Content Menu

● Introduction

● Overview of Powder Sieving Equipment

● Importance of Choosing the Right Powder Sieve

● Top Powder Sieve Manufacturers in Serbia

>> 1. Ramseier Koatings Technologies Holdings Ltd.

>> 2. Mlinostroj d.d.

>> 3. Kason Corporation

>> 4. Farleygreene

>> 5. Quadro Engineering

● Key Features of Quality Powder Sieves

● Innovations in Powder Sieving Technology

● Conclusion

● Frequently Asked Questions (FAQs)

>> Q1: What is a powder sieve?

>> Q2: Why is mesh size important in powder sieving?

>> Q3: How do I choose the right powder sieve for my business?

>> Q4: What industries use powder sieving equipment?

>> Q5: What are the benefits of using automated powder sieving systems?

Introduction

In the world of powder processing, the efficiency and effectiveness of powder sieving equipment are paramount. This article explores the top powder sieve manufacturers and suppliers in Serbia, highlighting their offerings and capabilities. Among these, Ramseier Koatings Technologies Holdings Ltd. stands out as a leader in the industry, providing innovative solutions tailored to meet the diverse needs of businesses engaged in powder processing.

Overview of Powder Sieving Equipment

Powder sieving equipment plays a crucial role in various industries, including food, pharmaceuticals, chemicals, and materials processing. These machines are designed to separate fine particles from larger ones, ensuring product quality and consistency. The demand for high-quality powder sieves has led to the emergence of several reputable manufacturers in Serbia.

Importance of Choosing the Right Powder Sieve

Selecting the right powder sieve is essential for optimizing production processes. Factors to consider include:

- Material Compatibility: Ensure the sieve is suitable for the type of powder being processed.

- Mesh Size: The mesh size determines the particle size that can pass through, affecting the final product's quality.

- Throughput Capacity: Evaluate the sieve's capacity to handle the required volume of powder efficiently.

Top Powder Sieve Manufacturers in Serbia

1. Ramseier Koatings Technologies Holdings Ltd.

As a leading manufacturer, Ramseier Koatings Technologies Holdings Ltd. specializes in high-performance powder sieving solutions. Their products are designed to enhance efficiency and ensure precise separation of powders. With a commitment to quality and innovation, Ramseier has established itself as a trusted partner for businesses in Serbia and beyond.

2. Mlinostroj d.d.

Mlinostroj d.d. is renowned for its advanced vibrating screens and sieves. Their equipment is widely used in various industries, including food and construction. Mlinostroj offers customized solutions to meet specific client needs, ensuring optimal performance in powder processing.

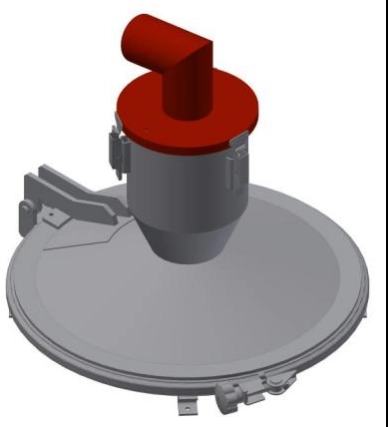

3. Kason Corporation

Kason Corporation provides a range of powder processing equipment, including static scalping sieves and batch dryers. Their innovative designs focus on efficiency and ease of use, making them a popular choice among manufacturers in Serbia.

4. Farleygreene

Farleygreene specializes in automated sieving solutions, particularly for metal powders. Their Sievmaster range is known for its high throughput and efficiency, catering to the needs of industries requiring precise powder separation.

5. Quadro Engineering

With over four decades of experience, Quadro Engineering offers a comprehensive line of milling and sieving equipment. Their solutions are tailored for the pharmaceutical and food industries, ensuring high-quality powder processing.

Key Features of Quality Powder Sieves

When evaluating powder sieves, consider the following features:

- Durability: High-quality materials ensure longevity and reliability.

- Ease of Cleaning: Equipment that is easy to disassemble and clean helps maintain hygiene standards.

- Versatility: The ability to handle various powder types and sizes increases the equipment's utility.

Innovations in Powder Sieving Technology

Recent advancements in powder sieving technology have led to the development of ultrasonic sieving systems and automated solutions. These innovations enhance efficiency, reduce waste, and improve product quality.

Conclusion

In conclusion, the powder sieving industry in Serbia is supported by several reputable manufacturers, with Ramseier Koatings Technologies Holdings Ltd. leading the way. By investing in high-quality powder sieving equipment, businesses can enhance their production processes and ensure the delivery of superior products.

Frequently Asked Questions (FAQs)

Q1: What is a powder sieve?

A powder sieve is a device used to separate fine particles from larger ones in powder processing.

Q2: Why is mesh size important in powder sieving?

Mesh size determines the particle size that can pass through the sieve, affecting the quality of the final product.

Q3: How do I choose the right powder sieve for my business?

Consider factors such as material compatibility, mesh size, and throughput capacity when selecting a powder sieve.

Q4: What industries use powder sieving equipment?

Powder sieving equipment is used in various industries, including food, pharmaceuticals, chemicals, and materials processing.

Q5: What are the benefits of using automated powder sieving systems?

Automated systems enhance efficiency, reduce labor costs, and improve product quality by ensuring consistent separation of powders.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.