Content Menu

● Understanding Powder Coating

>> What is Powder Coating?

>> The Importance of Quality in Powder Coating

● The Role of Vibrating Sieves in Powder Coating

>> What are Vibrating Sieves?

>> Key Functions of Vibrating Sieves

● Benefits of Using Vibrating Sieves

>> Enhanced Product Quality

>> Increased Efficiency

>> Reduced Waste

>> Versatility

● The Technology Behind Vibrating Sieves

>> How Do Vibrating Sieves Work?

>> Types of Vibrating Sieves

● Best Practices for Using Vibrating Sieves

>> Regular Maintenance

>> Choosing the Right Mesh Size

>> Monitoring Powder Quality

● Conclusion

>> Frequently Asked Questions

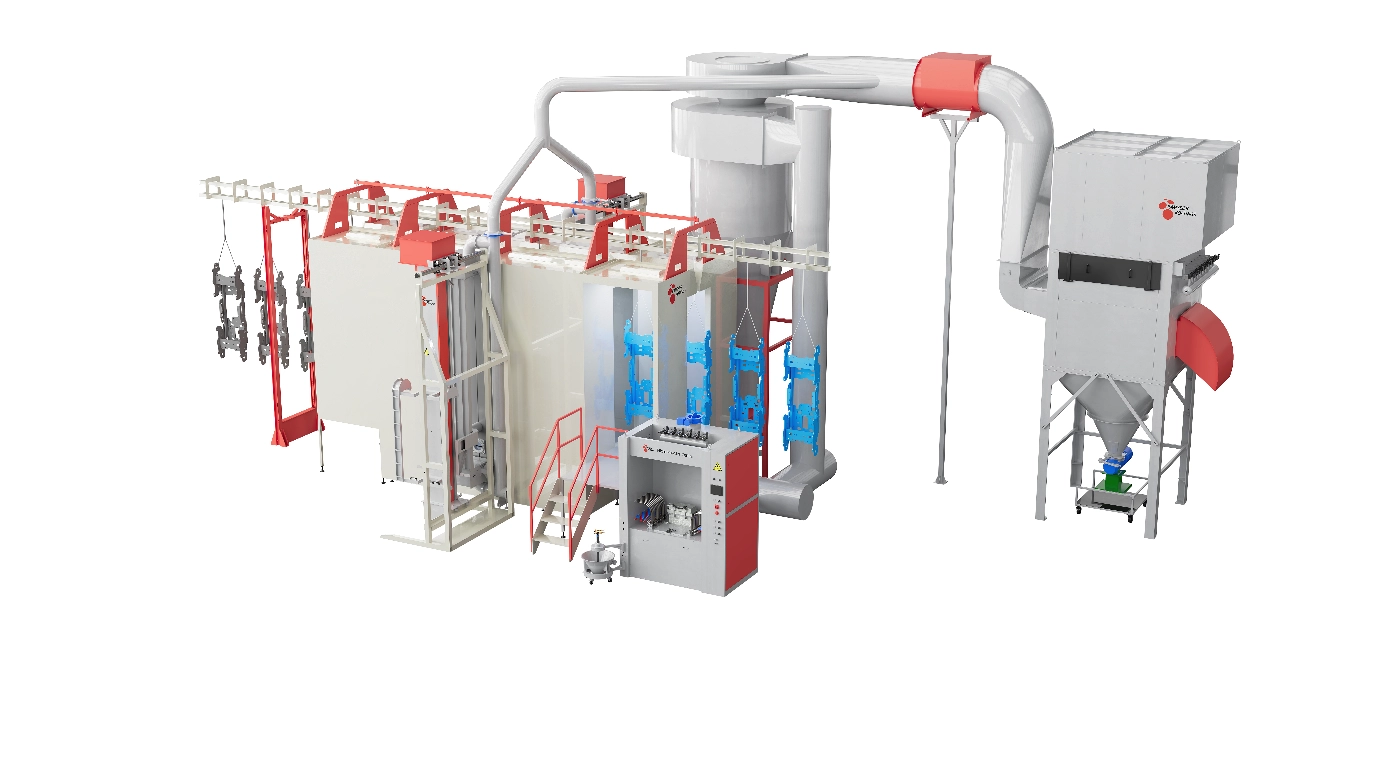

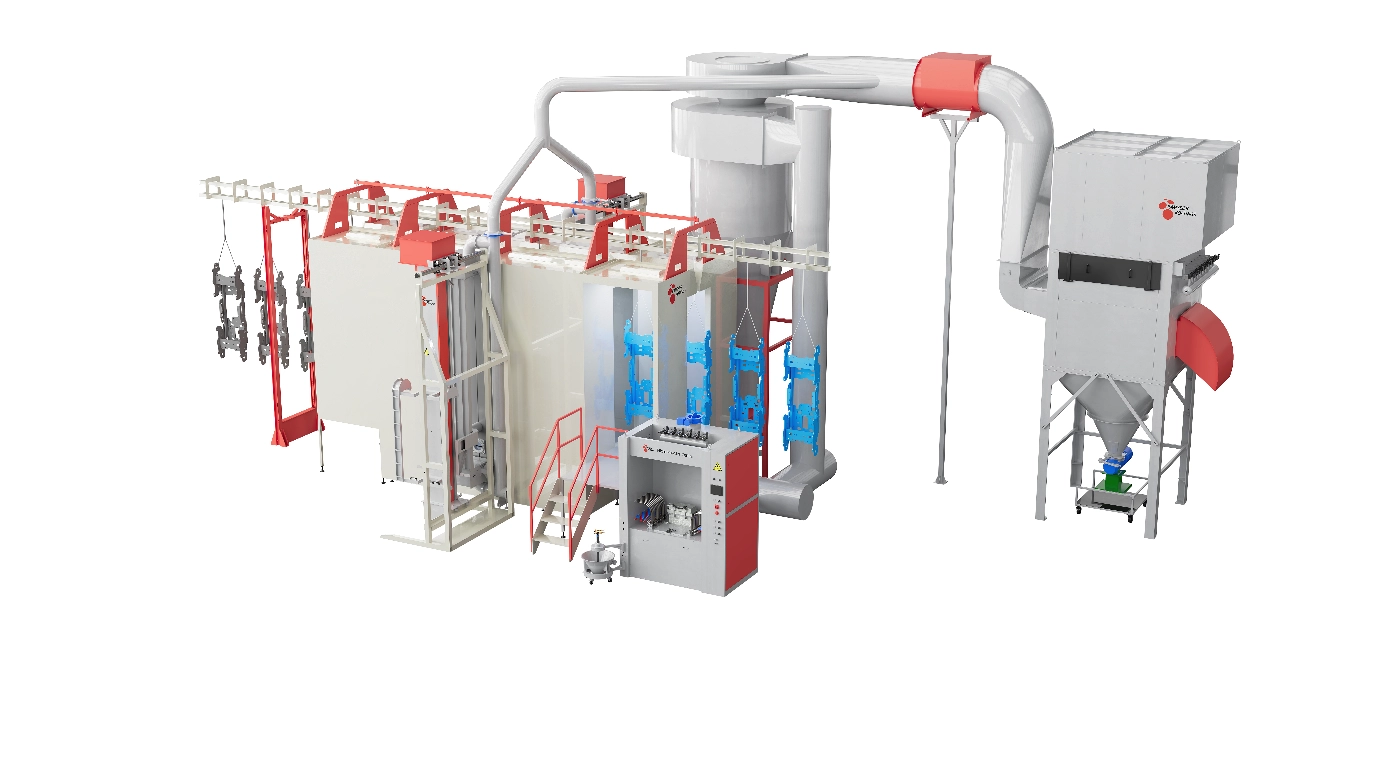

In the world of powder coating, achieving a high-quality finish is paramount. One of the critical components that contribute to this quality is the use of vibrating sieves. These machines play a vital role in ensuring that the powder used in coating processes is free from contaminants and has a consistent particle size. This article delves into the importance of vibrating sieves in powder coating systems, exploring their functions, benefits, and the technology behind them.

Understanding Powder Coating

What is Powder Coating?

Powder coating is a finishing process that involves applying a dry powder to a surface, which is then cured under heat to form a hard, protective layer. This method is widely used in various industries, including automotive, furniture, and appliances, due to its durability and aesthetic appeal.

The Importance of Quality in Powder Coating

The quality of the powder used in coating processes directly affects the final product's appearance and performance. Impurities or inconsistencies in particle size can lead to defects such as uneven finishes, poor adhesion, and reduced durability. Therefore, maintaining the integrity of the powder is crucial.

The Role of Vibrating Sieves in Powder Coating

What are Vibrating Sieves?

Vibrating sieves are machines designed to separate materials based on size. They use vibration to move powder through a mesh screen, allowing smaller particles to pass while retaining larger ones. This process is essential in powder coating to ensure that only the desired particle sizes are used.

Key Functions of Vibrating Sieves

1. Contaminant Removal: Vibrating sieves effectively remove foreign particles, such as dust, clumps, and other impurities, from the powder. This is crucial for maintaining the purity of the coating material.

2. Particle Size Classification: By using different mesh sizes, vibrating sieves can classify powders into specific particle size ranges. This ensures that the powder used in coating processes is uniform, which is vital for achieving consistent finishes.

3. Preventing Clogging: In powder coating systems, clogging can occur due to the accumulation of oversized particles. Vibrating sieves help prevent this by continuously moving the powder, ensuring smooth flow and reducing downtime.

Benefits of Using Vibrating Sieves

Enhanced Product Quality

The primary benefit of using vibrating sieves in powder coating is the enhancement of product quality. By ensuring that only clean, uniformly sized powder is used, manufacturers can achieve better adhesion, smoother finishes, and overall improved durability of the coated products.

Increased Efficiency

Vibrating sieves contribute to increased operational efficiency. By automating the sieving process, manufacturers can reduce manual labor and minimize the risk of human error. This leads to faster production times and lower operational costs.

Reduced Waste

With precise separation and classification, vibrating sieves help minimize material waste. Only the desired particles pass through the screen, ensuring that as much of the raw material as possible is utilized in production.

Versatility

Vibrating sieves are versatile machines that can be used in various applications beyond powder coating. They are effective in industries such as food processing, pharmaceuticals, and chemicals, making them a valuable addition to any manufacturing facility.

The Technology Behind Vibrating Sieves

How Do Vibrating Sieves Work?

Vibrating sieves operate using a combination of mechanical vibrations and gravity. The machine consists of a screen mesh that is mounted on a frame. When the sieve is activated, vibrations cause the powder to move across the screen, allowing smaller particles to pass through while larger ones are retained.

Types of Vibrating Sieves

1. Electromechanical Sieves: These use electric motors to create vibrations. They are commonly used for general sieving applications and are known for their reliability and efficiency.

2. Ultrasonic Sieves: These incorporate ultrasonic technology to enhance the sieving process. The high-frequency vibrations help prevent blinding of the mesh, allowing for higher throughput and better separation of fine particles.

3. Rotary Sieves: While not vibrating in the traditional sense, rotary sieves use a rotating drum to separate materials. They are effective for larger volumes of powder and can be integrated into automated systems.

Best Practices for Using Vibrating Sieves

Regular Maintenance

To ensure optimal performance, regular maintenance of vibrating sieves is essential. This includes cleaning the mesh screens, checking for wear and tear, and ensuring that the vibration settings are correctly calibrated.

Choosing the Right Mesh Size

Selecting the appropriate mesh size is crucial for effective sieving. A finer mesh allows for higher quality sieving but may reduce throughput. Conversely, a larger mesh increases throughput but may allow contaminants to pass through. Finding the right balance is key.

Monitoring Powder Quality

Implementing a quality control system to monitor the powder's characteristics can help identify issues early. Regular testing for particle size distribution and contamination levels can ensure that the powder meets the required standards.

Conclusion

Vibrating sieves are an indispensable part of powder coating systems, playing a crucial role in ensuring product quality and operational efficiency. By effectively removing contaminants and classifying powders, these machines help manufacturers achieve the high standards required in today's competitive market. As technology continues to evolve, the capabilities of vibrating sieves will only improve, further enhancing their importance in various industries.

Frequently Asked Questions

1. What types of materials can vibrating sieves process?

Vibrating sieves can process a wide range of materials, including powders, granules, and even some liquids, making them versatile for various industries.

2. How often should vibrating sieves be maintained?

Regular maintenance is recommended, typically every few weeks, depending on usage. This includes cleaning and inspecting the mesh screens and mechanical components.

3. Can vibrating sieves be used in food processing?

Yes, vibrating sieves are widely used in food processing to ensure the purity and quality of powders, such as flour and spices.

4. What is the difference between electromechanical and ultrasonic sieves?

Electromechanical sieves use electric motors for vibration, while ultrasonic sieves incorporate high-frequency vibrations to enhance sieving efficiency and prevent mesh blinding.

5. How do I choose the right mesh size for my application?

The right mesh size depends on the desired particle size distribution and the specific requirements of your application. It may require some testing to find the optimal balance between quality and throughput.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.