Content Menu

● Introduction

● Ramseier Koatings Technologies Holdings Ltd.

>> Overview

>> Key Products

● Other Notable Manufacturers in Monaco

>> 1. Farley Greene

>> 2. Palamatic Process

>> 3. Kason

>> 4. Rotex Group

>> 5. Prater Industries

● The Importance of Powder Sieving

>> Why Powder Sieving Matters

>> Applications of Powder Sieving

● Conclusion

● Frequently Asked Questions

>> 1. What is powder sieving?

>> 2. Why is powder sieving important in manufacturing?

>> 3. What types of equipment are used for powder sieving?

>> 4. How does ultrasonic sieving work?

>> 5. What industries benefit from powder sieving?

Introduction

In the world of powder processing, the efficiency and effectiveness of powder sieving equipment are paramount. This article explores the top powder sieve manufacturers and suppliers in Monaco, highlighting their unique offerings and contributions to the industry. Among these, Ramseier Koatings Technologies Holdings Ltd. stands out as a leader in providing high-quality powder sieving solutions.

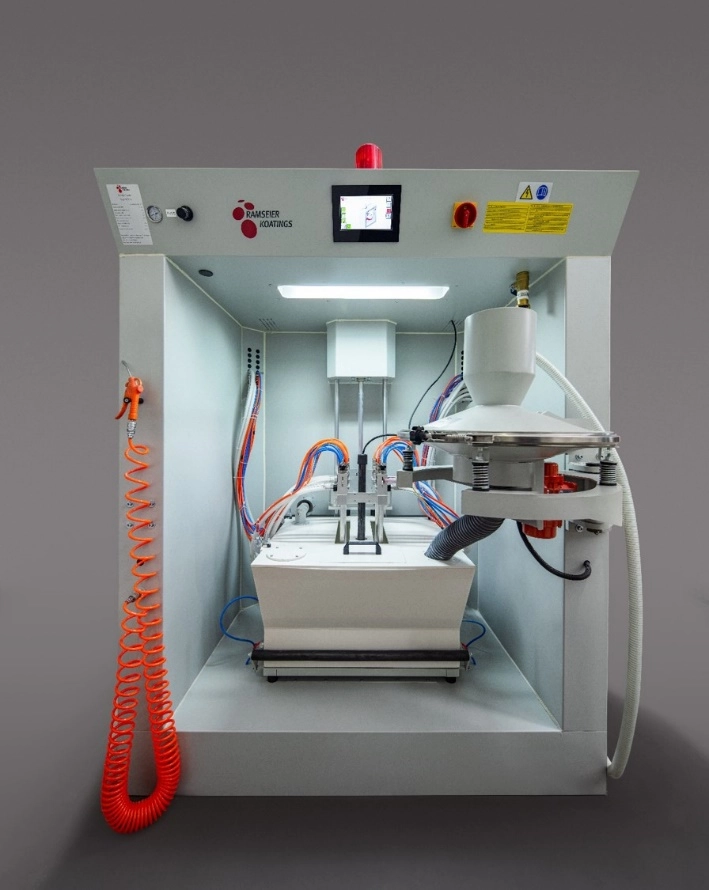

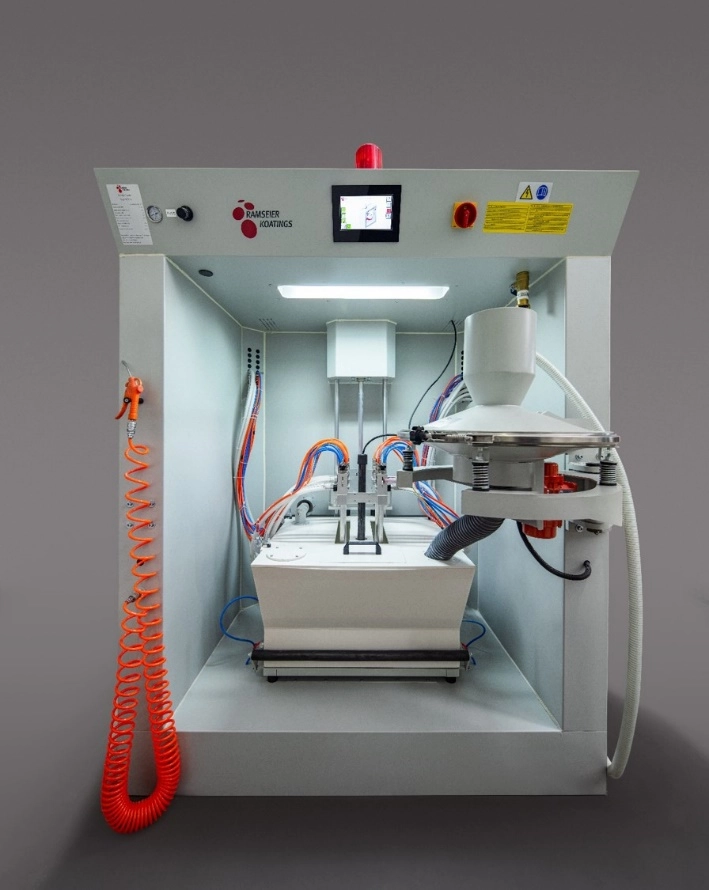

Ramseier Koatings Technologies Holdings Ltd.

Overview

Ramseier Koatings Technologies Holdings Ltd. is renowned for its innovative approach to powder sieving technology. With a commitment to quality and customer satisfaction, they offer a range of products designed to meet the diverse needs of various industries, including pharmaceuticals, food processing, and chemical manufacturing.

Key Products

- Ultrasonic Sieves: These advanced sieves utilize ultrasonic technology to enhance the efficiency of powder separation, ensuring a higher quality end product.

- Vibratory Screens: Designed for continuous operation, these screens are ideal for separating fine powders from larger particles, making them essential in many production lines.

- Centrifugal Sifters: These machines are perfect for removing oversized particles and ensuring a consistent powder size, crucial for applications in additive manufacturing.

Other Notable Manufacturers in Monaco

1. Farley Greene

Farley Greene specializes in automated metal powder sieving solutions. Their Sievgen 04-S model is particularly noteworthy for its environmentally sealed design and touch screen interface, making it a favorite among manufacturers looking for efficiency and ease of use.

2. Palamatic Process

Palamatic Process offers a comprehensive range of industrial screening solutions. Their centrifugal screens are designed to eliminate foreign bodies and reduce aggregates, ensuring the highest quality of powder products. They also provide hygienic designs that are easy to clean, making them suitable for food and pharmaceutical applications.

3. Kason

Kason is known for its CROSS-FLO static scalping sieves, which are ideal for continuous scalping applications. Their equipment is designed to handle various powder processing needs, including batch and continuous blending, granulation, and de-agglomeration.

4. Rotex Group

The Rotex Group has been a leader in industrial separations for over 175 years. Their patented gyratory reciprocating motion screeners are designed to achieve the best G-loads in the industry, making them highly effective for powder sieving applications.

5. Prater Industries

Prater Industries provides a wide array of powder processing equipment, including rotary airlock valves and lump breakers. Their products are designed to enhance the efficiency of powder handling and processing, making them a reliable choice for manufacturers.

The Importance of Powder Sieving

Why Powder Sieving Matters

Powder sieving is a critical process in many industries, ensuring that the final product meets quality standards. Effective sieving helps in:

- Eliminating Contaminants: By removing oversized particles and foreign bodies, manufacturers can ensure the purity of their products.

- Improving Product Quality: Consistent particle size distribution leads to better performance in applications such as pharmaceuticals and food processing.

- Enhancing Production Efficiency: Efficient sieving processes reduce downtime and increase throughput, contributing to overall productivity.

Applications of Powder Sieving

Powder sieving is utilized across various sectors, including:

- Pharmaceuticals: Ensuring the correct dosage and uniformity of powdered medications.

- Food Processing: Maintaining quality and safety standards in food products.

- Chemical Manufacturing: Ensuring consistency in chemical formulations.

Conclusion

In conclusion, the powder sieving industry in Monaco is supported by several key players, with Ramseier Koatings Technologies Holdings Ltd. leading the charge. Their innovative products and commitment to quality set a high standard for powder processing equipment. As industries continue to evolve, the importance of effective powder sieving will only grow, making these manufacturers essential partners in production.

Frequently Asked Questions

1. What is powder sieving?

Answer: Powder sieving is the process of separating fine particles from larger ones to ensure product quality and consistency in various industries.

2. Why is powder sieving important in manufacturing?

Answer: It helps eliminate contaminants, improves product quality, and enhances production efficiency by ensuring uniform particle size distribution.

3. What types of equipment are used for powder sieving?

Answer: Common equipment includes ultrasonic sieves, vibratory screens, and centrifugal sifters.

4. How does ultrasonic sieving work?

Answer: Ultrasonic sieving uses high-frequency vibrations to prevent particles from clogging the sieve mesh, allowing for more efficient separation.

5. What industries benefit from powder sieving?

Answer: Industries such as pharmaceuticals, food processing, and chemical manufacturing benefit significantly from effective powder sieving.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.