Content Menu

● Introduction to Spray Booths

>> Manual Spray Booths

>> Automated Spray Booths

>> Customization Options in Automated Booths

>> Comparison of Customization Options

● Conclusion

● Frequently Asked Questions

● Citations:

In the realm of spray booths, both manual and automated systems have their unique advantages and disadvantages. Manual spray booths are often praised for their flexibility and customization capabilities, while automated booths are renowned for their efficiency and consistency. This article delves into the customization options provided by manual spray booths compared to automated ones, exploring their design, functionality, and suitability for various applications.

Introduction to Spray Booths

Spray booths are specialized enclosures designed to control the painting environment, ensuring safety, efficiency, and quality in the coating process. They are widely used in industries such as automotive, aerospace, and electronics manufacturing. The choice between manual and automated spray booths largely depends on the specific needs of the operation, including production volume, product complexity, and desired finish quality.

Manual Spray Booths

Manual spray booths are operated by skilled technicians who manually apply coatings using spray guns. These booths are ideal for low-volume, high-customization projects where precision and detail are paramount. Manual booths offer several customization options:

- Flexibility in Coating Application: Manual booths allow operators to adjust the coating process in real-time, enabling them to handle complex geometries and unique finishes.

- Adaptability to Different Products: They can easily switch between different products or coating types, making them suitable for operations with diverse product lines.

- Cost-Effectiveness for Small Batches: For small-scale production or custom jobs, manual booths are often more cost-effective than investing in automated systems.

However, manual booths require skilled labor, which can increase labor costs and lead to inconsistencies in the finish quality.

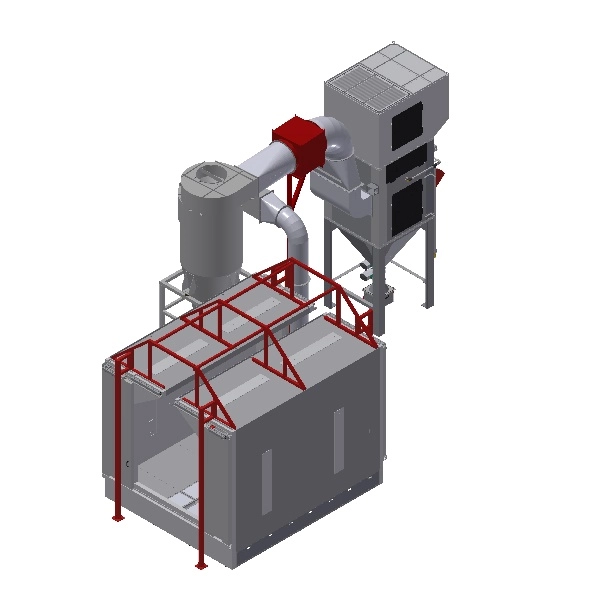

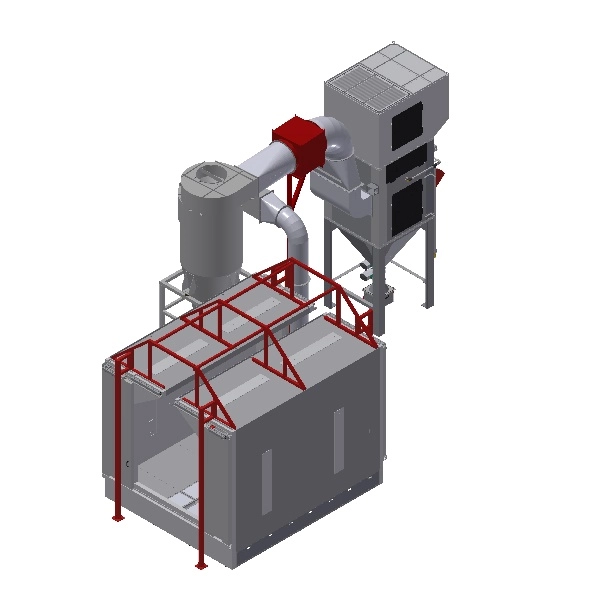

Automated Spray Booths

Automated spray booths utilize advanced technology, including robotic arms and conveyor systems, to streamline the painting process. These systems are designed for high-volume production environments where speed and consistency are crucial. Automated booths offer several advantages:

- Consistency and Efficiency: They ensure uniform coating application, reducing material waste and increasing production throughput.

- Safety Enhancements: By minimizing human involvement, automated booths reduce exposure to hazardous chemicals and improve worker safety.

- Scalability: They are ideal for large-scale operations and can be easily integrated into existing production lines.

Despite these benefits, automated booths have higher initial costs and require regular maintenance to ensure optimal performance.

Customization Options in Automated Booths

While manual booths are often seen as more flexible, automated booths can also be customized to meet specific needs:

- Programmable Controllers: Allow for precise control over various aspects of the painting process, such as airflow, temperature, and paint application.

- Robotic Arms: Can be programmed to follow specific paths, ensuring uniform coverage and reducing overspray.

- Customizable Settings: Many automated systems allow for multiple product profiles, enabling quick adjustments for different products.

However, these customization options may require significant technical expertise and investment.

Comparison of Customization Options

| Feature | Manual Spray Booths | Automated Spray Booths |

| Flexibility | Highly flexible for custom jobs | Less flexible but programmable |

| Adaptability | Easily adapts to different products | Requires setup for each product |

| Cost-Effectiveness | Cost-effective for small batches | Economical for large-scale production |

| Consistency | Dependent on operator skill | Consistent results with minimal variation |

| Safety | Higher risk due to manual handling | Enhanced safety with reduced human exposure |

Conclusion

Manual spray booths provide better customization options for low-volume, high-customization projects due to their flexibility and adaptability. However, automated booths offer superior consistency and efficiency, making them ideal for large-scale operations. The choice between manual and automated spray booths should be based on the specific needs and goals of the operation.

Frequently Asked Questions

1. What are the primary advantages of manual spray booths?

- Manual spray booths offer flexibility and adaptability, making them ideal for custom jobs and small-scale production. They allow for real-time adjustments and are cost-effective for low-volume operations.

2. How do automated spray booths enhance safety?

- Automated spray booths reduce human exposure to hazardous chemicals by minimizing manual labor in the painting process. They also integrate advanced safety features such as ventilation systems and emergency shutdowns.

3. Can automated spray booths be customized for different products?

- Yes, automated spray booths can be customized with programmable controllers and robotic arms to handle different products. They allow for multiple product profiles, enabling quick adjustments for various items.

4. What are the cost implications of choosing between manual and automated spray booths?

- Manual booths are generally more cost-effective for small-scale operations, while automated booths offer long-term savings through reduced labor costs and increased efficiency in high-volume production.

5. How do manual and automated spray booths differ in terms of consistency?

- Manual booths rely on operator skill, which can lead to variability in finish quality. Automated booths ensure consistent results by using robotic technology to apply coatings uniformly.

Citations:

[1] https://www.toolsusa.com/blog/spray-booth-customization/

[2] https://pfsspraybooths.com/custom-paint-booth-tailored-solutions-for-your-unique-needs

[3] https://ems-powdercoating.com/manual-powder-coating-booth/

[4] https://www.spraysystems.com/how-automated-spray-booth-systems-can-save-you-time-and-money/

[5] https://www.cxhuarui.com/The-Role-of-Automation-in-Spray-Booth-Efficiency-id48171556.html

[6] https://pfsspraybooths.com/advantages-of-using-automated-spray-booths-in-your-operation

[7] https://www.cxhuarui.com/The-Benefits-of-Using-an-Automatic-Spray-Booth-in-Manufacturing-id45271556.html

[8] https://www.paint-booths.com/custom-paint-booths.html

[9] https://www.annadale.com/pages/systems-components/manual-automatic-powder-coating-spray-booths

[10] https://www.californiapulse.com/indoor-paint-booths.html

[11] https://www.rohnerspraybooths.com/blog/benefits-of-custom-paint-booth

[12] https://www.pbmetalfinishingsystems.com/news/comparing-manual-vs-automated-spray-equipment-for-industrial-applications

[13] https://www.spraysystems.com/custom-solutions/

[14] https://www.nordson.com/en/products/industrial-coating-systems-products/manual-powder-coating-booth

[15] https://www.codinter.com/en/spray-booths-a-complete-guide/

[16] https://pfsspraybooths.com/the-benefits-of-custom-paint-booths-for-your-business

[17] https://globalfinishing.com/products/application/liquid-paint-booths/industrial-paint-booths/dry-filter-booths/open-face-paint-booths/

[18] https://www.hppneumatics.com/spray-booths/

[19] https://www.hppneumatics.com/spray-booth-benefits/

[20] https://www.nordson.com/en/products/industrial-coating-systems-products/lean-cell---manual-powder-coating-booths

[21] https://www.spraysystems.com

[22] https://www.ramseierkoatings.com/what-sets-automatic-spray-booth-systems-apart-from-manual-ones.html

[23] http://www.spraybooth-online.com/220163

[24] https://www.iqsdirectory.com/articles/paint-finishing-equipment/paint-spray-booths.html

[25] https://www.ramseierkoatings.com/what-are-the-key-differences-between-automatic-and-manual-spray-booths.html

[26] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/why-you-should-automate-your-paint-booth.html

[27] https://www.nordson.com/en/products/industrial-coating-systems-products/automatic-powder-coating-booths

[28] https://gsbindustries.com/customize-your-paint-booth-what-to-consider/

[29] https://www.gayoetech.com/automatic-paint-booth-systems.html

[30] https://www.kajaglow.com/blog/automated-vs-airbrush

[31] https://www.ssindustries.com.au/news/manual-vs-automatic-paint-gun-which-one-should-choose/

[32] https://www.ramseierkoatings.com/news/Maintenance-Requirements-Automatic-Vs-Manual-Spray-Booth-Systems.html

[33] https://vntvietnam.vn/comparison-of-automatic-and-manual-powder-coating-systems

[34] https://conceptsystemsinc.com/painting-processes-today-and-the-benefits-of-automated-painting/

[35] https://arnoldmachine.com/expertise/coating-systems/

[36] https://www.salongeek.com/threads/automatic-booth-or-manual-spray-tan-your-opinions-please.79967/

[37] https://www.ceflafinishing.com/en/products/manual-spray-booths-for-finishing

[38] https://ems-powdercoating.com/automated-paint-booth/

[39] https://sunlessinc.com/brand/mystic-tan-unity/

[40] https://gsbindustries.com/the-evolution-of-paint-booth-technology/

[41] https://www.spraysystems.com/essential-design-elements-of-a-spray-booth-coatings-involved-in-the-finishing-process/

[42] https://roboticpaint.com/how-to-select-a-suitable-paint-booth/

[43] https://www.spraysystems.com/key-decisions-for-powder-coatings-batch-or-automated-spray-to-waste-or-reclaim/

.

.