Content Menu

● Introduction

● 1. Ramseier Koatings Technologies Holdings Ltd.

>> Overview

>> Key Features

● 2. Kason Corporation

>> Overview

>> Key Features

● 3. Russell Finex

>> Overview

>> Key Features

● 4. Farleygreene

>> Overview

>> Key Features

● 5. Zeochem

>> Overview

>> Key Features

● Applications of Powder Sieves

● Benefits of Using Powder Sieves

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What is a powder sieve?

>> 2. How does a powder sieve work?

>> 3. What industries use powder sieves?

>> 4. How do I choose the right powder sieve for my application?

>> 5. Are there maintenance requirements for powder sieves?

Introduction

In the realm of powder processing, the importance of high-quality sieving equipment cannot be overstated. This article explores the top powder sieve manufacturers and suppliers in Bosnia and Herzegovina, with a special focus on Ramseier Koatings Technologies Holdings Ltd., a leading player in the industry. We will delve into the features, benefits, and applications of powder sieves, while also addressing common questions related to this essential equipment.

1. Ramseier Koatings Technologies Holdings Ltd.

Overview

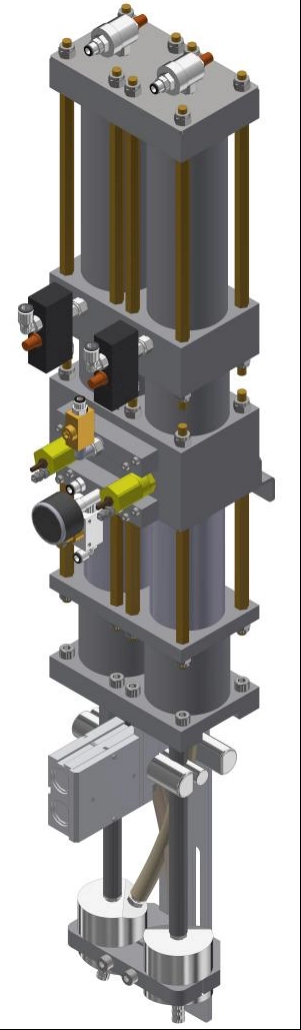

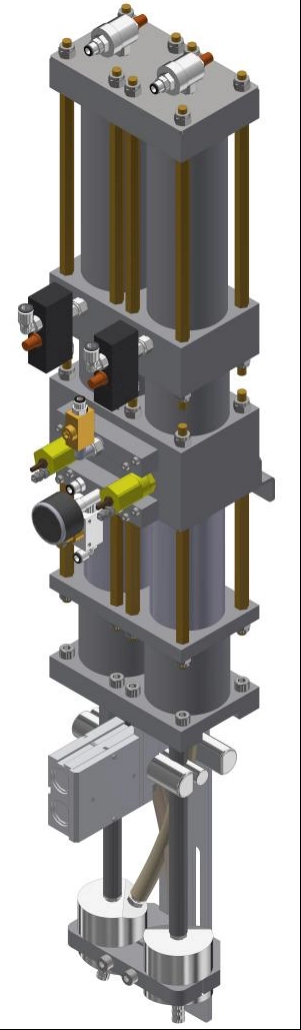

Ramseier Koatings Technologies Holdings Ltd. stands out as a premier manufacturer of powder sieving systems. With a commitment to innovation and quality, Ramseier offers a range of products designed to meet the diverse needs of the powder processing industry. Their powder sieve systems are engineered for precision, ensuring consistent results and high efficiency.

Key Features

- Advanced Technology: Utilizing cutting-edge technology, Ramseier's powder sieves provide superior performance in various applications.

- Durability: Built to last, these sieves are made from high-quality materials that withstand rigorous use.

- Customization: Ramseier offers tailored solutions to meet specific customer requirements, ensuring optimal performance.

2. Kason Corporation

Overview

Kason Corporation is another notable manufacturer in the powder sieving market. They specialize in producing vibratory screeners and separators that are widely used in various industries, including food, pharmaceutical, and chemical processing.

Key Features

- Versatile Applications: Kason's sieves are suitable for a wide range of materials, making them ideal for diverse industries.

- High Efficiency: Their equipment is designed to maximize throughput while minimizing waste.

- Robust Design: Kason sieves are built to endure harsh operating conditions, ensuring longevity and reliability.

3. Russell Finex

Overview

Established in 1934, Russell Finex has become a leader in fine mesh separation technology. Their innovative powder sieving solutions are used globally across multiple sectors.

Key Features

- Custom Solutions: Russell Finex offers bespoke sieving equipment tailored to specific industry needs.

- Advanced Technology: Their ultrasonic mesh deblinding systems enhance the efficiency of powder sieving processes.

- Global Reach: With a presence in numerous countries, Russell Finex provides excellent customer support and service.

4. Farleygreene

Overview

Farleygreene specializes in providing high-quality sieving solutions for the powder processing industry. Their products are designed to enhance productivity and ensure product quality.

Key Features

- Automated Solutions: Farleygreene's automated sieving systems improve efficiency and reduce manual labor.

- High Throughput: Their equipment is engineered to handle large volumes of powder, making it suitable for industrial applications.

- Quality Assurance: Farleygreene emphasizes quality control, ensuring that their sieves meet stringent industry standards.

5. Zeochem

Overview

Zeochem is known for its high-performance molecular sieve products, including powder sieves. With production facilities in Bosnia and Herzegovina, they offer localized support and expertise.

Key Features

- Specialized Products: Zeochem's sieves are designed for specific applications, ensuring optimal performance.

- Technical Support: Their experienced team provides guidance on product selection and application.

- Sustainability: Zeochem is committed to environmentally friendly practices in their manufacturing processes.

Applications of Powder Sieves

Powder sieves play a crucial role in various industries, including:

- Food Processing: Ensuring the purity and quality of food products by removing contaminants.

- Pharmaceuticals: Guaranteeing the consistency and quality of powdered medications.

- Chemical Manufacturing: Facilitating the production of high-quality chemical powders.

Benefits of Using Powder Sieves

1. Improved Product Quality: By removing impurities, powder sieves enhance the overall quality of the final product.

2. Increased Efficiency: High-performance sieves allow for faster processing times and higher throughput.

3. Cost Savings: Investing in quality sieving equipment can lead to significant savings in production costs over time.

Conclusion

In conclusion, the powder sieving industry in Bosnia and Herzegovina is supported by several reputable manufacturers, with Ramseier Koatings Technologies Holdings Ltd. leading the way. Their commitment to quality and innovation sets a high standard for powder processing equipment. As industries continue to evolve, the demand for efficient and reliable powder sieves will only grow.

Frequently Asked Questions (FAQs)

1. What is a powder sieve?

A powder sieve is a device used to separate particles of different sizes in powdered materials, ensuring uniformity and quality in the final product.

2. How does a powder sieve work?

Powder sieves use a combination of mechanical vibration and gravity to allow smaller particles to pass through a mesh screen while larger particles are retained.

3. What industries use powder sieves?

Powder sieves are commonly used in food processing, pharmaceuticals, chemicals, and other industries that require precise particle size separation.

4. How do I choose the right powder sieve for my application?

Consider factors such as the type of material, desired particle size, throughput requirements, and any specific industry regulations when selecting a powder sieve.

5. Are there maintenance requirements for powder sieves?

Yes, regular maintenance is essential to ensure optimal performance. This includes cleaning, inspecting for wear and tear, and replacing any damaged components.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.