workmanship.

Maintenance and Best Practices for Sustained Quality

Regular Filter Replacement

Filters must be checked and replaced regularly to maintain air quality and prevent the buildup of hazardous materials. Clogged or worn filters can compromise both product quality and worker safety.

Booth Cleaning and Inspection

Routine cleaning of booth interiors, floors, and walls prevents the accumulation of dust and paint residues. Scheduled inspections ensure that ventilation, lighting, and safety systems are functioning correctly.

Operator Training

Skilled operators are essential for maximizing the benefits of manual spray booths. Ongoing training in spraying techniques, equipment maintenance, and safety protocols ensures consistent, high-quality results.

Industry Applications and Case Examples

Automotive and Aerospace

Manual spray booths are widely used in the automotive and aerospace industries for tasks requiring high precision, such as custom paint jobs, repairs, and the finishing of complex components.

Furniture and Woodworking

In furniture manufacturing, manual spray booths enable artisans to apply intricate finishes and stains, achieving unique looks that automated systems may not replicate.

Metal Fabrication

For metal parts with varied geometries or low production volumes, manual spray booths provide the flexibility needed to ensure each piece meets exacting quality standards.

Frequently Asked Questions

Q1: How does a manual spray booth differ from an automated booth in terms of quality?

A: Manual spray booths offer greater flexibility and precision for custom or intricate work, relying on operator skill to achieve high-quality finishes. Automated booths excel in consistency for large-scale, repetitive tasks.

Q2: What are the main safety features of manual spray booths?

A: Key safety features include advanced ventilation, filtration systems, explosion-proof lighting, and fire suppression mechanisms. These protect operators from hazardous fumes and reduce fire risks.

Q3: How do manual spray booths help reduce environmental impact?

A: By containing overspray, filtering emissions, and minimizing material waste, manual spray booths lower the release of pollutants and reduce the facility's environmental footprint.

Q4: Can manual spray booths handle all types of coatings?

A: Yes, manual spray booths can be adapted for a wide range of coatings, including paints, varnishes, and specialized industrial finishes. Environmental controls can be adjusted to suit different materials.

Q5: What maintenance is required to keep a manual spray booth operating at peak quality?

A: Regular filter changes, thorough cleaning, equipment inspections, and ongoing operator training are essential for maintaining optimal performance and product quality.

Citations:

[1] https://www.hppneumatics.com/spray-booth-benefits/

[2] https://www.codinter.com/en/spray-booths-a-complete-guide/

[3] https://masterflo-uk.com/essential-guide-to-spray-booth-safety-regulations-best-practices-and-maintenance/

[4] https://www.airblasteurospraydirect.com/blog/what-are-the-environmental-benefits-of-using-a-paint-booth/

[5] https://www.pbmetalfinishingsystems.com/news/comparing-manual-vs-automated-spray-equipment-for-industrial-applications

[6] https://pfsspraybooths.com/how-spray-booths-improve-safety-quality-and-compliance

[7] https://www.ceflafinishing.com/en/products/manual-spray-booths-for-finishing

[8] https://www.rohnerspraybooths.com/blog/benefits-of-custom-paint-booth

[9] https://www.dbmtec.com/en/industrial-spray-booths/

[10] https://sites.disney.com/app/uploads/sites/53/2022/05/UK_RA_Gen-Spray-Booth.pdf

[11] https://www.ramseierkoatings.com/automatic-vs-manual-spray-booths-which-offers-better-environmental-protection.html

[12] https://www.ramseierkoatings.com/what-is-the-best-way-to-optimize-efficiency-with-manual-spray-booths.html

[13] https://www.ramseierkoatings.com/what-are-the-top-benefits-of-using-manual-spray-booth-systems.html

[14] https://www.usiitalia.com/en/5-paint-booth-safety-measures-to-keep-in-mind/

[15] https://des.sc.gov/sites/des/files/docs/Environment/docs/AutobodySelfCertWorkbook4.pdf

[16] https://pfsspraybooths.com/the-ultimate-paint-booth-usage-guide-for-perfect-results

[17] https://globalfinishing.com/2020/01/14/how-industrial-manufacturers-can-benefit-from-recirculating-spray-booths/

[18] https://www.spraysystems.com/booth-codes/

[19] https://www.paintbooth.com/how-do-paint-booths-control-overspray-and-emissions/

[20] https://www.iqsdirectory.com/articles/paint-finishing-equipment/paint-spray-booths.html

---

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.